-

0 items in quote

No products in the Quote Basket.

SMART CUT® 6045 Sectioning Saw

SMART CUT® 6045 is a versatile, high-precision sectioning saw designed for cutting a wide range of materials including circuit boards, glass, ceramics, composites, semiconductors, hard metals, and rocks. Engineered for research laboratories, materials science, failure analysis, and industrial quality control, this machine delivers exceptional cutting accuracy up to 0.01mm, making it ideal for demanding sample preparation applications.

The system is powered by a robust 750-watt motor with variable speed control from 0 to 1,500 RPM, allowing users to adjust cutting speed based on material hardness and brittleness. Unlike traditional saws, cutting speed remains constant under load, ensuring repeatable performance and consistent results. The machine utilizes a gravity weight feed mechanism, enabling unattended sectioning with minimal operator supervision.

A fully enclosed Plexiglas safety cover combined with an emergency stop switch ensures maximum operator protection, while the automatic stop function after cut completion allows users to work more efficiently.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide

Since 1990

DESCRIPTION

SPECIFICATIONS

ADVANTAGES

INDUSTRIES USED IN

FAQ

OPERATING MANUALS

ACCESSORIES

DESCRIPTION

The integrated recirculating coolant system provides continuous cooling, helping to minimize thermal damage, extend blade life, and improve overall cut quality.

One of the key advantages of SMART CUT® 6045 is the comprehensive set of sample holding fixtures included at no extra cost. This includes seven unique clamps and vises, such as those for irregular shapes, inset samples, long parts, and cylindrical components, making it suitable for almost any geometry or sample type. An optional cutting platform is available for preparing large flat specimens like sheet materials, glass, or large printed circuit boards.

The system supports the use of ultra-thin diamond blades as small as 0.4mm thick, ensuring high-precision sectioning with minimal kerf loss and excellent surface finish. The LED digital display, closed-loop control, and automatic cooling function all contribute to making this saw a top-tier solution for micro-precision sectioning.

SMART CUT® 6045 is extremely user-friendly, requiring no complex software or programming. Everything is controlled with simple, intuitive adjustments, making it accessible for both novice and experienced users. When compared to other low and high-speed sectioning machines, it provides significantly better value, thanks to its expanded RPM range, variety of included fixtures, and ability to handle a broad spectrum of materials and sample types.

If you are looking for a precision cutting machine that delivers clean, fast, and accurate results, offers exceptional versatility, and includes more standard accessories than the competition, SMART CUT® 6045 is the best value in its class.

SPECIFICATIONS

Cutting Action: Gravity & Linear Feed

Motor Power: 750w

RPM’s (Variable Speed) : 50-1,500 rpm

Blades SMART CUT® 6010 can accommodate:

Wafering & Abrasive Blade Diameters: 3” (75mm) to 7” (175mm)

Blade Thickness: .004″ (0.10mm) to .075″ (1.9mm)

Can be used with:

- SMART CUT Diamond Wafering Blades

- Other manufacturers Diamond Wafering Blades

- Abrasive Cut Off blades.

Coolant Capacity: 1/2″ gallon (1.9 liters)

Load Capacity: 0 to 1,500 grams

Micrometer Feed: 0 to 1” (0 to 25.4mm)

Electrical Specifications: 110v/220v single phase

Cutting Capacity: 2” (50.8mm)

Arbor: ½” (12.7mm)

Shipping Weight: 33 kg (72.75 lbs)

Dimensions: 455 mm (17.91″) W x 610 mm (24.02″) L x 380 mm (14.96″) H

ADVANTAGES

Advantages:

- Exceptional precision: Achieves cutting accuracy up to 0.01 mm, ensuring exact cross-sectioning of delicate and critical samples.

- Unattended operation: Gravity weight feed system allows for automatic cutting without constant operator supervision, improving productivity.

- Damage-free cutting: Low-force sectioning and optimized cooling help preserve the true microstructure of samples without deformation.

- High-speed efficiency: Variable RPM range (0–1,500) accommodates a wide variety of materials and enables faster cutting compared to traditional low-speed saws.

- Versatile material compatibility: Capable of cutting glass, ceramics, semiconductors, composites, PCBs, metals, and more.

- Wide range of included fixtures: Comes standard with seven different clamps and vises, allowing users to secure virtually any sample shape without needing additional accessories.

- Low operating cost: Uses long-life sintered diamond blades and recirculating coolant system to minimize consumable usage and reduce maintenance frequency.

- Space-saving and portable: Compact bench-top design with small footprint (610 x 460 x 380 mm) and manageable weight (33 kg).

- Built-in safety features: Fully enclosed cutting area with emergency stop switch to ensure operator safety.

- Simple and intuitive operation: No need for complex programming, software, or training – plug and play functionality suitable for both beginners and experienced technicians.

- Excellent value: Combines the precision and versatility of high-end sectioning saws with affordability and robust construction, making it one of the best cost-to-performance machines in its class.

- Future-ready expandability: Optional accessories like a flat cutting platform and various blade sizes allow you to adapt the machine for evolving application needs.

INDUSTRIES USED IN

Tab Content

FAQ

Tab Content

OPERATING MANUALS

Tab Content

ACCESSORIES

Tab Content

Features:

- Precision cutting accuracy of 0.01 mm, ideal for high-accuracy sample sectioning.

- Powerful 750W motor with variable speed control from 0 to 1,500 RPM for enhanced versatility across different materials.

- Gravity weight feed system allows for unattended, automated cutting with consistent pressure.

- Closed-loop control system prevents overload and protects the motor and electronics.

- Automatic stop function halts the cutting process when the operation is complete, enabling safe and efficient use.

- Fully enclosed transparent Plexiglas safety cover with emergency stop switch for enhanced operator protection.

- Supports ultra-thin diamond blades (as thin as 0.4mm) for minimal material loss and ultra-precise cuts.

- Sample movement precision of 0.01 mm, allowing for exact lateral advancement during cutting.

- Integrated recirculating coolant system provides effective cooling, reducing heat damage and increasing blade life.

- Includes 7 different sample holding fixtures to accommodate irregular shapes, insets, long parts, and more — all included as standard.

- Optional large flat cutting platform available for sectioning sheet materials, large PCBs, glass, and similar substrates.

- Simple, user-friendly controls with no complex programming required — easy to operate and maintain.

- Ideal for scientific research labs, universities, and industrial applications requiring high-precision, low-damage sectioning.

8 chucks/holding fixtures and table saw cutting attachment is included with each machine

SMART CUT® 6045 Table Saw Attachment (optional)

The Table Saw Attachment is a precision workholding accessory designed for use with low to medium-speed diamond saws. It enables controlled sectioning, trimming, and angled cutting of larger flat workpieces such as printed circuit boards, ceramic substrates, composite panels, and other hard or brittle materials. The attachment provides a stable, flat cutting surface that ensures straight, repeatable cuts with high accuracy.

Made from corrosion-resistant materials, it offers rigid support that minimizes vibration and chatter. It features an integrated guide or adjustable fence system for clean, parallel or angled cuts. The large work area supports samples up to 1″ in size, including PCBs, ceramic tiles, and glass substrates.

Designed for manual trimming applications, this attachment is easy to use and requires minimal setup. It’s ideal for jobs that demand operator control and flexibility, especially when cutting fragile or miniature parts.

Installation is quick and tool-friendly, with a bolt-on design that fits most saws. It requires no machine modifications. The attachment helps reduce breakage and chipping by fully supporting the sample during the cut.

This tool is widely used in R&D, prototyping, and light production for trimming, cross-sectioning, and sample preparation in microelectronics, MEMS, and materials research.

Best of all, the Table Saw Attachment is offered at a fraction of the cost of similar machines in its class, making it a cost-effective solution for achieving precision cuts in hard materials.

- Cuts straight and angled lines with high accuracy

- Works with most low to medium-speed diamond saws

- Great for trimming PCBs, ceramics, and composites

- Easy manual operation with full control

- Reduces breakage and chipping

- Fast and simple to install

- Durable and corrosion-resistant

- Very affordable—costs much less than similar machines

SMART CUT® 6045 Standard Package

| Item Number | Description | Picture |

| 8068102 | Smart Cut 6045 sectioning saw with 0.5 inch arbor, 0.25 hp motor, integral coolant reservoir, gravity & manual table feed, 110V & 220v includes, (8) eight chucks, (1) micrometer, (1) one Wafering Blade any specification, one (1) dressing stick, one (1) quart of SMART CUT water soluble coolant or mineral oil |  |

| Ukam60010-1 | Universal single saddle vise |  |

| Ukam60010-2 | 1.25-inch Round holder |  |

| Ukam60010-75 | Round holder |  |

| Ukam60010-3 | Specimen vise for adhering specimens |  |

| Ukam60010-4 | Specimen vise for irregular shaped specimens |  |

| Ukam60010-5 | Tear Drop chuck |  |

| Ukam60010-6 | Fastener vise for longitudinal sectioning for fasteners, tubes etc |  |

| Ukam60010-8 | Large single saddle vise Double saddle vise |  |

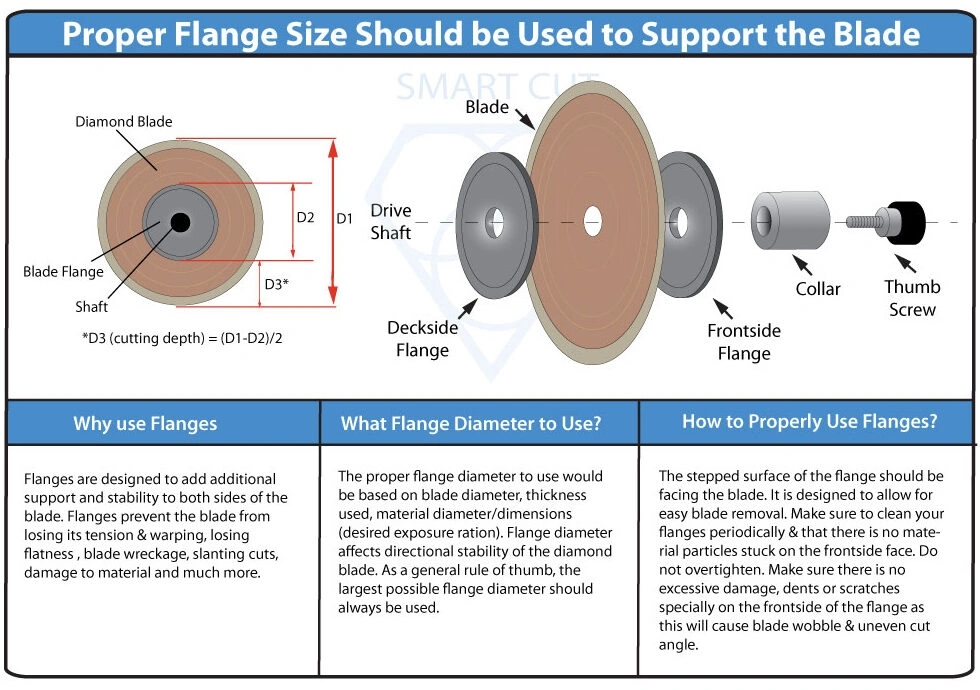

| Ukam60010-9 Ukam60010-10 | Flanges 50mm and Flanges 100mm |  |

| UKAMLS016 | 1 quart of SMART CUT water soluable coolant (advanced materials) formula or Mineral Oil (your choice) mix ration 1:20 (1 part coolant, 20 parts water) will make 5.7 gallons of coolant |  |

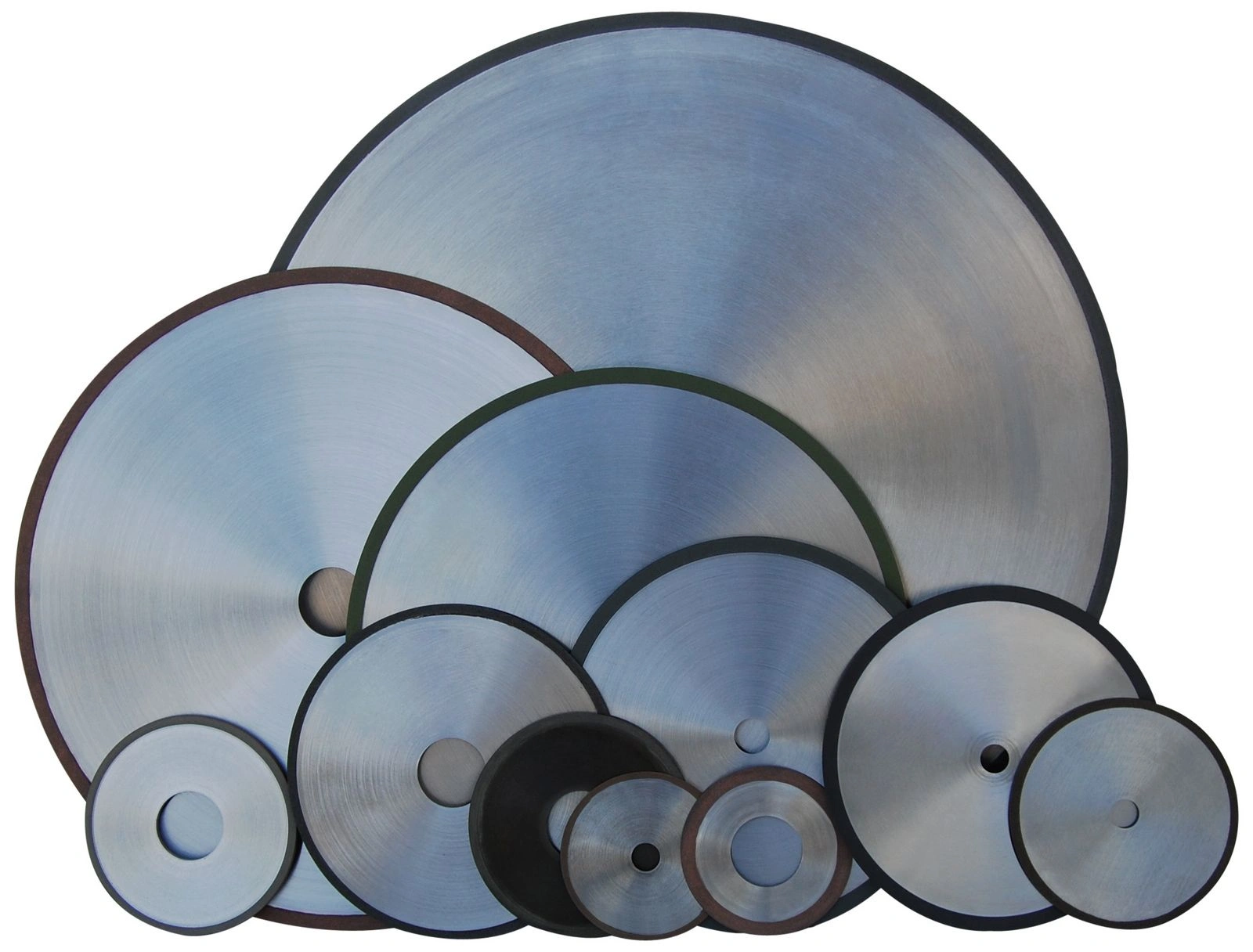

| Select Right Wafering Blade for your application | 6″ x .020″ x 1/2″ Diamond or CBN Wafering Blade. Sintered (metal bond) any specification. How to select the Right Diamond Wafering Blade for your application >>> |  |

| Dressing Stick (1/2″ x 1/2″ x 6″) alumina oxide white color 120, 220, or 320 grit (depending on your blade selection) |  |

SMART CUT® Coolants

Your choice of one (1) quart of SMART CUT® Water Soluble Coolant or Mineral Oil is included with machine. SMART CUT® Water Soluble Coolant Reduces material thermal stress, edge damage, and internal cracking, increases blade life, provides better cut quality, preserves material micro structure

Hence, assuring long-term integrity of material being sectioned. Since SMART CUT® coolant is both a coolant and lubricant, both the wafering blade and material benefit. Mix ratio is 1:20 (1 part coolant, 20 parts water) on very hard and dense materials and 1:40 (1 part coolant, 40 parts water) on softer materials. Depending on mix ratio 1 quart will produce 5.7 to 9 gallons of coolant when mixed with water. As a coolant, SMART CUT® KOOL reduces heat caused by friction. As a lubricant, SMART CUT® KOOL lowers friction and surface tension, which increases swarf dispersion.

LARGEST SELECTING OF DIAMOND & CBN WAFERING BLADES AVAILABLE

one (1) diamond wafering blade any specification is included FREE OF CHARGE with purchase of any machine (any specification). we have almost unlimited number of diamond & CBN wafering blade specifications in stock available for immediate delivery. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness’s. With several thousand unique blade specification in stock not listed on our standard stock program. This insures you will receive the best blade specification possible for your specific application.

THE RIGHT DRESSING STICK FOR YOUR APPLICATION

One (1) dressing stick is included with the purchase of any machine free of charge. The dressing stick we supply is similar to the diamond size of the wafering blade you have chosen (or we recommended) for your application. Wafering Blades must be diamonds particles/crystals exposed properly through frequent dressing. Otherwise, the diamond tool will glaze over. They will begin to tear rather than grind which is very destructive. Tearing caused from unexposed diamonds creates friction. This causes uneven wear and/or heat cracks in the wafering blade and/or material being cut. Resulting in premature blade wear, blade tensioning problems, and will eventually destroy the blade. The more frequently the blade is dressed the freer and cooler it will cut with lot more consistency.