Menu

-

0 items in quote

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

UKAM Industrial Superhard Tools offers a wide range of water-based and oil-based diamond suspensions, tailored to the requirements of specific applications. Our ready-to-use diamond suspensions combine micron diamond sizes graded at the highest level of precision with chemical formulations engineered to offer excellent material removal rate and surface quality. Diamond suspensions are used in various industries for lapping and polishing of hard materials.

Diamond suspensions are used during the sample preparation stages for fast stock removal and to produce a perfect polished surface ready for analysis. The type of diamond suspension to use depends on the material being polished and the surface finish required. Generally Monocrystalline diamond will provide a good performance for most processes but in some cases Polycrystalline diamond suspension will be required. For example, polishing hard or sintered materials, Polycrystalline Diamond offers outstanding stock removal and polishing performance.

UKAM Industrial Superhard Tools diamond suspensions are specially formulated to allow for versatility of application by automatic, manual or gravity fed systems. Our liquid carrier permits the diamond particles to remain totally suspended, thus avoiding agglomerates and sedimenting. This homogeneity allows the diamond to abrade evenly and consistently resulting in minimizing defects and maximizing yields.

our formula contains no hazardous chemicals and is not produced using any restricted or regulated chemicals. This ensures that now and in the future, no formula changes will need to be made or that expensive disposal methods need be used.

Table Content

UKAM diamond suspensions are specialized solutions containing micron-sized diamond particles designed for lapping and polishing hard materials. These suspensions provide a high material removal rate while ensuring an excellent surface finish.

Diamond suspensions are used in various industries during sample preparation stages for rapid stock removal and to produce a polished surface ready for analysis.

Generally, monocrystalline diamond suspensions are ideal for softer material preparation, whereas polycrystalline diamond suspensions are best suited for hard or sintered materials, especially where high removal rates are needed.

They are specifically formulated to allow the diamond particles to remain in suspension, preventing sedimentation. This ensures a consistent and even abrasion leading to minimized defects and maximized yields.

Yes, our formula contains no hazardous chemicals and isn’t produced using any restricted or regulated substances. This makes it environmentally friendly and ensures consistent quality without the need for future formula changes.

Our Diamond Suspensions are available in quantities of 125ml, 250ml, 500ml, 1 L, 1 gallon, and 5 gallons.

Yes, UKAM diamond suspensions are suitable for application by automatic, manual, or gravity-fed systems.

The provided description mainly highlights water-based diamond suspensions which are 99% water-based, environmentally friendly, and ideal for manual applications or “spray”/”drip” dispensing systems. The choice between water-based and oil-based generally depends on specific application requirements.

The prices vary based on the type (monocrystalline or polycrystalline), micron size of the diamond, and the quantity of the suspension. Detailed pricing can be found in the product listings.

You can purchase our diamond suspensions directly from our website. Simply choose the desired product, select the quantity, and click “Add to Cart.”

Yes, our team of experts is here to assist you in making the best selection for your requirements. Please reach out to our customer support for tailored advice.

Store in a cool, dry place away from direct sunlight. Ensure the cap is tightly closed after each use to maintain the suspension’s quality.

Our diamond suspensions are formulated for versatility and should be compatible with most lapping and polishing machines. However, it’s always a good idea to check the compatibility with your specific equipment manufacturer or reach out to our team for guidance.

Under proper storage conditions, our diamond suspensions typically have a shelf life of 12-24 months. Please refer to the product label for specific expiration dates.

While our suspensions are formulated to be safe and environmentally friendly, it’s always recommended to use gloves when handling and to avoid direct contact with skin or eyes. If contact occurs, rinse immediately with plenty of water.

We advise against mixing different types or sizes as it might affect the performance and intended results of the suspension.

Yes, we do offer discounts for bulk purchases. Please contact our sales team for specific pricing details.

Our diamond suspensions use diamond particles graded at the highest level of precision, ensuring consistent quality and performance.

“Spray” systems atomize the suspension, dispersing it as a fine mist onto the working surface, while “drip” systems release the suspension in droplets. Our water-based suspensions are suitable for both methods.

Absolutely. Please provide us with detailed information about your material, and our team will guide you in selecting the most appropriate diamond suspension.

As our diamond suspension formula is environmentally friendly and does not contain hazardous chemicals, disposal should follow standard procedures for non-hazardous materials. However, always refer to local regulations to ensure compliance.

Yes, we provide shipping to various countries. Please check our shipping policy or contact our team for more details regarding international orders.

The ideal storage temperature for our diamond suspensions is between 10°C to 25°C (50°F to 77°F). Avoid freezing or extremely hot conditions.

The application technique might vary based on the material and the desired finish. However, for best results, ensure the surface is clean, apply a uniform layer of suspension, and use consistent pressure during the lapping or polishing process.

Our suspensions are formulated for optimal performance as-is. Diluting them might reduce their effectiveness. We don’t recommend diluting unless you have specific requirements and understand the implications.

If the suspension appears thicker than usual, give it a good shake. If it’s dried out, it’s best to replace it. Do not add water or any other solvent to rehydrate it.

Yes, we do provide sample quantities for testing purposes. Please contact our sales team to request samples.

Shipping and handling charges vary based on the destination, quantity, and mode of transport. Please refer to our shipping policy or contact our customer service for specific details.

We stand by the quality of our products. If you face any quality issues or are unsatisfied with the performance of our suspension, please reach out to our customer support for assistance.

Monocrystalline diamonds are generally suited for softer materials due to their blocky crystal structure. Polycrystalline diamonds, with their multiple sharp edges, are more suited for harder materials where high removal rates are necessary. However, specifics can vary, and our team is always available to offer guidance.

A mild detergent and warm water usually suffice for cleaning after using the diamond suspensions. Ensure to rinse and dry thoroughly to prevent any residue.

Yes, we have a range of instructional materials and videos available on our website. We also offer training sessions for large teams or specialized applications.

Our diamond suspensions are versatile and should work with ultrasonic polishing machines. However, always check with your machine manufacturer’s guidelines.

The typical shelf life of our diamond suspensions is 24 months when stored under recommended conditions. However, always check the expiry date on the label.

Our diamond suspensions are formulated for versatility and can be used on most lapping and polishing machines. Ensure to follow machine-specific guidelines.

Always wear appropriate safety gear, including gloves and safety glasses. Although our formula contains no hazardous chemicals, it’s crucial to prevent any contact with eyes or ingestion. Refer to the product’s safety data sheet (SDS) for comprehensive safety information.

Our diamond suspensions are formulated without any restricted or regulated chemicals, making disposal simpler. However, always follow local regulations and guidelines for disposal of industrial products.

We do offer volume discounts for bulk purchases. Please contact our sales department for detailed pricing based on quantities.

No, our standard suspensions don’t contain UV-reactive components. However, if you have specific requirements, please get in touch with our team for custom formulations.

We aim to be eco-friendly in our operations. Our packaging materials are recyclable, but always check local recycling guidelines.

The micron sizes represent the average particle size of the diamond in the suspension. These sizes are determined using advanced particle size analysis techniques to ensure consistency.

Our diamond suspensions are manufactured under strict quality control guidelines and adhere to several industry standards. You can find specific certifications and standards on our product datasheets.

While it’s possible to use different grades sequentially to achieve desired results, it’s essential to thoroughly clean the surface between each grade to avoid cross-contamination.

We continually strive for innovation. While there isn’t a set schedule, we periodically release new formulations based on industry demands and technological advancements.

Yes, we offer custom formulations to meet unique needs. Please reach out to our R&D team with your specifications.

UKAM diamond suspensions are formulated with diamond particles graded at the highest precision levels, ensuring consistent performance every time.

Absolutely! Our suspensions are versatile and can be used with automatic, manual, or gravity-fed systems.

Our unique formulation ensures that diamond particles remain completely suspended, avoiding agglomeration issues that might occur with other brands.

Yes, our suspensions are 99% water-based, free from hazardous chemicals, and do not use any restricted or regulated chemicals.

While offering competitive performance, UKAM often provides more value for the price when compared to some premium-priced brands.

Yes! We offer custom formulations to cater to unique customer requirements.

UKAM has served a diverse range of industries globally, and our wide acceptance speaks to the quality and reliability of our suspensions.

Our dedicated customer service ensures that clients receive the necessary support and guidance throughout their product usage.

While brands like Buehler, Struers, and LECO have their strengths and established reputations, UKAM offers precision, versatility, safety, competitive pricing, customizability, global reach, and dedicated customer support, making it a top choice for many.

Store our diamond suspensions in a cool, dry place away from direct sunlight. Ensure the cap is tightly closed after each use to prevent contamination.

While our diamond suspensions are formulated for a wide range of hard materials, it’s essential to select the right type (Monocrystalline or Polycrystalline) based on the material you’re working with. If unsure, consult our technical team for guidance.

Give the bottle a gentle shake before each use to ensure the diamond particles are evenly distributed.

We don’t recommend mixing our suspensions with other brands as it may affect performance and result in unpredictable outcomes.

Our diamond suspensions perform best at room temperature. Avoid using them in extreme hot or cold conditions.

Use a mild detergent and water for cleanup. Always wear protective gloves and eye protection when handling the suspension and during cleanup.

Yes, our suspensions are formulated to be safe for a variety of equipment components. However, always check the equipment manufacturer’s guidelines.

Always wear protective eyewear and gloves. Work in a well-ventilated area and avoid ingestion or inhalation.

Yes, contact our sales team for sample requests and they will assist you further.

Our suspensions are formulated to provide consistent performance, even in humid conditions. However, always store them in a dry place.

The specific concentration varies depending on the product. Consult the product datasheet or contact our technical team for specific details.

Contaminants like dust, dirt, or other abrasive particles can affect the suspension’s performance. Always ensure the working surface and tools are clean.

Monocrystalline is suitable for softer materials, while Polycrystalline is recommended for harder materials requiring high removal rates. Consult our product guidelines or reach out to our experts for specific recommendations.

Water-based suspensions are environmentally friendly and suitable for manual application or “spray”/”drip” systems. The choice between water-based and oil-based depends on your specific application and equipment. Contact our technical team for a recommendation tailored to your needs.

Yes, our suspensions are compatible with most ultrasonic polishing systems. Ensure you follow the equipment manufacturer’s guidelines.

Our suspensions are formulated to be free from hazardous chemicals and won’t interfere with subsequent analytical processes. Always ensure thorough cleaning after polishing.

The duration depends on the application and usage frequency. Refer to our product usage guidelines or consult our team for more specific details.

UKAM is committed to stringent quality control measures, ensuring consistency in every batch of our suspensions. Our formula undergoes rigorous testing to maintain the highest standards.

We pride ourselves on offering competitive pricing without compromising quality. For specific price comparisons, please contact our sales team or consult our online catalog.

All our suspensions are securely packaged to prevent leakage or damage during transit. We use high-quality containers with tight seals and robust external packaging.

Yes, our suspensions are formulated for compatibility with both manual and automated polishing systems. Always refer to your equipment’s guidelines to ensure proper application.

Our diamond suspensions have a controlled particle size distribution to ensure consistent polishing results. Specific distribution details can be found on the product datasheet.

Our suspensions are formulated to be environmentally friendly. However, always consult local regulations for the disposal of polishing compounds to ensure compliance.

Some settling is natural over extended periods. Gentle shaking or stirring will re-disperse the particles evenly.

Yes, we work closely with our clients to cater to their specific needs. Contact our sales and technical team for customized solutions and bulk purchase inquiries.

Our suspensions are versatile and compatible with most standard polishing pads and compounds. However, always conduct a test to ensure desired results.

We offer comprehensive guides and tutorials on our website. Additionally, our technical support team is always available to assist with any queries or application-specific recommendations.

UKAM’s diamond suspensions undergo rigorous quality control checks and are formulated using high-quality raw materials. Our unique formulations provide consistent and superior polishing performance across a range of applications.

Our suspensions are designed for broad compatibility. However, always consult our product guidelines or contact our technical support team for specific compatibility concerns.

UKAM diamond suspensions are ideal for precision polishing and surface preparation in metallurgy, geology, electronics, and other fields requiring high-quality surface finishes.

Table Content

Table Content

Table Content

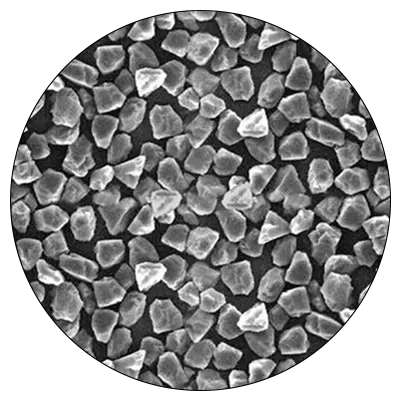

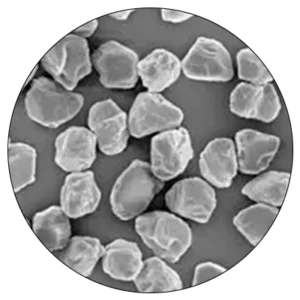

Monocrystalline diamonds consist of one, blocky crystal with fewer cutting edges. They are not as efficient as polycrystalline diamonds, but very well suites for the preparation of softer material

Polycrystalline diamonds consists of many small individual crystals. They break down during use revealing continuously new cutting edges. They remain sharp when breaking down and are well suites for hard materials and where high removal rates are required

SMART CUT® Mono (Monocrystalline Diamond Suspension) is a high-quality abrasive solution designed for precise sample preparation and polishing. Its water-based formula makes it environmentally friendly and easy to clean, reducing harmful emissions. This suspension contains monocrystalline diamond particles with a uniform size distribution, ensuring consistent cutting performance and a smooth, defect-free surface finish.

SMART CUT® Mono is engineered to meet the rigorous demands of metallography and high-precision sample preparation. Monocrystalline diamonds are composed of a single, blocky crystal with fewer cutting edges, which makes them ideal for softer materials. While they might not cut as efficiently as polycrystalline diamonds, they are perfect for applications requiring a gentle approach. The 99% water-based formula is suitable for manual applications and automatic spray or drip systems, especially when used with additional lubricant.

SMART CUT® Mono diamond suspensions are formulated to keep diamond particles suspended and evenly distributed in a stable liquid carrier, ensuring consistent application over the cloth or platen surface. This feature leads to uniform polishing results. Our formula contains no hazardous chemicals and is not produced using any restricted or regulated chemicals. This ensures that now and in the future, no formula changes will need to be made or that expensive disposal methods need be used. recommended for manual application or automatic "spray"/"drip" dispensing systems, where lubricant is also applied.

SMART CUT® Mono diamond suspensions are specifically formulated to assure that the diamond particles remain suspended and separated throughout the stable liquid carrier. They are excellent for distributing diamond easily and uniformly over the cloth or platen surface.

Compare to many well know brand names such as Buehler, Struers, Leco and many others. Why pay more? Available form 0.05 to 45 microns, in 125ml, 250ml, 500ml, 1 L, 1 gallon, 5 gallon containers.

SMART CUT® suspensions are manufactured on the same day an order is placed, guaranteeing the freshest product with the longest possible shelf life. This rapid production process ensures that customers receive suspensions at their peak quality, delivering optimal polishing performance and reducing the risk of degradation over time. Custom Specifications are available upon request with usually no minimum order quantity & very fast lead times.

Prod# | Image | Name | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

$62.00 | Max: Min: 1 Step: 1 | ||||

$62.00 | Max: Min: 1 Step: 1 | ||||

$62.00 | Max: Min: 1 Step: 1 | ||||

$63.00 | Max: Min: 1 Step: 1 | ||||

$66.00 | Max: Min: 1 Step: 1 | ||||

$77.00 | Max: Min: 1 Step: 1 | ||||

$77.00 | Max: Min: 1 Step: 1 | ||||

$77.00 | Max: Min: 1 Step: 1 | ||||

$77.00 | Max: Min: 1 Step: 1 |

PROD# | Name | Price | Quantity | Add to Cart |

|---|---|---|---|---|

$260.00 | Max: Min: 1 Step: 1 | |||

$260.00 | Max: Min: 1 Step: 1 | |||

$260.00 | Max: Min: 1 Step: 1 | |||

$295.00 | Max: Min: 1 Step: 1 | |||

$295.00 | Max: Min: 1 Step: 1 | |||

$355.00 | Max: Min: 1 Step: 1 | |||

$355.00 | Max: Min: 1 Step: 1 | |||

$355.00 | Max: Min: 1 Step: 1 | |||

$355.00 | Max: Min: 1 Step: 1 |

Image | Name | Price | Quantity | Add to cart |

|---|---|---|---|---|

$260.00 | Max: Min: 1 Step: 1 | |||

$295.00 | Max: Min: 1 Step: 1 | |||

$295.00 | Max: Min: 1 Step: 1 |

Experience unparalleled polishing performance with SMART CUT® Poly Polycrystalline Diamond Suspension, meticulously engineered for superior surface finishing across a wide range of applications. This high-precision suspension is designed to deliver consistent, reliable results, making it ideal for advanced materials research, metallography, composites, ceramics, optics, and other demanding fields.

SMART CUT® Poly Diamond Suspension contains carefully graded diamond particles that exhibit multiple cutting edges, ensuring efficient material removal and a consistent, uniform finish. The polycrystalline structure allows for rapid polishing without compromising surface quality, significantly reducing processing time. Is the ideal solution for applications where accuracy and quality are critical.

Compare to many well know brand names such as Buehler, Struers, Leco and many others. Why pay more? Available form 0.05 to 45 microns, in 125ml, 250ml, 500ml, 1 L, 1 gallon, 5 gallon containers.

SMART CUT® suspensions are manufactured on the same day an order is placed, guaranteeing the freshest product with the longest possible shelf life. This rapid production process ensures that customers receive suspensions at their peak quality, delivering optimal polishing performance and reducing the risk of degradation over time. Custom Specifications are available upon request with usually no minimum order quantity & very fast lead times.

PROD # | Name | Price | Quantity | Add to cart |

|---|---|---|---|---|

$36.00 | Max: Min: 1 Step: 1 | |||

$37.00 | Max: Min: 1 Step: 1 | |||

$41.00 | Max: Min: 1 Step: 1 | |||

$41.00 | Max: Min: 1 Step: 1 | |||

$41.00 | Max: Min: 1 Step: 1 | |||

$48.00 | Max: Min: 1 Step: 1 | |||

$49.00 | Max: Min: 1 Step: 1 | |||

$53.00 | Max: Min: 1 Step: 1 | |||

$63.00 | Max: Min: 1 Step: 1 | |||

$96.00 | Max: Min: 1 Step: 1 |

Water soluble and environmentally friendly, this 99% water based formula is recommended for manual application or automatic "spray"/"drip" dispensing systems, where lubricant is also applied.

UKAM Industrial Monocrystalline diamond suspensions are specifically formulated to assure that the diamond particles remain suspended and separated throughout the stable liquid carrier. They are excellent for distributing diamond easily and uniformly over the cloth or platen surface.

Prod# | Image | Name | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

$62.00 | Max: Min: 1 Step: 1 | ||||

$62.00 | Max: Min: 1 Step: 1 | ||||

$62.00 | Max: Min: 1 Step: 1 | ||||

$63.00 | Max: Min: 1 Step: 1 | ||||

$66.00 | Max: Min: 1 Step: 1 | ||||

$77.00 | Max: Min: 1 Step: 1 | ||||

$77.00 | Max: Min: 1 Step: 1 | ||||

$77.00 | Max: Min: 1 Step: 1 | ||||

$77.00 | Max: Min: 1 Step: 1 |

PROD # | Name | Price | Quantity | Add to cart |

|---|---|---|---|---|

$36.00 | Max: Min: 1 Step: 1 | |||

$37.00 | Max: Min: 1 Step: 1 | |||

$41.00 | Max: Min: 1 Step: 1 | |||

$41.00 | Max: Min: 1 Step: 1 | |||

$41.00 | Max: Min: 1 Step: 1 | |||

$48.00 | Max: Min: 1 Step: 1 | |||

$49.00 | Max: Min: 1 Step: 1 | |||

$53.00 | Max: Min: 1 Step: 1 | |||

$63.00 | Max: Min: 1 Step: 1 | |||

$96.00 | Max: Min: 1 Step: 1 |

Prod# | Image | Name | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

$129.50 | Max: Min: 1 Step: 1 | ||||

$129.50 | Max: Min: 1 Step: 1 | ||||

$129.50 | Max: Min: 1 Step: 1 | ||||

$129.50 | Max: Min: 1 Step: 1 | ||||

$129.50 | Max: Min: 1 Step: 1 | ||||

$129.50 | Max: Min: 1 Step: 1 | ||||

$137.50 | Max: Min: 1 Step: 1 | ||||

$137.50 | Max: Min: 1 Step: 1 | ||||

$137.50 | Max: Min: 1 Step: 1 | ||||

$137.50 | Max: Min: 1 Step: 1 | ||||

$137.50 | Max: Min: 1 Step: 1 | ||||

$137.50 | Max: Min: 1 Step: 1 |

ITEM NO | NAME | PRICE | QUANTITY | ADD TO CART |

|---|---|---|---|---|

$439.50 | Max: Min: 1 Step: 1 | |||

$439.50 | Max: Min: 1 Step: 1 | |||

$439.50 | Max: Min: 1 Step: 1 | |||

$439.50 | Max: Min: 1 Step: 1 | |||

$439.50 | Max: Min: 1 Step: 1 | |||

$439.50 | Max: Min: 1 Step: 1 | |||

$439.50 | Max: Min: 1 Step: 1 | |||

$439.50 | Max: Min: 1 Step: 1 | |||

$439.50 | Max: Min: 1 Step: 1 | |||

$439.50 | Max: Min: 1 Step: 1 | |||

$439.50 | Max: Min: 1 Step: 1 | |||

$439.50 | Max: Min: 1 Step: 1 |

PROD # | Name | Price | Quantity | Add to cart |

|---|---|---|---|---|

$1,145.00 | Max: Min: 1 Step: 1 | |||

$1,145.00 | Max: Min: 1 Step: 1 | |||

$1,145.00 | Max: Min: 1 Step: 1 | |||

$1,145.00 | Max: Min: 1 Step: 1 | |||

$1,395.00 | Max: Min: 1 Step: 1 | |||

$1,395.00 | Max: Min: 1 Step: 1 | |||

$1,395.00 | Max: Min: 1 Step: 1 | |||

$1,395.00 | Max: Min: 1 Step: 1 | |||

$1,395.00 | Max: Min: 1 Step: 1 | |||

$1,395.00 | Max: Min: 1 Step: 1 | |||

$1,395.00 | Max: Min: 1 Step: 1 |

|

Feature |

Monocrystalline Diamond Suspension |

Polycrystalline Diamond Suspension |

|---|---|---|

|

Particle Structure |

Single crystal particles |

Multiple crystal particles per grain |

|

Cutting Action |

Provides uniform, consistent cutting edges |

Self-sharpening, offers fresh cutting edges as particles fracture |

|

Surface Finish |

Generates very smooth surfaces with consistent scratch patterns |

Capable of both smooth finishes and rapid stock removal depending on particle size |

|

Material Suitability |

Ideal for softer to medium-hard materials that do not easily fracture diamond particles |

Suitable for very hard materials, including advanced ceramics and composites |

|

Thermal Stability |

Higher thermal stability due to robust single-crystal structure |

Good thermal management through particle fragmentation |

|

Chemical Stability |

Generally high, but depends on the purity and manufacturing process |

Excellent, often enhanced by the toughness and varied crystal orientations |

|

Cost |

Typically more expensive due to higher production costs of uniform, single crystals |

Generally less expensive, offering a cost-effective solution for high wear conditions |

|

Application Examples |

Used in precision engineering, optics polishing, fine-finish metallography |

Used in high-stress environments such as machining hard composites, aggressive material removal |

|

Advantages |

Superior for achieving high-quality finishes, maintains edge integrity under less severe conditions |

Effective for rapid material removal, versatile across a broad range of hard materials |

|

Disadvantages |

Higher cost, less effective for rapid stock removal or very hard materials |

May produce less consistent surface finishes due to particle fracturing |

|

Durability |

Tends to wear down more slowly due to the strength of the single crystals |

Higher rate of particle breakdown can be beneficial for maintaining aggressive cutting action |

|

Particle Fracture |

Lower tendency to fracture, maintains a consistent cutting surface longer |

Higher tendency to fracture, but this creates new sharp edges for effective material removal |

|

Consistency of Results |

Consistently smooth finish ideal for applications requiring high precision |

Variability in scratch patterns, suitable for applications where finish is less critical |

|

Economic Efficiency |

Higher upfront costs but can be offset by longer lifespan and less frequent need for replacement |

Lower initial cost, efficient for large volume applications due to frequent renewing of edges |

|

Environmental Impact |

Manufacturing process is less intensive in terms of energy and waste production |

Manufacturing can be more resource-intensive, but modern techniques are improving sustainability |

|

Ease of Use |

May require more skilled operation to achieve best results due to uniform particle size |

Generally easier to achieve effective results quickly, less sensitive to operational variations |

We produce diamond consumables for some of the leading world OEM manufacturers. We offer Manufacturers Direct Prices

We have the largest variety of diamond & cbn wafering blades available in stock. As well as large inventory of diamond & abrasive consumables. We also custom manufacture diamond and cbn tools, consumables and machines to better fit customer specific needs. Just about any tools & consumables can be designed and manufactured per client drawing or specificrtion

WE ARE A PARTNER IN YOUR SUCCESS

Our proprietory diamond chemistory , precision , manufacturing metods , quality control methods allow us to control and regulate the dozens of variables to that affect consumable life , quality , and consistency.

The more you understand about what we can do for you the better our partnership will be. Here you will find most comprehensive source of information and optimizing and improving your cutting , drilling , grinding and polishing on the web. find everything you ever wanted to know about diamond tools.

AMERICAN MANUFACTURER

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Save Money Save up to 650%

COMPARE TO: BUEHLER , STRUERS , LECO & MANY OTHERS

Large Inventory & Custom Manufacturing

Umatched Technical Support

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency

Superior Quality & Consistency

EXPECT MORE FROM YOUR TOOLS

Comprehensive Source Of Information For Sample Preparation

Advanced Technology

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool

manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry .Depend on us to bring you technology of tomorrow today.

Experience Makes All The Differences

Over the years we have worked with some of the leading Fortune 500 companies , thousands of universities , government and private research labs , and small organisations. We have made thousands of custom tools , built custom machines , work-holding fixtures , etc for hundreds of applications. Many of our staff members have been working in their respective fields for over 50 years and have gained a wealth of knowledge over the years

Let Us Help You

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales