-

0 items in quote

No products in the Quote Basket.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide

Since 1990

DESCRIPTION

SPECIFICATIONS

ADVANTAGES

INDUSTRIES USED IN

FAQ

OPERATING MANUALS

ACCESSORIES

DESCRIPTION

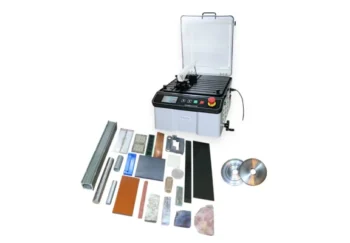

SMART CUT® 6025-A Precision Cut-Off Saw is a versatile and advanced laboratory tool designed for both manual and automatic precision cutting. Engineered to accommodate a wide range of applications, it is capable of sectioning various materials such as metals, PCB circuit boards, semiconductors, crystals, ceramics, quartz glass, and petrographic samples. This saw is an essential instrument for sample preparation in laboratories, research facilities, and academic institutions.

Equipped with a powerful 1.0 HP (750W) motor, the saw operates at variable speeds ranging from 500 to 3,000 RPM or 100 to 800 RPM, allowing precise control for cutting different materials. It can handle samples up to 2 inches (50 mm) in diameter, cutting most materials within seconds or minutes while preserving their true microstructure and minimizing deformation.

SMART CUT® 6025-A offers three cutting modes to suit various requirements. Manual cutting provides full user control over speed and parameters, while automatic cutting uses a program-controlled system for efficient, hands-free operation. The pulsing cutting mode is specifically designed to minimize surface burning on heat-sensitive samples, and the speed automatic adjustment cutting mode optimizes cutting speed to improve cut quality and motor protection.

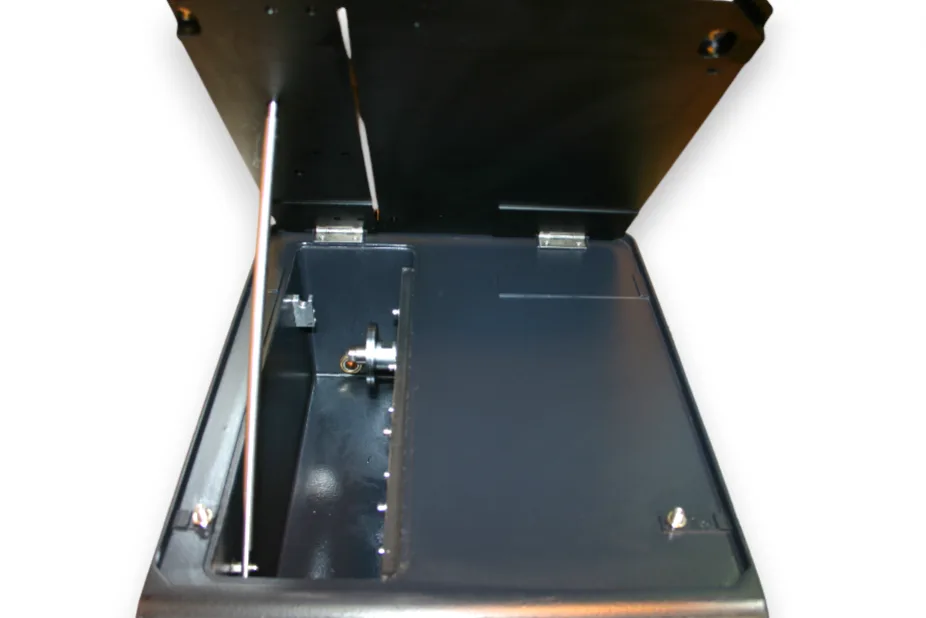

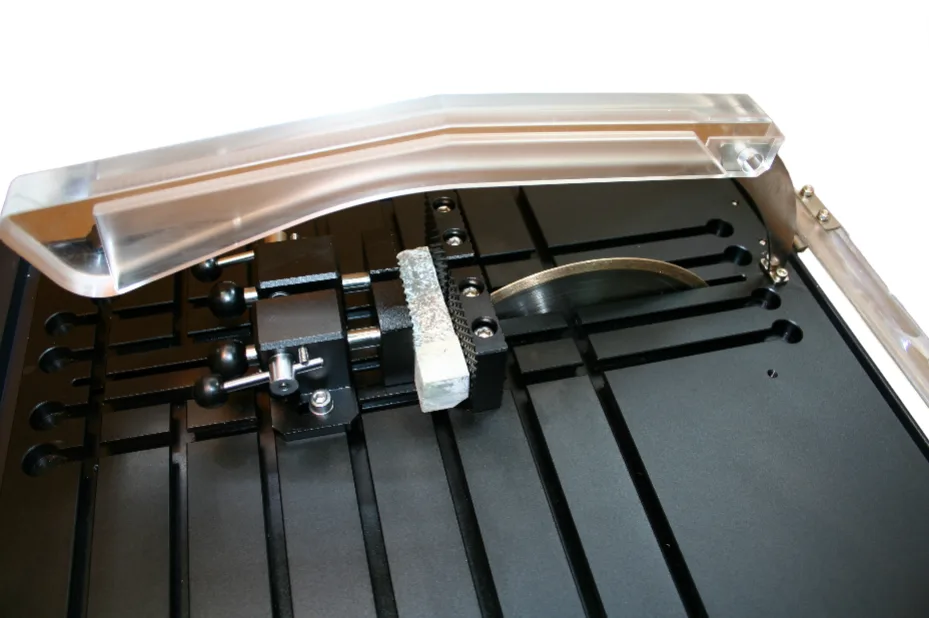

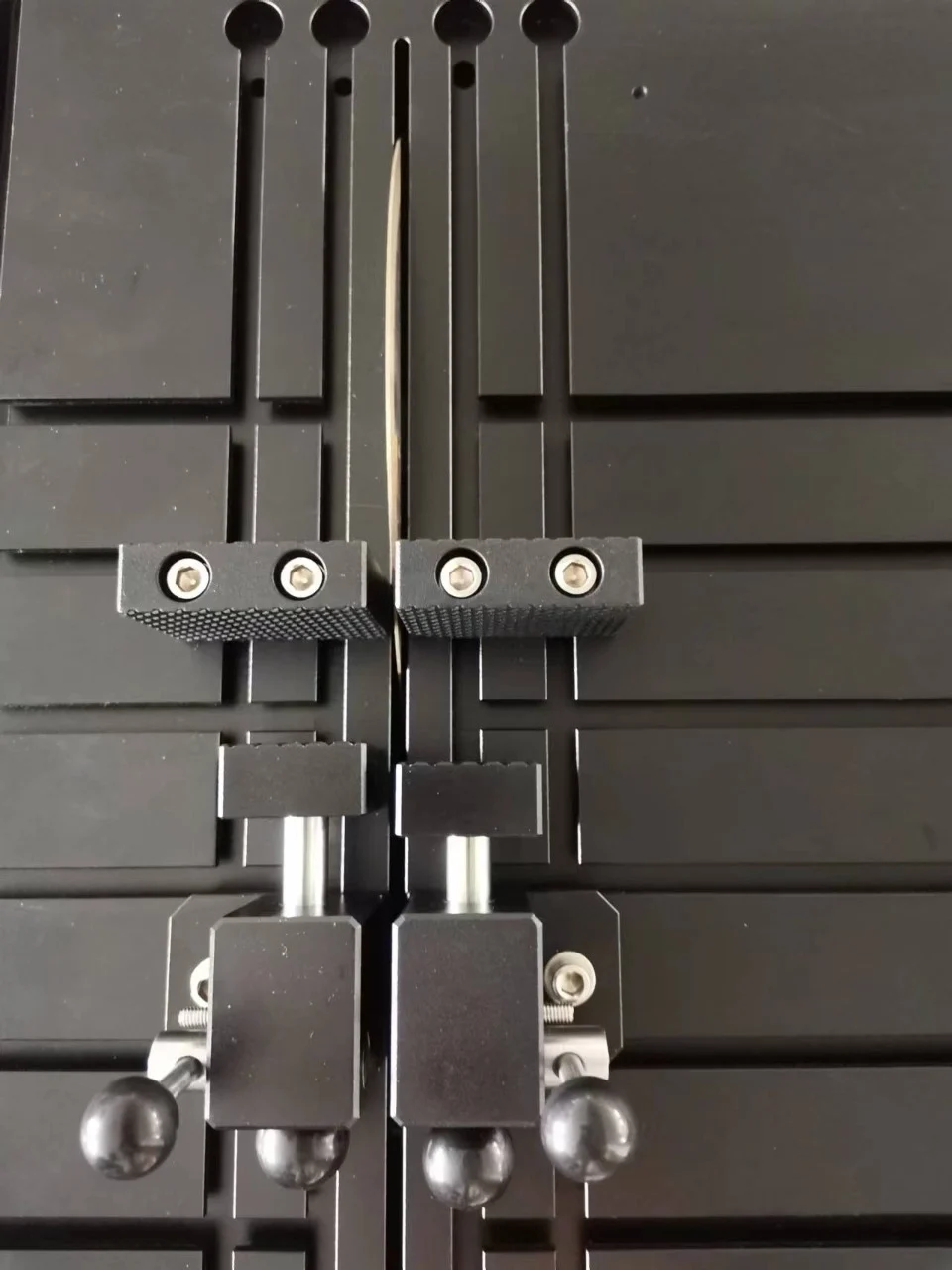

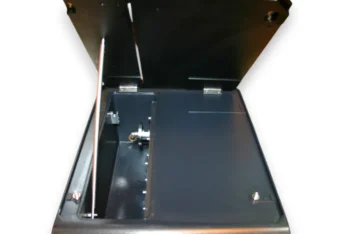

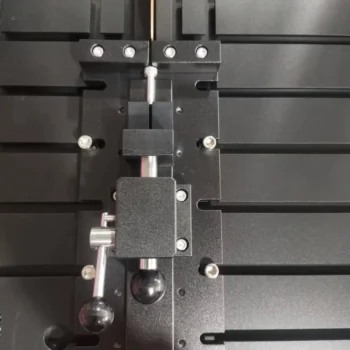

Constructed with a hard-anodized aluminum cutting table, the SMART CUT® 6025-A offers a durable and corrosion-resistant work surface measuring 400 mm x 450 mm, capable of accommodating oversized samples. The table’s lip-free design provides unobstructed access to materials, and its T-slot configuration allows for the use of a variety of clamping vises. Irregularly shaped workpieces can be easily secured with the included fixtures, while an optional angle-holding vise is available for more advanced cutting needs.

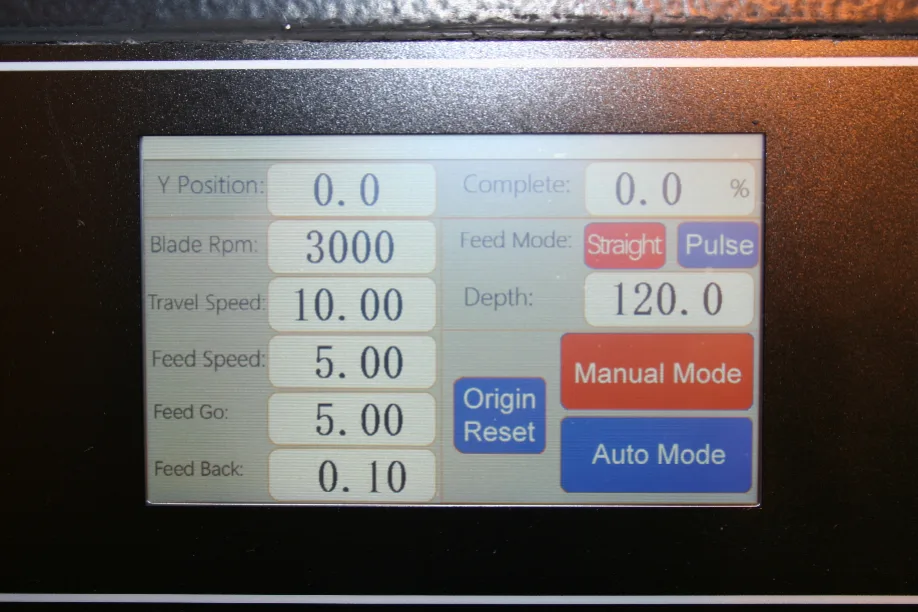

Operation is simplified with a 100 mm x 60 mm touchscreen interface that allows users to program and control the cutting process. Pre-set speed adjustment buttons provide quick and precise changes during cutting, while a mechanical rotary handle on the right-hand side offers full control over blade movement. The cutting environment is enclosed within a transparent Plexiglas cover, ensuring user safety while allowing clear observation of the process.

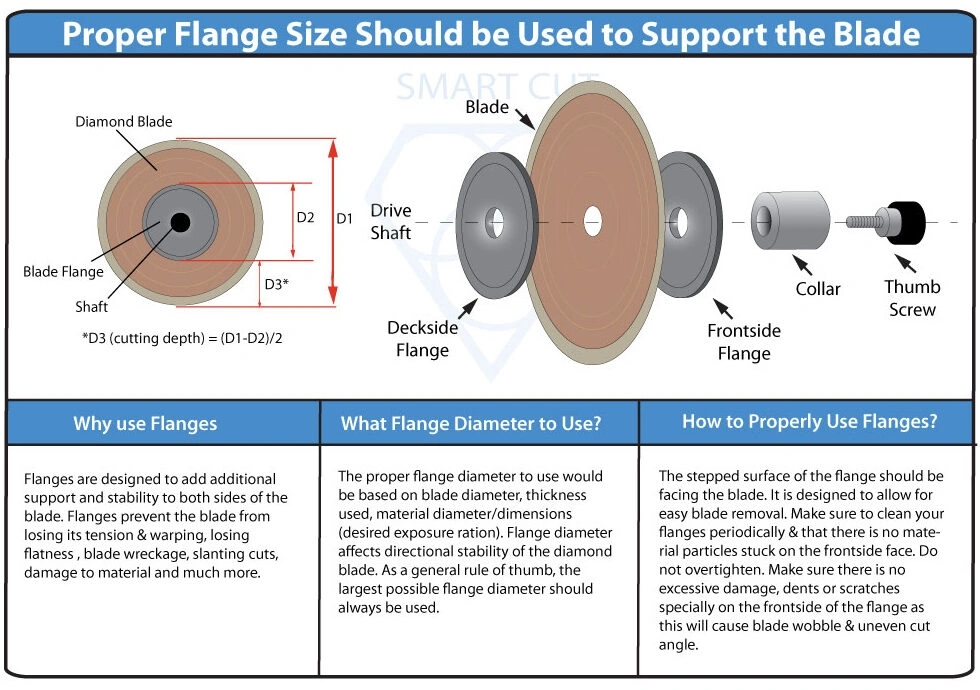

The saw is compatible with a wide range of blades, including diamond, CBN, abrasive, and high-speed steel or carbide types, and supports both wet and dry cutting methods. A hidden coolant system enhances cutting performance by reducing heat and wear on the blade and sample. Additionally, an optional vacuum cleaning attachment can be integrated to remove material particles as they are generated, ensuring a clean workspace.

Designed with safety and efficiency in mind, the SMART CUT® 6025-A includes overload protection to extend motor life and a magnetic safety switch that immediately halts blade operation when the cover is opened. The large speed range allows for the use of blades with various specifications, achieving superior cut quality and speed compared to traditional low-speed saws. With a feed distance of 4.3 inches (110 mm), the saw provides precise depth control for cutting operations.

SMART CUT® 6025-A is an innovative solution for precision sectioning, offering a combination of high-speed operation, advanced features, and robust construction. Its ability to handle a variety of materials with accuracy and speed makes it an indispensable tool for modern laboratories and manufacturing environments.

SPECIFICATIONS

Cutting Action:

- inear blade feeds into the material/sample

- Material is slowly fed into the rotating blade for precise sectioning.

Motor Power:

- 1.0 HP (750W).

- Operates on 110V or 220V power configurations.

Speed Range (Variable Speed):

- High range: 500–3,000 RPM.

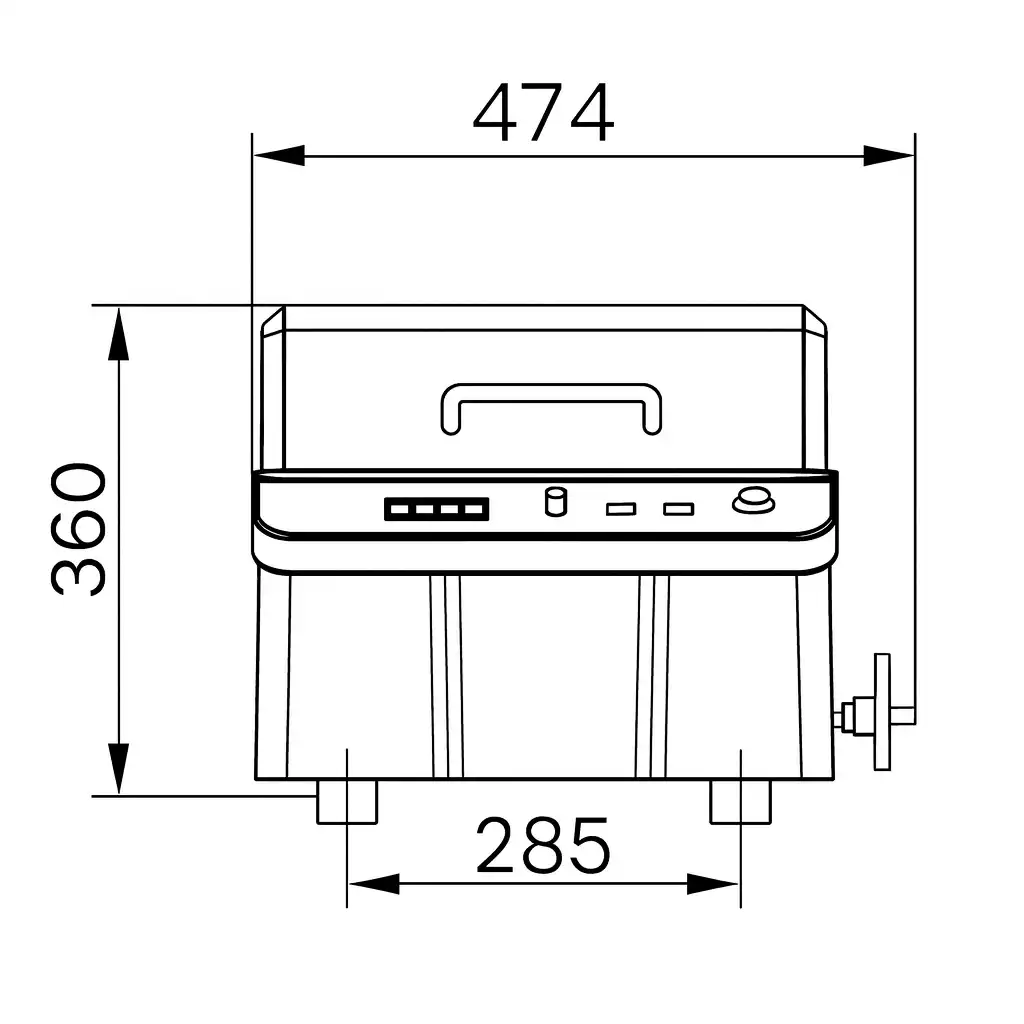

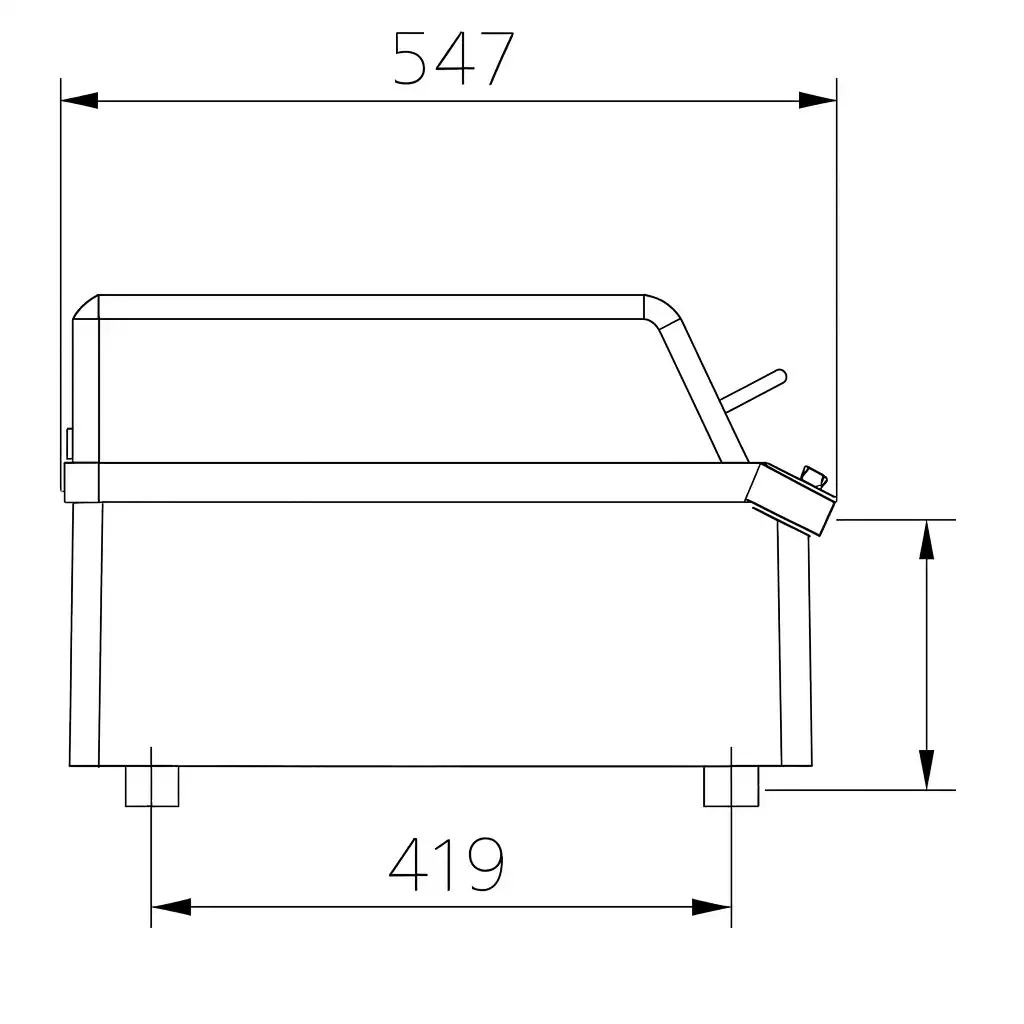

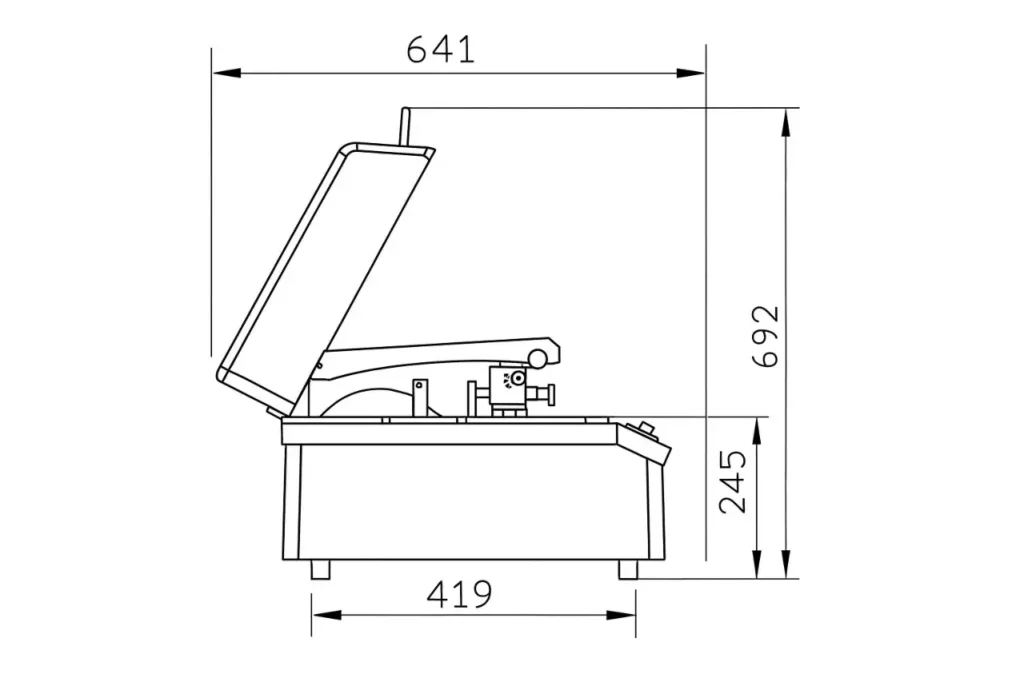

Cutting Capacity:

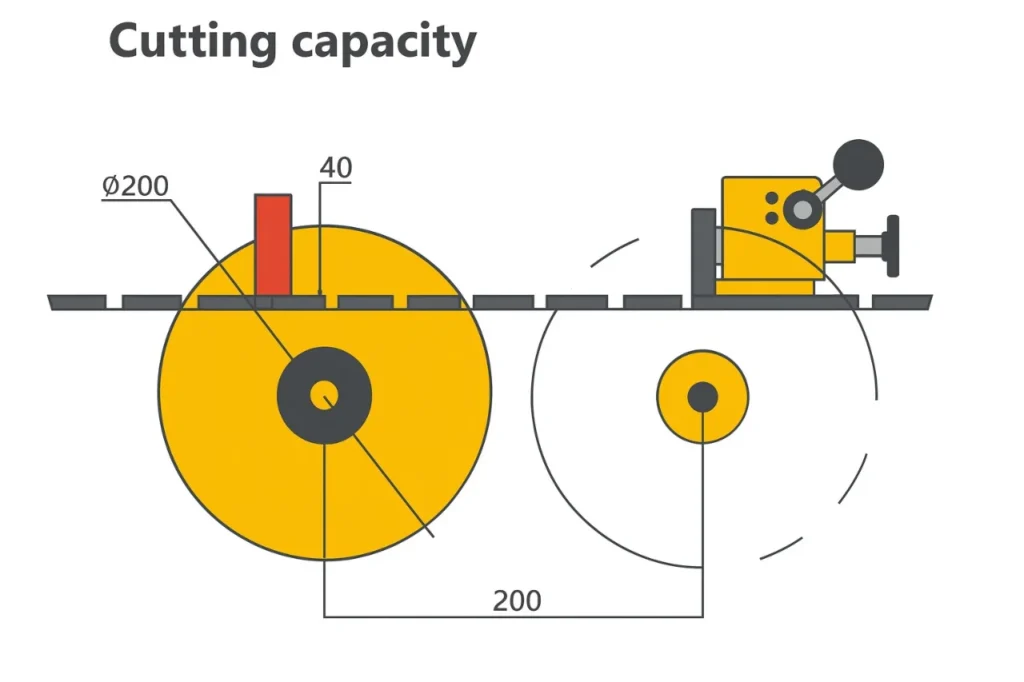

- Maximum sample diameter: 2 inches (50 mm).

Blade Compatibility:

- Wafering & Abrasive Blade Diameters: 6″ (152.4 mm), 7″ (177.8 mm), and 8″ (200 mm).

- Blade Thickness Range: .009″ (0.22 mm) to .075″ (1.9 mm).

- Compatible with:

- SMART CUT® Diamond Wafering Blades.

- Other manufacturers’ diamond wafering blades.

- Abrasive cut-off blades.

Cutting Table Dimensions:

- Hard-anodized aluminum table measuring 400 mm x 450 mm.

- Lip-free design for unobstructed access to larger samples.

Feed Distance:

- 4.3 inches (110 mm).

Coolant System:

- Built-in hidden cooling system for wet cutting.

- Coolant capacity with a ¼

Material Compatibility:

- Suitable for cutting metals, PCB circuit boards, semiconductors, ceramics, crystals, quartz glass, and petrographic samples.

Cutting Modes:

- Manual: Full user control over cutting speed and parameters.

- Automatic: Program-controlled cutting process.

- Pulsing: Reduces surface burning on heat-sensitive samples.

- Speed Automatic Adjustment: Automatically adjusts cutting speed for optimized performance and motor protection.

Control Interface:

- 100 mm x 60 mm touchscreen for simple operation and programming.

- Pre-set speed adjustment buttons for quick and precise speed changes.

Safety Features:

- Magnetic safety switch halts blade operation when the cover is opened.

- Transparent Plexiglas cover for safety and observation during cutting.

- Overload protection to enhance motor durability.

Workholding Options:

- T-slot table accommodates various clamping vises.

- Optional angle-holding vise for advanced cutting configurations.

Construction:

- Hard-anodized aluminum cutting table ensures durability and corrosion resistance.

- Robust metal housing for long-lasting performance.

Optional Features:

- Vacuum cleaning attachment for efficient removal of swarf during cutting.

- Angle-holding vise for improved positioning and advanced sample cutting.

Shipping Information:

- Weight: 93 lbs (42 kg).

- Dimensions: 18″ x 20″ x 13.8″.

Applications:

- Designed for laboratories in factories, R&D institutes, and academic settings.

- Ideal for sample preparation requiring precision, low deformation, and preservation of true material microstructure.

ADVANTAGES

- Most Affordable Entry Level Lab Cutting Saw on Market Today

- Reduce Consumables Cost by up to 400%

- Equal or Better Cut Quality on most Applications to Fully Automatic Sectioning Saws, at small Fraction of cost.

- No Material Deformation

- Can withstand more exploitation that conventional precision sectioning saws

- Very Easy to use (reduce operator error & training)

- Can be used for just about any material or application

- Very compact, requires minimum space

- Powerful motor designed for cutting very hard to soft materials

- Straight forward design allows the operator to concentrate on sectioning samples, not operating the machine

- The durable housing is made from unbreakable cross linked

- polyethylene which cannot rust. Housing and all plastic parts are guaranteed for life.

- Larger speed range allow for almost unlimited number of blade specification choices to achieve desired results

- Perfect for Manufacturing and R & D Organizations on a Budget

INDUSTRIES USED IN

INDUSTRIES USED IN:

- Advanced Ceramics

- Composites

- Glass

- Geology

- Quartz

- Materials Research

- Medical Devices

- Metallography

- Photonics / Optics

- Semiconductor

Ferrous & Non-Ferrous Metals:

- Plain Carbon Steels

- Electronic Packages

- Stainless Steels Plastics

- Tool Steels Fasteners

- Aluminum Refractories

- Copper Base Alloys Integrated Circuits

- Magnesium Thermal Spray Coatings

- Titanium Metal Matrix Composites

- Biomedical Wafers

- Petrographic

- PCB.s Ceramics

FAQ

The SMART CUT® 6025 is designed for precision sectioning of a wide variety of materials, including PCB Boards, Silicon Wafers, Optical Glass, Ferrite Chunks, ceramic substrates, electronic packages, and more.

The SMART CUT® 6025 is versatile and can function both as a manual and an automatic precision laboratory cutting saw.

The saw is equipped with a powerful 1.0 hp (750 W) motor, running at a variable speed of 500 to 3,000 RPM or 100 to 800 RPM.

Coolant is stored below and is applied to the sample by the rotating blade.

The saw table has a large working area measuring 400mm x 450mm.

The cutting table is made from hard anodized aluminum, and the saw housing is metal.

The material is held in place by a vice, and the blade moves into the cutting sample using a mechanical rotary handle on the right-hand side.

Yes, users can adjust the RPM to better fit the sample/material being cut, and the motor ensures that the selected speed remains constant under any load.

The machine can be used with almost any type of diamond, cbn, abrasive, or high-speed steel/carbide blade.

Yes, the machine can be used both wet and dry.

The cutting action involves a linear blade feed into the workpiece, where the material is slowly fed into the rotating blade.

The saw can accommodate wafering and abrasive blade diameters of 6″ (152.4mm), 7″ (177.8mm), and 8” (200mm) with blade thickness ranging from .009″ (0.22mm) to .075″ (1.9mm).

The coolant capacity is ¼, and the arbor size is ½” (12.7mm).

The shipping weight is 93 lbs (42 kg), and the dimensions are 18″ x 20″ x 13.8″.

Yes, an optional vacuum cleaning attachment is available to remove material swarf particles as they are being cut.

The saw is designed for fast and precision sectioning, preserving the sample/material’s true microstructure.

Yes, the machine is compatible with SMART CUT Diamond Wafering Blades, other manufacturers’ Diamond Wafering Blades, and Abrasive Cut Off blades.

Warranty and after-sales support details would be provided by the manufacturer or distributor. It’s advisable to check with them directly for specific terms and conditions.

The SMART CUT® 6025 offers a combination of precision, versatility, and affordability, making it a preferred choice for many laboratory applications.

Sectioning is done in a closed environment using a Plexiglas Cover to ensure safety. Users should always wear appropriate safety gear and follow the guidelines provided in the user manual for safe operation.

Most samples can be sectioned in seconds or a few minutes, depending on the material and blade used.

The T Slot table allows for t-slot clamping vises to be placed, ensuring a secure hold on most samples during the cutting process.

The machine is designed for ease of setup, but it’s always advisable to refer to the user manual for any assembly or setup instructions.

Regular cleaning of the saw table, blade, and coolant reservoir is recommended. The removable saw table makes cleanup easy. Always refer to the user manual for specific maintenance guidelines.

Yes, the SMART CUT® 6025 is versatile and can handle a wide range of materials, from soft to hard, given the right blade selection.

Yes, the machine comes with a digital readout that displays the RPMs at which the machine is running.

The variable speed allows users to adjust the RPMs to better fit the sample/material being cut, ensuring optimal cutting conditions for different materials.

Yes, an optional angle holding vice and a vacuum cleaning attachment are available for the machine.

The motor of the SMART CUT® 6025 is designed to ensure that the selected speed remains constant under any load, providing consistent cutting performance.

Users should always wear safety goggles and gloves, ensure the work area is clean, and follow the safety guidelines provided in the user manual.

The built-in coolant system helps dissipate heat generated during cutting, ensuring the material and blade remain cool and reducing the risk of heat-induced deformities.

Yes, the SMART CUT® 6025 typically comes with a user manual that provides detailed instructions on setup, operation, and maintenance.

The user manual typically provides a troubleshooting section. For more complex issues, contacting the manufacturer or distributor is recommended.

The rustproof housing ensures long-term durability without corrosion risks, making the machine more reliable and long-lasting.

The precise blade feed mechanism and the ability to adjust the RPMs ensure minimal deformation of the material being cut.

The precision design, variable speed control, and appropriate blade selection ensure that the SMART CUT® 6025 provides clean cuts with minimal chipping.

Regularly checking the blade for wear, using the appropriate coolant, and ensuring the material is fed at the correct rate can help prolong the blade’s life.

When using the machine for dry cutting, ensure proper ventilation, wear a dust mask, and regularly clean the machine to prevent dust accumulation.

OPERATING MANUALS

Download Operating Manuals

ACCESSORIES

Vertical clamping vise with shoe (pair)

Cutting Guide

Features

- Versatile manual and automatic cutting modes.

- Capable of cutting various materials including metals, PCB circuit boards, semiconductors, crystals, ceramics, quartz glass, and petrographic samples.

- Powerful 1.0 HP (750W) motor with variable speed ranges: 500–3,000 RPM or 100–800 RPM.

- Three cutting modes: manual, automatic, and pulsing (to reduce surface burning).

- Speed automatic adjustment mode to optimize cutting quality and protect the motor.

- Hard-anodized aluminum cutting table measuring 400 mm x 450 mm.

- Lip-free table design for unobstructed material access.

- T-slot configuration to accommodate various clamping vises.

- Optional angle-holding vise for advanced cutting needs.

- 100 mm x 60 mm touchscreen interface for simplified programming and operation.

- Pre-set speed adjustment buttons for quick changes.

- Transparent Plexiglas cover for safety and visibility during cutting.

- Compatible with diamond, CBN, abrasive, and high-speed steel/carbide blades.

- Supports both wet and dry cutting methods.

- Hidden coolant system for heat and wear reduction.

- Optional vacuum cleaning attachment to remove material particles.

- Magnetic safety switch to immediately halt blade operation when the cover is opened.

- Overload protection to extend motor life.

- Feed distance of 4.3 inches (110 mm) for precise depth control.

- Large speed range supporting a variety of blade specifications for superior cut quality and speed.

- Affordable Precision Lab Cutting Saw on Market Today

- Reduce Consumables Cost by up to 400%

- Equal or Better Cut Quality on most Applications to Fully Automatic Sectioning Saws, at small Fraction of cost.

- No Material Deformation

- Can withstand more exploitation that conventional precision sectioning saws

- Very Easy to use (reduce operator error & training)

- Can be used for just about any material or application

- Very compact, requires minimum space

- Powerful motor designed for cutting very hard to soft materials

- Straight forward design allows the operator to concentrate on sectioning samples, not operating the machine

- The durable housing is made from unbreakable cross linked

- Larger speed range allow for almost unlimited number of blade specification choices to achieve desired results

- Perfect for Manufacturing and R & D Organizations looking for versatile and affordable solution

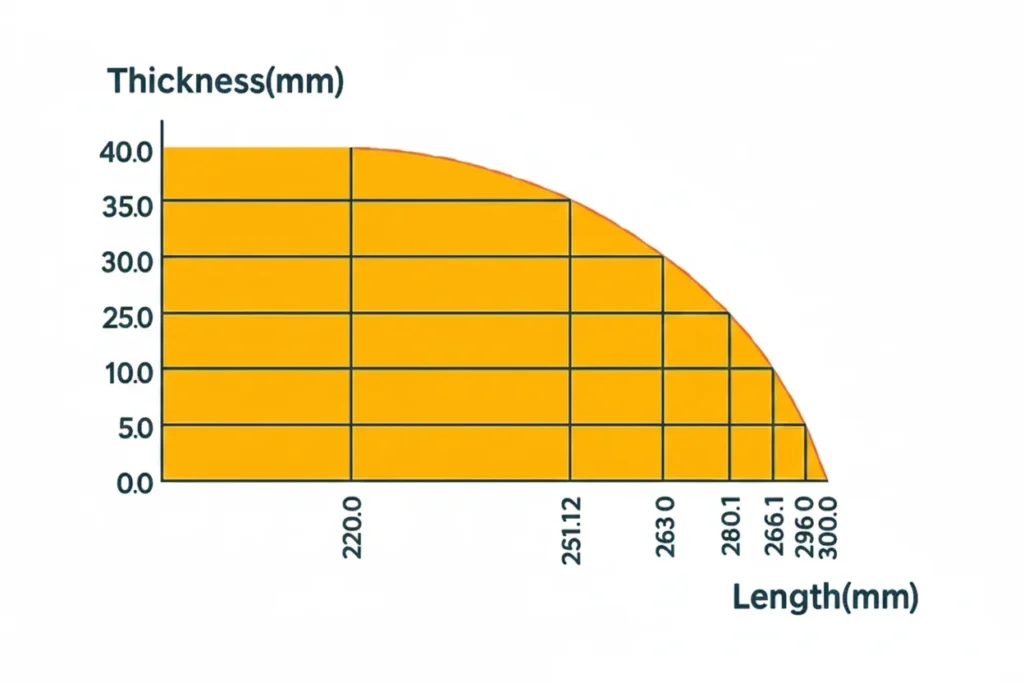

Cutting Capacity

safe operating range for cutting different thickness and length combinations. Use it to confirm that your application falls within stable cutting conditions for best accuracy and blade life.

This diagram shows the maximum cutting depth and reach your machine can achieve using a 200 millimeter blade. It helps you verify that your workpiece size fits within the machine’s operating limits for stable, accurate, and efficient cutting.

maximum cutting depth and reach your machine can achieve using a 200 millimeter blade. It helps you verify that your workpiece size fits within the machine’s operating limits for stable, accurate, and efficient cutting.

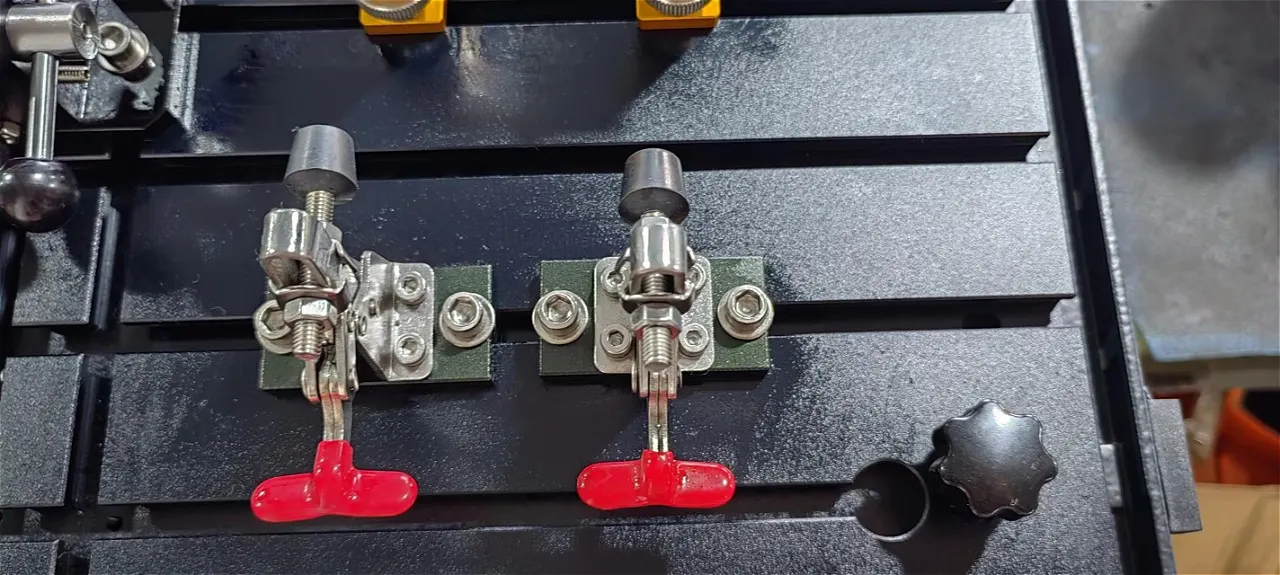

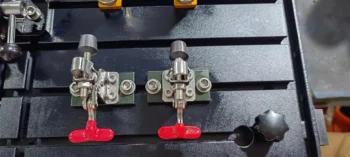

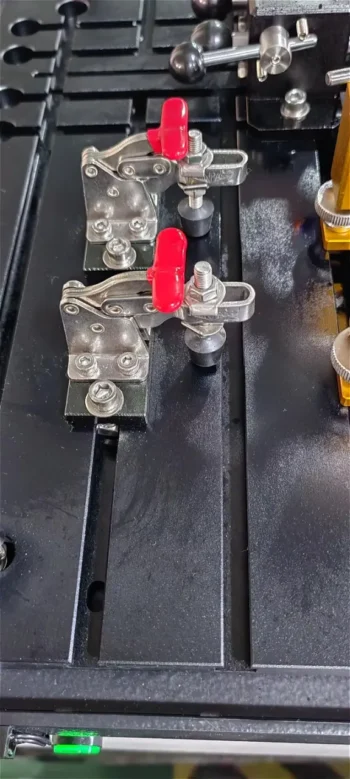

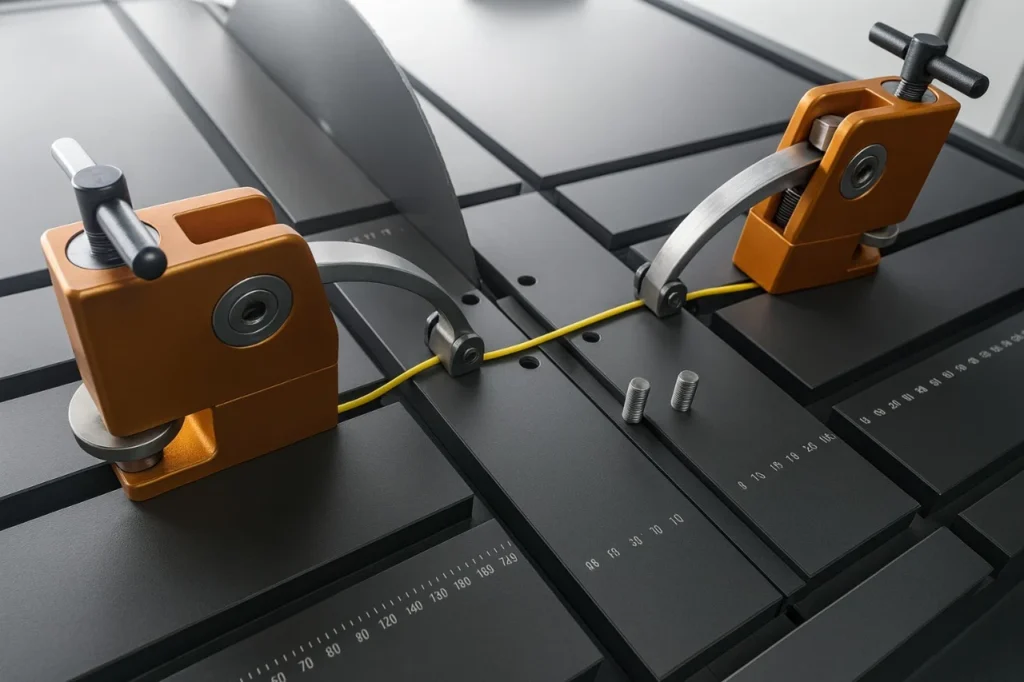

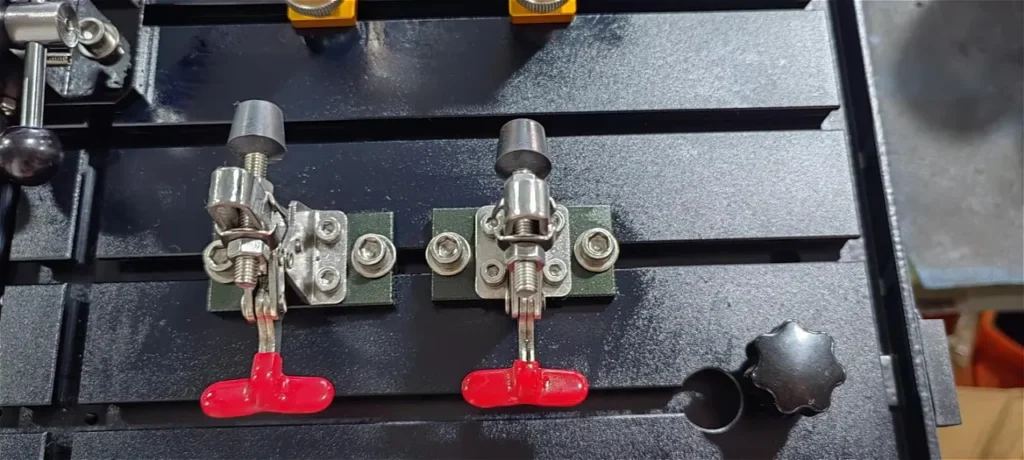

Fast Cam Locking Vises with T-Slot Table

The slotted cutting table provides stable and flexible workpiece positioning for sectioning saw applications. Its precision-machined slots allow you to mount fixtures and adjust clamping points to match the size and geometry of each sample. The aluminium fast cam locking vise adds quick clamping capability and works smoothly with the slotted tableto hold parts secure during cutting.

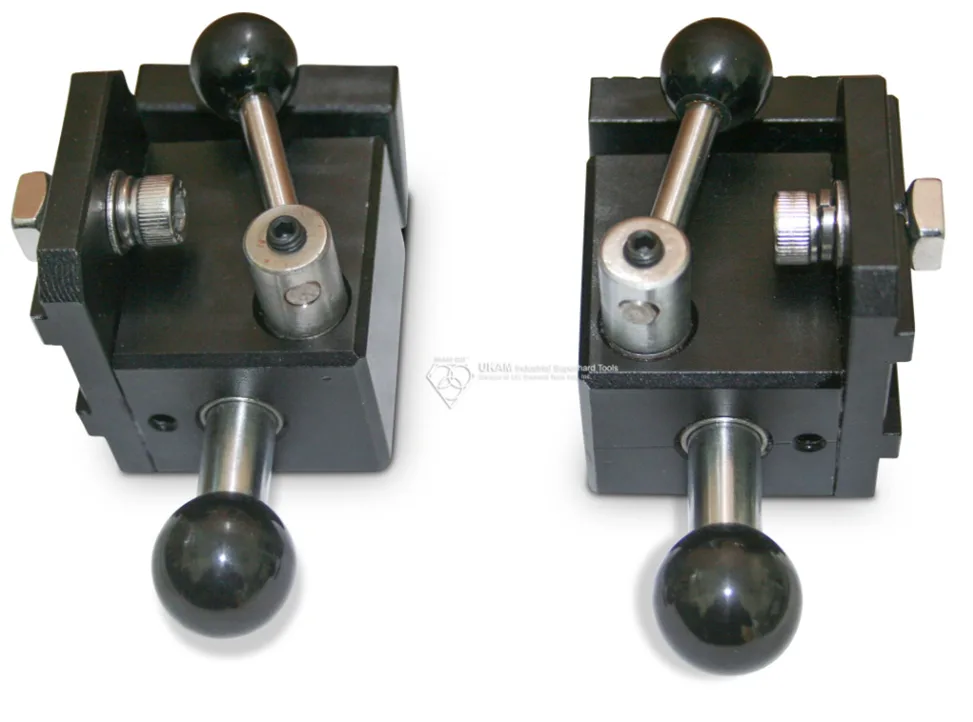

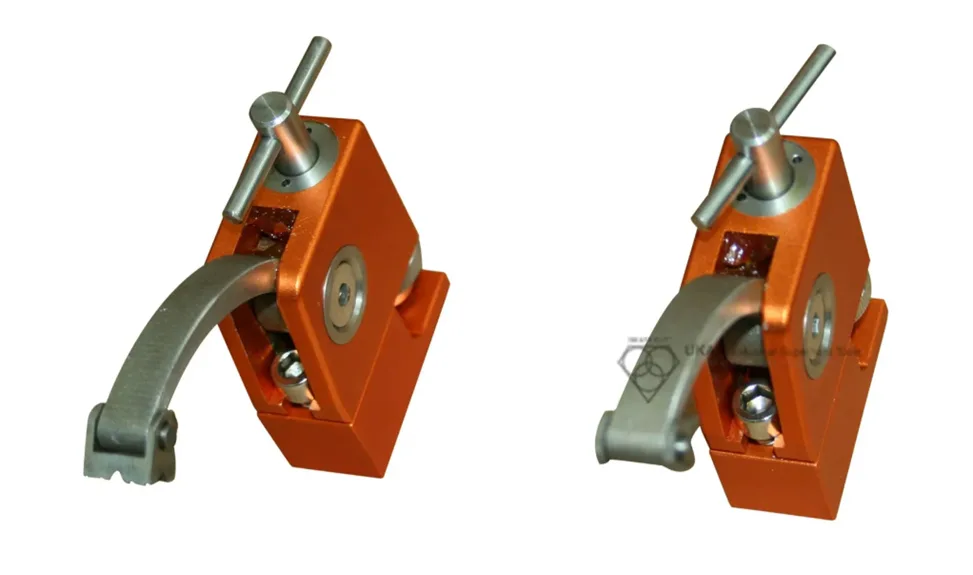

Vertical Clamping Vise

A Vertical Clamping Vise holds materials in a vertical orientation. This type of vice is commonly used in precision cutting operations where the material must remain fixed while the blade moves horizontally.

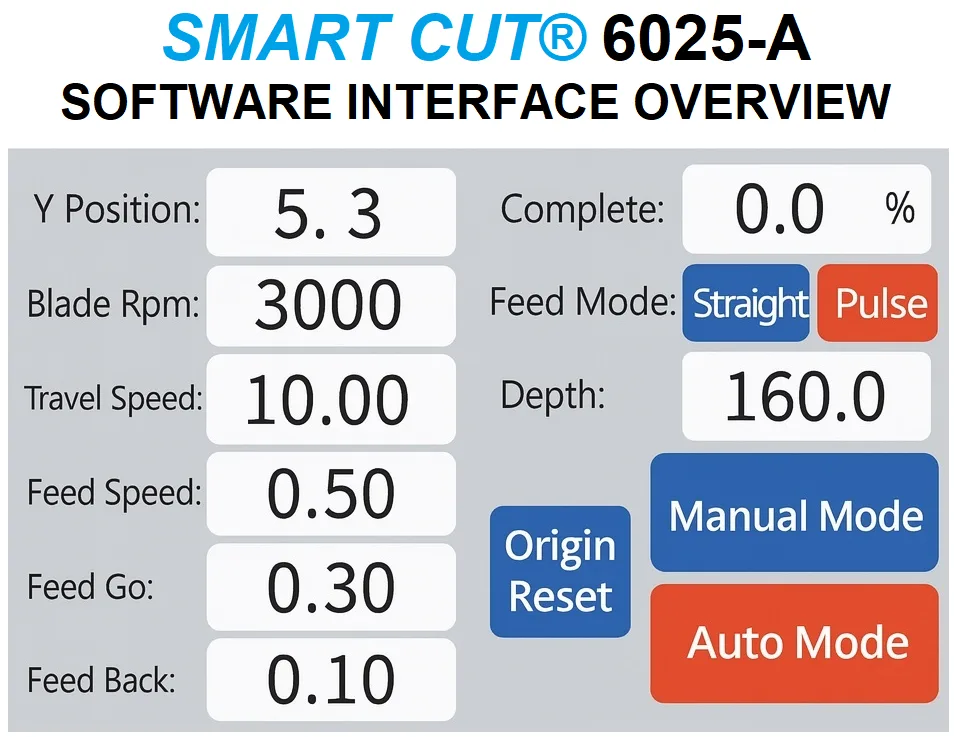

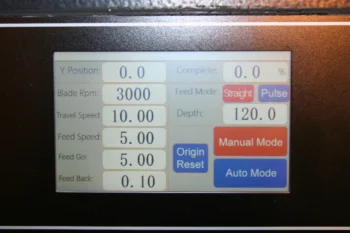

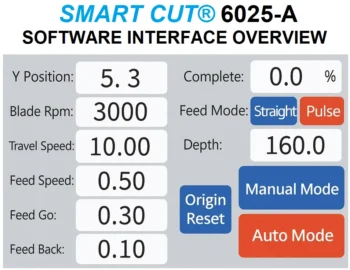

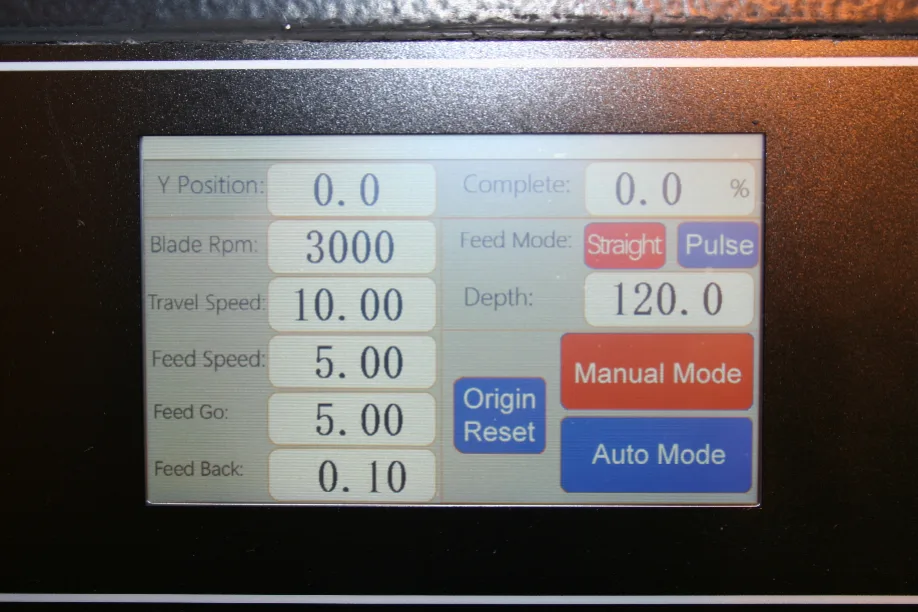

Control Pannel Overview

Y Position: Displays the relative position (coordinate value) of the Y-axis motion in automatic mode.

Blade RPM: shows the rotational speed of the cutting blade

Travel Speed: Indicates the speed at which the Y-axis moves

back and forward without cutting in automatic mode. The speed is adjustable between 0-10mm/s.

Feed Speed: Shows the Y-axis cutting speed in automatic mode during linear cutting, adjustable between 0.1-6mm/s.

Feed Go (Feed Distranc): Represents the feeding distance (0.15mm) of the Y-axis in pulse cutting mode, based on the set cutting speed in automatic mode.

Feed Back: determines the retract distance of the blade duringpulse mode

Complete: Reflects the set cutting length and progress of

the cutting process in automatic mode.

Feed Mode:The Feed Mode selection allows the operator to choose between Straight cutting and Pulse cutting.

Depth:The Depth field defines the total cutting depth that the machine will reachduring the operation

Origin Reset: The Origin Reset button establishes the current blade position as the reference zero point for all automatic movements.

Manual Mode:The Manual Mode button enables full manual control of blade movement.

Auto Mode:The Auto Mode button starts a fully automated cutting cycle based on all programmed

parameters, including depth, feed speed, feed mode, and cutting length.

Mechanical Key Function Analysis:

- Automatic Mode (Move Forward): Click to move the Y-axis forward in automatic mode.

- Automatic Mode (Move Backward): Click to move the Y-axis backward in automatic mode.

- START Button: Click to start cutting in automatic mode.

- STOP Button: Click to stop cutting in automatic mode.

- Emergency Stop Button: Press this button to immediately stop the device, cutting, and power supply to the panel.

SMART CUT® 6025-A Vices

Fast Cam Locking Vises

Fast Cam Locking Vises are designed for quick and secure clamping of materials. They use a cam mechanism to rapidly lock or release the workpiece, making them ideal for tasks that require frequent setup changes. This is standard options that comes with each machine

- Quick Setup and Removal: The primary benefit of this type of vice is its ability to clamp and release the material quickly. This is especially useful in high-volume or repetitive cutting operations.

- Handling Multiple Materials: These vices are versatile and can be used for a variety of materials, including metals, plastics, and composites.

- Ideal for Non-Delicate Materials: They provide a strong grip but may not be suitable for fragile or delicate materials that could be damaged by excessive clamping force.

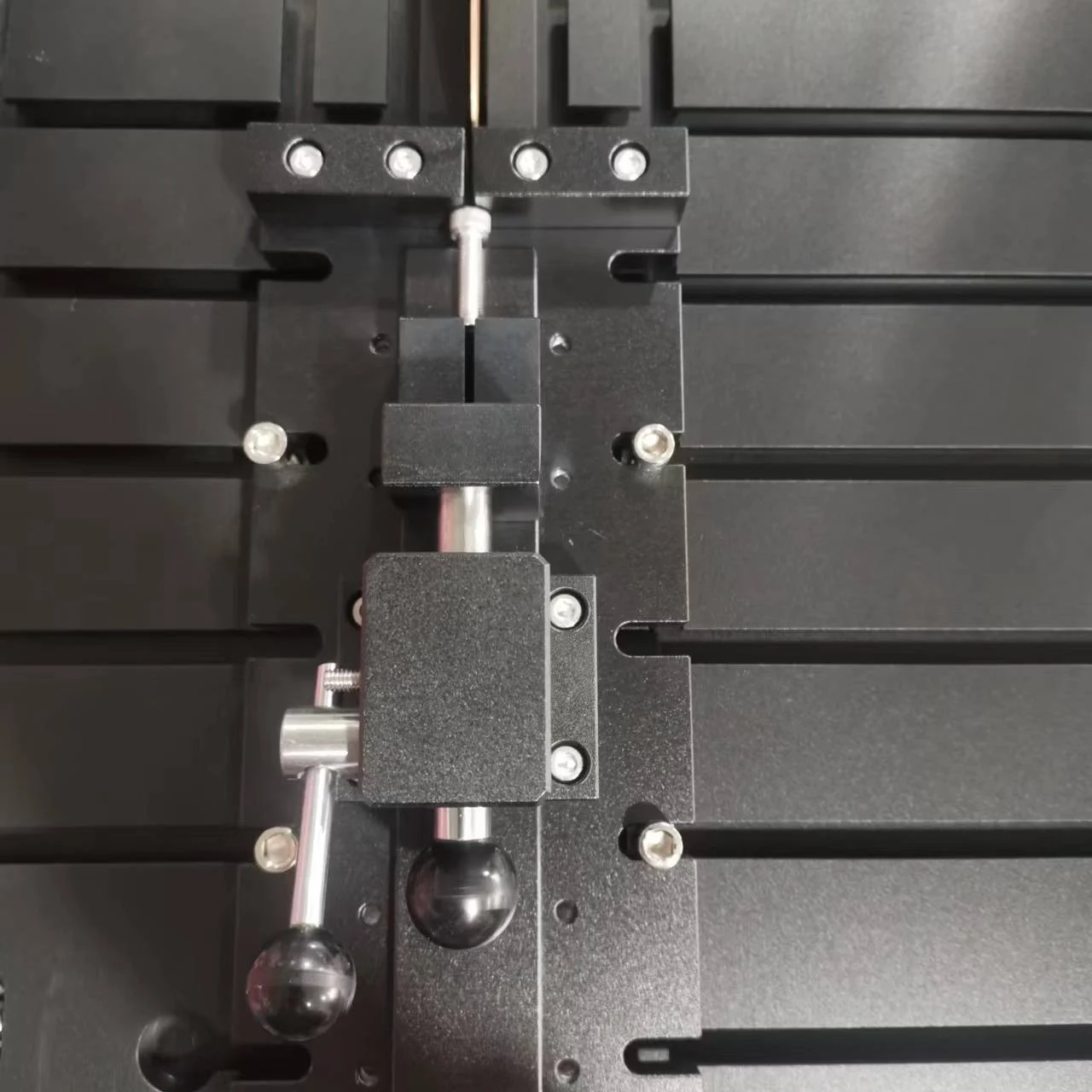

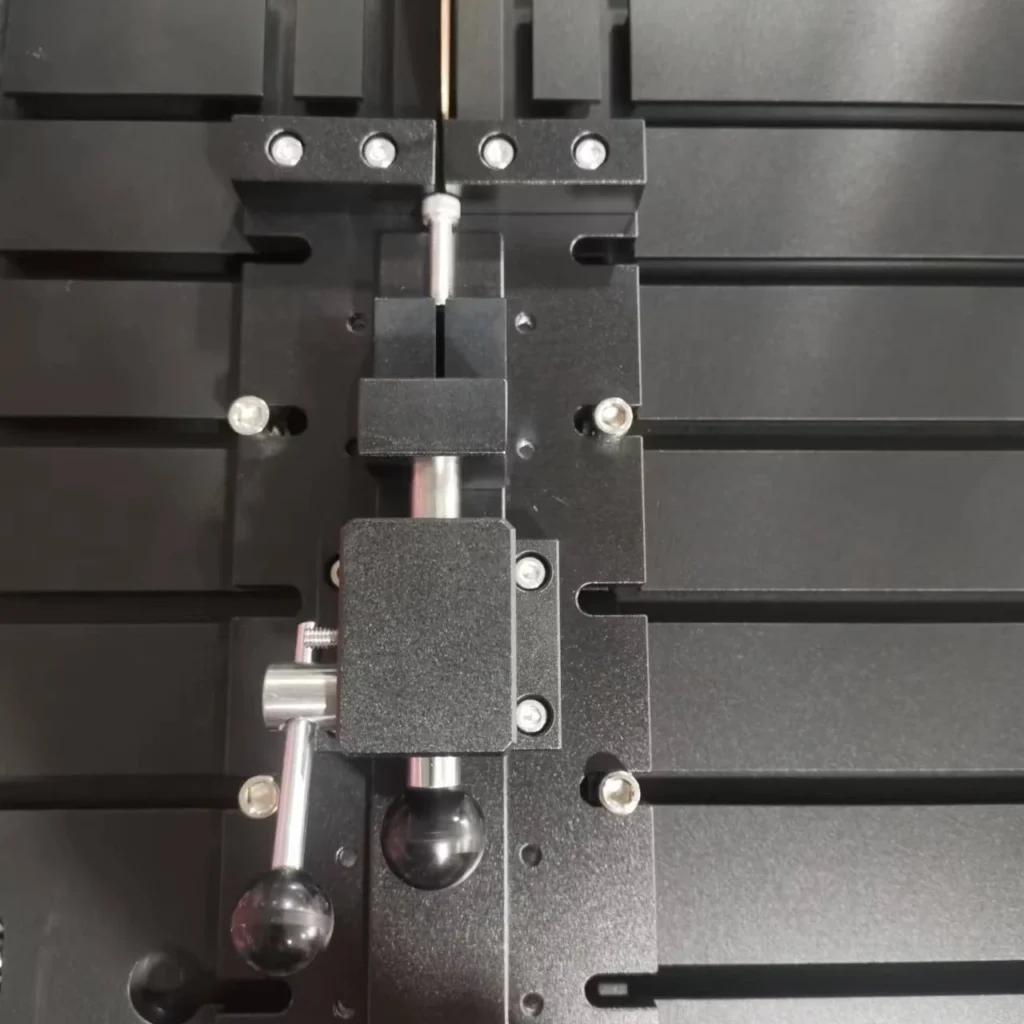

X-Feed Fixture

An X-Feed Fixture is designed to facilitate movement of the material along the X-axis, typically when continuous or uniform feeding is required during the cutting process. This fixture helps in achieving controlled and consistent cutting.

- Automated Feed Control: The fixture provides automated movement for materials fed into the cutting machine. This is ideal for applications where multiple materials are processed in succession.

- High-Speed Cutting Applications: In high-speed cutting scenarios, the X-Feed Fixture ensures that the material is consistently fed at the correct rate, contributing to improved efficiency and precision.

- Material Shaping: It is also used in shaping applications where the material needs to be progressively moved through the cutting area for uniform cutting depth or pattern.

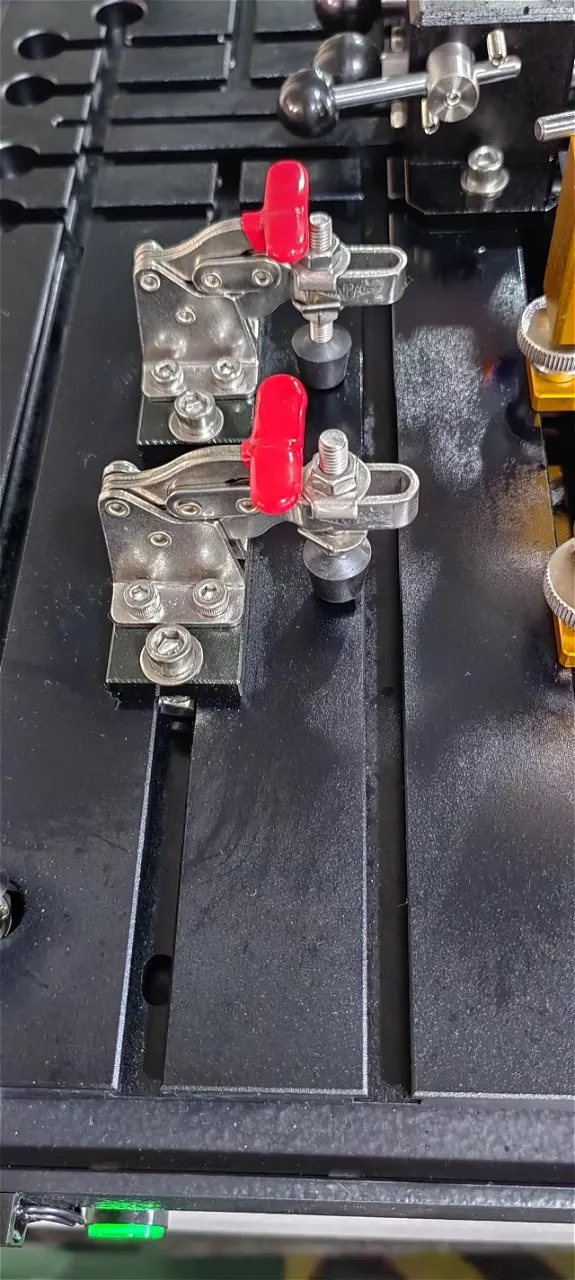

Vertical Quick Clamp

Fast Cam Locking Vises are designed for quick and secure clamping of materials. They use a cam mechanism to rapidly lock or release the workpiece, making them ideal for tasks that require frequent setup changes. This is standard options that comes with each machine

Vertical Clamping Vise

A Vertical Clamping Vise holds materials in a vertical orientation. This type of vice is commonly used in precision cutting operations where the material must remain fixed while the blade moves horizontally.

- Precision Cutting: It ensures that the material remains perfectly aligned during the cutting process, making it suitable for high-precision tasks such as PCB cutting or material slicing for semiconductor applications.

- Ideal for Thin or Delicate Materials: Vertical vices are often used to hold thin materials like foils, wafers, or thin ceramic sheets without distorting or damaging them.

- Longitudinal Cutting: Particularly effective when cutting along the length of a material, such as bars or rods, which need to be securely fixed along their entire length.

Cutting Vise for Longitudinal Direction (Screws, Bars, etc.)

This specialized vice is designed for securely clamping cylindrical or long materials such as rods, bars, or screws. The vice holds the material in place while the blade cuts along the material’s length.

- Longitudinal Cutting of Bars or Rods: It is specifically designed for longitudinal cuts, making it ideal for cutting long and cylindrical materials, such as bars, pipes, and screws.

- Precision Slicing of Thin Long Materials: For materials like aluminum rods, stainless steel bars, or composite tubes, this vice ensures the material remains stable during the entire cutting process.

- Handling Fragile Materials: The adjustable clamps allow for precise and secure holding of materials without damaging or distorting them.

SMART CUT® COOLANTS

Your choice of one (1) quart of SMART CUT™ Water Soluble Coolant or Mineral Oil is included with machine. SMART CUT™ Water Soluble Coolant Reduces material thermal stress, edge damage, and internal cracking, increases blade life, provides better cut quality, preserves material micro structure

Hence, assuring long-term integrity of material being sectioned. Since SMART CUT coolant is both a coolant and lubricant, both the wafering blade and material benefit. Mix ratio is 1:20 (1 part coolant, 20 parts water) on very hard and dense materials and 1:40 (1 part coolant, 40 parts water) on softer materials. Depending on mix ratio 1 quart will produce 5.7 to 9 gallons of coolant when mixed with water. As a coolant, SMART CUT KOOL reduces heat caused by friction. As a lubricant, SMART CUT KOOL lowers friction and surface tension, which increases swarf dispersion.

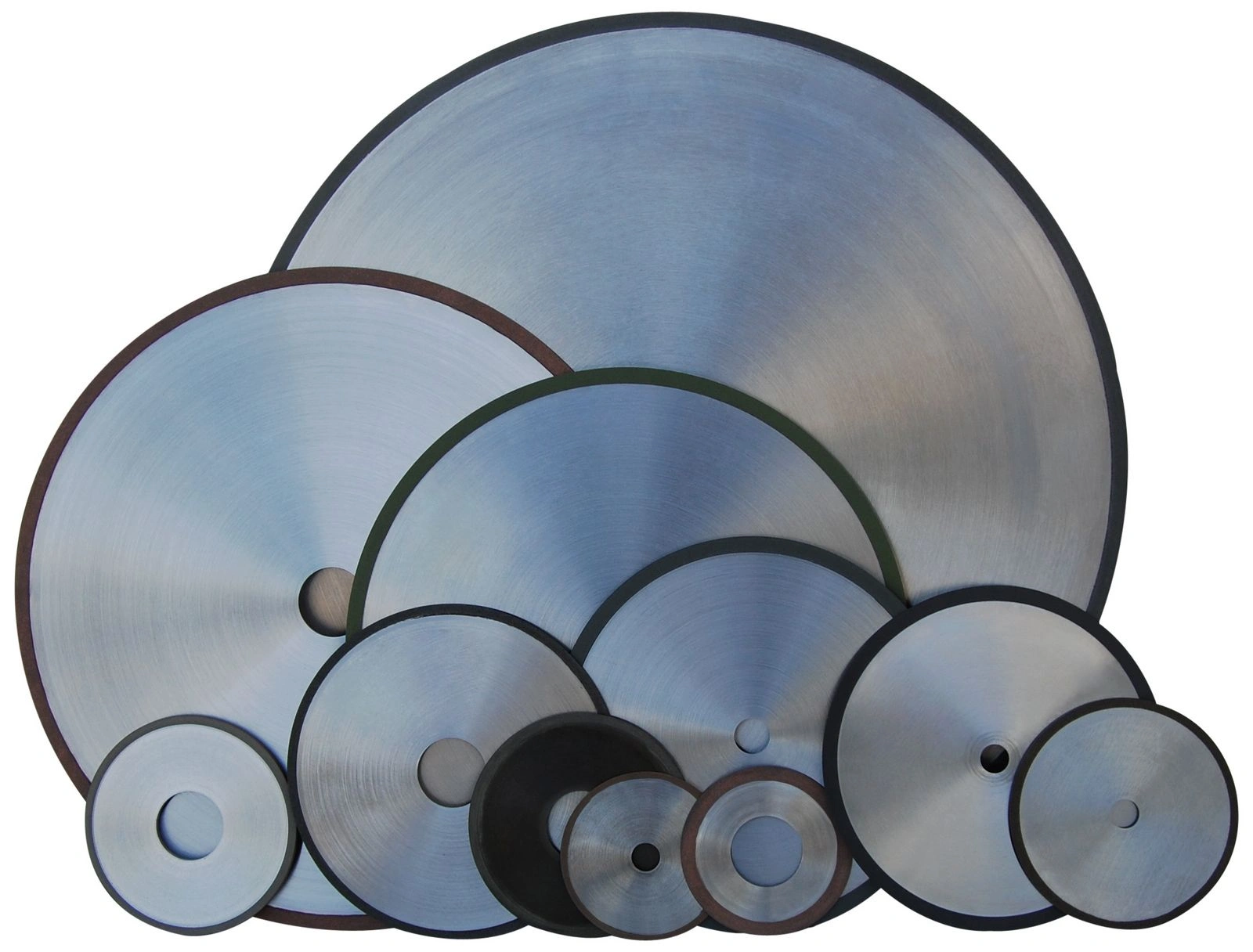

LARGEST SELECTING OF DIAMOND &

CBN WAFERING BLADES AVAIALBLE

one (1) diamond wafering blade any specification is included FREE OF CHARGE with purchase of any machine (any specification). we have almost unlimited number of diamond & CBN wafering blade specifications in stock available for immediate delivery. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness’s. With several thousand unique blade specification in stock not listed on our standard stock program. This insures you will receive the best blade specification possible for your specific application.

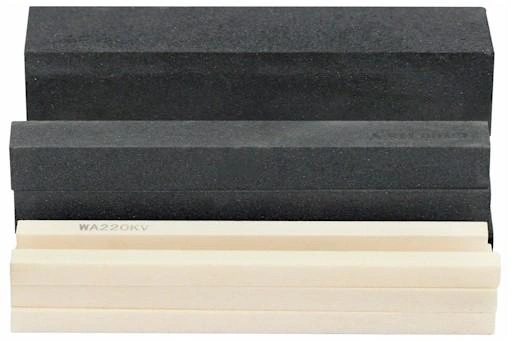

THE RIGHT DRESSING STICK FOR YOUR APPLICATION

One (1) dressing stick is included with the purchase of any machine free of charge. The dressing stick we supply is similar to the diamond size of the wafering blade you have chosen (or we recommended) for your application. Wafering Blades must be diamonds particles/crystals exposed properly through frequent dressing. Otherwise, the diamond tool will glaze over. They will begin to tear rather than grind which is very destructive. Tearing caused from unexposed diamonds creates friction. This causes uneven wear and/or heat cracks in the wafering blade and/or material being cut. Resulting in premature blade wear, blade tensioning problems, and will eventually destroy the blade. The more frequently the blade is dressed the freer and cooler it will cut with lot more consistency.

Related Products

Item # 8054245-2 SMART CUT® 1800 – Precision Saw

Item # 8054245-1-1 SMART CUT® 1805 – Precision Saw

Item # 9000361 SMART CUT® 6018 – Automatic Saw

Item # 9014006 SMART CUT® 6025 – Manual Sectioning Saw

$5,675.00

Recently Viewed Products

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Knowledge Center

02

Nov

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

29

Aug

Selecting the Right Coolant Method for your Diamond & CBN Tools

Coolant is one of the most important factors in CNC machining when using diamond and CBN tools. These tools are made to cut and grind very hard materials, which naturally produces high amounts of friction...

02

Jun

How to Selecting Right Diamond Tools for your application

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Serving Global Manufacturers

Since 1990

American Based Manufacturer

Established in 1990

Expert technical support

Custom manufacturing

Thousands of Stock Products

Same day shipping

Share this Article...

02

Jun

Why use diamond

Serving Global Manufacturers

Since 1990

American Based Manufacturer

Established in 1990

Expert technical support

Custom manufacturing

Thousands of Stock Products

Same day shipping

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

17

May

Choosing The Correct Diamond Bond Type

Selecting the appropriate diamond bond type for specific applications is crucial for several reasons. Diamond bond type directly affects the tool's performance, efficiency, and longevity. Different bond types determine how well a tool can withstand...

03

Jan

How to Properly Use Diamond Tools: A Complete Guide to Performance, Safety, and Tool Life

The use of diamond tools in the manufacturing and precision machining industries, as well as in construction, research, etc., is essential. They are used for a wide range of materials, including sharpening, cutting, grinding, and polishing...