-

0 items in quote

No products in the Quote Basket.

SMART CUT® Mineral Oil

SMART CUT® Mineral Oil is a premium-grade lubricant and coolant specifically designed for precision cutting, drilling, grinding, and machining applications. It is ideal for use with a wide range of materials, particularly those with high metallic content, ceramics, precious and semi-precious stones, and other ultra-hard materials.

This mineral oil is formulated with a hydro-finished paraffin base, ensuring exceptional purity and consistent performance. It is non-dilutable, meaning it maintains its integrity and efficacy throughout its use. Rated as a food-grade oil, SMART CUT® Mineral Oil is non-toxic, non-hazardous, and non-flammable under normal conditions. With a flash point of 390°F, it provides reliable protection against heat buildup, making it suitable for demanding applications where high temperatures are a concern.

DESCRIPTION

SPECIFICATIONS

FREQUENTLY ASKED QUESTIONS

INDUSTRIES USED IN

ACCESSORIES

USAGE RECOMMENDATION

DESCRIPTION

Additionally, SMART CUT® Mineral Oil has a neutral odor, making it more pleasant to work with compared to many other oils. It is safe to the skin, offering minimal risk of irritation unless you have extreme sensitivity. This oil is ideal for industries that require consistent lubrication and cooling during machining processes, ensuring the longevity of both tools and workpieces.

Engineered to withstand high heat and deliver optimal cutting performance, SMART CUT® Mineral Oil provides unparalleled value for anyone working with tough, hard-to-machine materials.

SMART CUT® Mineral Oil is not dilutable, making it ideal for applications requiring a consistent, stable lubricant. Its effective cooling properties help minimize thermal stress, prevent surface cracking, and extend the life of both tools and materials, ensuring efficient, reliable cutting performance. Whether used for cutting, drilling, grinding, or other precision machining operations, this mineral oil delivers the high-quality results professionals demand.

SPECIFICATIONS

Reduced Friction: Mineral oil forms a thin film between the diamond or cbn tools and the material, providing less friction. This reduction in friction helps to extend the life of the tool.

Minimize Heat Generation: Provides needed lubrication that helps in reducing am out of heat generated during machining processes. This helps in minimizing and preventing thermal damage to both the tool and the material being worked on.

Improve Surface Finish: improved lubrication helps in providing smoother surface finish, especially in grinding operations.

Minimize & Prevent of Oxidation and Rust: creates a protective barrier that prevents the oxidation of metal surfaces, providing protection for tools and material from rust and corrosion.

Minimize Dust and Remove Material Debris: helps in suspending and flushing away the dust and debris, preventing it from becoming airborne, which can be a health hazard.

Increase Tool Life: By minimizing friction and heat, mineral oil reduces the wear and tear on diamond & cbn tools. This equates to longer tool life and less tool changes.

Increased Cutting Speeds: Mineral oil provides liberation needed increased cutting or grinding speeds, providing shorter machining times

Low Cost: Mineral oil is one of the most economical coolant/lubricant options that can be used for many applications.

FREQUENTLY ASKED QUESTIONS

no this is not water soluble. use soap and water. Store in a cool, dry place away from direct sunlight and heat sources. Shelf life is usually 2 years from date the mineral oil was produced 475 degrees F In some industrial settings, mineral oil can be filtered and reused, though its performance might degrade over time. Follow local regulations. Typically, used mineral oil should be collected and disposed of as hazardous waste. Prolonged exposure or spills can harm the environment Use in well-ventilated areas and avoid prolonged skin contact. Keep out of direct sunlight and High temperatures and anything that can cause flames Mineral oil itself doesn’t produce harmful fumes, but when used in high-heat applications, any lubricant can produce vapors. Should be cleaned promptly using absorbent materials. Avoid slips and falls. Use in well-ventilated areas and avoid prolonged skin contact. Prolonged skin exposure might cause mild irritation in some people. Generally, there are no significant restrictions, but it depends on quantity and destination.

INDUSTRIES USED IN

Tab Content

ACCESSORIES

Tab Content

USAGE RECOMMENDATION

Tab Content

Features:

-

Premium Quality Hydro-Finished Paraffin Base: Ensures exceptional purity and consistent performance during machining.

Premium Quality Hydro-Finished Paraffin Base: Ensures exceptional purity and consistent performance during machining.

-

Non-Dilutable: Maintains its integrity and efficacy throughout its use without the need for dilution.

Non-Dilutable: Maintains its integrity and efficacy throughout its use without the need for dilution.

-

High Flash Point of 390°F: Provides stability and reliable protection against heat buildup during high-temperature machining.

High Flash Point of 390°F: Provides stability and reliable protection against heat buildup during high-temperature machining.

-

Food-Grade, Non-Toxic, and Non-Hazardous: Safe for use in environments where worker safety is a priority.

Food-Grade, Non-Toxic, and Non-Hazardous: Safe for use in environments where worker safety is a priority.

-

Non-Flammable Under Normal Conditions: Adds an extra layer of safety, even in high-speed or high-temperature processes.

Non-Flammable Under Normal Conditions: Adds an extra layer of safety, even in high-speed or high-temperature processes.

-

No Odor: Makes it more pleasant to work with compared to many other oils.

No Odor: Makes it more pleasant to work with compared to many other oils.

-

Skin Safe: Won’t burn the skin unless extremely sensitive, making it safe for handling.

Skin Safe: Won’t burn the skin unless extremely sensitive, making it safe for handling.

-

Versatile: Ideal for cutting, drilling, grinding, and machining a wide range of ultra-hard materials, including advanced ceramics, precious and semi-precious stones, and materials with high metallic content.

Versatile: Ideal for cutting, drilling, grinding, and machining a wide range of ultra-hard materials, including advanced ceramics, precious and semi-precious stones, and materials with high metallic content.

-

Enhances Tool Life: Reduces friction and wear on cutting tools, extending tool longevity and reducing the need for frequent replacements.

Enhances Tool Life: Reduces friction and wear on cutting tools, extending tool longevity and reducing the need for frequent replacements.

-

Improves Performance: Ensures smoother cuts, cleaner finishes, and better material integrity during machining.

Improves Performance: Ensures smoother cuts, cleaner finishes, and better material integrity during machining.

-

Environmentally Responsible: Non-toxic and non-hazardous, making it safer for both workers and the environment.

Environmentally Responsible: Non-toxic and non-hazardous, making it safer for both workers and the environment.

Advantages:

- Reduced Friction: Mineral oil forms a thin film between the diamond or cbn tools and the material, providing less friction. This reduction in friction helps to extend the life of the tool.

- Minimize Heat Generation: Provides needed lubrication that helps in reducing am out of heat generated during machining processes. This helps in minimizing and preventing thermal damage to both the tool and the material being worked on.

- Improve Surface Finish: improved lubrication helps in providing smoother surface finish, especially in grinding operations.

- Minimize & Prevent of Oxidation and Rust: creates a protective barrier that prevents the oxidation of metal surfaces, providing protection for tools and material from rust and corrosion.

- Minimize Dust and Remove Material Debris: helps in suspending and flushing away the dust and debris, preventing it from becoming airborne, which can be a health hazard.

- Increase Tool Life: By minimizing friction and heat, mineral oil reduces the wear and tear on diamond & cbn tools. This equates to longer tool life and less tool changes.

- Increased Cutting Speeds: Mineral oil provides liberation needed increased cutting or grinding speeds, providing shorter machining times.

- Low Cost: Mineral oil is one of the most economical coolant/lubricant options that can be used for many applications.

Showing 1 – 3 of 3 results Showing all 3 results Showing the single result No results found

Sort by

Filters Sort results

Reset Apply

Image | Item no | Name | Price | Quantity | Add to cart | |

|---|---|---|---|---|---|---|

$28.71 | Max: Min: 1 Step: 1 | |||||

$65.00 | Max: Min: 1 Step: 1 | |||||

$198.72 | Max: Min: 1 Step: 1 |

Related Products

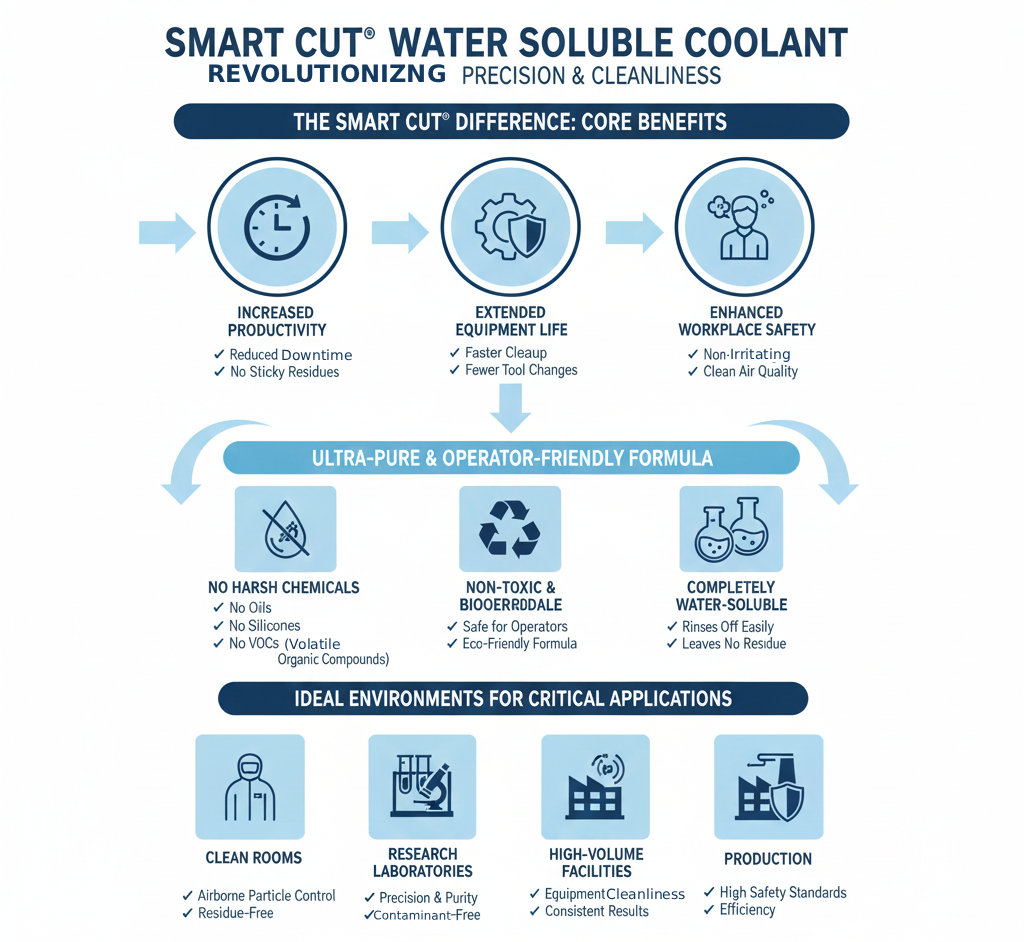

SMART CUT® Water Soluble Coolant

(General Materials Formula)

High-Performance Fully Synthetic Coolant & Lubricant for Diamond Slicing, Dicing, Drilling, and Grinding & Machining of Ceramics, Glass, Optics, Quartz, Silicon, and Other Hard & Brittle Materials

SMART CUT® Water Soluble Coolant (General Materials Formula) is a fully synthetic, non-oily, and non-foaming coolant and lubricant engineered to meet the rigorous demands of slicing, dicing, drilling, sectioning, wafering, grinding, and polishing operations involving hard and brittle materials. This advanced formula has been specifically developed for use with ceramics, precision optics, quartz, silicon, sapphire, and other materials commonly found in semiconductor, photonics, and materials research applications.SMART CUT® HD Synthetic Low IFT Coolant/Lubricant For Diamond Wire Sawing Silicon

SMART CUT® is a synthetic coolant specifically designed for the cutting of semiconductor materials, including sapphire, silicon, germanium, single-crystal SiC, and II-VI crystals. This coolant offers excellent cut rates and imparts outstanding surface finishes with reduced warp and total thickness variation (TTV). It is ideal for diamond abrasive cropping, squaring, and wafering of silicon ingots using ID, band, and wire saws. SMART CUT® HD-2B can also be used as a non-re-circulating edge grinding coolant or lubricant for silicon wafers and ingots.

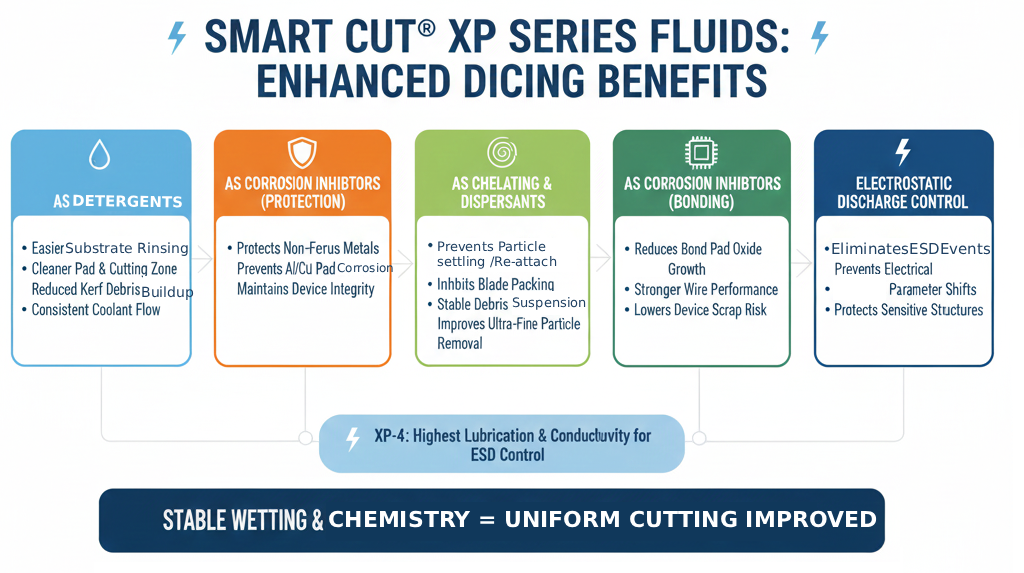

SMART CUT® Water Soluble Dicing Coolant

SMART CUT® XP Water Soluble Dicing Coolant added to deionized (DI) water reduces surface tension flowing from saws injection system and is carried directly of dicing blade.

This reduces material thermal stress, edge damage, and internal cracking, assuring long-term integrity of material being processed. Since SMART CUT® XP Dicing Coolant is a coolant and lubricant, and Surfactant both the dicing blade and substrate / wafer / package benefit.

SMART CUT® XP Dicing Coolant/Lubricant is a specially formulated low-foaming dicing and sawing coolant/lubricant designed for precision applications involving wafers with integrated circuits, MEMS devices, and IC packaging. This aqueous-based synthetic formulation enhances the dicing process by ensuring superior cleanliness of the die or package after dicing while preventing corrosion and oxidation on exposed metals. It eliminates electrostatic discharge, which can be generated during the rotation of the dicing blade, protecting delicate components from damage.

Recently Viewed Products

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Knowledge Center

02

Nov

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

29

Aug

Selecting the Right Coolant Method for your Diamond & CBN Tools

Coolant is one of the most important factors in CNC machining when using diamond and CBN tools. These tools are made to cut and grind very hard materials, which naturally produces high amounts of friction...

02

Jun

How to Selecting Right Diamond Tools for your application

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

17

May

Choosing The Correct Diamond Bond Type

Selecting the appropriate diamond bond type for specific applications is crucial for several reasons. Diamond bond type directly affects the tool's performance, efficiency, and longevity. Different bond types determine how well a tool can withstand...

03

Jan

How to Properly Use Diamond Tools: A Complete Guide to Performance, Safety, and Tool Life

The use of diamond tools in the manufacturing and precision machining industries, as well as in construction, research, etc., is essential. They are used for a wide range of materials, including sharpening, cutting, grinding, and polishing...