Guide to Diamond Wire Sawing: Technologies, Wire Types, and Machine Designs

-

Posted by

Alexander Schneider

Alexander Schneider

Table of Contents

ToggleDiamond wire saws provide one of the most precise and reliable methods for sectioning both hard and fragile materials. The principle behind the process is simple yet highly effective. A thin wire embedded with fine diamond particles, typically between 20 and 120 microns, is drawn across the material under controlled speed and tension. As the wire moves, the exposed diamond particles perform a gentle lapping action rather than a heavy grinding or tearing motion. This allows the tool to remove material gradually and evenly, producing smooth surfaces with minimal damage.

This article explains the main types of diamond wire: electroplated, resin bond, and conventional slurry. Along with continuous, segmented, and hybrid configurations. It also compares the different machine systems, from open-end and endless wire saws to multi-wire production equipment. By understanding how each option affects speed, tool life, surface finish, and overall cost, you can make informed decisions that balance precision, efficiency, and reliability in your cutting operations.

Typically this type of wire saw can travel at surface speed of 6 mm/sec. The wire moves forward for abut 300mm and this is retraced for abut 200mm. Net advance of the new wire is at an average speed of 2 m/sec with about 100 m new wire passed through each cycle. The wire can run continuously for more than 300 km long. More than 500 slices can be sawn simultaneously. In a production environment 8” (200mm) silicon boul can be cut in less than 8 hours and 12” (300mm) boul in less than 12 hours.

Why Use Diamond Wire Blades & Saws

Unlike rotary blades, which apply concentrated forces at a single cutting edge, the contact zone in diamond wire sawing is distributed along a length of wire. This distribution reduces localized stress and vibration. As a result, the cutting forces remain very low, usually less than one pound (400 grams), even when slicing through extremely hard substrates. The reduced stress is critical for brittle materials such as sapphire, gallium arsenide, lithium niobate, quartz, and advanced ceramics, which can crack or chip under higher forces.

Because of this controlled cutting action, the surfaces produced by diamond wire saws often display a ground-like finish with excellent edge retention, eliminating the need for extensive post-processing. This is particularly valuable in industries where dimensional accuracy and surface quality directly affect performance, such as semiconductor manufacturing, optics, and aerospace engineering. For example, when preparing semiconductor wafers, even a minor surface flaw can cause downstream failures in lithography or assembly. Similarly, in optics, a clean edge ensures consistent light transmission and reduces the risk of fracture during polishing.

Another key advantage is the ability to section large or irregularly shaped materials with consistent precision. Whether slicing a fragile crystal into thin wafers or sectioning a large composite panel, the wire maintains stability throughout the cut. Combined with appropriate coolants and precise control of wire tension and feed rate, this makes diamond wire sawing one of the most versatile techniques available for cutting valuable and delicate materials.

Today diamond wire sawing is preferred by majority of solar silicon manufacturers, crystal growers, advanced ceramic manufacturers over other technologies/ cutting methods. diamond Wire saw operates similarly to horizontal hack saw, where head containing a pack of blades lengths of plain edge stainless or spring steel mounted parallel to head travel oscillates back and forth over the work piece or pieces which are mounted on a bed. The bed can be fed up into the blades at selected pressures. The diamond wire provides cutting or lapping action between the blades and material.

The wire saw allows slicing of hundreds of wafers simultaneously with the same continuous wire. In the past abrasives slurry wire saws were the main method used for cutting these ultra hard and brittle materials. Copper plated piano wires was used to trap abrasive particles (such as alumina or SiC) suspended in mechanical oil or water based coolant. To provide the cutting action and lubrication of the moving wire. The wire diameter used was smaller than 0.15mm and cutting kerf is about 0.19mm and 0.15mm and smaller. Abrasive slurry grit ranged from 1000 to 250 grit.

Viscosity and continuous mixing of the slurry must be maintained in order to produces consistent results. The improvement in diamond wire manufacturing technology and reduction in cost has made diamond wire cutting and industry standard. Diamond wire bonded with diamond offers many advantages in terms of faster cutting speed (frequently triple the speed) and improved surface finish quality (less secondary operations such as polishing).

Using Diamond Wire is much cleaner and faster process Today most Diamond Wire is wound around 2, 3,or 4 grooved mandrels in order to allow multiple loops for simultaneous slicing of the same ingot. When the looped wire is running across the ingot, the diamond particles on the surface of the wire will slowly lap/ grind off silicon on micro level (bit by bit). The cutting action is done by reciprocating motion. The wire is used once, and replaced with a new roll.

Evolution of Diamond Wire Sawing

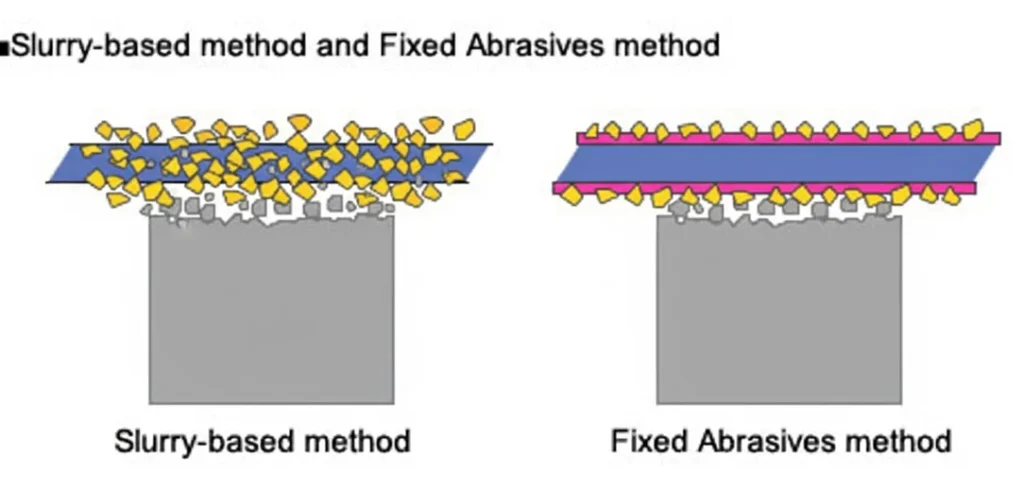

The evolution of diamond wire sawing reflects centuries of progress in abrasive cutting technology. The idea of embedding abrasives into a moving wire has its earliest roots in ancient stone cutting, where craftsmen used sand or crushed minerals in slurry form to slowly wear away hard materials. This principle survived into modern times in the form of slurry-based wire systems. In these early designs, a plain wire was pulled across the workpiece while abrasive slurry carried out the cutting action. While effective for certain applications, slurry methods were inefficient and had major drawbacks. Wire drift was a persistent problem, as the loose particles provided no stabilization. This often caused cuts to wander off line. Precision was limited, surface finishes were inconsistent, and the process required constant replenishment of slurry.

A significant advance came with the development of diamond-impregnated wire. By embedding diamond particles directly into the wire surface rather than relying on slurry, engineers created a cutting medium that delivered both stability and repeatability. The fixed abrasives provided consistent engagement with the workpiece, solving the problem of drift and greatly improving accuracy. For the first time, wire sawing could achieve straight, controlled cuts through very hard or brittle materials without the unpredictability of free abrasives.

From this breakthrough, the technology rapidly expanded. Electroplated wires made it possible to place a single layer of sharp, protruding diamonds on the wire, ideal for aggressive cutting of hard crystals. Resin-bonded wires introduced a more forgiving surface, allowing for smoother finishes and lower risk of microcracking in delicate substrates. Sintered wires extended tool life, as multiple layers of diamond particles became available as the outer layers wore down, ensuring steady performance in production environments.

These developments transformed diamond wire sawing from a niche laboratory method into a mainstream process used in semiconductors, optics, ceramics, geology, and even the jewelry industry. What began as slurry-assisted abrasion has evolved into a highly controlled precision cutting technology capable of producing wafer-thin sections, minimizing kerf loss, and delivering surface finishes that rival fine grinding.

Diamond Wire Blade Types

Diamond wire blades come as loops for precision cutting of wafers, crystals, and optics, or spools for long cuts on large blocks like stone, silicon, and ceramics.

Diamond Wire Loops

Diamond wire loops are made as continuous closed wires mounted on a set of pulleys. Because the loop runs without interruption, the cutting process is steady, predictable, and repeatable. The closed-loop system maintains consistent wire tension across its entire length, which is essential for high accuracy.

Vibration is reduced to a minimum, so the cuts are smooth, with clean edges and very little risk of chipping. The uniform pressure along the wire produces surfaces that often appear ground and polished, reducing or even eliminating the need for secondary finishing steps. These qualities make loops especially valuable in semiconductor wafer slicing, sapphire and optical crystal sectioning, and other precision industries where dimensional tolerances are tight and surface quality is critical.

Another advantage of loop wires is their long service life. Because wear is distributed evenly around the loop, they last longer than spool-based wires and can maintain performance for extended cutting operations. They are also capable of producing ultra-thin kerf widths, which increases yield and reduces wasted material. For these reasons, loop-based diamond wire machines are preferred in both laboratory and production environments where consistency and repeatability are vital.

Advantages

- Long service life due to even wear across the loop.

- Capable of achieving ultra-thin kerf widths for maximum yield.

- Preferred in laboratory and production environments requiring repeatability.

|

Specification |

Typical Values / Range |

Primary Applications |

|---|---|---|

|

Wire Diameter |

80 – 350 µm (0.08 – 0.35 mm) |

Fine wires (80–150 µm) are used for wafers and optics; thicker wires (200–350 µm) for ceramics and composites. |

|

Core Material |

High-tensile steel, tungsten, molybdenum, NiTi alloys |

Choice depends on required strength, flexibility, and corrosion resistance. |

|

Abrasive Grit Size |

5 – 50 µm (diamond particle size) |

Finer grits (5–15 µm) for smooth surfaces and thin wafers; coarser grits (30–50 µm) for faster cutting of harder substrates. |

|

Bond Type |

Electroplated (nickel), resin bond, multi-layer |

Electroplated is most common for loops; resin bond and multi-layer used where surface finish is critical. |

|

Loop Length (Circumference) |

600 – 1500 mm (lab systems) and larger for production |

Must match machine pulley spacing. |

|

Kerf Width |

As low as 10–25 µm |

Ultra-thin kerfs maximize yield and reduce material loss. |

|

Wire Speed Range |

0.5 – 20 m/s |

Lower speeds for brittle substrates; higher speeds for silicon and glass where throughput matters. |

|

Tensile Strength |

2000 – 4000 MPa |

Ensures stable performance under high-speed tension. |

|

Service Life |

Longer than spool-based wires due to even wear across the loop |

Extended lifespan is a key advantage of loop designs. |

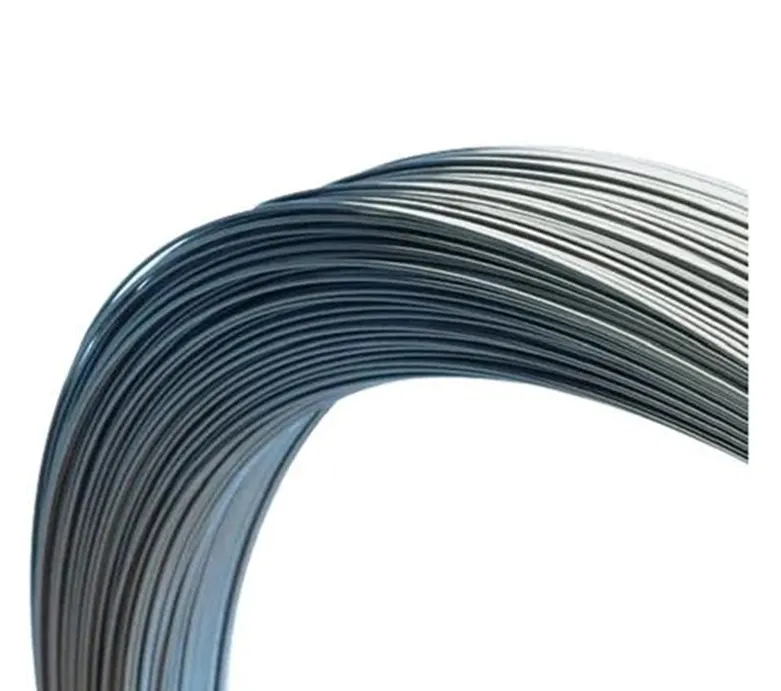

Diamond wire spools (Bobbin-Based)

Diamond wire spools, sometimes referred to as bobbin-based systems, operate differently. In this method, wire is wound onto reels or bobbins and fed continuously through the workpiece.

As the worn section of wire exits the cutting zone, it is replaced by fresh wire from the spool, ensuring sharp cutting edges are always in contact with the material. This design makes spool-based systems particularly effective for very long cuts or for processing large blocks of material that loops cannot accommodate.

The consumable nature of the wire allows them to tackle abrasive and challenging materials without a drop in performance, though wire usage is higher compared to loops. Surface quality is generally good, but because the wire is constantly replaced, it may not be as uniform as what is achieved with a loop system. These machines are common in industries that need to cut large stone slabs, silicon ingots, ceramic blocks, or advanced composites. Spool systems have a lower initial machine cost, making them attractive for industrial-scale production, but long-term operating costs can be higher due to continuous wire consumption. Their main strength lies in their flexibility and ability to handle heavy-duty, long-duration cutting operations that loop wires are less suited for.

Advantages

- Ability to process very large materials, such as industrial stone slabs or photovoltaic silicon blocks.

- Flexible use across many industries, from construction materials to advanced ceramics.

- Lower initial equipment cost compared to loop-based machines, though wire consumption can be higher.

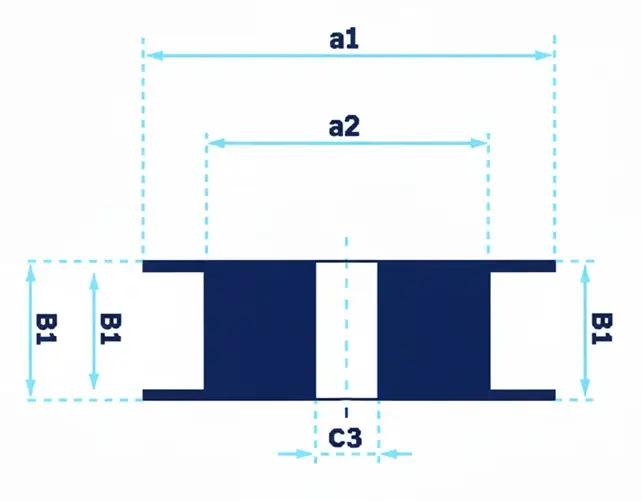

The specifications of spool-based diamond wire generally include:

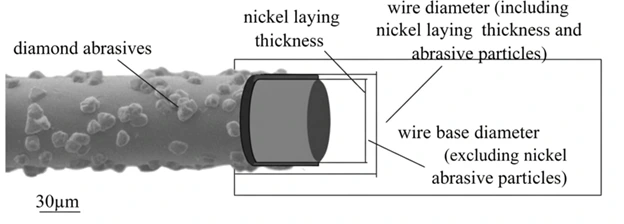

- Wire Diameter (a1, a2): Commonly ranges from 100 µm to over 400 µm. Larger diameters are stronger and better for cutting massive blocks of stone, silicon ingots, or ceramics. Finer diameters are used for precision applications where kerf loss must be minimized.

- Core Diameter (B1): The steel, tungsten, or alloy core determines tensile strength and flexibility. Typical cores range from 100–320 µm depending on the application.

- Diamond Size (a3): The abrasive layer is usually specified by grit size, such as 10–15 µm for fine wafers or 40–50 µm for heavy-duty cutting. Larger diamond sizes cut faster but leave rougher surfaces, while smaller grits provide smoother finishes.

- Spool Length: Wires are supplied in lengths ranging from a few hundred meters up to tens of kilometers, depending on diameter and machine compatibility. Long spools reduce downtime from wire changes and are especially useful in photovoltaic silicon wafer slicing and stone processing.

- Bond Type: Electroplated wires (nickel bond) are most common for spools, though resin wires are also available for applications requiring smoother finishes or longer tool life.

Specifications for Diamond Wire Spools

|

Specification |

Typical Range / Details |

|---|---|

|

Wire Outer Diameter |

Commonly ranges from 0.05 mm to 0.52 mm (50–520 µm) |

|

Core Wire Diameter |

Typically between 40 µm and 400 µm, depending on overall wire thickness and tensile strength requirement |

|

Diamond Grit Size |

Between 5–50 µm, with finer grits (5–20 µm) used for precision cutting and coarser grits (30–50 µm) for faster cutting or abrasive materials |

|

Tensile Strength |

Ranges from about 6 N to 320 N, increasing with wire thickness and diamond concentration |

|

Spool Length |

Standard lengths include 30, 60, 120, 180, 300, 500, and 1000 meters, with custom lengths available on request |

|

Minimum Pulley Diameter |

The minimum wheel or pulley diameter for safe use ranges from 40 mm to 250 mm, depending on wire thickness |

|

Application Scope |

Spool-based wire systems are ideal for long, unbroken cuts, high flexibility across materials, and are cost-attractive for industrial-scale production. |

Table of Comparison Between Diamond wire loops & Diamond wire spools

|

Feature |

Diamond Wire Loops |

Diamond Wire Spools (Bobbin-Based) |

|---|---|---|

|

Design |

Continuous closed-loop mounted on pulleys |

Wire wound on reels/bobbins and fed continuously |

|

Cutting Stability |

Very stable, minimal vibration |

Stability depends on spool feed and wire tension |

|

Surface Quality |

High surface quality, smooth finishes |

Good quality but may vary as wire wears during feed |

|

Kerf Width |

Capable of ultra-thin kerfs (micron-level precision) |

Typically wider kerfs compared to loops |

|

Wire Wear |

Even wear across the loop, longer life |

Wire is consumable; replaced as spool unwinds |

|

Cutting Capacity |

Best for thin wafers, small samples, precision parts |

Suitable for large blocks, long cuts, and bulk materials |

|

Applications |

Semiconductor wafers, sapphire, optical crystals, R&D |

Stone, silicon ingots, ceramics, composites, construction materials |

|

Equipment Cost |

Higher initial machine cost, lower wire consumption |

Lower machine cost, higher wire consumption |

|

Production Scale |

Ideal for high-precision lab or production environments |

Ideal for industrial-scale, high-volume cutting |

|

Advantages |

Superior accuracy, repeatability, and surface finish |

Flexibility, ability to cut large workpieces, continuous operation |

|

Limitations |

Limited to smaller materials, higher machine investment |

Wire cost is higher due to constant consumption, less precise |

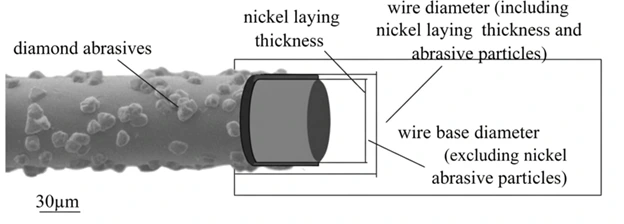

Electroplated Diamond Wire

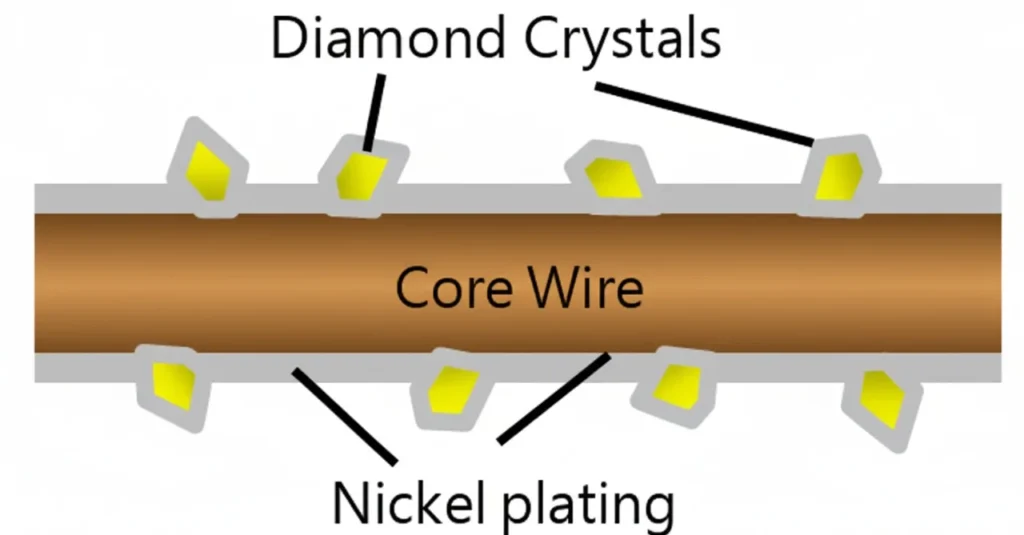

Electroplated diamond wire is made with a single layer of diamond particles bonded to the wire surface using nickel plating. Because all the abrasive particles are exposed, the wire offers very high initial sharpness and fast cutting speeds.

This makes it suitable for applications where short cycle times and aggressive material removal are required. It is widely used in semiconductor wafer slicing, glass substrates, sapphire, optical crystals, and other high-value materials where precision and throughput are important. The main limitation is tool life. Since only one diamond layer is available, the wire wears faster than multi-layered or resin-based options. Electroplated wire is often chosen when cost per cut, consistency of sharpness, and cutting speed matter more than maximum lifespan.

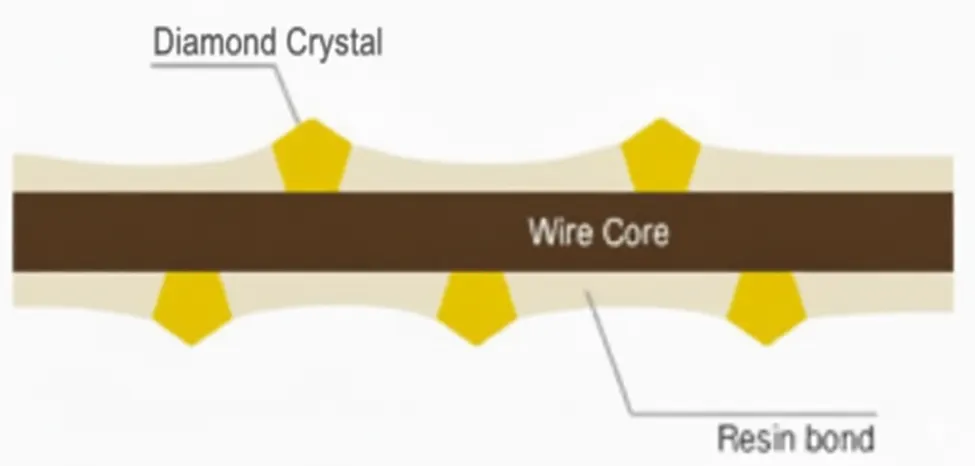

Resin Bond Diamond Wire

Resin bond diamond wire is produced by embedding diamond particles within a resin matrix, rather than fixing them in a single external layer as in electroplated wire. As the resin gradually wears away during cutting, new layers of sharp diamond particles are continuously exposed, which ensures a steady cutting action and consistent performance throughout the life of the wire. This self-renewing property makes resin bond wire especially effective for applications that require stable sharpness and extended tool life.

One of the key advantages of resin bond wire is its ability to deliver a smoother cutting action, cleaner surface finishes, and reduced chipping compared to electroplated wire. Because the diamonds are released gradually, cutting forces are lower and heat generation is minimized, which in turn reduces the risk of microcracking and subsurface damage. These qualities make resin bond wire the preferred choice for delicate or brittle materials where surface integrity is more important than maximum cutting speed. Typical applications include advanced ceramics, thin and specialty glass, high-performance composites, and precision optical substrates, where even minor surface defects can compromise functionality.

While resin bond wire generally cuts more slowly than electroplated wire, it provides superior control over the cutting interface and greater process reliability. This trade-off is often justified in high-value industries, where maintaining the quality of the workpiece is more important than achieving the fastest possible throughput. For example, in electronics and photonics manufacturing, resin bond wire is used to process wafers or components that require high dimensional accuracy, low levels of edge chipping, and minimal surface contamination.

Conventional Abrasive Slurry Wire

Conventional slurry-based diamond wire is a plain steel or tungsten wire used with an external abrasive slurry made of loose diamond particles suspended in a liquid carrier. As the wire moves through the material, the slurry provides the cutting action.

This method was one of the earliest adaptations of diamond wire technology and is still used in certain applications. Slurry wire allows flexibility in abrasive selection, since the slurry composition can be tailored to the material being cut. It is commonly applied in research, laboratory sample preparation, and older photovoltaic silicon wafer slicing systems. While slurry wires can produce good results, they are less efficient than electroplated or resin bond wires. They require continuous slurry supply and handling systems, generate more waste, and involve higher maintenance costs. As a result, slurry wires are being phased out in many modern production environments in favor of fixed-abrasive wires, but they remain useful for specialized applications where process control and flexibility are valued.

Table of comparison between different types of diamond wire

|

Feature |

Electroplated Diamond Wire |

Resin Bond Diamond Wire |

Conventional Abrasive Slurry Wire |

|---|---|---|---|

|

Construction |

Single layer of diamond particles bonded with nickel plating |

Diamonds embedded in a resin matrix |

Plain wire (steel or tungsten) used with external diamond slurry |

|

Cutting Characteristics |

Very sharp, aggressive cutting, fast material removal |

Smoother cutting, consistent sharpness as resin wears |

Cutting depends on slurry; less efficient and slower |

|

Surface Quality |

Good precision but may leave micro-scratches due to aggressive action |

Cleaner surfaces, reduced chipping, less subsurface damage |

Variable surface finish; depends on slurry and operator control |

|

Tool Life |

Shorter (only one diamond layer) |

Longer (new diamonds exposed as resin wears) |

Wire lasts long, but slurry requires constant replenishment |

|

Cutting Speed |

High |

Moderate to low |

low |

|

Best Suited For |

High-value materials, semiconductor wafers, sapphire, optical crystals, glass substrates |

Delicate, brittle materials like ceramics, thin glass, specialty composites |

Research, older photovoltaic wafer slicing, lab sample prep |

|

Main Advantage |

High throughput and consistent sharpness |

Superior surface finish, reduced microcracking |

Flexible slurry composition, adaptable to different materials |

|

Main Limitation |

Limited life, higher replacement cost |

Slower cutting, less suited for high-volume production |

Inefficient, messy, generates waste, high maintenance |

|

Current Use |

Widely adopted in modern precision industries |

Growing in delicate and brittle material cutting |

Declining; being phased out, but still used in specialized research |

Continuous Diamond Wire

Continuous diamond wire is manufactured by coating the entire length of the wire with diamond abrasives, leaving no gaps or uncoated areas. This uninterrupted design ensures that every portion of the wire contributes to the cutting process, which results in uniform engagement between the abrasive and the material. The continuous contact reduces fluctuations in cutting pressure, leading to a stable process with predictable results.

Because the cutting edge is always in contact with the workpiece, continuous diamond wire is known for producing exceptionally smooth surfaces and narrow kerf widths. This reduces material waste, increases yield, and minimizes the need for secondary finishing steps such as grinding or polishing. In delicate materials such as semiconductor wafers, sapphire, quartz, and advanced ceramics, continuous wire helps avoid micro-cracks, thermal stress, and subsurface damage that could compromise part performance.

Another advantage is its compatibility with precision cutting machines that operate at controlled speeds and feed rates. Continuous wires are less prone to vibration compared to segmented wires, which translates into greater accuracy and longer tool life when used under proper operating conditions. This makes them the preferred choice in industries where tight tolerances, repeatability, and surface quality are critical, such as microelectronics, photonics, and optics.

However, continuous wires do have trade-offs. Because the diamond abrasive layer covers the entire wire, chip clearance and coolant flow can be more limited compared to segmented designs. This means operators must use optimized coolant delivery systems and controlled feed rates to avoid clogging and maintain efficient cutting. For large block cutting or highly abrasive materials, continuous wire may not be as efficient as segmented wire, but for precision applications, it remains the industry standard.

Segmented Diamond Wire

Segmented (interval-coated) diamond wire is engineered with abrasive zones separated by uncoated intervals. The purpose of this design is to give the wire built-in chip clearance pockets, which allow cutting debris, slurry, and coolant to circulate freely around the wire. This reduces the chance of clogging, lowers the cutting temperature, and keeps the diamonds exposed for longer periods. The result is a wire that can maintain performance even when cutting materials that tend to load or generate heavy swarf.

This configuration is especially valuable in semiconductor ingot slicing, advanced ceramics, composites, and other high-density or abrasive materials. In these cases, a fully coated wire might overheat or glaze because there is no room for the debris to escape. By spacing out the abrasive zones, segmented wire maintains cutting efficiency without the same risk of overheating.

The trade-off is that segmented wire does not always achieve the ultra-smooth surfaces or the finest kerf control that continuous wire can provide. Instead, it prioritizes cooler operation, stable cutting speeds, and longer effective wire life. For example, in silicon or SiC ingot processing, segmented wire allows higher throughput while still producing wafers with acceptable surface quality for subsequent polishing. In ceramic and composite processing, it minimizes breakage and extends tool life compared to fully coated wires.

It is important to distinguish segmented (interval-coated) wire from beaded diamond wire used in stone cutting. Beaded wire is built with discrete diamond-impregnated beads strung on a steel cable, intended for quarrying or cutting massive stone blocks. In contrast, interval-coated segmented wire is a precision cutting tool developed for electronics, optics, and advanced materials, where the focus is on controlled chip evacuation and improved reliability rather than rough shaping.

When applied with proper tension, coolant delivery, and feed rates, segmented diamond wire provides a strong balance of cutting efficiency, durability, and cost-effectiveness, particularly in industries where productivity and throughput are as important as precision.It is important to distinguish segmented (interval-coated) wire from beaded diamond wire used in stone cutting. Beaded wire is built with discrete diamond-impregnated beads strung on a steel cable, intended for quarrying or cutting massive stone blocks. In contrast, interval-coated segmented wire is a precision cutting tool developed for electronics, optics, and advanced materials, where the focus is on controlled chip evacuation and improved reliability rather than rough shaping.

Multi-Layer or Spiral-Coated Diamond Wire

Multi-layer or spiral-coated diamond wire is designed to combine the benefits of speed, surface finish, and tool life. Instead of relying on a single uniform coating, these wires are built with several layers of diamond abrasive or a spiral arrangement along the wire’s length. This design places more cutting points in contact with the material, which improves efficiency while keeping the cutting action stable. The spiral spacing also creates natural channels for debris and coolant evacuation, reducing the chance of clogging and helping the wire stay cooler during operation.

Because multiple layers of abrasive are present, new cutting edges are exposed as the outer diamonds wear away. This extends tool life beyond what is possible with single-layer electroplated wires. At the same time, the wire maintains a sharper and more consistent cutting action than resin bond wires, which typically cut more slowly. The result is a balanced performance, offering faster cutting than resin systems and smoother surfaces than aggressive electroplated wires.

These qualities make multi-layer or spiral-coated wires well suited for mid-range applications where both throughput and surface quality are important. They are widely applied in photovoltaic silicon wafer slicing, advanced ceramics, composites, and specialty glasses. In these areas, they provide reliable performance without sacrificing finish quality or generating excessive heat. They are also valued in research and prototyping, where one versatile wire may be required to handle different materials efficiently.

The main limitation of spiral-coated wires is that they are not optimized for extremes. Electroplated wires remain superior for maximum cutting speed, while resin bond wires are better for ultra-delicate substrates where minimizing chipping and microcracking is critical. Cost can also be a factor, since producing spiral or multi-layer wires is more complex. Even so, for many industrial users, the balance of speed, finish, and longevity makes them a cost-effective solution for demanding but versatile cutting requirements.

Hybrid Diamond Wire

Hybrid diamond wires are designed to combine the strengths of multiple abrasive configurations into a single tool. Instead of relying on one coating strategy, these wires may use a mix of continuous and segmented zones or even integrate different bond types such as electroplated, resin, or multi-layer coatings. This allows the wire to deliver greater versatility and adapt to a wider range of cutting conditions without frequent tool changes.

A major benefit of hybrid wires is their ability to cut mixed-material assemblies or multi-layered components. In these situations, a continuous section of the wire ensures smooth surfaces and precise dimensional accuracy, while the segmented or spiral-coated zones promote better debris evacuation and cooler operation. This balance makes them suitable for applications such as advanced composites, ceramic–glass hybrids, and semiconductor devices where both speed and surface integrity matter.

Hybrid configurations also perform well when cutting parameters vary. They can tolerate changes in feed rate, wire tension, and coolant flow better than single-purpose wires, which reduces downtime and provides consistent performance. This stability is highly valued in industries such as aerospace, photonics, and microelectronics, where small variations in cut quality can lead to expensive rework or rejected parts.

The drawback is that hybrid wires are generally more expensive to manufacture due to their complex construction and quality control requirements. They may also fall short when compared with specialized wires in extreme conditions: electroplated wires remain the fastest for aggressive cutting, while resin bond wires still provide the smoothest finish for ultra-delicate substrates. Even so, for many users who need one tool capable of balancing speed, surface finish, and longevity, hybrid diamond wires offer a practical and cost-effective solution.

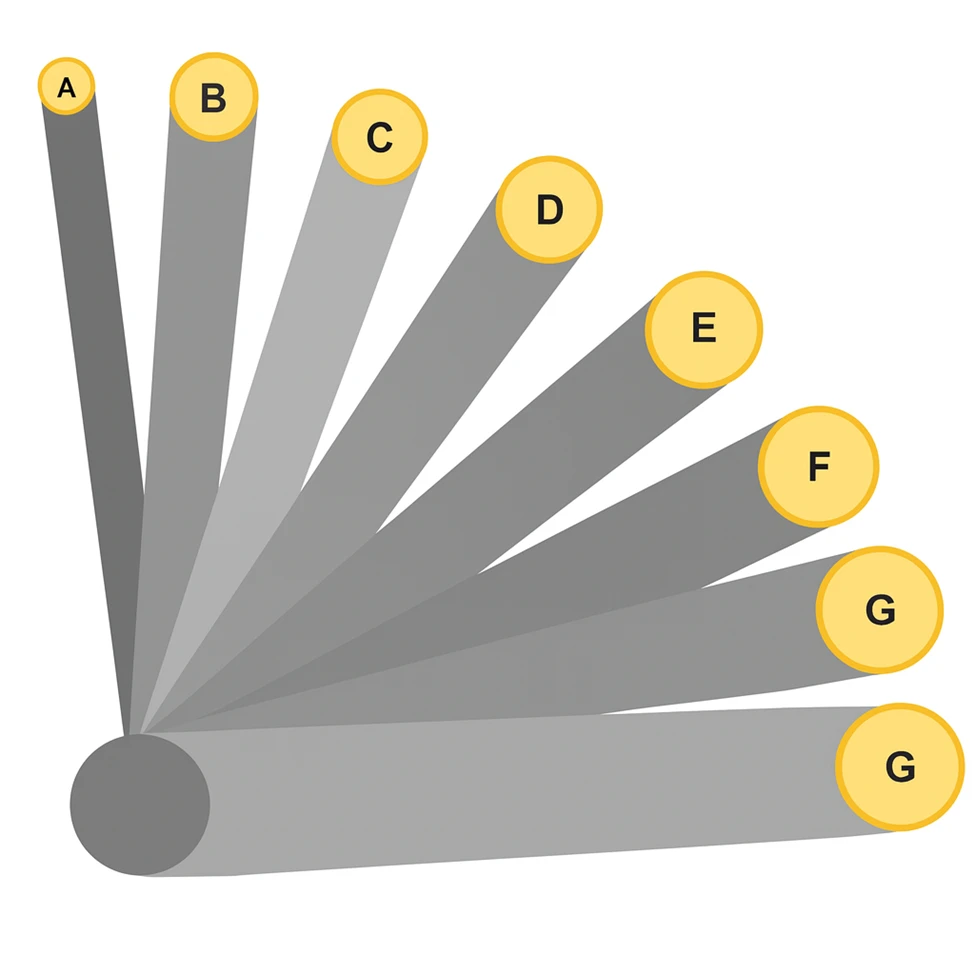

Diamond Wire Blade Diameters

Diamond wire is manufactured in different diameters, and the choice of size directly affects cut quality, speed, tool life, and suitability for various applications. The core wire thickness, combined with the diamond grit size, determines both the kerf width and the stability of the cutting process.

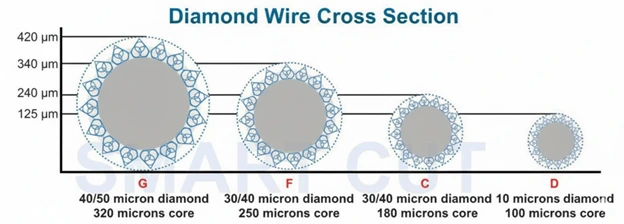

Larger diameter wires (such as 420 µm with a 320 µm steel core) provide greater strength and are typically coated with coarser diamond grits like 40/50 µm. These wires are well suited for large block cutting (stone, silicon ingots, ceramics, and composites) where durability and stability are more important than the thinnest kerf or highest surface finish. They resist breakage under long cuts but generate a wider kerf and consume more material.

Medium diameter wires (340 µm with a 250 µm core or 240 µm with a 180 µm core) offer a balance between cutting efficiency and precision. With diamond sizes around 30–40 µm, they are used in photovoltaic wafer slicing, optical glass sectioning, and advanced ceramics. These wires cut faster than fine wires while still producing acceptable surface finishes with moderate kerf widths.

Fine diameter wires (125–180 µm with 100 µm cores) are coated with fine diamonds, typically 10–30 µm, and are designed for precision cutting applications. They are the preferred choice for semiconductor wafers, sapphire, and optical crystals, where ultra-thin kerfs, high accuracy, and superior surface finishes are critical. Because they are more delicate, careful control of wire tension, feed rate, and coolant is required to prevent breakage.

Diamond Wire Based Material Types

The base material of a diamond wire plays a critical role in its performance, durability, and suitability for different applications. While the abrasive layer does the actual cutting, the core wire determines how much tension the wire can withstand, how flexible it is during operation, and how resistant it is to fatigue or corrosion. Selecting the right base material ensures that the wire maintains stability, delivers consistent cutting results, and operates safely under demanding conditions. Different core materials such as high-tensile steel, stainless steel, tungsten, molybdenum, and specialty alloys each offer unique advantages that make them better suited for specific industries and cutting requirements. Understanding these options helps in choosing the most efficient and reliable wire for the material being processed.

High-Tensile Steel Wire

High-tensile steel is the most common base material for diamond wire. It offers strength, flexibility, and relatively low cost. Steel cores are widely used in electroplated, resin bond, and slurry wire systems. Their main advantages are high pulling strength and good fatigue resistance, which allow long continuous cuts without breaking. Steel-based wires are standard in industries such as semiconductors, photovoltaics, optics, and stone cutting.

Stainless Steel Wire

Stainless steel cores are used when corrosion resistance is important, particularly in processes where water-based coolants or slurries are present. They also provide good flexibility and fatigue resistance, though they are generally softer than high-tensile carbon steel. Stainless steel base wires are common in laboratory-scale cutting and in applications requiring clean processing environments.

Tungsten Wire

Tungsten is chosen when exceptional strength and wear resistance are required. Tungsten wires are stiffer than steel, with a higher modulus of elasticity, which makes them less prone to elongation under high tension. They are used in applications involving very hard or abrasive materials such as advanced ceramics, sapphire, and semiconductor substrates. Tungsten also has high-temperature resistance, making it suitable for demanding cutting environments.

Molybdenum Wire

Molybdenum wires combine strength, good fatigue life, and corrosion resistance. They are lighter and softer than tungsten but still stronger than most steels. Molybdenum is often used in precision diamond wire saws for electronics, optics, and specialty ceramics. It is valued for maintaining wire straightness and stability under high tension while still being workable for fine diameters.

Other Specialty Alloys

Some diamond wires use nickel-titanium (NiTi) alloys or composite cores. NiTi alloys provide excellent flexibility and fatigue resistance, allowing very thin wires to be used without breaking. Composite cores, combining steel with polymer or other metallic coatings, are engineered for specific applications that demand reduced vibration, better wear resistance, or specialized coolant compatibility. These are less common but are growing in use for ultra-precise applications such as advanced semiconductor slicing and R&D.

Comparison table of the main diamond wire base material types:

|

Base Material |

Key Properties |

Advantages |

Limitations |

Typical Applications |

|---|---|---|---|---|

|

High-Tensile Steel |

Strong, flexible, good fatigue resistance |

Low cost, reliable, widely available |

Can corrode in wet environments, lower wear resistance than tungsten or molybdenum |

Semiconductor wafers, photovoltaics, optics, stone cutting |

|

Stainless Steel |

Corrosion-resistant, softer than carbon steel |

Good flexibility, resists rust in water-based coolants |

Lower tensile strength than high-tensile steel, shorter lifespan in abrasive cutting |

Laboratory cutting, cleanroom or wet-process environments |

|

Tungsten |

Very high strength, stiff, high modulus of elasticity |

Excellent wear resistance, resists elongation under tension, withstands high temperatures |

Brittle compared to steel, higher cost, less flexible |

Sapphire, ceramics, semiconductor substrates, heavy-duty industrial cutting |

|

Molybdenum |

Strong, corrosion-resistant, lighter than tungsten |

Good fatigue life, maintains straightness under high tension |

Softer than tungsten, moderate cost, less wear resistant |

Precision cutting of electronics, optics, specialty ceramics |

|

Specialty Alloys (NiTi, composites) |

Flexible, high fatigue resistance, customizable |

Ultra-thin diameters possible, reduced vibration, tailored for demanding environments |

Higher cost, less widely available, specialized use only |

Advanced semiconductor slicing, R&D, high-precision optics |

Types of Diamond Wire Cutting Machines and Wire Blade Types

Selecting the right type of diamond wire cutting machine is important to achieving the desired balance of precision, throughput, and cost efficiency. Each machine design is tailored to specific applications, and its performance is closely tied to the type of diamond wire blade it uses. Understanding how machine construction relates to wire configuration helps determine which system is best suited for a given material and cutting requirement.

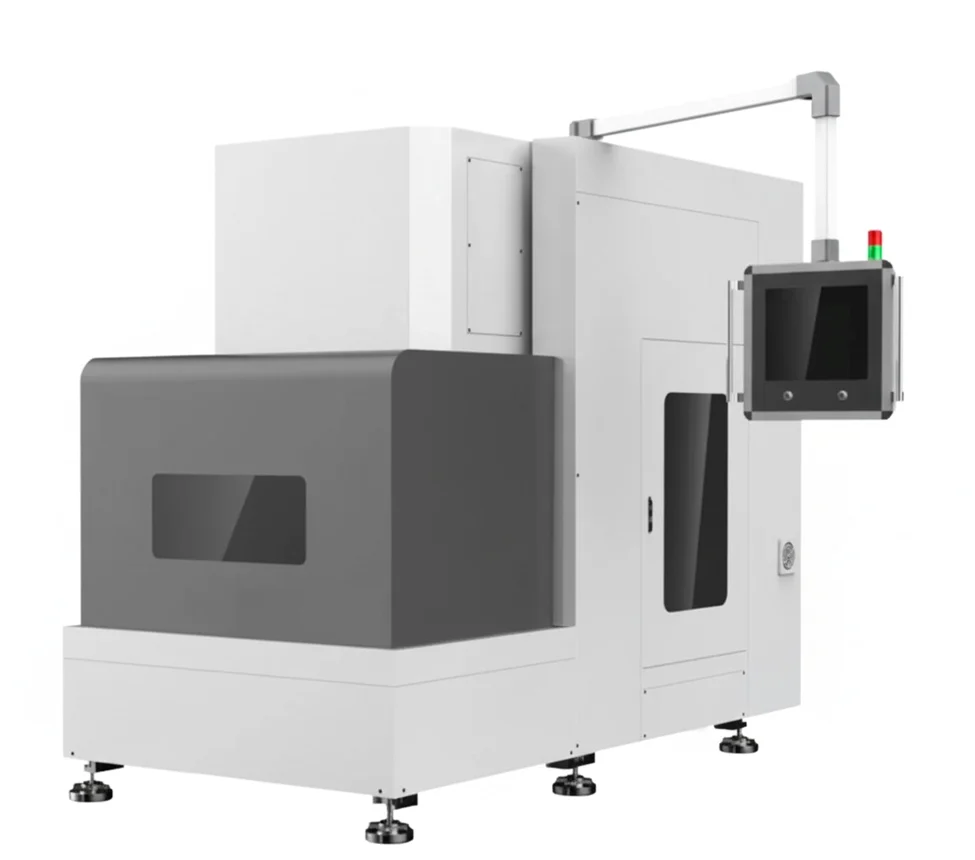

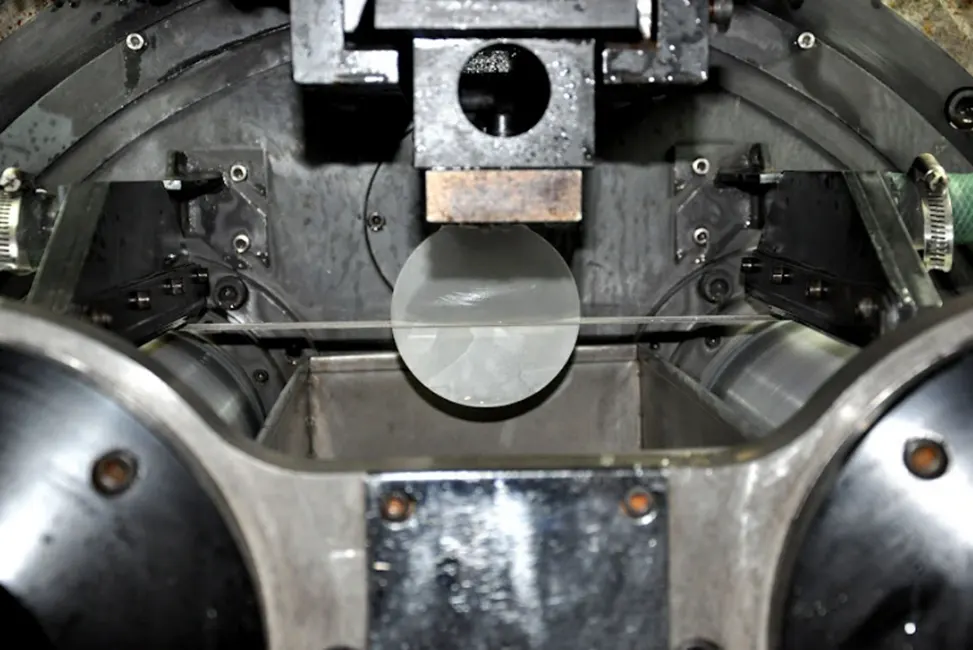

Loop Wire Machines operate with a continuous diamond wire loop mounted on pulleys. Such as our SMART CUT 6035 wire machine. The closed-loop design ensures stable tension, repeatable performance, and excellent surface finish. These machines are highly precise and are most often used in semiconductor wafer slicing, sapphire processing, and optical crystal cutting. Their ability to maintain dimensional accuracy and deliver clean cuts makes them standard in laboratory and advanced manufacturing environments.

For a long time known they are the epitome of precision cuts for the sample preparation in microscopy. Extremely fine wires can be used (eg 100 microns in diameter) which makes it possible to cut very thin slices (the effective slice thickness depends on the material properties and can not be quantified). This saws work with low wire speed (eg, 2m/s), the contact pressure between wire and sample (gravity feed) is in the gram range (eg, 100g). No appreciable heat is created and in addition, the cutting wire is continuously wound on a metal cylinder, to whom he gives the residual heat. The cutting times are relatively long, which is, since the saw is designed for small samples, irrelevant. As the diamond wire constantly changes the cutting direction (the wire is typically 10m in length) a self-cleaning effect is created on the wire, but will also produce fine scratches (less than 5μm depth). The fluid is used solely for the removal of particles to keep the wire clean.

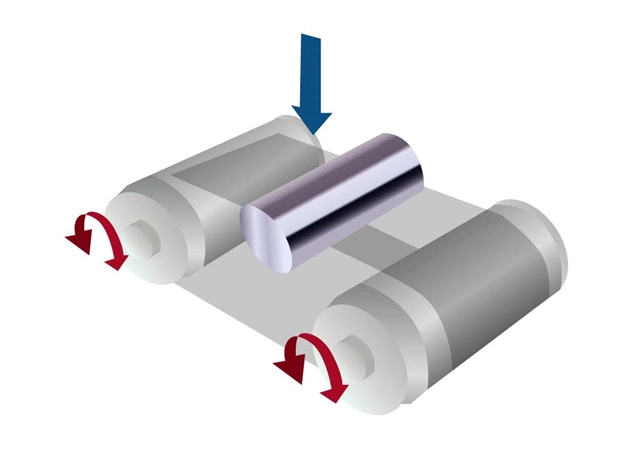

Endless Wire Machines use a single continuous wire moving in one direction rather than recirculating in a loop. By eliminating the need for splicing, these machines reduce weak points and improve reliability. Endless systems are widely applied in photovoltaic industries for silicon ingot slicing, where high throughput and long, consistent cuts are necessary. They are designed to handle large workpieces while maintaining efficiency.

Still little known, since the introduction into the market just began, this saw type has unimagined applications. The wire speed is very high (typically 20 m/s), the cutting times correspondingly short. Hard materials such as glass and ceramics can be easily cut, the heat generated during cutting can be partially eliminated by a liquid (usually water). The wires range from 0.35 to 0.60 mm. Soft materials have a risk of sticking to the wire (by reducing the wire speed this can sometimes be prevented). If necessary, these saws can cut parts led by hand (shapes). It is of particular interest that in case of accidental touching the ongoing wire, no cuts on fingers are produced. This advantage is unique and not known from others saw types. The wire exchange can be accomplished very easily and quickly. Since the diamond wire runs in only one direction, the surface is largely groove – free. Normally this saw type is used in relation with electrical feed.

Reciprocating Wire Machines move the diamond wire back and forth in short strokes, such as our SMART CUT 6012 saw. This simpler mechanism makes them more affordable and easier to maintain, though they do not achieve the same productivity levels as loop or endless systems. These machines are well suited for small-scale research labs, academic settings, and low-volume production. They are commonly applied to ceramics, composites, and specialty materials where flexibility and low investment costs are priorities.

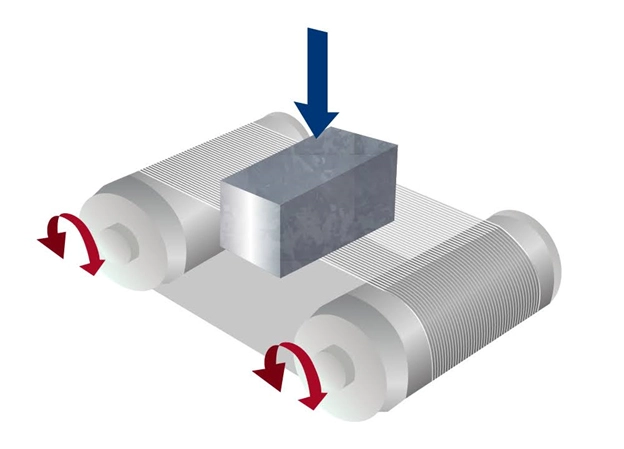

Multi-wire (Gang Saw) Machines use multiple wires simultaneously to cut several wafers or slices from a block in a single pass. By running many wires in parallel, these machines significantly reduce processing time and maximize throughput. They are especially important in the solar industry, where hundreds of wafers must be cut efficiently from silicon ingots. Multi-wire systems deliver high-volume production with good consistency, making them essential for industries where scale and efficiency outweigh the need for ultra-fine surface finishes.

Each machine type comes with its strengths and limitations. Loop and endless wire machines dominate in high-precision applications where quality is paramount, while reciprocating and multi-wire systems are more common where cost control and production output take priority. Matching the right machine type with the correct wire blade configuration ensures both performance and longevity in advanced material processing.

Wire Saw Table of Comparison

|

Machine Type |

How It Works |

Key Features |

Advantages |

Limitations |

Typical Applications |

|---|---|---|---|---|---|

|

Loop Wire Machines |

Continuous diamond wire loop mounted on pulleys, low wire speed (~2 m/s), light contact pressure (grams range) |

Stable tension, repeatable performance, precise thin slices (down to ~100 µm wire), self-cleaning effect from direction change |

Excellent dimensional accuracy and surface finish, minimal heat generation, ideal for microscopy sample prep and delicate materials |

Slow cutting times, limited to small samples, fine scratches (<5 µm) may appear |

Semiconductor wafers, sapphire, optical crystals, microscopy sample preparation |

|

Endless Wire Machines |

Single continuous wire runs in one direction at high speed (~20 m/s), wires 0.35–0.60 mm |

Groove-free surface, eliminates splicing weak points, simple wire change |

Very fast cutting, can cut hard materials (glass, ceramics) easily, safer (no finger injury on contact), long continuous cuts |

Risk of soft materials sticking to wire, newer technology with limited adoption |

Photovoltaic silicon ingots, large workpieces, glass, ceramics |

|

Reciprocating Wire Machines |

Wire moves back and forth in short strokes |

Simple, low-cost mechanism, small footprint |

Affordable, easy to maintain, flexible for small projects |

Lower productivity, slower compared to loop or endless, limited for high-volume needs |

Research labs, universities, ceramics, composites, specialty materials |

|

Multi-wire (Gang Saw) Machines |

Many wires run in parallel to cut multiple wafers at once |

High throughput, industrial-scale systems |

Extremely efficient for mass slicing, consistent wafer thickness, large-scale productivity |

Expensive, less focus on ultra-fine surface finish, high maintenance |

Solar industry, silicon ingots, high-volume wafer production |

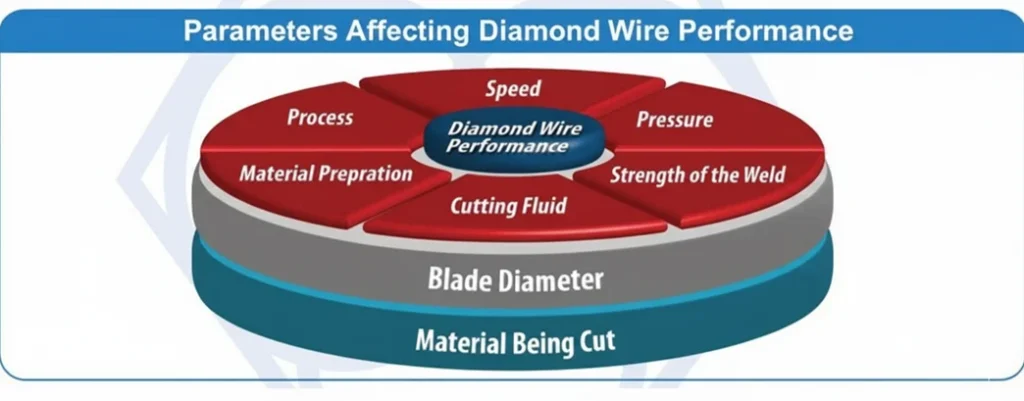

Key Parameters Affecting Diamond Wire Performance

While the type of diamond wire is important, several other factors also significantly affect cutting performance.

Diamond Wire Speed

Diamond wire speed is one of the most critical parameters in the cutting process because it directly affects material removal rate, surface quality, wire life, and heat generation. A higher wire speed increases throughput, which is valuable in production environments where cycle times must be minimized. However, as speed rises, it also causes greater friction and heat, leading to faster wear of the wire and the possibility of thermal damage to sensitive materials such as silicon wafers, lithium niobate, or optical crystals. Even small increases in temperature in these substrates can result in microcracks, warping, or subsurface damage.

At lower wire speeds, the cutting action is gentler and more controlled, which reduces the risk of edge chipping, maintains straighter kerf paths, and produces smoother surface finishes. This is particularly important when cutting brittle ceramics, thin glass, or parts requiring tight dimensional tolerances. The trade-off is that cutting times increase, which may limit productivity in high-volume production, though it is often acceptable in laboratory and precision applications.

The optimal wire speed is not fixed but depends on material hardness, brittleness, and abrasiveness, as well as other cutting variables such as wire tension, feed rate, coolant type, and abrasive grit size. For example, higher speeds are possible when coolant flow is optimized to remove heat and debris, while lower speeds are required for highly abrasive materials like zirconia or silicon carbide to control wear and extend wire life.

Achieving the right balance requires empirical testing and following manufacturer recommendations. In industries such as semiconductors, optics, and advanced ceramics, speed ranges are carefully defined to ensure process consistency and minimize material loss. Proper speed management often makes the difference between a clean, efficient cut and one that causes wire breakage or surface defects. By treating wire speed as part of a holistic system—together with pressure, coolant, and wire type—operators can achieve both high productivity and reliable quality.

|

Aspect |

Impact of Speed on Diamond Wire Cutting |

|---|---|

|

Material Removal Rate |

Higher speeds generally increase the rate at which material is removed, beneficial for reducing cycle times in production settings. However, optimal speeds vary based on material hardness and abrasiveness. |

|

Wire Wear |

Increased speed intensifies friction, leading to faster wear and tear on the diamond wire. Balancing speed to minimize wear can extend wire life and reduce tooling costs. |

|

Heat Generation |

Faster speeds raise friction and heat generation, which can alter material properties and cause damage, especially in thermally sensitive materials. Managing speed is crucial to avoid these effects. |

|

Control and Precision |

High speeds can compromise cutting precision, especially in delicate or complex shapes. Lower speeds enhance control, aiding in achieving precise cuts with minimal deviations. |

|

Interactions with Other Parameters |

Speed interacts with other cutting parameters such as pressure, blade diameter, and cutting fluid type. A holistic approach is essential for optimizing overall cutting performance. |

|

Application-Specific Speed Recommendations |

Developing specific speed settings based on material characteristics and empirical data ensures consistency and quality in cuts, particularly vital in precision-required industries like semiconductor or optics. |

Recommended Diamond Wire Speed Ranges by Material

|

Material / Application |

Typical Speed Range |

Notes |

|---|---|---|

|

Silicon (PV & semiconductor wafers) |

10–15 m/s |

Standard for wafer slicing. Balances throughput and surface quality. Verified by multiple sources |

|

Sapphire |

5–12 m/s |

Lower speeds reduce risk of microcracks and chipping. Precision coolant control required. |

|

Quartz / Optical Glass |

5–15 m/s |

Moderate speeds prevent thermal stress and subsurface damage. Widely used in optics processing. |

|

Gallium Arsenide (GaAs) |

3–8 m/s |

Very brittle; requires slower speeds to minimize wafer breakage and edge chipping. |

|

Lithium Niobate (LiNbO₃) |

3–7 m/s |

Thermally sensitive. Lower speeds prevent warping or cracking during dicing. |

|

Advanced Ceramics (Si₃N₄, ZrO₂, Al₂O₃) |

4–10 m/s |

Abrasive materials shorten wire life. Lower speeds reduce wire wear and microfracture risk. |

|

Composites (CFRP, GFRP, laminates) |

6–12 m/s |

Mid-range speeds prevent delamination and fiber pull-out. Adequate coolant flow essential. |

|

Stone / Large Blocks (Granite, Marble, SiC ingots) |

20–35 m/s |

High speeds maximize productivity. Softer materials like marble closer to 30–35 m/s; granite typically 20–30 m/s |

|

Laboratory Precision Cuts (optical or micro-samples) |

0–4 m/s |

Used in research saws for delicate samples where control and accuracy outweigh speed |

Diamond Wire Pressure

Pressure is one of the most important variables in diamond wire cutting because it directly influences how the wire engages with the material. The applied pressure translates into the actual cutting force, and small deviations can change both the quality of the cut and the lifespan of the wire.

When excessive pressure is applied, the wire is forced too aggressively into the workpiece. This increases friction and heat generation, leading to premature abrasive wear, core fatigue, or sudden wire breakage. The cut surface can also suffer from microcracks, edge chipping, and dimensional inaccuracies. Operators may see a temporary increase in cutting speed, but it comes at the expense of tool life and surface integrity.

On the other hand, insufficient pressure means the wire does not penetrate the material effectively. The result is reduced cutting efficiency, slower feed rates, and glazing of the diamonds as they rub rather than cut. This condition also increases the risk of the wire slipping or wandering, which compromises precision.

The goal is to maintain an optimal pressure range where the wire is allowed to cut freely without being forced. Proper pressure provides stable cutting action, minimal heat buildup, maximum wire life, and consistent surface quality. Finding this balance depends on several factors, including the wire diameter, bond type, diamond grit size, feed rate, and the hardness of the material being cut. For high-value applications like semiconductor wafers or sapphire, precise pressure control is critical, while in stone or composite block cutting, slightly.

Strength of the Weld

Strength of the Weld is a critical factor in diamond wire performance because the weld joints connect the core wire and carry the full tension load during cutting. These welds must withstand constant stress, vibration, and abrasive contact. If the weld is weak or improperly formed, the wire can fail prematurely, often snapping at the joint. This is especially likely when cutting hard, brittle, or abrasive materials where wire tension is high and feed rates are demanding.

High-quality welds ensure that the tensile strength of the joint matches or exceeds the strength of the base wire itself. Properly engineered welds also provide consistent alignment, preventing irregularities that could cause uneven wear or surface defects on the material being cut. On the other hand, poor weld quality leads to sudden breakage, machine downtime, and loss of productivity.

In practice, manufacturers use advanced welding methods, such as laser or resistance welding, to ensure weld joints are strong, uniform, and repeatable. Quality control checks, including tensile testing and microscopic inspection, are often performed to guarantee that every spool or loop of wire meets reliability standards. For critical industries like semiconductors, optics, and photovoltaics, weld strength is a key specification because a single wire break can damage expensive materials and disrupt production runs.

Maintaining strong weld joints ultimately ensures longer tool life, fewer machine stoppages, and more consistent cutting performance across the full life of the diamond wire.

Recommended Coolant

When using diamond wire blades, the choice of coolant is just as important as selecting the correct wire diameter and bond type. Coolant plays a critical role in heat removal, lubrication, and debris flushing during cutting. Without proper cooling, diamond wire performance drops significantly, leading to wire breakage, poor surface finish, and reduced tool life.

The recommended coolant for diamond wire blades is typically deionized (DI) water or a water-based solution formulated with specific additives, such our SMART CUT HD coolant. DI water prevents contamination and mineral deposits, which is especially important when cutting semiconductors, silicon, sapphire, quartz, or optical crystals. For demanding applications, specialized water-soluble coolants are preferred. These contain lubricants, corrosion inhibitors, and surfactants that reduce surface tension, improve flushing, and minimize micro-cracking or chipping.

For semiconductors and optics, a low-foaming water-soluble coolant is recommended. This ensures stable wire contact, clean surfaces, and reduced particle contamination. In cases where materials are sensitive to electrostatic discharge, antistatic coolant formulations should be used to prevent charge buildup at the cutting interface.

For stone, ceramics, and composites, plain water may be sufficient for cooling, but performance is improved with the addition of wetting agents or lubricants. These help the coolant penetrate deeper into the cut, carry away abrasive swarf more effectively, and reduce overall friction.

Key considerations for selecting coolant include:

- Thermal control: Prevents heat buildup that can warp wafers or crack brittle substrates.

- Lubrication: Reduces friction and wire wear, extending tool life.

- Flushing action: Clears debris and prevents clogging of the diamond layer.

- Material compatibility: Ensures the coolant does not react with or contaminate the workpiece.

- Cleanliness: Especially critical for semiconductor and optical applications where microscopic contamination can lead to defects.

In most cases, DI water with a purpose-formulated diamond wire coolant additive is the best solution. The coolant should be monitored regularly for pH, conductivity, and cleanliness to maintain consistent cutting performance.

Alexander Schneider is a senior applications engineer and leading authority in the industrial diamond tooling industry, with over 35 years of hands-on experience in the development, application, and optimization of ultra-thin and high-precision diamond blades, diamond core drills, and diamond and CBN grinding wheels. His work spans a wide range of advanced materials including ceramics, glass, composites, semiconductors, and high-performance metals.

Throughout his career, he has collaborated with leading R&D institutions, national laboratories, and high-tech manufacturing companies across Europe, North America, and Asia, providing technical expertise and tailored solutions for demanding cutting and surface preparation applications.

Mr. Schneider has played a pivotal role in advancing precision cutting, sectioning, dicing, and grinding technologies used in research, production, and failure analysis. He is widely respected for his ability to optimize tool design and cutting parameters to meet exacting industry standards—balancing factors such as cut quality, blade life, material integrity, and process consistency.

As an author, Mr. Schneider is known for delivering practical, application-focused insights that translate complex technical challenges into clear, actionable strategies. His articles and technical guides serve as trusted resources for engineers, researchers, and manufacturers seeking to improve precision, reduce process variability, and enhance tool performance in critical applications.

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Knowledge Center

How to Selecting Right Diamond Tools for your application

How to properly use Diamond Tools

Why use diamond

Diamond vs CBN (cubic boron nitride) Tools

What is Diamond Mesh Size and how to select best one for your application

What is Diamond Concentration and which to use for your application

Diamond Tool Coolants Why, How, When & Where to Use

Choosing The Correct Diamond Bond Type

Alexander Schneider is a senior applications engineer and leading authority in the industrial diamond tooling industry, with over 35 years of hands-on experience in the development, application, and optimization of ultra-thin and high-precision diamond blades, diamond core drills, and diamond and CBN grinding wheels. His work spans a wide range of advanced materials including ceramics, glass, composites, semiconductors, and high-performance metals.

Throughout his career, he has collaborated with leading R&D institutions, national laboratories, and high-tech manufacturing companies across Europe, North America, and Asia, providing technical expertise and tailored solutions for demanding cutting and surface preparation applications.

Mr. Schneider has played a pivotal role in advancing precision cutting, sectioning, dicing, and grinding technologies used in research, production, and failure analysis. He is widely respected for his ability to optimize tool design and cutting parameters to meet exacting industry standards—balancing factors such as cut quality, blade life, material integrity, and process consistency.

As an author, Mr. Schneider is known for delivering practical, application-focused insights that translate complex technical challenges into clear, actionable strategies. His articles and technical guides serve as trusted resources for engineers, researchers, and manufacturers seeking to improve precision, reduce process variability, and enhance tool performance in critical applications.