-

0 items in quote

No products in the Quote Basket.

Precision Machining Services

SLICING, DICING, DRILLING & MICRO DRILING

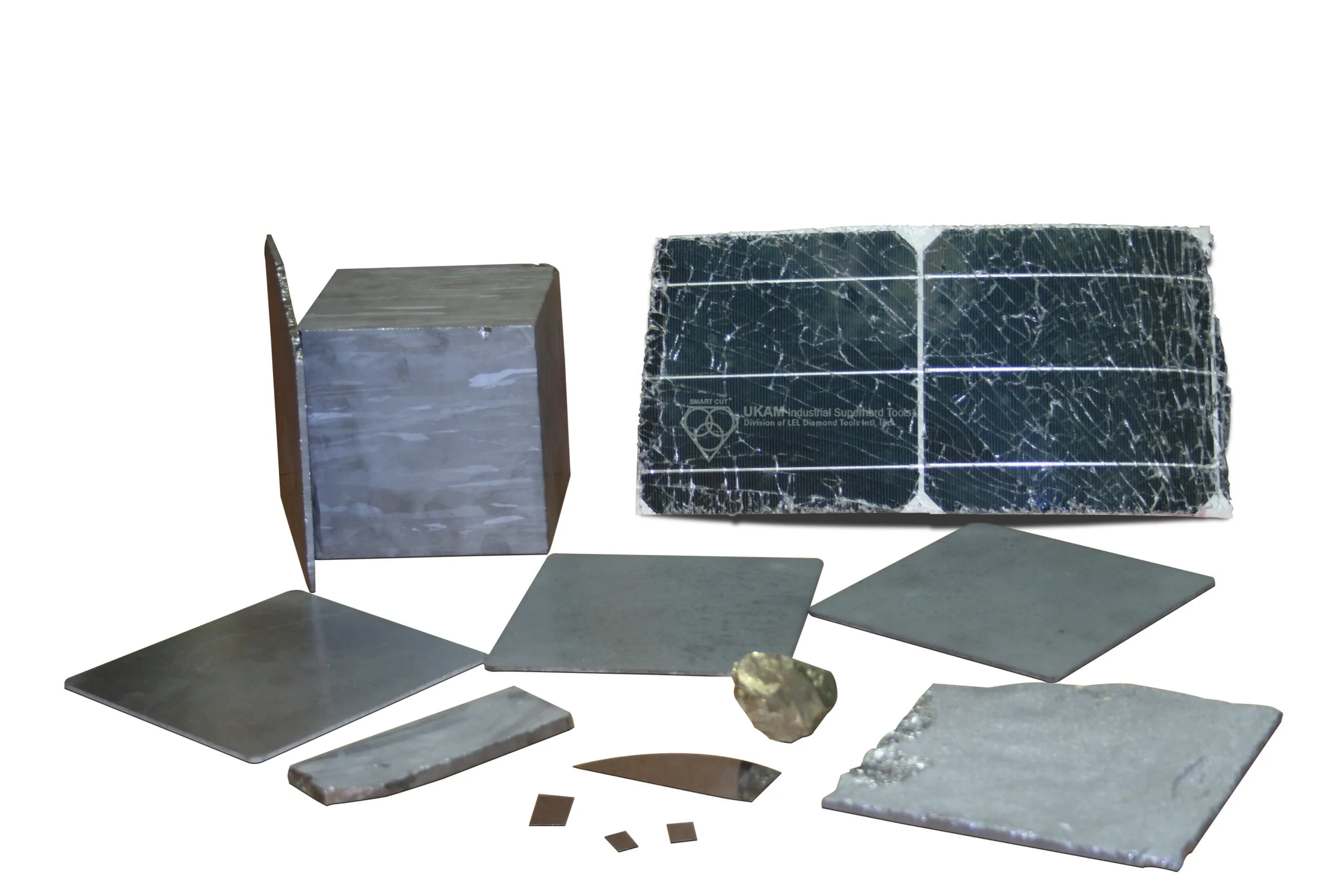

In addition to producing Precision Diamond Tools, UKAM Industrial Superhard Tools offers a variety of services such as precision dicing, slicing, rough cutting, and diamond drilling.

We possess the expertise to cut, slice, dice, and drill nearly any material with a hardness range from 9.8 to 4 on the Mohs scale.

Whether you are in the research and development stage or full-scale production, outsourcing to UKAM Industrial Superhard Tools can provide substantial time and cost savings. We pride ourselves on our unique capabilities in diamond slicing, dicing, and micro-drilling.

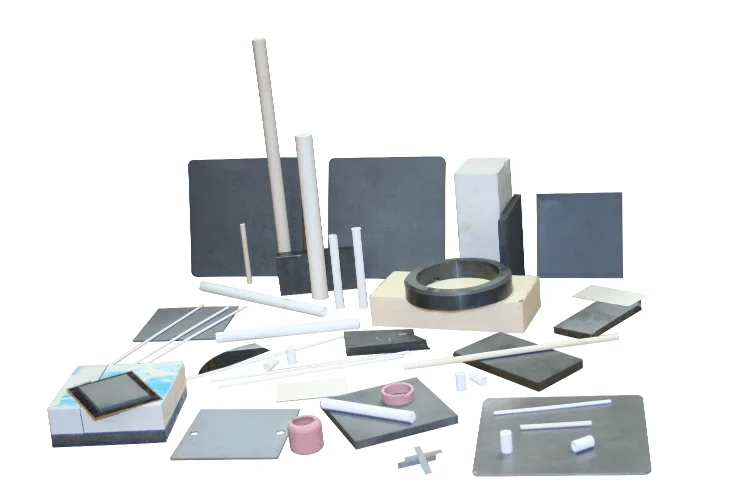

We have experience working with a diverse range of materials including all types of metallic materials, ceramics, optics, substrates, and wafers.

Our Experienced Engineers and Application laboratory, equipped with some of the latest Slicing, Dicing, Wafering, Drilling, & Micro Drilling Equipment is available to help you develop not only the right tools, but the Right Process for your specific Material/Application. Working with a company that has the expertise and proven track record of producing innovative solutions for challenging slicing, dicing, drilling, grinding and polishing applications is crucial.

SERVICE

Ultra Precision Diamond Micro Drilling

The demand for smaller hole sizes and micromachining has led to technological advancements and the use of new-generation materials. Engineers are always pushing the envelope of what is possible. To answer this challenge, we have developed a line of standard stock and custom diamond micro tools

Our Diamond Micro Drilling Service can create holes with a minimum diameter of 0.0005 inches, with tolerances of +/- 0.005 mm. Our equipment meets the technical specifications required to achieve super precision tolerances and superior accuracy.

Our diamond micro drills and micro tools are used to create highly precise and complex parts and components.

These tools are designed to remove material at a very fine scale and are made using a diamond plating method. Through a proprietary galvanic plating/electroplating process, diamond particles are evenly deposited on the tip over time. This unique process allows for the diamond particles to protrude from the bond matrix, resulting in a faster cutting action with minimal heat generation.

We offer a wide variety of custom diamond and CBN micro drills and tools

We offer a wide variety of custom diamond and CBN micro drills and tools that can be tailored to your specific requirements and drawings. High-precision tolerances are available with various head lengths, shank diameters, tip radiuses Carbide micro tooling with or without coatings such as CVD (chemical vapor deposition) and PCD (polycrystalline diamond) is also available for certain applications, where synthetic or natural diamond is not feasible or not economical to use

Materials We Work With

- Quartz

- Fused Silica

- Glass

- Wafers

- Semiconductor materials

- Compound semiconductor materials

- Ceramic substrates

- Piezo Ceramics

- Hybrid substrate sawing

- Capacitors

- Sapphire

- Metals

- Ferrites

- Bonded wafers

- Special materials

- Many Others

SERVICE

Precision Diamond Slicing, Sectioning, Wire Cutting Service

Precision Cutting of Large Variety of Flat Coupons, Samples & Other Materials

Utilizing our larger variety of precision cutting saw we can provide Precision cutting of larger and longer sample coupons such as PCB Boards, FR4 composite panels, ceramic substrates, electronic packages, plate material, composites, optical or flat glass pieces, ultra hard material tiles, and other glass, carbon fiber, honeycomb, and many other materials.

Sectioning & Sample Preparation Service

We specialize in handling a variety of materials, including metals, polymers, ceramics, composites, and biological samples. Our skilled technicians are experienced in working with both hard and soft materials, and we can accommodate samples of different sizes and shapes. Our sectioning process is designed to minimize damage and deformation, ensuring that the integrity of the sample is maintained.

Tube & Rod Cutting

Sevice

cutting of larger variety of tubing and rods such as glass, ceramic, metals, composites outside diameter of the tubing from .045” (1.143 mm) to .150” (3.810 mm). The length of the cut part can run from .060” (1.524 mm) to 4.0” (101.60 mm). Tolerance of the length runs from .002” (0.050 mm) to .005” (0.127 mm).

Precision Diamond Slicing Service

Our Precision Slicing Services of large variety of materials with our state-of-the-art slicing service. We utilize larger variety of equipment and diamond slicing blades from stock. Our experience in producing diamond slicing blades and precision cutting

Diamond Wire Cutting

Service

precision cropping, dicing, wafering, slicing, and shaping (0.25 mm thin slots can be cut for example). less waste and no extra machining required after cutting. Cutting materials ranging from the softest to the hardest, without heating the material. Clean, smooth, splinter-free, burr-free, and with sharp edges

SERVICE

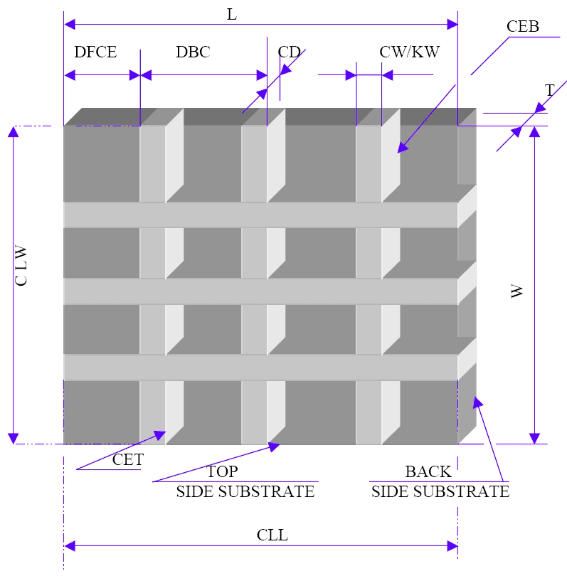

High Precision Diamond Gang Slicing & Cutting Service

Gain a competitive advantage with our state-of-the-art diamond slicing gang saw services, designed to minimize expenses while maximizing productivity. This cutting-edge technology enables simultaneous slicing with multiple blades, ensuring optimal throughput without compromising quality or efficiency. Elevate your operations to new heights with this innovative solution!

Reduced Overheads

Our advanced gang saw dicing technology streamlines your processes, effectively cutting down both time and financial costs to maximize your benefits.

Increase Production & Output

Leverage the efficiency of gang dicing saws to significantly reduce operating and loading times, thereby amplifying your production output to meet demand with ease. Cut thousands of parts per minute with high degree of accuracy and very minimum to no chipping

SERVICE

Precision Drilling, Core Drilling Coring Service

- Diamond Drilling Of Hole Diameters From .0255" - .500"

- Hole Placement Tolerance ± .001”, Repeatability + .0002”

We offer precision hole drilling services utilizing larger variety of diamond core drills, drills, and other diamond tooling that produces stress-free holes with minimum to no chipping, excellent surface finish, no cracks, minimum stress to material and no deformation

SERVICE

Drill Precision Core Samples Of All Sizes And Lengths

We can also drill precision core samples of all sizes and lengths ranging from 0.5mm to very large in large verity of materials including ceramics, optical glass, composites, rocks, semiconductor and many other materials using large variety of diamond core drills and tools that we have in stock and custom produce for the application

We Have Large Variety Of Diamond Core Drills In Stock And Custom Manufacture Almost Any Specification Within Few Ddays

SERVICE

Surface Grinding, OD and ID Grinding Service

We offer grinding service of large variety of materials. Lengths 0.005 to 30 inches, tolerances to 0.00005. Mirror mounts and shapes, wear rings, seal rings, are just a few of the types of parts manufactured to customer specifications. C.N.C. is available for complex shapes.

Other Materials We Work With

- Aluminum

- Aluminum Nitride

- Barium Fluoride

- BK7

- Brass

- Cadmium Telluride

- Carbide

- Ceramics

- Composites

- Cordierite

- Filter Glasses

- Fused Silica

- Gallium Arsenide

- Garnet

- Germanium

- Graphite

- InGaAs

- InP

- Zinc Selenide

- Zerodur

- Zinc Sulfide

- Zirconia

- Lanthinum Aluminate

- Magnets

- Metals

- MgO

- MgTiO3

- Mica

- Molybdenum

- Niobates

- PZT

- Pyrex

- Quartz

- Roulon

- Sapphire

- Silicon Carbide

- Silicon

- Soda-Lime

- Steatite

- Teflon

- Titanates

- Titanium Carbide

- Windows

- Many Others

Applications and products include

- Beamsplitters

- DWDM filter

- Substrates

- Glass

- Blocks/rods/spacers

- Lenses

- Mirrors

- Prisms

- Solar cells

- Waveguides

- Wedges

- Polarizers

- Bandpass filters

- Laser diodes

- SEMI standard dummy

- Wafers

SERVICE

Industries used in

- Optics/photonics

- Telecommunications

- Aerospace

- Medical

- Semiconductor

- Microelectronics

- Research industries

Some of our valued clients

Why Choose Us?

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price

Why Work With Us?

Comprehensive Source Of Information On Dicing Blades

We understand that your success depends on select the right dicing blade, and optimizing your dicing parameters to best fit your applications/needs. The more you understand about what we can do for you, the better our partnership will be. On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond dicing blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Precision & Ultra Thin Diamond Dicing Blades in the U.S. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness's.

Experience Makes All The Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary dicing blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced

Technology

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality &

Consistency

Expect More From Your Tools

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Related Products

Precision Machining Services

Nickel Bond Hubbed Dicing Blades

Tungsten Carbide Dicing Blades

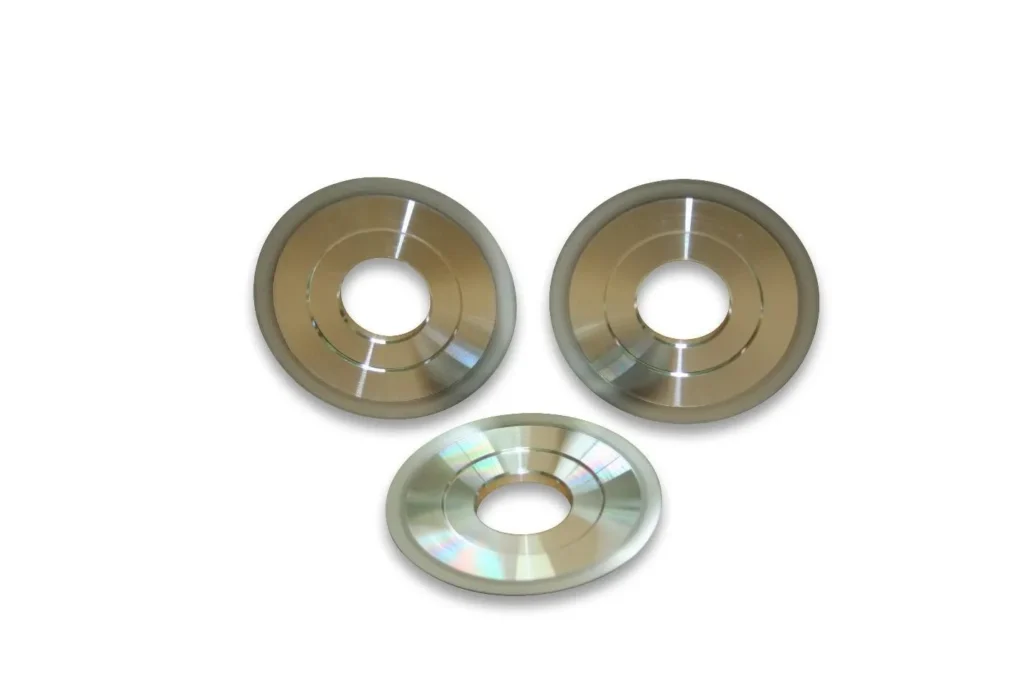

SMART CUT® Fully Sintered (Metal Bond) Diamond & CBN, Wafering Blades

SMART CUT® Fully Sintered (Metal Bond) diamond wafering blades are fully sintered from OD to ID of the blade. Meaning they have diamonds completely impregnated through the blade. Unlike standard diamond & cbn wafering blades with steel core and diamond section. Instead of having a steel core and small diamond bond edge (usually 1/8"/3.2mm). The diamond edge is all the way through the blade, from its Outside Diameter to Inside Diameter of the blade. You can use until the entire Outside Diameter of the blade is consumed.

Resin Bond Diamond Discs

Resin Bond Discs are designed removal of material/sample scratches, chips. high spots, & as well as pre-polishing on a larger variety of materials. Using a propriety technique, a high concentration of premium diamond is loaded onto each disc to provide an extremely aggressive grinding rate yet leaves an exceptionally smooth surface finish. Each disc is color coded to easily determine the diamond size of the disc. These resin bond diamond discs are guaranteed to out-perform many cloth polishing discs using loose conventional abrasive or diamond compound/slurry finishing systems. Depending on the application and process these discs on average will last for 100-200 parts/samples & maintain consistent level of performance. These are perfect for hard materials such as metals, ceramics, refractories, cement, geological rocks, glass, optics, composites, and many other materials 35 and up Rockwell C scale of hardness. All discs come with a 3M pressure-sensitive adhesive backing that bonds to backing plates, or with magnetic backing to attach to steel plates. Must be used with coolant. Not recommended for heavy stock material removal

SMART CUT® Water Soluble Dicing Coolant

SMART CUT® XP Water Soluble Dicing Coolant added to deionized (DI) water reduces surface tension flowing from saws injection system and is carried directly of dicing blade.

This reduces material thermal stress, edge damage, and internal cracking, assuring long-term integrity of material being processed. Since SMART CUT® XP Dicing Coolant is a coolant and lubricant, and Surfactant both the dicing blade and substrate / wafer / package benefit.

SMART CUT® XP Dicing Coolant/Lubricant is a specially formulated low-foaming dicing and sawing coolant/lubricant designed for precision applications involving wafers with integrated circuits, MEMS devices, and IC packaging. This aqueous-based synthetic formulation enhances the dicing process by ensuring superior cleanliness of the die or package after dicing while preventing corrosion and oxidation on exposed metals. It eliminates electrostatic discharge, which can be generated during the rotation of the dicing blade, protecting delicate components from damage.

DIAMOND BACKGRINDING WHEELS

SMART CUT® Diamond Backgrinding Wheels are designed for precision thinning and flattening of silicon wafers, glass, and ceramic substrates. These high-performance wheels are used on backgrinding machines, including models from Disco, Okamoto, Strasbaugh, and other leading manufacturers. Available in sizes ranging from 8” to 14” O.D., they are engineered to handle a wide range of materials and applications, from semiconductor wafers to microelectronic packages.

Recently Viewed Products

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Knowledge Center

02

Jun

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected diamonds...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

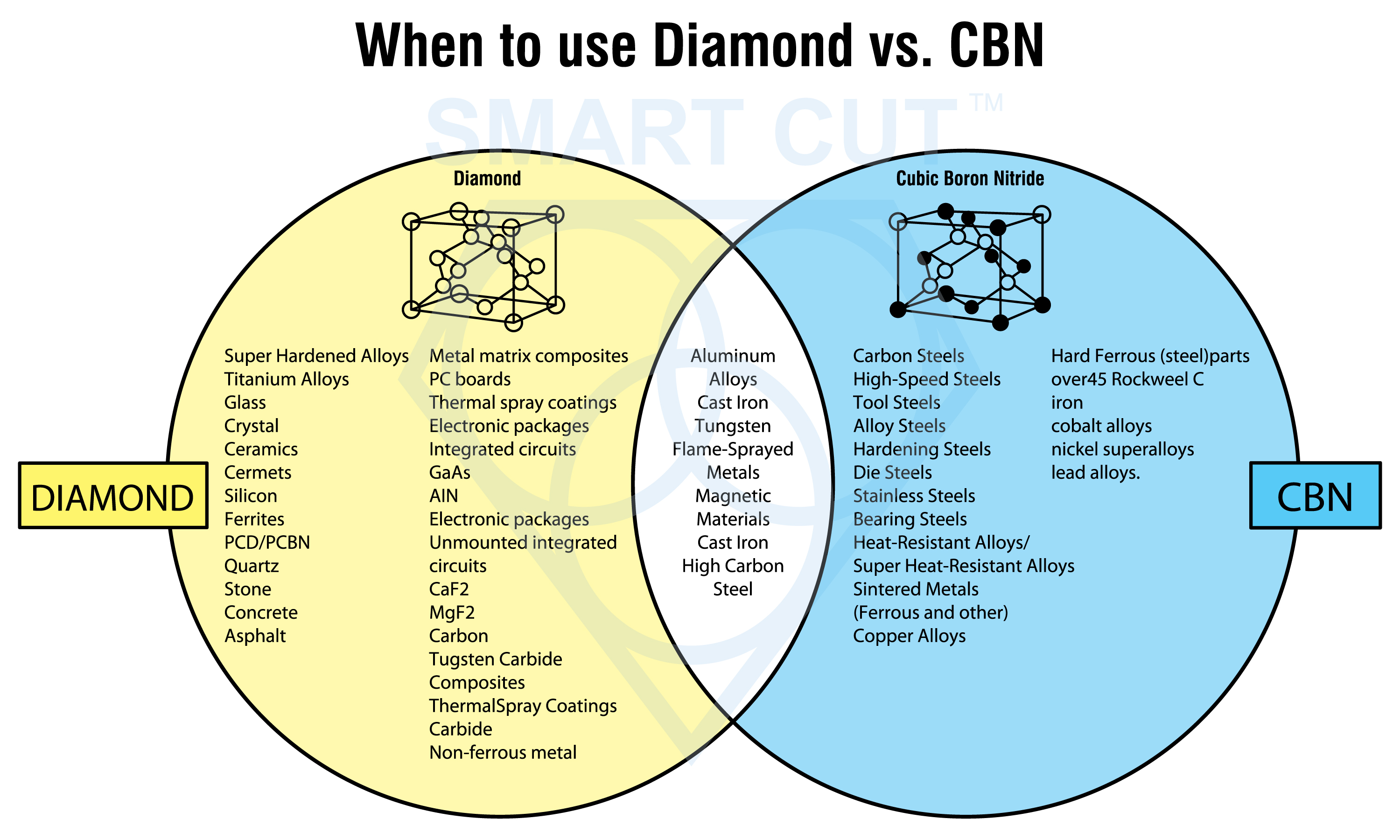

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

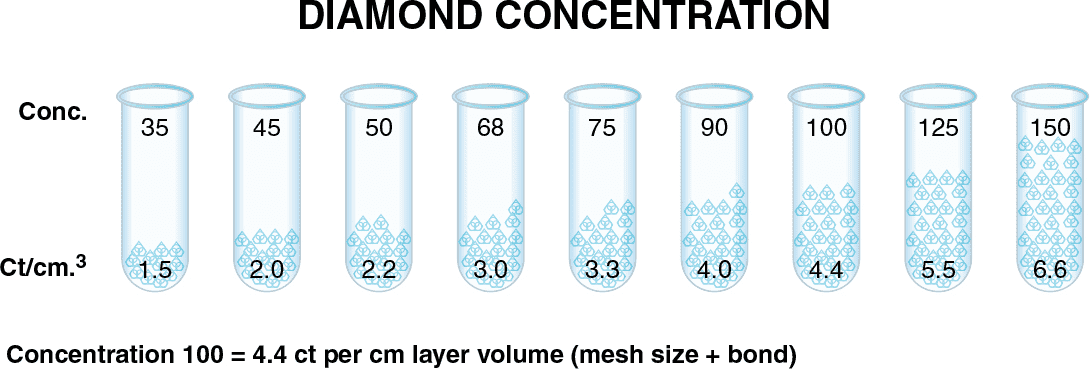

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

02

Jun

Diamond Tool Coolants Why, How, When & Where to Use

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

17

May

Get to Know the Diamond Tool Bond Types and Which to use for your application

Selecting the appropriate diamond bond type for specific applications is crucial for several reasons. Diamond bond type directly affects the tool's performance, efficiency, and longevity. Different bond types determine how well a tool can withstand...

09

Oct

How to Properly Use Diamond Carving Points

Diamond carving points are essential tools for anyone working with hard materials like glass, stone, and metals. These tools help with detailed tasks like engraving and finishing, providing good control and helping you work efficiently....

- Unmatched Selection For Many Applications

- Superior Quality & Consistency

- Immediate Worldwide Delivery

- Technical Support & Expertise

- American Based Manufacturer

- Different Product

- Different Technology

- Different Company

- Expect MORE from your tools

Let Us HELP You!

Subscribe To Our Newsletter

Signup for email offers, updates, and more

Contact Us

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

DIAMOND TOOLS BY BOND

EQUIPMENT

KNOWLEDGE CENTER

OUR PRODUCTS

COMPANY

CUSTOMER SERVICE

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use