Diamond & CBN Wheel Troubleshooting Guide

-

Posted by

contactor6

02

Jun

Our illustrated troubleshooting guide was designed to help you optimize your grinding operations. It assists in diagnosing most possible issues that may arise when using diamond & CBN WHEELS. This guide highlights the signs to watch out for, their potential causes, their impact on cutting performance, and recommended solutions for resolving these issues and preventing them in the first place. Additionally, please be sure to explore our KNOWLEDGE CENTER articles. You can also contact our technical support for further assistance.

|

Problem |

Possible Cause(s) |

Suggested Solution(s) |

|---|---|---|

SHORT WHEEL LIFE

Signs: Wheels worn out in a very short period of time compared to normal life span |

|

|

MATERIAL BURNING

Signs: Discoloration of the surface |

|

|

|

DIFFICULTY OF ACHIEVING PRECISON TOLERANCES |

|

|

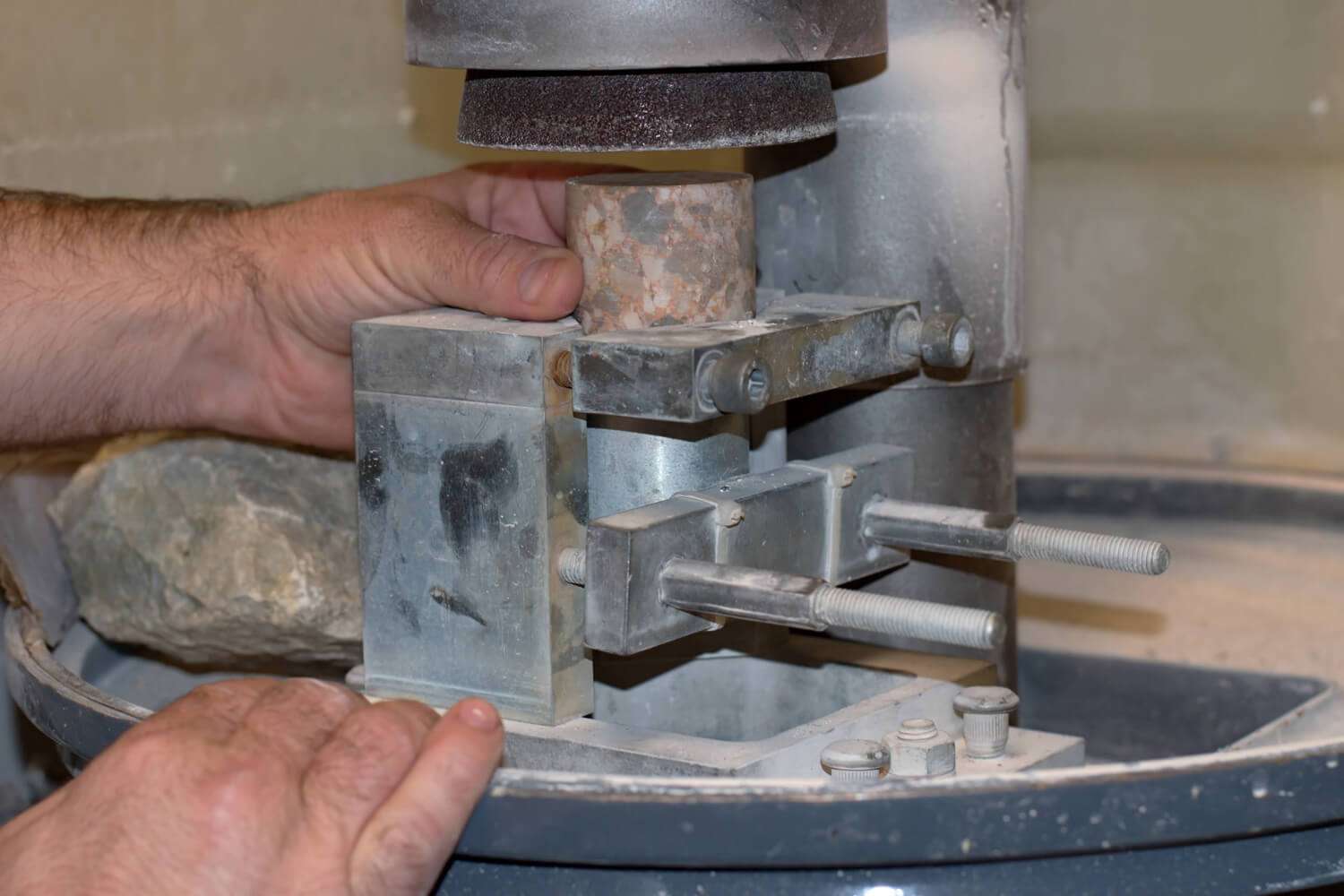

DIFFICULTY DRESSING

|

|

|

WHEEL DOES NOT MAINTAIN PROFILE

|

|

|

PREMATURE DIAMOND FRACTURE

|

|

|

WHEEL GLAZING & LOADING

|

|

|

WHEEL BREAKAGE

|

|

|

POOR SURFACE FINISH

|

|

|

MATERIAL WARIPING

|

|

|

WHEEL LOADING / MATERIAL STICKING

|

|

|

DIAMOND WHEEL SPINDLE INTERFACE ISSUES

|

|

|

POOR FINISH OR SCRATCH ON MATEIRAL

|

|

|

EXCESSIVE POWER CONSUMPTION

|

|

|

INCONSISTENT WHEEL PERFORMANCE

|

|

|

DRESSING WHEEL WEARS OUT QUICKLY

|

|

|

OUT OF ROUND WHEEL

|

|

|

MATERIAL CHATTER MARKS

|

|

|

DRESSING WHEEL LIFE IS SHORT

|

|

|

MATERIAL DISCOLORATION

|

|

|

MATERIAL MICRO CRACKS

|

|

|

DIAMOND OR CBN WHEEL EXHIBITS UNUSUAL WEAR

|

|

|

Uneven wear on the wheel's face

|

|

|

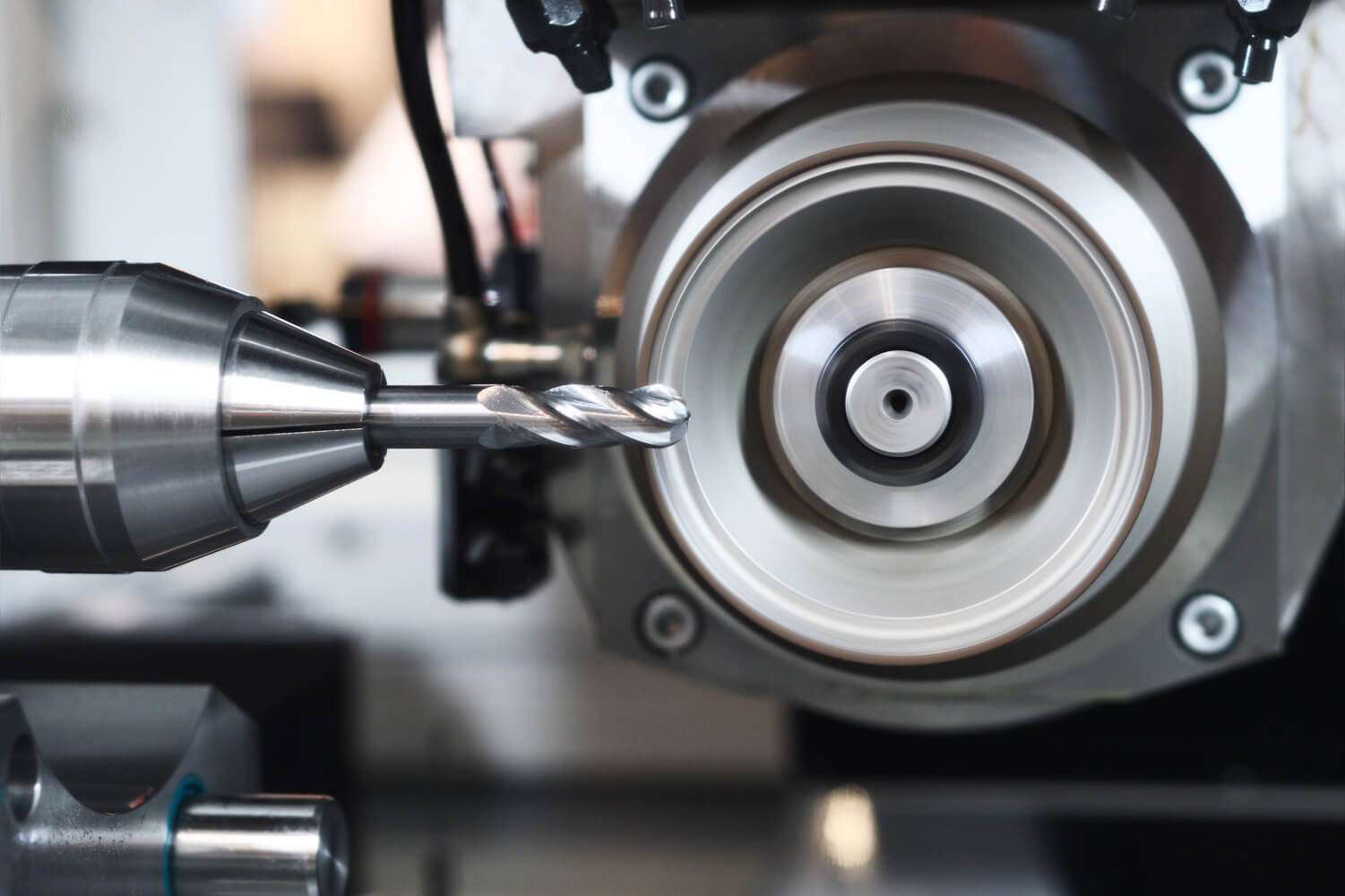

WHEEL DOES NOT CUT EFFECTIVELY

|

|

|

DIAMOND / CBN LAYER COMING OFF

|

|

|

MACHINE VIBRATION AFFECTING FINISH

|

|

|

DUST OR DEBRIS CONTAMINATION

|

|

|

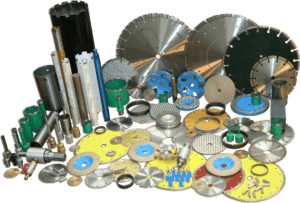

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Knowledge Center

02

Jun

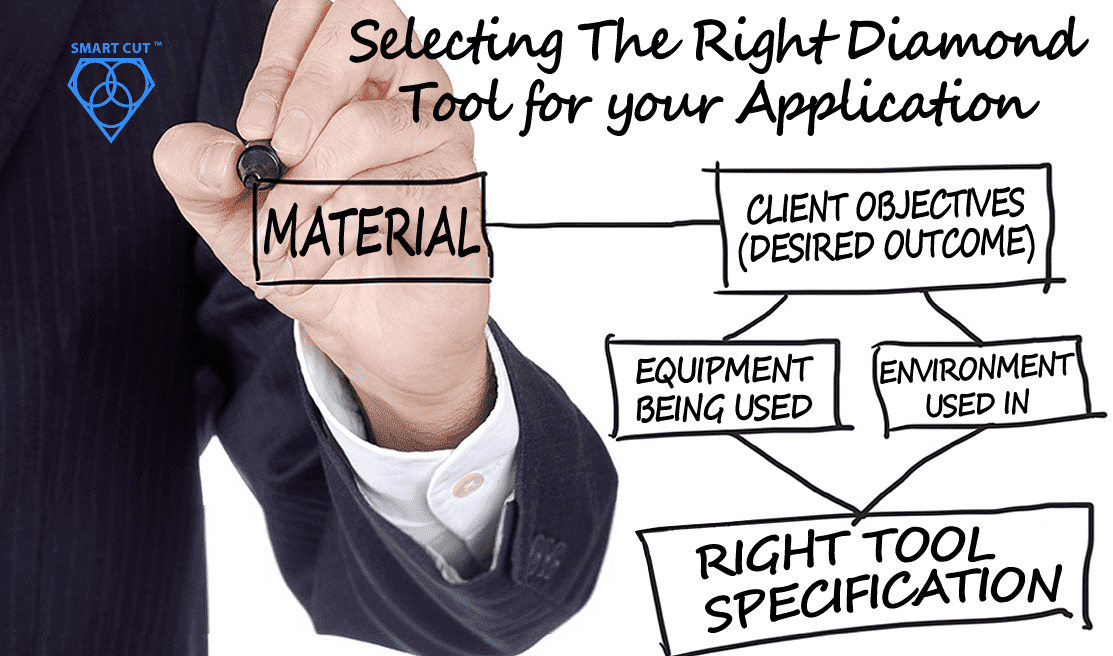

How to Selecting Right Diamond Tools for your application

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

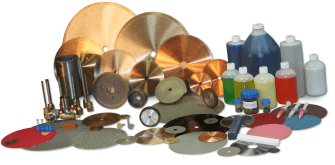

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

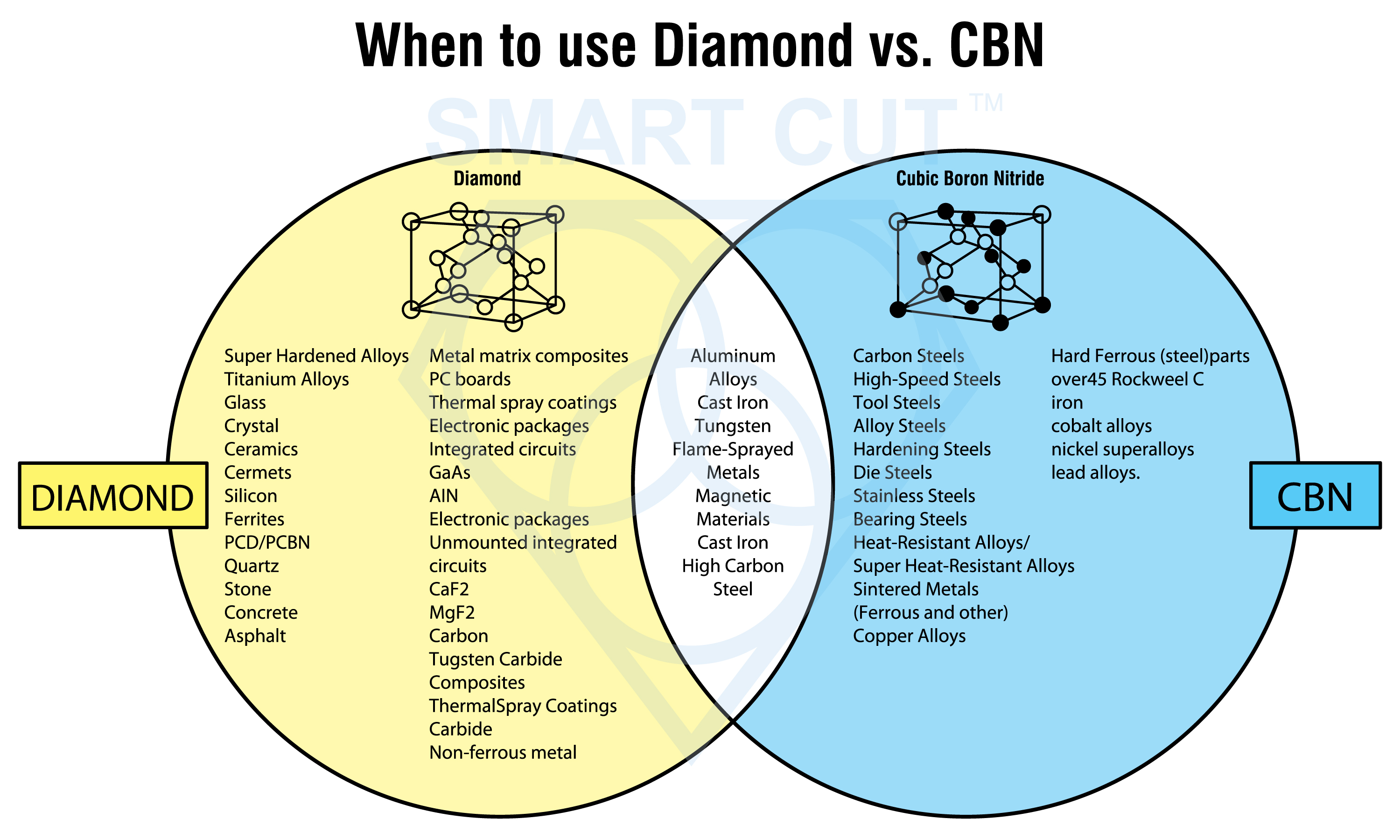

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

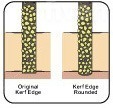

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

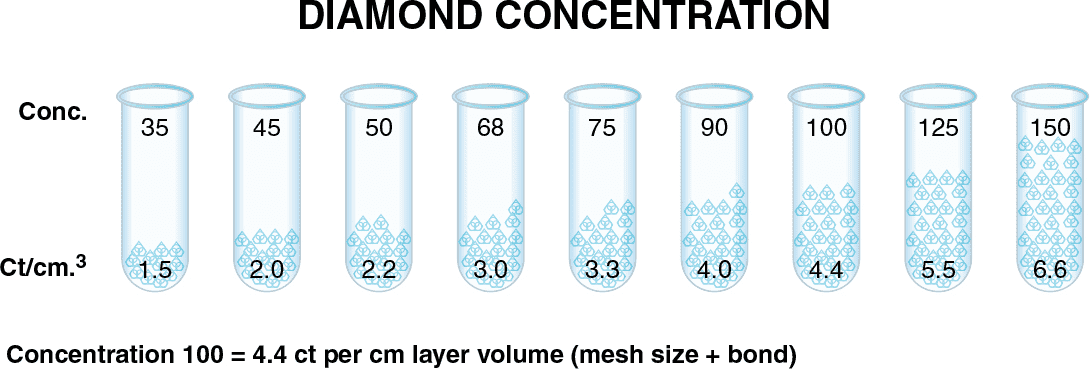

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

02

Jun

Diamond Tool Coolants Why, How, When & Where to Use

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

17

May

Get to Know the Diamond Tool Bond Types and Which to use for your application

Selecting the appropriate diamond bond type for specific applications is crucial for several reasons. Diamond bond type directly affects the tool's performance, efficiency, and longevity. Different bond types determine how well a tool can withstand...