Menu

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

-

We manufactures a full line of diamond & CBN compounds for applications ranging from aggressive material removal rates to ultra super finishing and polishing. Our Diamond Compounds are stocked and sold primarily using our premium Metal Bond diamond powder. Custom Diamond compounds are manufactured using our premium Resin Bond Diamond, Natural Diamond, Polycrystalline Diamond, or CBN powders.

Our Diamond Compounds are available in three solubilities: oil, water, and universal soluble.

Our compounds are color coded for your convenience in all of our powder types and complete size range.

Oil Soluble(OS): This product is best suited for the controlled lapping carbide dies and many other polishing applications where finish is critical. This is the choice where water solubility will corrode the work-piece.

Water Soluble(WS): This product has been formulated for efficient lapping and polishing where fast removal rates with high surface finish is required. This is the choice where easy cleanup is required.

Our compounds are offered packaged in 2, 5, 10, 15, 18, 20, and 25 gram syringes or jars ranging from 2 to 500 grams

Tab Content

Diamond Polishing Compounds are precision abrasives used to polish various materials to a high finish. They contain micron-sized diamond particles suspended in a paste or liquid. The compounds come in various types, such as Polycrystalline Diamond (PCD), Monocrystalline Diamond, Natural Diamond, and Cubic Boron Nitride (CBN), each suited to different applications.

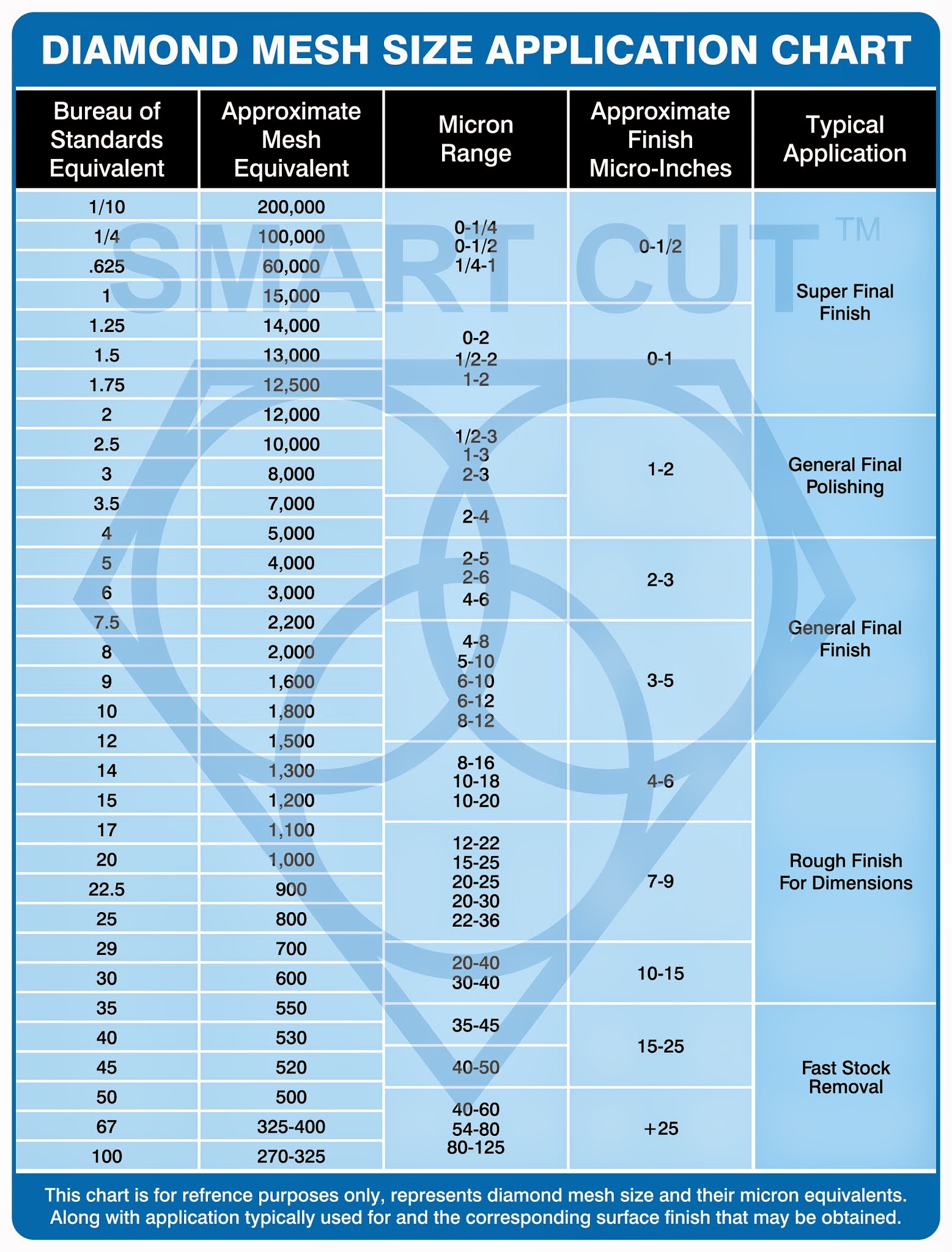

Particle size selection depends on the desired finish and the material being polished. Start with a coarser grit to remove any major imperfections and gradually move to finer grit sizes for a smooth finish.

Apply a small amount of compound to the polishing cloth or lap. Spread evenly, using a rolling or dabbing motion to ensure uniform distribution. Only use the amount necessary to cover the work area without excess.

Some diamond polishing compounds can be recycled or reclaimed, especially in an industrial setting. However, the performance may not be as effective as fresh compound, and it is essential to ensure that the reclaimed compound is free from contaminants.

Use a clean, soft cloth with an appropriate solvent, such as alcohol or acetone, for oil-based compounds, or water for water-based compounds. For a thorough clean, ultrasonic cleaning may be necessary.

Yes, always wear appropriate personal protective equipment (PPE), such as gloves and eye protection. Ensure that you work in a well-ventilated area and follow safety data sheets for specific handling and disposal guidelines.

Yes, these compounds can degrade over time. Store them in a cool, dry place and tightly seal containers after use. Always check the manufacturer’s recommendations for shelf life.

The amount of pressure depends on the material and the desired outcome. Generally, start with light pressure and increase as needed. Too much pressure can cause scratches or damage to the workpiece.

The optimal speed varies depending on the material and the type of compound used. Refer to the manufacturer’s guidelines and start with recommended speeds, adjusting as necessary based on the results.

Use separate polishing cloths or laps for each grit size and clean the workpiece thoroughly when switching between different grit sizes to prevent cross-contamination.

Check the particle size and type of compound to ensure it’s suitable for your material. Review your application technique, the amount of compound used, and the condition of the polishing surface. Adjust your process as needed, and consult the manufacturer if the problem persists.

Mixing different brands or types of compounds is not recommended unless specified by the manufacturer. Different formulations may react with each other and compromise the polishing performance.

Store compounds in their original containers with lids securely tightened. Keep them in a cool, dry place, away from direct sunlight and extreme temperatures to prevent the suspension from drying out or separating.

Oil-based compounds offer longer working times and are often preferred for their lubricating properties. Water-based compounds are easier to clean up and are often used when contamination with oil could be problematic.

Disposal should follow local environmental regulations. Typically, used compounds should be collected and disposed of as chemical waste. Do not pour them down the drain or into the environment.

The polishing time can vary widely depending on the material and the initial condition of the surface. Generally, you should polish until you achieve the desired surface finish, regularly checking the progress.

The choice of cloth or pad depends on the application. For aggressive polishing, a harder cloth is used, while for final polishing, a softer, napped cloth is preferred. Manufacturers often provide recommendations for their specific compounds.

The level of polish is usually determined visually or by measuring the surface finish using instruments like a surface profilometer. For critical applications, other metrology equipment may be necessary.

While diamond is extremely hard and can polish most materials, some materials (such as soft metals) may require different abrasives to prevent embedding or excessive material removal.

Replace polishing cloths or pads when they show signs of wear, contamination, or when they no longer produce the desired results. Overused cloths can lead to poor-quality finishes and increased polishing times.

Increasing the speed of polishing can lead to increased heat and potential damage to the workpiece. It’s better to optimize the process through the correct choice of compound, pad, and technique rather than simply increasing the speed.

Ensure that the work area is clean. Use dedicated tools for each type of compound, and clean the workpiece between steps. If contamination occurs, clean the surface thoroughly and, if necessary, revert to a previous step to re-polish.

If the compound dries out, refer to the manufacturer’s instructions. Some oil-based compounds may be rejuvenated with a suitable extender or oil. For water-based compounds, adding distilled water may help, but this could affect the concentration and performance.

Effectiveness can be measured by the achieved surface roughness, visual inspection, and the time taken to achieve the desired finish. For precision applications, use quantitative methods such as surface profilometry or interferometry.

Yes, Diamond Polishing Compounds can be used on a wide range of hard materials, including plastics and composites. However, care must be taken to select the appropriate grit size and type to avoid excessive material removal or heat generation that could damage these materials.

The polishing direction can impact the final finish. It’s often recommended to alternate directions between stages to ensure uniform material removal. Follow specific guidelines for your material and application.

Adjust the consistency using the appropriate thinner or extender recommended by the manufacturer. For oil-based compounds, a compatible oil can be used, while for water-based compounds, distilled water is typically recommended.

If the highest grit does not provide the desired finish, you may need to follow up with a specialized final polishing step, such as using a chemical-mechanical planarization (CMP) slurry or a pad with a higher nap.

Maintain flat surfaces by using a lapping guide or a flat polishing jig, ensuring even distribution of pressure, and using a flat, hard polishing pad.

Factors that can affect compound life include polishing pressure, speed, temperature, material hardness, and the amount of compound used. Proper application and storage are key to maximizing the life of the compound.

Some separation is normal, especially in oil-based compounds. Stir or shake the compound before use to ensure a uniform distribution of diamond particles.

While it is technically possible, it is not always optimal. Different materials may require different diamond particle sizes or types to achieve the best results. It is also important to prevent cross-contamination.

Diamond pullout can be minimized by using the correct pressure, speed, and by ensuring the diamond particles are properly embedded in the binder of the polishing cloth or pad.

Lubricants in polishing compounds serve to facilitate the movement of the abrasive particles over the surface, help in the removal of waste material, reduce heat generation, and prolong the life of the diamond particles.

Temperature can significantly affect the polishing process. Higher temperatures can cause compounds to become more fluid, potentially altering their effectiveness, and can also affect the material being polished, especially if it is temperature sensitive.

Yes, many industrial applications use automated polishing machines with diamond compounds. Ensure that the machine is compatible with the compound type and that it can accurately control pressure and speed.

Using too much compound can waste material and may not improve the polishing results. Using too little may not provide enough abrasive action to achieve the desired finish. Precision in application ensures cost-effectiveness and optimal results.

While they can be used for mild edge rounding, diamond polishing compounds are primarily designed for surface finishing. For significant edge shaping, other tools and techniques are typically required.

Yes, Diamond Polishing Compounds can be used manually with a hand polisher or a polishing cloth. This approach may be suitable for delicate items or when precise control is needed.

Switch to a finer grit when the current grit has removed all the scratches from the previous step and the surface appears uniformly polished at the current grit level.

If a polishing pad becomes glazed, it should be cleaned or conditioned according to the manufacturer’s instructions or replaced if it cannot be restored to an effective condition.

While diamond compounds are typically used with a lubricant, some formulations can be used dry. However, dry polishing often results in faster wear of the abrasive and can increase the risk of overheating the material.

Higher concentrations of diamond may increase the rate of material removal and can improve the compound’s longevity, but they also increase the cost. Lower concentrations may be more cost-effective but require more frequent application.

Streaks or uneven finishes could be due to uneven application of the compound, inconsistent pressure during polishing, or contamination on the surface. Clean the material thoroughly and reapply the compound, ensuring even distribution and consistent polishing technique.

Some compounds can be diluted with a compatible extender or solvent to achieve a thinner consistency if required. Always follow the manufacturer’s recommendations when diluting.

The working time is influenced by the type of carrier fluid used in the compound, the temperature, the polishing environment, and the material being polished. Oil-based compounds generally have a longer working time than water-based compounds.

Materials that are softer than the diamond particles, such as certain soft metals and polymers, might embed the diamond particles rather than be polished by them. For these materials, alternative polishing compounds should be used.

Using multiple grits on the same cloth is not recommended because it can lead to cross-contamination of grit sizes, which can compromise the polishing results. Always use a separate cloth or pad for each grit size.

To achieve a high-gloss finish on hard materials, proceed through the sequence of progressively finer grits without skipping steps. Final polishing may require using the finest available grit and a high-nap cloth to achieve a mirror-like finish.

A foggy or hazy surface can result from several factors, such as contamination, insufficient polishing, or using a grit that’s too coarse for the final finish. Re-polish with a finer grit and ensure that the surface and tools are clean.

Consistency can be maintained by applying a small, measured amount of compound at regular intervals and using a dispenser or syringe for precision.

Use consistent force, speed, and compound application. Also, ensure that the workpieces are secured and that the equipment used, like rotary plates, is balanced and in good working condition.

Reusing diamond compounds is not generally recommended as the abrasive particles may be worn down and unevenly distributed after initial use, leading to suboptimal polishing performance.

Synthetic diamonds offer consistent size and shape, which can lead to more predictable results. Natural diamonds may have a broader range of particle sizes and shapes. The choice depends on the specific application and the desired outcome.

Monocrystalline diamond compounds maintain a sharp edge and are typically used for materials that require sharp, precise polishing. Polycrystalline diamond compounds have multiple cutting edges that break off during polishing and are used where more aggressive material removal is needed.

Improving the efficiency of the polishing process without sacrificing quality can be achieved by optimizing the polishing parameters, such as the type of diamond compound, polishing pad, speed, and pressure, rather than simply increasing the speed.

If scratches appear during final polishing stages, they may be due to contamination or using a compound that is too coarse. Clean the surface and equipment thoroughly and repeat the polishing step with a fine compound.

Using the same compound with different pads can alter the effective grit size and polishing action. However, for best results, it is recommended to use the appropriate compound designed for each stage.

The pH of the carrier fluid can affect the stability of the diamond suspension and the chemical interactions with the material being polished. It is important to choose a compound with a carrier fluid that is compatible with the material.

The shelf life can vary depending on the formulation and storage conditions. Typically, when stored properly, diamond compounds can last several years. Always check the manufacturer’s expiration date.

A tight particle size distribution can lead to a more uniform finish, whereas a broad distribution might be used for more aggressive material removal followed by refining with a tighter distribution.

If contamination occurs, stop the polishing process, clean the workpiece and equipment thoroughly, and start over with a fresh application of compound to avoid further issues.

Some diamond compounds can be used with ultrasonic polishers, which can enhance the polishing action due to the ultrasonic vibrations. Always confirm compatibility with the equipment manufacturer.

High humidity can affect the evaporation rate of the carrier fluid in water-based compounds, potentially leading to a change in performance. In such cases, adjustments in the polishing technique or environment may be required.

If the compound dries too quickly, consider using a slower evaporating carrier fluid, adjusting the amount applied, or using a humidifier to control the environment during polishing.

Yes, the type of carrier fluid can affect the adhesion of diamond particles. Oil-based carriers typically provide better adhesion, while water-based carriers may require surfactants to improve adhesion.

Dispose of used compounds according to local regulations. Do not pour them down the drain. Some compounds may be considered hazardous waste, so consult with waste management authorities.

When transitioning between different types of compounds, thoroughly clean the surface and the polishing equipment to prevent cross-contamination. Adjust polishing parameters to the new compound’s specifications.

Effectiveness can be assessed by the surface finish quality, the time taken to achieve the desired result, and the amount of material removed. Microscopic examination can help in assessing the surface quality.

Color is typically added for identification purposes and does not indicate quality. Grit size and concentration are determined by the manufacturer’s specifications, not the color of the compound.

Use a soft polishing pad, lower pressures, and a fine grit size to avoid substrate damage. Consider a compound with a high-quality, uniform particle size distribution for delicate work.

Thoroughly clean the surface with appropriate solvents and consider ultrasonic cleaning for residue-free surfaces. Always follow with a rinse of distilled or deionized water.

Mixing compounds is not recommended as it can lead to unpredictable results due to differences in formulation. Use the specifically designed grit size for the application.

If the material heats up, reduce the polishing speed, use a lubricant with better cooling properties, or implement intermittent polishing with cooling periods.

Pressure is critical; too much can cause scratches or damage the abrasive, while too little can result in inadequate polishing. Use manufacturer-recommended pressures for optimal results.

The hardness of the pad should be chosen based on the material being polished. Harder pads are typically used for harder materials and to maintain flatness, while softer pads are used for softer or more delicate materials.

Stir or shake the compound regularly to prevent settling. Some compounds also have additives to help maintain suspension stability.

Polishing materials with varying hardness together is not recommended as the harder material may scratch the softer one. Separate sessions with appropriate compounds and pads should be used.

In high-volume production, it’s essential to automate the process with precision dispensing equipment, maintain equipment calibration, and use a consistent batch of compounds.

Yes, but with caution. Ensure that the electroplated layer is sufficiently thick to withstand polishing without being removed or damaged.

Tab Content

Tab Content

The finishing process is as much an art as it is a science, and developing expertise takes experience. The feel for the correct amount of compound, the right pressure, and when to change cloths or laps often comes with time. It’s important to be patient and allow yourself to learn from each polishing task.

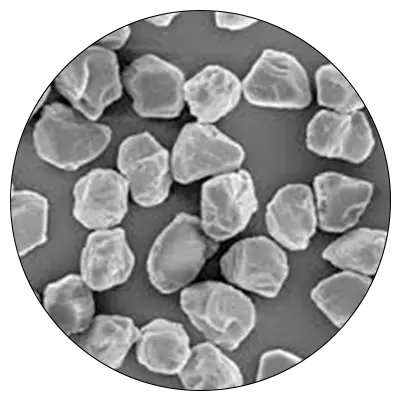

Monocrystalline diamonds consist of one, blocky crystal with fewer cutting edges. They are not as efficient as polycrystalline diamonds, but very well suites for the preparation of softer material

Polycrystalline diamonds consists of many small individual crystals. They break down during use revealing continuously new cutting edges. They remain sharp when breaking down and are well suites for hard materials and where high removal rates are required

SMART CUT® Monocrystalline Diamond Compound, a premium choice for materials laboratories worldwide. Standard & Most Popular product in the materials Laboratory, economically priced for general polishing applications. Available in convenient 5 and 20-gram syringes, this economically priced diamond compound maintains uncompromising quality, making it the standard and most popular product for general polishing applications. Can be used with Grinding Discs and Polishing Cloths.

SMART CUT® Monocrystalline Diamond Paste is crafted to exceed American standards for purity, size, and uniformity, ensuring exceptional consistency and reliability. The water-soluble (WS) formulation is ideal for environments requiring exceptional cleaning and where petroleum contamination is prohibited. Each syringe is color-coded for easy identification and precise dispensing, simplifying the application process and reducing waste.

Designed for superior cutting efficiency, SMART CUT® diamond compound achieves excellent cutting rates while ensuring a smooth, polished finish. It is recommended for polishing a wide range of materials, including metals, alloys, minerals, glass, ceramics, carbides, and semiconductors. This compound is perfectly suited for use with grinding discs and polishing cloths, enhancing its versatility and utility in various laboratory settings.

Manufactured to the highest standards, SMART CUT® diamond compound offers unmatched quality and performance. The water-soluble formula ensures that residues can be easily removed, maintaining the cleanliness of your work environment. Free from petroleum contaminants, this compound is safer for both the user and the environment. Compare to many well know brand names such as Buehler, Struers, Leco and many others. Why pay more?

SMART CUT® diamond compounds are manufactured on the same day an order is placed, guaranteeing the freshest product with the longest possible shelf life. This rapid production process ensures that customers receive suspensions at their peak quality, delivering optimal polishing performance and reducing the risk of degradation over time. Custom Specifications are available upon request with usually no minimum order quantity & very fast lead times.

Standard & Most Popular product in the materials Laboratory, economically priced for general polishing applications

Our Monocrystalline Diamond Paste used for sample preparation is Water Soluble (WS) for use where exceptional cleaning is require quired and petroleum contamination is prohibited. ready-packed for dispensing in syringes which are color-coded. Graded sizes and compounded for good dispersion. Exceeds US standards for purity, size and uniformity. Excellent cutting rates and provides a good smooth finish. Recommended for polishing various metals, alloys, minerals, glass, ceramics, carbides, semiconductors. Can be used with Grinding Discs and Polishing Cloths.. Available in 5 and 20 gram syringes.

9020000

Image | Name | Description | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

9020001 | Diamond Polishing Compound, 45µm size, 5g, Brown | $20.50 | Max: Min: 1 Step: 1 | ||

9020003 | item # 9020003 Diamond Polishing Compound, 30µm size, 5g, Red | $20.50 | Max: Min: 1 Step: 1 | ||

9020005 | Diamond Polishing Compound, 15µm size, 5g, Blue | $20.50 | Max: Min: 1 Step: 1 | ||

9020007 | Diamond Polishing Compound, 9µm size, 5g, Green | $20.50 | Max: Min: 1 Step: 1 | ||

9020009 | Diamond Polishing Compound, 6µm size, 5g, Orange | $20.50 | Max: Min: 1 Step: 1 | ||

9020011 | Diamond Polishing Compound, 3µm size, 5g, Yellow | $20.50 | Max: Min: 1 Step: 1 | ||

9020013 | Diamond Polishing Compound, 1µm size, 5g, White | $20.50 | Max: Min: 1 Step: 1 | ||

9020015 | Diamond Polishing Compound, 0.5µm size, 5g, Light Grey | $20.50 | Max: Min: 1 Step: 1 | ||

9020017 | Diamond Polishing Compound, 0.25µm size, 5g, Light Grey | $20.50 | Max: Min: 1 Step: 1 | ||

9020019 | Diamond Polishing Compound, 0.1µm size, 5g, Light Grey | $20.50 | Max: Min: 1 Step: 1 | ||

9020012 | Diamond Polishing Compound, 3µm size, 20g, Yellow | $64.00 | Max: Min: 1 Step: 1 | ||

9020014 | Diamond Polishing Compound, 1µm size, 20g, White | $64.00 | Max: Min: 1 Step: 1 | ||

9020016 | Diamond Polishing Compound, 0.5µm size, 20g, Light Grey | $64.00 | Max: Min: 1 Step: 1 | ||

9020018 | Diamond Polishing Compound, 0.25µm size, 20g, Light Grey | $64.00 | Max: Min: 1 Step: 1 | ||

9020020 | Diamond Polishing Compound, 0.1µm size, 20g, Light Grey | $64.00 | Max: Min: 1 Step: 1 | ||

9020000 | Diamond Polishing Compound in Syringes, set of 5 sizes: Set includes 5 sizes (5g syringes) each: 0.25µm, 0.5µm, 1µm, 3µm and 6µm. | $69.50 | Max: Min: 1 Step: 1 | ||

9020002 | Diamond Polishing Compound, 45µm size, 20g, Brown | $69.50 | Max: Min: 1 Step: 1 | ||

9020004 | Diamond Polishing Compound, 30µm size, 20g, Red | $69.50 | Max: Min: 1 Step: 1 | ||

9020006 | Diamond Polishing Compound, 15µm size, 20g, Blue | $69.50 | Max: Min: 1 Step: 1 | ||

9020008 | Diamond Polishing Compound, 9µm size, 20g, Green | $69.50 | Max: Min: 1 Step: 1 | ||

9020010 | Diamond Polishing Compound, 6µm size, 20g, Orange | $76.70 | Max: Min: 1 Step: 1 |

SMART CUT® Polycrystalline Diamond Compound, available in convenient 5 and 20-gram syringes, designed specifically for sample preparation and materials research. This advanced formulation leverages the unique properties of polycrystalline diamond particles to achieve higher material removal rates and superior surface finishes, making it particularly suitable for composites, ceramics, sintered products, and heterogeneous materials. The compound's water-soluble (WS) nature ensures exceptional cleaning and compatibility with sensitive environments.

SMART CUT® Polycrystalline diamond is ideally suited for the lapping and polishing of both extremely hard and soft materials. Its unique characteristics allow for maximum material removal rates and superior surface quality. The polycrystalline diamond particles are ultra-rough, possessing three times the surface area of monocrystalline particles, significantly enhancing their cutting efficiency. This makes the compound highly effective on hard-to-polish materials such as ceramics, tool steels, sapphire, and super alloys.

SMART CUT® Polycrystalline diamond compound is designed with more facets or cutting edges, maintaining its cutting ability by being less friable than the more common and less costly monocrystalline diamonds. Monocrystalline diamonds, which have longer and sharper edges, are more suitable for less hard materials like brass or soft steel.

SMART CUT® Polycrystalline Diamond Compound can be used with grinding discs and polishing cloths, providing versatility in various laboratory and industrial settings. Available in convenient 5 and 20-gram syringes, it ensures precise application and reduces waste. The spherical shape of polycrystalline diamond particles, with a greater number of cutting facets, reduces subsurface deformation and provides more precise results when surfaces are etched.

Manufactured to the highest standards, SMART CUT® diamond compound offers unmatched quality and performance. The water-soluble formula ensures that residues can be easily removed, maintaining the cleanliness of your work environment. Free from petroleum contaminants, this compound is safer for both the user and the environment. Compare to many well know brand names such as Buehler, Struers, Leco and many others. Why pay more?

SMART CUT® diamond compounds are manufactured on the same day an order is placed, guaranteeing the freshest product with the longest possible shelf life. This rapid production process ensures that customers receive suspensions at their peak quality, delivering optimal polishing performance and reducing the risk of degradation over time. Custom Specifications are available upon request with usually no minimum order quantity & very fast lead times.

Our Advanced formulation Polycrystalline Diamond Compound use polycrystalline diamond particles for higher material removal rates. Good quality surface finish. Particularly suitable for composites, ceramics, sintered products and heterogeneous material. Our Polycrystalline Diamond Paste used for sample preparation is Water Soluble (WS).

Polycrystalline diamond is best suited for lapping and polishing of both extremely hard and soft materials. Thanks to its unique characteristics, maximum material removal rates and superior surface quality are achieved. Polycrystalline diamond particles are ultra rough with three times the surface area of Monocrystalline particles.

The polycrystalline is typically used on hard to polish materials such as ceramics, tool steels, sapphire, and super alloys. It has more facets or cutting edges and keeps its cutting ability by being less friable (easily crumbled or pulverized) than the more common and less costly monocrystalline diamonds. Monocrystalline diamonds tend to have longer, sharper edges and are more suitable for less hard materials such as brass or soft steel. Can be used with Grinding Discs and Polishing Cloths.. Available in 5 and 20 gram syringes.

Polycrystalline diamond is somewhat spherical in shape and it has a greater number of cutting facets than monocrystalline diamond, therefore reducing subsurface deformation, giving more precise results when surfaces are etched.

Image | Name | Description | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

9030010 | Polycrystalline Diamond Paste, 5g/syringe, 30.0µm | $35.50 | Max: Min: 1 Step: 1 | ||

9030011 | Polycrystalline Diamond Paste, 5g/syringe, 15.0µmz

| $35.50 | Max: Min: 1 Step: 1 | ||

Polycrystalline Diamond Paste, 5g/syringe, 9.0µm | $35.50 | Max: Min: 1 Step: 1 | |||

9030009 | Polycrystalline Diamond Paste, 5g/syringe, 6.0µm | $35.50 | Max: Min: 1 Step: 1 | ||

9030007 | Polycrystalline Diamond Paste, 5g/syringe, 3.0µm | $35.50 | Max: Min: 1 Step: 1 | ||

9030005 | Polycrystalline Diamond Paste, 5g/syringe, 1.0µm | $35.50 | Max: Min: 1 Step: 1 | ||

9030003 | Polycrystalline Diamond Paste, 5g/syringe, 0.5µm | $35.50 | Max: Min: 1 Step: 1 | ||

9030002 | Polycrystalline Diamond Paste, 5g/syringe, 0.25µm | $35.50 | Max: Min: 1 Step: 1 | ||

9030000 | Polycrystalline Diamond Paste, 5g/syringe, 0.1µm | $35.50 | Max: Min: 1 Step: 1 | ||

9030021 | Polycrystalline Diamond Paste, 20g/syringe, 1.0µm | $91.70 | Max: Min: 1 Step: 1 | ||

9030019 | Polycrystalline Diamond Paste, 20g/syringe, 0.5µm | $91.70 | Max: Min: 1 Step: 1 | ||

9030018 | Polycrystalline Diamond Paste, 20g/syringe, 0.25µm | $91.70 | Max: Min: 1 Step: 1 | ||

9030016 | Polycrystalline Diamond Paste, 20g/syringe, 0.1µm | $91.70 | Max: Min: 1 Step: 1 | ||

9030023 | Polycrystalline Diamond Paste, 20g/syringe, 3.0µm | $105.00 | Max: Min: 1 Step: 1 | ||

9030028 | Polycrystalline Diamond Paste, 20g/syringe, 30.0µm | $172.00 | Max: Min: 1 Step: 1 | ||

9030027 | Polycrystalline Diamond Paste, 20g/syringe, 15.0µm | $172.00 | Max: Min: 1 Step: 1 | ||

9030026 | Polycrystalline Diamond Paste, 20g/syringe, 9.0µm | $172.00 | Max: Min: 1 Step: 1 | ||

9030025 | Polycrystalline Diamond Paste, 20/syringe, 6.0µm | $172.00 | Max: Min: 1 Step: 1 |

|

Feature |

Monocrystalline Diamond Compound |

Polycrystalline Diamond Compound |

|---|---|---|

|

Particle Structure |

Single crystal particles |

Multiple crystal particles per grain |

|

Cutting Action |

Provides uniform, consistent cutting edges |

Self-sharpening, offers fresh cutting edges as particles fracture |

|

Surface Finish |

Generates very smooth surfaces with consistent scratch patterns |

Capable of both smooth finishes and rapid stock removal depending on particle size |

|

Material Suitability |

Ideal for softer to medium-hard materials that do not easily fracture diamond particles |

Suitable for very hard materials, including advanced ceramics and composites |

|

Thermal Stability |

Higher thermal stability due to robust single-crystal structure |

Good thermal management through particle fragmentation |

|

Chemical Stability |

Generally high, but depends on the purity and manufacturing process |

Excellent, often enhanced by the toughness and varied crystal orientations |

|

Cost |

Generally less expensive, offering a cost-effective solution for high wear conditions |

Typically more expensive due to higher production costs of uniform, single crystals |

|

Application Examples |

Used in precision engineering, optics polishing, fine-finish metallography |

Used in high-stress environments such as machining hard composites, aggressive material removal |

|

Advantages |

Superior for achieving high-quality finishes, maintains edge integrity under less severe conditions |

Effective for rapid material removal, versatile across a broad range of hard materials |

|

Disadvantages |

Higher cost, less effective for rapid stock removal or very hard materials |

May produce less consistent surface finishes due to particle fracturing |

|

Durability |

Tends to wear down more slowly due to the strength of the single crystals |

Higher rate of particle breakdown can be beneficial for maintaining aggressive cutting action |

|

Particle Fracture |

Lower tendency to fracture, maintains a consistent cutting surface longer |

Higher tendency to fracture, but this creates new sharp edges for effective material removal |

|

Consistency of Results |

Consistently smooth finish ideal for applications requiring high precision |

Variability in scratch patterns, suitable for applications where finish is less critical |

|

Economic Efficiency |

Higher upfront costs but can be offset by longer lifespan and less frequent need for replacement |

Lower initial cost, efficient for large volume applications due to frequent renewing of edges |

|

Environmental Impact |

Manufacturing process is less intensive in terms of energy and waste production |

Manufacturing can be more resource-intensive, but modern techniques are improving sustainability |

|

Ease of Use |

May require more skilled operation to achieve best results due to uniform particle size |

Generally easier to achieve effective results quickly, less sensitive to operational variations |

We produce diamond consumables for some of the leading world OEM manufacturers. We offer Manufacturers Direct Prices

We have the largest variety of diamond & cbn wafering blades available in stock. As well as large inventory of diamond & abrasive consumables. We also custom manufacture diamond and cbn tools, consumables and machines to better fit customer specific needs. Just about any tools & consumables can be designed and manufactured per client drawing or specificrtion

WE ARE A PARTNER IN YOUR SUCCESS

Our proprietory diamond chemistory , precision , manufacturing metods , quality control methods allow us to control and regulate the dozens of variables to that affect consumable life , quality , and consistency.

The more you understand about what we can do for you the better our partnership will be. Here you will find most comprehensive source of information and optimizing and improving your cutting , drilling , grinding and polishing on the web. find everything you ever wanted to know about diamond tools.

AMERICAN MANUFACTURER

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Save Money Save up to 650%

COMPARE TO: BUEHLER , STRUERS , LECO & MANY OTHERS

Large Inventory & Custom Manufacturing

Umatched Technical Support

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency

Superior Quality & Consistency

EXPECT MORE FROM YOUR TOOLS

Comprehensive Source Of Information For Sample Preparation

Advanced Technology

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool

manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry .Depend on us to bring you technology of tomorrow today.

Experience Makes All The Differences

Over the years we have worked with some of the leading Fortune 500 companies , thousands of universities , government and private research labs , and small organisations. We have made thousands of custom tools , built custom machines , work-holding fixtures , etc for hundreds of applications. Many of our staff members have been working in their respective fields for over 50 years and have gained a wealth of knowledge over the years

Let Us Help You

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales