-

0 items in quote

No products in the Quote Basket.

SMART CUT® 6055

Precision Automatic Diamond Cut-Off Saw

The SMART CUT® 6055 is a high-performance, fully automatic diamond cut-off saw designed for laboratories and production environments that demand exceptional cutting precision, surface quality, and repeatability. Engineered for sectioning a wide range of advanced materials—including ceramics, composites, metals, semiconductors, crystals, biomaterials, and geological specimens—this machine combines intelligent automation, robust construction, and intuitive controls.

It features an enclosed transparent safety cover with interlock protection, offering full visibility of the cutting operation while ensuring operator safety. A gravity-based feed loading system provides precise control over the feed speed, helping to minimize sample deformation and edge damage. Integrated within the unit is a closed-loop water cooling system that maintains a consistent cutting temperature, significantly improving blade life and cut surface integrity.

The saw utilizes a high-torque servo motor with overload and thermal protection, ensuring long-term durability and safeguarding critical components from damage.

DESCRIPTION

SPECIFICATIONS

ADVANTAGES

INDUSTRIES USED IN

FAQ

OPERATING MANUALS

ACCESSORIES

DESCRIPTION

With a blade spindle speed range of 500 to 3000 RPM, users can fine-tune cutting speeds to suit different material properties. A unique capability allows the operator to program and execute multiple feed rates and spindle speeds within a single cut, ideal for processing multi-phase or heterogeneous samples.

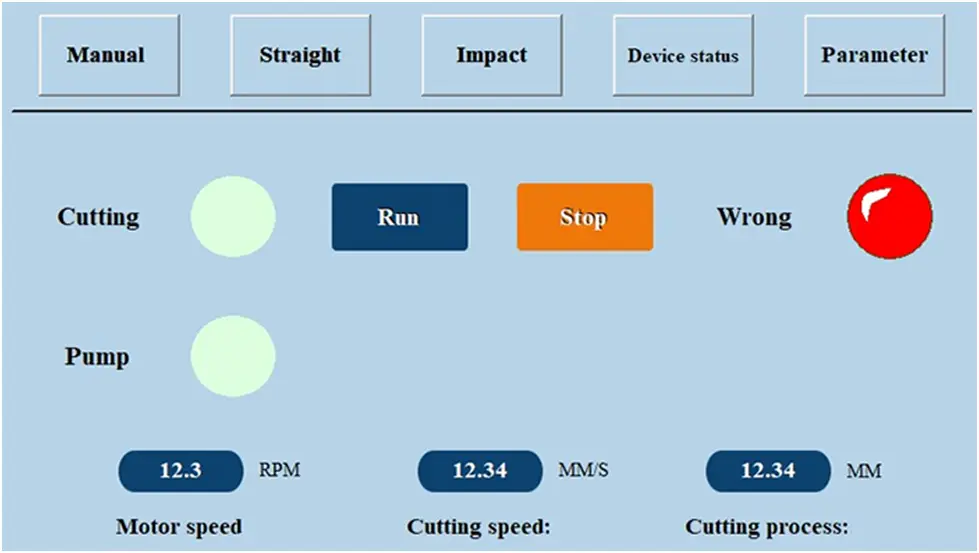

An intuitive HMI touchscreen interface and PLC-based control system make parameter setup and operation simple. The machine can store up to 99 unique cutting programs, eliminating the need to reset configurations between sample runs. When cutting is complete, the machine automatically stops and retracts the blade to the start position, even without pre-setting the stroke.

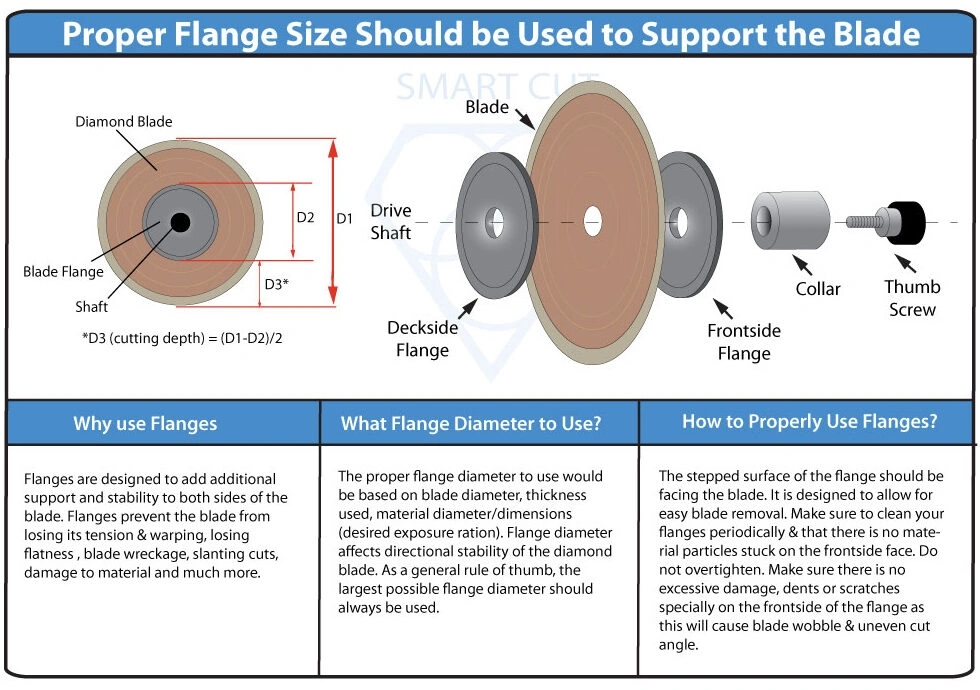

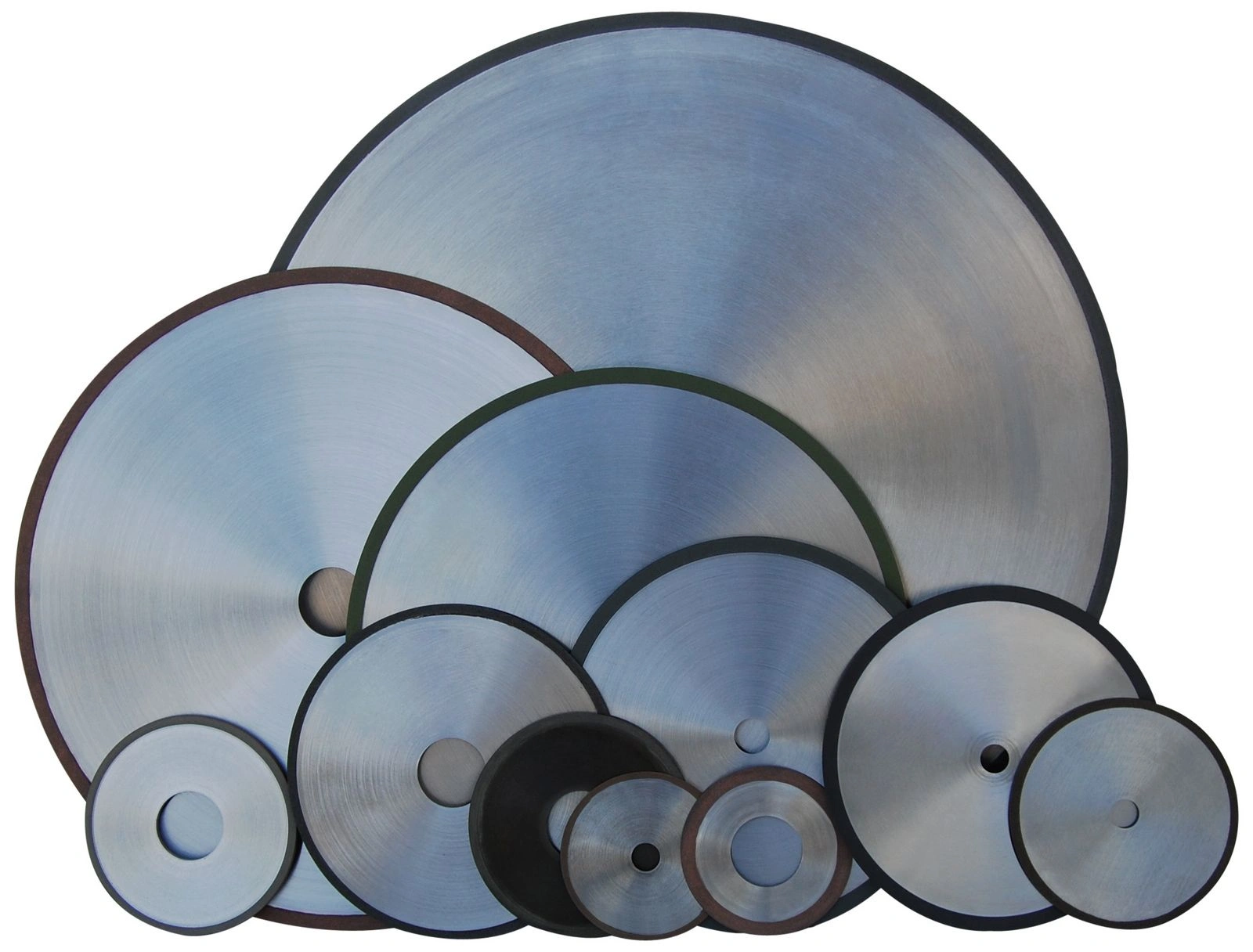

The SMART CUT® 6055 accepts 200 mm diameter blades with a 32 mm arbor hole, and can cut samples up to 60 mm in diameter. It includes 7 specialized sample clamping fixtures for various geometries. Optional enhancements include X-axis movement (up to 50 mm) and sample rotation (0–30 RPM) to increase flexibility and throughput.

Cutting feed speed is adjustable between 0.01–3 mm/s, with manual jog speeds up to 15 mm/s. The system supports two cutting modes: Direct Cutting for standard applications and Impact Cutting for hard, brittle, or clog-prone materials. In impact mode, the user can define pulsed blade engagement (0.1–2 mm) to reduce heat buildup and blade loading.

The unit’s external coolant circulation device ensures efficient, closed-loop water flow to maintain consistent cooling during the entire cutting cycle.

With a compact benchtop footprint of 790 × 870 × 455 mm and a weight of 126 kg, the SMART CUT® 6055 is ideal for precision cutting tasks in research, failure analysis, metallography, microelectronics, and sample preparation.

SPECIFICATIONS

- Maximum Cutting Diameter: 60 mm

- Cut-Off Blade Size (Standard): 200 mm diameter × 0.9 mm thick × 32 mm arbor

- Spindle Speed Range: 500 – 3000 RPM (optional: 500 – 5000 RPM)

- Cutting Feed Speed: 0.01 – 3 mm/s (incremental adjustment in 0.01 mm/s)

- Manual Inching Feed Speed: 0 – 15 mm/s

- Blade Return Speed: 0 – 15 mm/s (automated retraction to initial position)

- Impact Cutting Distance: 0.1 – 2 mm (used in impact cutting mode only)

- Y-Axis Stroke (Blade Movement): 200 mm

- X-Axis Movement (Optional): 50 mm

- Sample Rotation (Optional): 0 – 30 RPM

- Clamping Capacity – Max Sample Length: 150 mm

- Clamping Capacity – Max Sample Width: 200 mm

- Sample Clamp Options: 7 different interchangeable clamps (included)

- Motor Type: High-torque Servo Motor

- Motor Power: 1.5 kW (noted once as 1100W in the GTQ description, but 1.5 kW is correct for US 110V)

- Control Interface: HMI touchscreen with PLC logic control

- Process Memory: Store up to 99 different cutting process programs

- Cut Completion Detection: Yes, with automatic blade stop and return

- Cutting Modes:

- Direct Cutting: For standard and economic operation

- Impact Cutting: For hard, brittle, or clog-prone materials

- Cooling System:

- Type: External circulation system

- Function: Water cooling via tank recirculation

- Protective Enclosure:

- Material: Transparent, enclosed cover

- Safety: Integrated safety interlock switch

- Language Options: English / Chinese (switchable on interface)

- Power Requirements:

- Voltage: 110V

- Frequency: 60 Hz

- Current: 20A

- Plug Type: Standard American 3-hole socket

- Required Bench Dimensions:

- Minimum Surface Area: 950 mm × 860 mm

- Load Capacity: 178 kg

- Overall Machine Dimensions:

- Width: 790 mm

- Depth: 870 mm

- Height: 455 mm

- Weight: Approximately 126 kg

ADVANTAGES

Advantages:

- High-Precision Cutting: Ensures deformation-free sectioning of even the most delicate or brittle materials, such as ceramics, crystals, semiconductors, biomaterials, and composites.

- Programmable Automation: Store and recall up to 99 cutting process settings, enabling fast setup and consistent repeatability across different materials or users.

- Dual Cutting Modes: Offers both Direct Cutting and Impact Cutting to accommodate a wide range of materials, including high-hardness or heat-sensitive substrates.

- Adaptive Feed Control: Gravity-based feed mechanism combined with adjustable feed rates (0.01–3 mm/s) minimizes sample damage while optimizing cutting efficiency.

- Closed-Loop Servo System: Delivers high-torque power with integrated overload and thermal protection, safeguarding internal components and ensuring cutting consistency.

- Automatic Blade Retraction: Automatically detects the completion of the cut and retracts the blade to the start position—no need to set stroke length manually.

- Multi-Speed Process Flexibility: Allows multiple feed rates and spindle speeds within the same cutting cycle, ideal for complex or layered samples.

- Advanced User Interface: Intuitive HMI touchscreen with PLC control simplifies operation, supports both English and Chinese, and reduces training time.

- Compact & Laboratory-Friendly Design: Small footprint (790 × 870 × 455 mm) with integrated coolant circulation system, making it ideal for cleanroom, research, and production environments.

- Extensive Clamping Options: Includes 7 interchangeable sample clamps for stable and accurate cutting of varied sample sizes and geometries.

- Powerful Cooling System: Enclosed external cooling device recirculates water around the blade, preventing heat damage and extending blade life.

- Versatile Blade Compatibility: Supports 200 mm (8″) diameter blades with a 32 mm arbor, suitable for a wide range of material hardness and thickness.

- Optional Upgrades Available: Expandable with X-axis movement, sample rotation, and higher RPM range (up to 5000) for increased flexibility.

- Built for Industrial Use: Heavy-duty construction with 1.5 kW motor, robust axis drives, and corrosion-resistant components designed for long service life.

- Comprehensive Support: Backed by 12-month warranty, lifetime technical support, and U.S.-based service and training from experienced engineers.

INDUSTRIES USED IN

Tab Content

FAQ

Tab Content

OPERATING MANUALS

Tab Content

ACCESSORIES

Tab Content

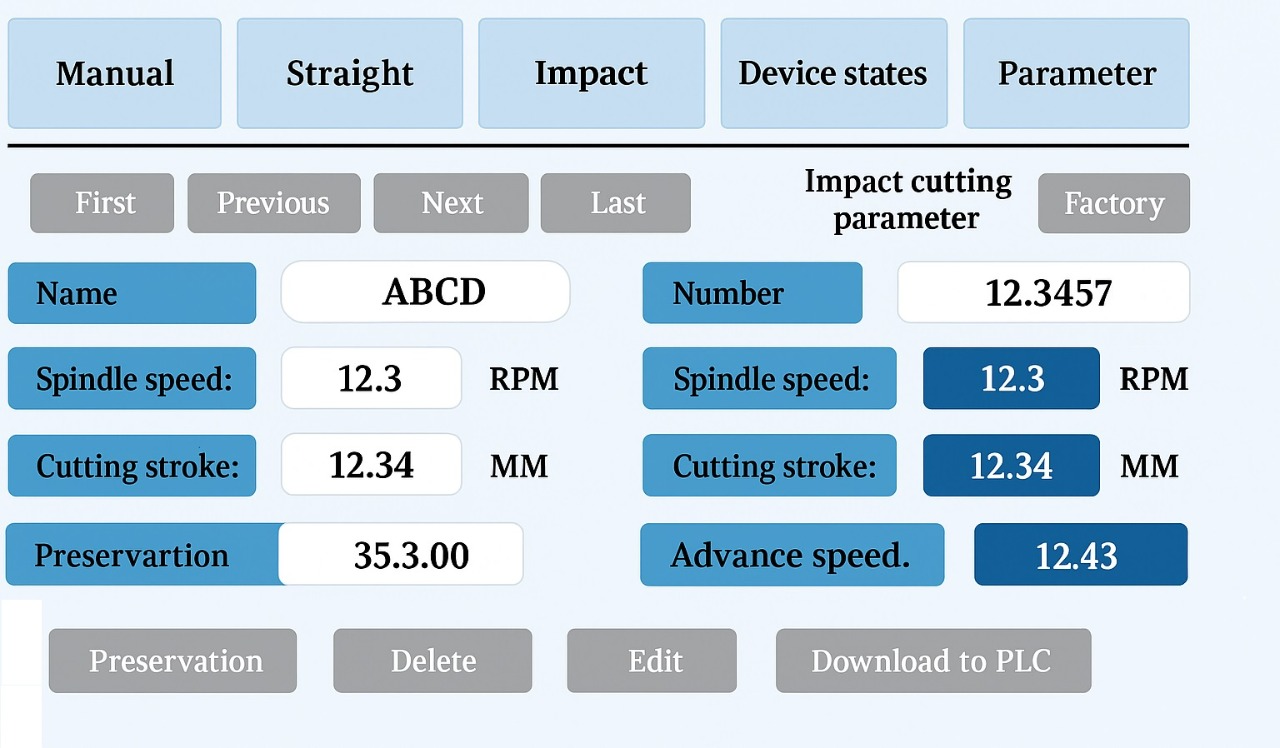

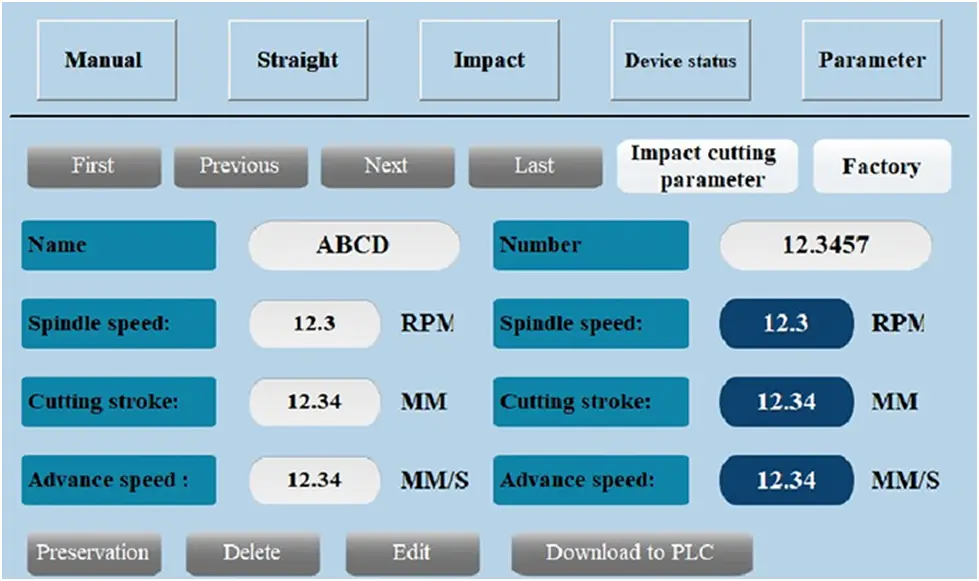

Parameter Configuration and Operational Settings

The SMART CUT® 6055 offers a robust and highly customizable control system, allowing users to precisely define all cutting parameters through the integrated HMI touchscreen. These settings can be stored and recalled for repeat use, enabling consistent results across different materials and operators.

Spindle Speed

The spindle speed is fully adjustable between 500 and 3000 RPM (optionally upgradable to 5000 RPM), accommodating a wide range of material hardness and cutting conditions. Speed control is enabled through a stepless variable frequency drive, providing smooth acceleration and deceleration for enhanced cut quality and blade life.

Cutting Stroke

The machine supports a maximum Y-axis travel of 200 mm. Users can define a fixed cutting stroke within this range to automatically terminate the cut once the defined distance is reached. This is especially useful for batch processing, as it allows multiple identical samples to be cut without repositioning.

Cutting Feed Speed

Feed rate is adjustable from 0.01 to 3.00 mm/s in fine increments. This setting controls how fast the blade advances through the sample and must be selected based on material hardness, density, and desired surface finish. Note that feed speed cannot be changed dynamically during operation; it must be preset before the cut begins.

Return (Back) Speed

Return speed ranges from 0 to 15 mm/s and determines how quickly the blade retracts to its home position after a cut is complete. Higher values enable faster cycle times, particularly in automated or batch operations.

Manual Inching Speed

Manual feed, or inching speed, is adjustable between 0 and 15 mm/s. This setting governs the rate at which the operator can manually jog the blade forward or backward during setup or alignment. For new operators or when working with fragile samples, slower inching speeds are recommended to avoid accidental blade impact with the sample.

Cutting Mode Selection

Two cutting modes are available, allowing the user to choose the optimal cutting method based on material type and desired outcome:

Direct Cutting

This is the standard mode used for the majority of materials. The blade advances continuously through the workpiece at the set feed rate. Direct cutting is ideal for uniform materials and offers the fastest processing speed with minimal blade wear.

Impact Cutting

Designed for specialized applications, impact cutting is useful when working with high-hardness, brittle, or abrasive materials that are difficult to cut using conventional methods. In this mode, the blade engages the sample intermittently (in a pulsed motion), which minimizes heat buildup, reduces the risk of workpiece overheating, and avoids clogging from debris. However, it may result in higher blade wear and slightly longer cycle times.

Impact Cutting Distance

This setting, adjustable from 0.1 to 2.0 mm, defines the intermittent step size used during impact cutting. Smaller step sizes result in finer engagement and slower overall cutting but reduce heat generation and mechanical shock. This parameter has no effect when direct cutting mode is selected.

Process Memory and Repeatability

All parameter configurations can be saved into the onboard memory, with up to 99 individual process profiles storable for instant recall. This enables repeatable, high-precision cutting without the need for reconfiguration, making the SMART CUT® 6055 highly efficient for multi-material laboratories or production environments.

SMART CUT® Coolants

Your choice of one (1) quart of SMART CUT® Water Soluble Coolant or Mineral Oil is included with machine. SMART CUT® Water Soluble Coolant Reduces material thermal stress, edge damage, and internal cracking, increases blade life, provides better cut quality, preserves material micro structure

Hence, assuring long-term integrity of material being sectioned. Since SMART CUT® coolant is both a coolant and lubricant, both the wafering blade and material benefit. Mix ratio is 1:20 (1 part coolant, 20 parts water) on very hard and dense materials and 1:40 (1 part coolant, 40 parts water) on softer materials. Depending on mix ratio 1 quart will produce 5.7 to 9 gallons of coolant when mixed with water. As a coolant, SMART CUT® KOOL reduces heat caused by friction. As a lubricant, SMART CUT® KOOL lowers friction and surface tension, which increases swarf dispersion.

LARGEST SELECTING OF DIAMOND & CBN WAFERING BLADES AVAIALBLE

one (1) diamond wafering blade any specification is included FREE OF CHARGE with purchase of any machine (any specification). we have almost unlimited number of diamond & CBN wafering blade specifications in stock available for immediate delivery. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness’s. With several thousand unique blade specification in stock not listed on our standard stock program. This insures you will receive the best blade specification possible for your specific application.

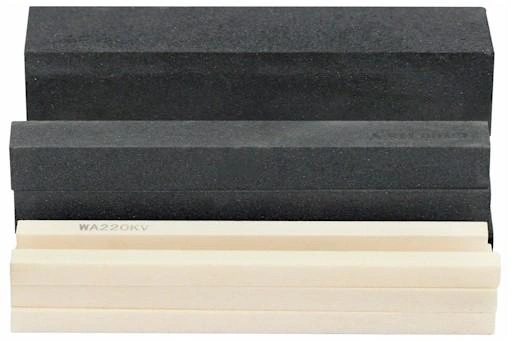

THE RIGHT DRESSING STICK FOR YOUR APPLICATION

One (1) dressing stick is included with the purchase of any machine free of charge. The dressing stick we supply is similar to the diamond size of the wafering blade you have chosen (or we recommended) for your application. Wafering Blades must be diamonds particles/crystals exposed properly through frequent dressing. Otherwise, the diamond tool will glaze over. They will begin to tear rather than grind which is very destructive. Tearing caused from unexposed diamonds creates friction. This causes uneven wear and/or heat cracks in the wafering blade and/or material being cut. Resulting in premature blade wear, blade tensioning problems, and will eventually destroy the blade. The more frequently the blade is dressed the freer and cooler it will cut with lot more consistency.

Related Products

Item # 8054245-2 SMART CUT® 1800 – Precision Saw

Item # 8054245-1-1 SMART CUT® 1805 – Precision Saw

Item # 9000361 SMART CUT® 6018 – Automatic Saw

Item # 9014006 SMART CUT® 6025 – Manual Sectioning Saw

$5,675.00