-

0 items in quote

No products in the Quote Basket.

DESCRIPTION

SPECIFICATIONS

FREQUENTLY ASKED QUESTIONS

INDUSTRIES USED IN

ACCESSORIES

USAGE RECOMMENDATION

DESCRIPTION

What are Bushings and How are they used?

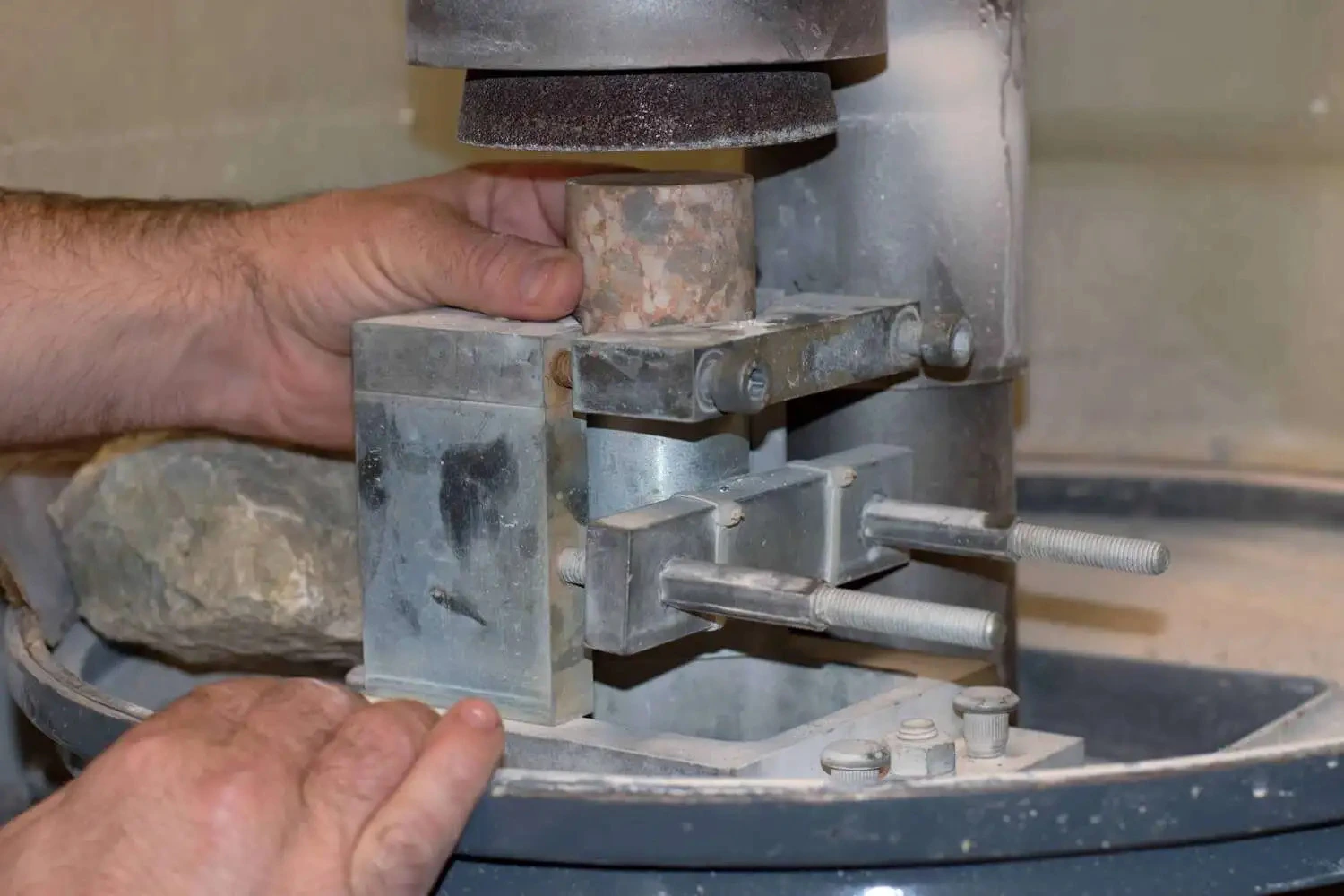

bushings, or adapters, are used to reduce the inner diameter of the blade to allow it to fit onto the spindle or arbor of a different cutting machine. These bushings are crucial for ensuring that the blade is properly centered and secured on the machine, allowing for precise and efficient cutting.

Typically, diamond blades come with a standard inner diameter size, but cutting machines can have spindles of varying sizes. The bushing acts as a spacer that fills the gap between the blade’s inner diameter and the machine’s spindle, ensuring a snug and secure fit. This helps to reduce vibration and wobbling during cutting, resulting in a smoother and more accurate cut.

Bushings for diamond blades are usually made from durable materials such as steel or aluminum and are designed to withstand the high speeds and friction generated during cutting. They are also typically easy to install and remove, allowing for quick and convenient blade changes.

SPECIFICATIONS

Tab Content

FREQUENTLY ASKED QUESTIONS

Blade bushings or adapters are used to reduce the inner diameter of diamond blades to fit the spindle or arbor of different cutting machines.

Bushings are necessary to ensure a proper and secure fit between the diamond blade and the cutting machine, allowing for precise and efficient cutting.

Bushings and adapters are typically made from durable materials such as steel or aluminum to withstand the high speeds and friction generated during cutting.

Yes, they are designed to be easy to install and remove, allowing for quick and convenient blade changes.

Yes, as long as the bushing/adapter is the correct size for the inner diameter of the blade and the spindle of the cutting machine.

Using the wrong size bushing/adapter can result in an improper fit between the diamond blade and the cutting machine, causing the blade to wobble or vibrate during cutting. This can lead to uneven cuts, excessive wear on the blade, and potentially damage the cutting machine.

Bushings/adapters can be used with any type of diamond blade as long as they are the correct size for the blade’s inner diameter and the machine’s spindle.

The lifespan of a bushing/adapter depends on several factors, including the material it is made from, the conditions it is used in, and how often it is used. In general, bushings/adapters made from durable materials such as steel or aluminum should last for a long time with proper care and maintenance.

Yes, it is recommended to clean and maintain the bushing/adapter to ensure its longevity. Be sure to remove any debris or dirt that may have accumulated during use and store the bushing/adapter in a dry place when not in use.

If the bushing/adapter becomes damaged, it should be replaced immediately to avoid further damage to the blade or cutting machine. Do not attempt to use a damaged bushing/adapter as this can result in an unsafe operating condition.

Yes, bushings/adapters are designed to be compatible with cutting machines and diamond blades of different brands as long as they are the correct size for the blade’s inner diameter and the machine’s spindle.

The size of the bushing/adapter you need will depend on the inner diameter of your diamond blade and the size of the spindle on your cutting machine. Be sure to check the specifications of your blade and machine to ensure a proper fit.

If the bushing/adapter is not the correct size or is not properly installed, it can cause the blade to wobble or vibrate during cutting, affecting the accuracy and smoothness of the cut. It is important to use the correct size bushing/adapter and ensure that it is properly installed to achieve optimal performance.

Yes, blade bushings/adapters are available in a range of sizes to fit the inner diameter of different diamond blades and the spindle of different cutting machines.

To determine the size of the bushing/adapter you need, measure the inner diameter of the diamond blade and the diameter of the spindle on the cutting machine. The bushing/adapter should match these measurements to ensure a proper fit.

Yes, bushings/adapters can be used with wet cutting diamond blades as long as they are the correct size for the blade’s inner diameter and the machine’s spindle.

A properly sized and installed bushing/adapter helps to reduce vibration and wobbling during cutting, resulting in a smoother and more accurate cut. It also helps to prevent excessive wear on the blade and prolong its lifespan.

: Yes, bushings/adapters can be purchased separately from the diamond blade. They are typically available from the same suppliers that sell diamond blades.

While the terms “bushing” and “adapter” are often used interchangeably, some people distinguish between the two based on their function. A bushing is typically used to reduce the size of an opening, while an adapter is used to convert one size or type of connection to another.

Installation of a bushing/adapter is typically a straightforward process. First, insert the bushing/adapter into the inner diameter of the diamond blade, ensuring a snug fit. Next, mount the blade onto the spindle or arbor of the cutting machine, making sure that the bushing/adapter is properly aligned with the spindle. Finally, secure the blade in place according to the manufacturer’s instructions.

Yes, bushings/adapters can be used with dry cutting diamond blades as long as they are the correct size for the blade’s inner diameter and the machine’s spindle.

If the bushing/adapter doesn’t fit properly, do not attempt to use it. Using an improperly fitting bushing/adapter can result in uneven cuts, excessive wear on the blade, and potential damage to the cutting machine. Instead, check the measurements to ensure that you have the correct size bushing/adapter for the blade and machine. If necessary, contact the manufacturer or supplier for assistance.

No, bushings/adapters are designed to simply adapt the size of the diamond blade to the spindle of the cutting machine. They do not alter the machine’s speed or RPM. However, it’s essential to ensure that both the blade and machine are compatible in terms of safe operating speeds.

It’s not recommended to stack or use multiple bushings/adapters together, as this can lead to alignment issues or imbalances. Always use a single, correctly sized bushing/adapter for the best performance and safety.

It’s recommended to inspect the bushing/adapter each time you change or install a diamond blade to ensure it’s still in good condition and providing a secure fit.

Always ensure that the machine is powered off and unplugged when installing or changing a bushing/adapter. Make sure the bushing/adapter fits snugly and is correctly aligned before starting the cutting machine. Also, regularly inspect the bushing/adapter for signs of wear or damage.

A malfunctioning bushing/adapter can result in improper alignment or excessive vibration, which could potentially cause a diamond blade to become unstable or even break during operation. Always replace damaged or worn-out bushings/adapters immediately.

INDUSTRIES USED IN

Tab Content

ACCESSORIES

Tab Content

USAGE RECOMMENDATION

Tab Content

Related Products

Petrographic Diamond Blades

Abrasive Polishing Powders

Grinding & Polishing Powders Aluminum Oxide, & Silicon Carbide Powdered Abrasives

UKAM Industrial Superhard Tools offers a wide range of precision abrasives for grinding and polishing large variety of samples. Including petrographic specimens other metals, alloys, electronic devices, semiconductors, ceramics, ferrous metals and many others. Abrasive Powders are available in the following quantities: 1 lb, 5 lb, 10 lb containers Grit Sizes: 120 grit to 8 micronsDiamond, Nickel Bond Cut Off Blades for Laboratory & Other Saws

SMART CUT® Fully Sintered (Metal Bond) Diamond & CBN, Wafering Blades

SMART CUT® Fully Sintered (Metal Bond) diamond wafering blades are fully sintered from OD to ID of the blade. Meaning they have diamonds completely impregnated through the blade. Unlike standard diamond & cbn wafering blades with steel core and diamond section. Instead of having a steel core and small diamond bond edge (usually 1/8"/3.2mm). The diamond edge is all the way through the blade, from its Outside Diameter to Inside Diameter of the blade. You can use until the entire Outside Diameter of the blade is consumed.

Recently Viewed Products

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Knowledge Center

02

Jun

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected diamonds...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

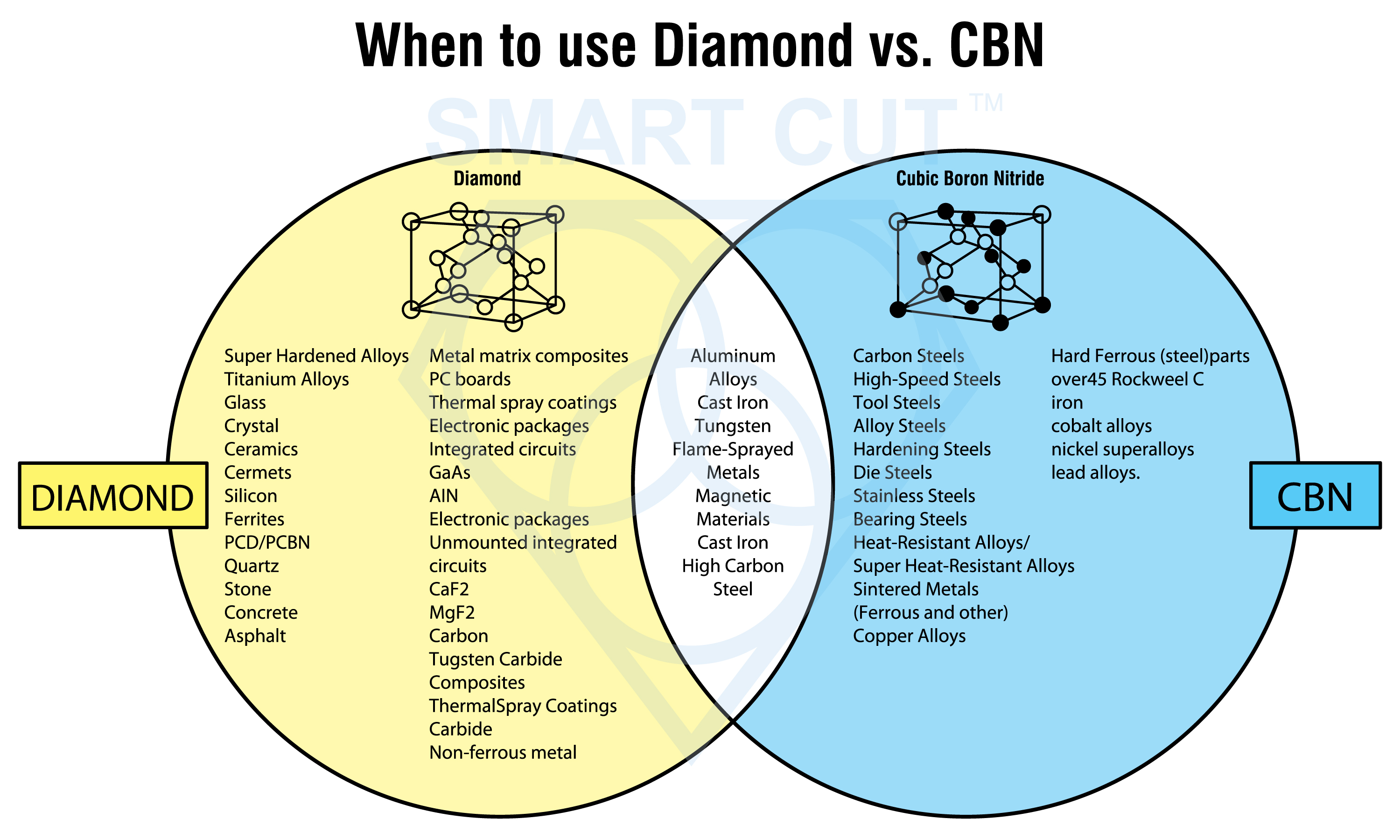

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

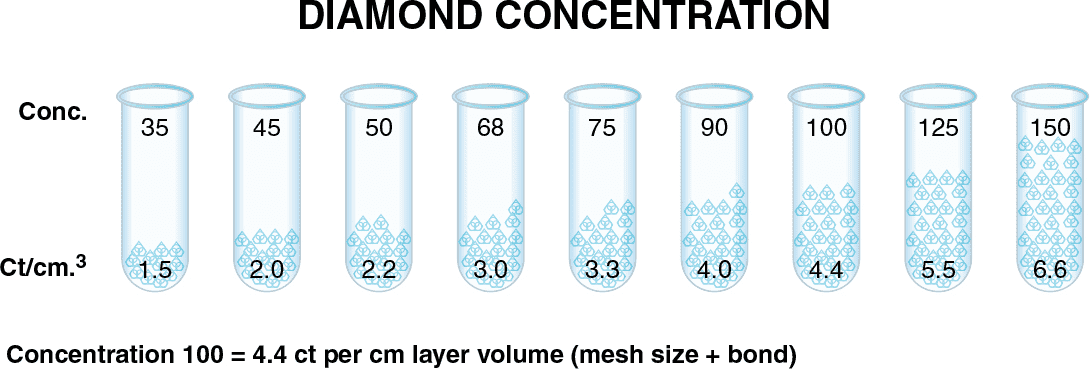

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

02

Jun

Diamond Tool Coolants Why, How, When & Where to Use

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

17

May

Get to Know the Diamond Tool Bond Types and Which to use for your application

Selecting the appropriate diamond bond type for specific applications is crucial for several reasons. Diamond bond type directly affects the tool's performance, efficiency, and longevity. Different bond types determine how well a tool can withstand...

09

Oct

How to Properly Use Diamond Carving Points

Diamond carving points are essential tools for anyone working with hard materials like glass, stone, and metals. These tools help with detailed tasks like engraving and finishing, providing good control and helping you work efficiently....

- Unmatched Selection For Many Applications

- Superior Quality & Consistency

- Immediate Worldwide Delivery

- Technical Support & Expertise

- American Based Manufacturer

- Different Product

- Different Technology

- Different Company

- Expect MORE from your tools

Let Us HELP You!

Subscribe To Our Newsletter

Signup for email offers, updates, and more

Contact Us

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

DIAMOND TOOLS BY BOND

EQUIPMENT

KNOWLEDGE CENTER

OUR PRODUCTS

COMPANY

CUSTOMER SERVICE

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use