-

0 items in quote

No products in the Quote Basket.

SMART CUT® HD-2B

Synthetic Low IFT Coolant/Lubricant For Diamond Wire Sawing & ID Cropping Blades, Diamond Band Saws, Edge Grinding of Semiconductor materials

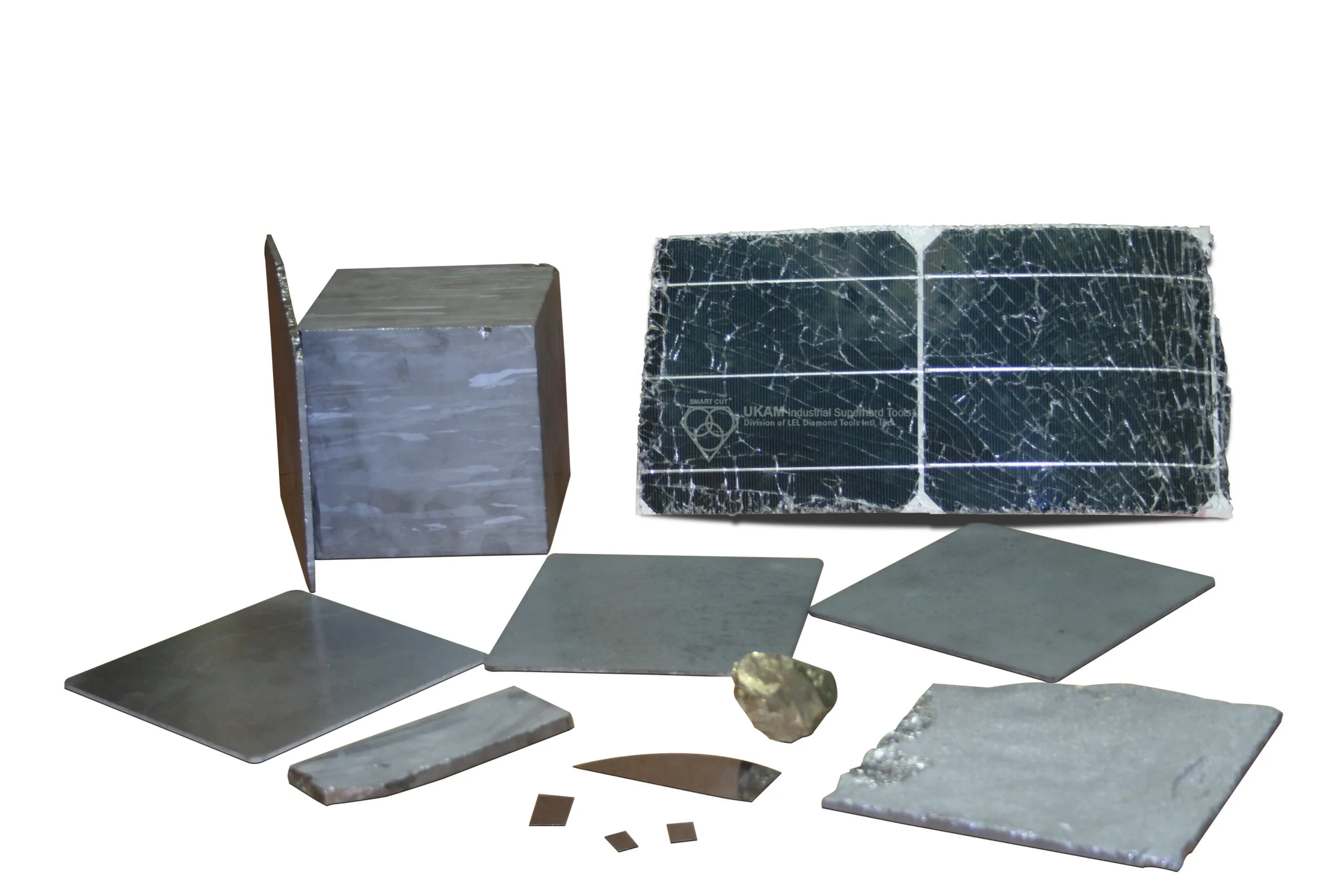

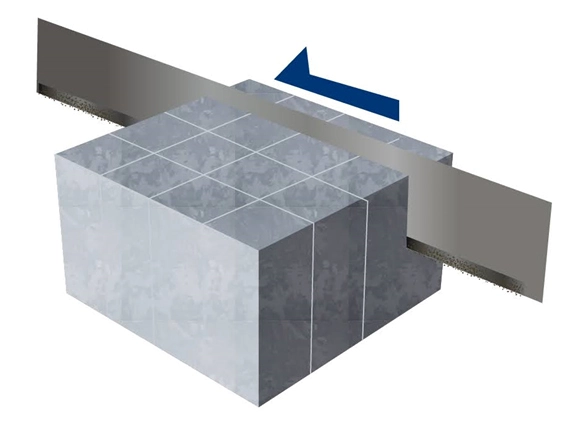

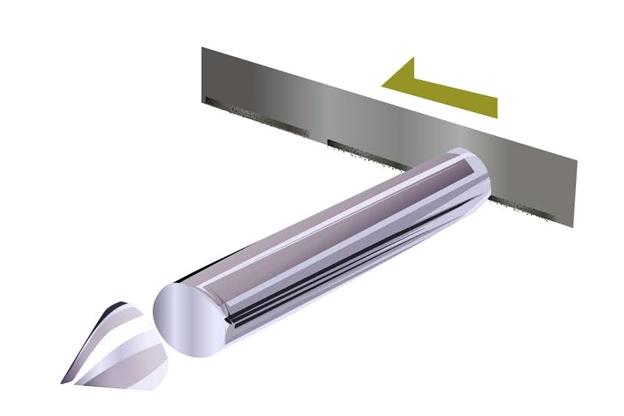

SMART CUT® is a synthetic coolant specifically designed for the cutting of semiconductor materials, including sapphire, silicon, germanium, single-crystal SiC, and II-VI crystals. This coolant offers excellent cut rates and imparts outstanding surface finishes with reduced warp and total thickness variation (TTV). It is ideal for diamond abrasive cropping, squaring, and wafering of silicon ingots using ID, band, and wire saws. SMART CUT® HD-2B can also be used as a non-re-circulating edge grinding coolant or lubricant for silicon wafers and ingots.

DESCRIPTION

SPECIFICATIONS

FREQUENTLY ASKED QUESTIONS

INDUSTRIES USED IN

ACCESSORIES

USAGE RECOMMENDATION

DESCRIPTION

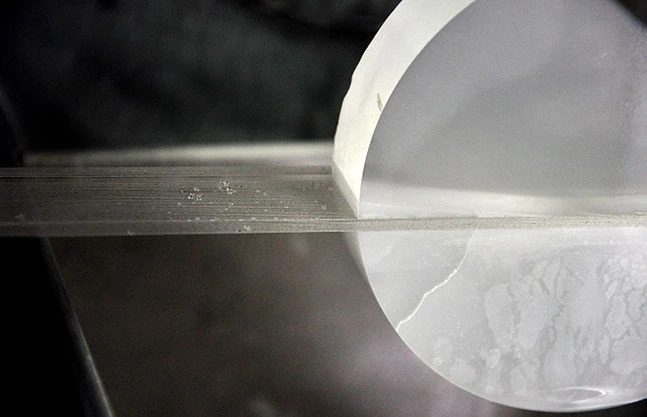

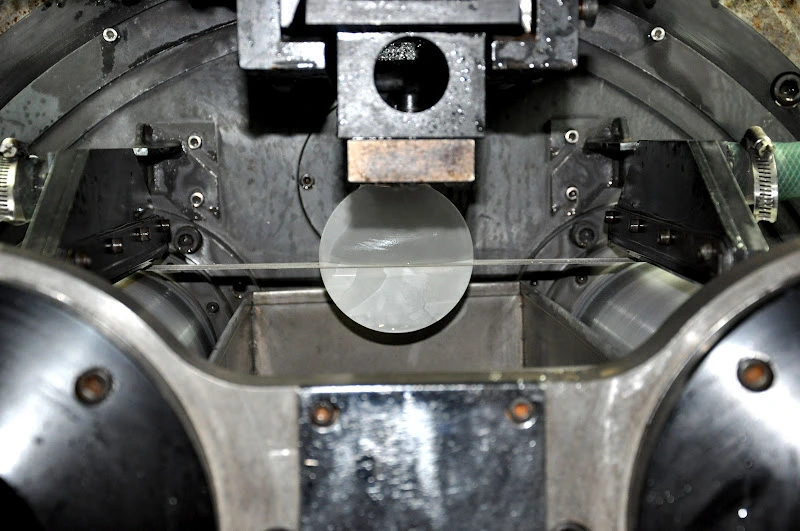

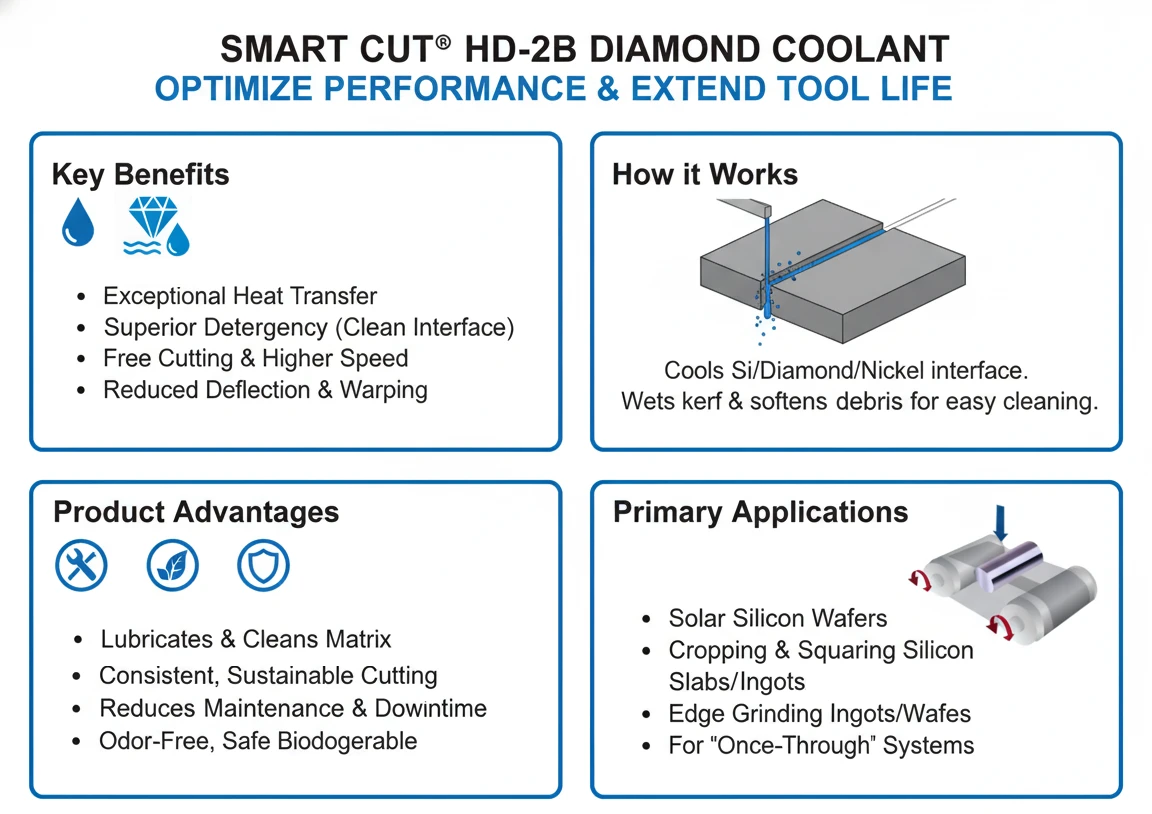

SMART CUT® HD-2B is designed for use in “once-through” systems with diamond blades or wires. Its exceptional heat transfer capabilities help quickly cool diamond blades or wires, wheels, & other tools extending their lifespan. The product’s superior detergency properties keep the diamond interface clean, ensuring a free cutting process, higher cutting speed, and reduced deflection of blades or wires.

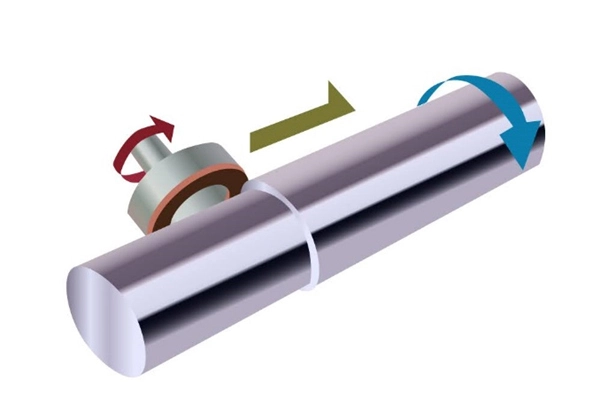

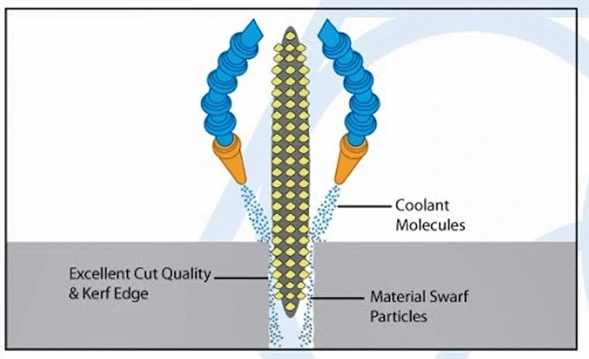

SMART CUT® HD-2B allows the diamond wire to saw properly through silicon by penetrating through the kerf and wetting the Si/Diamond/Nickel interface. As an added benefit, the coolant keeps the debris generated from the saw soft and easier to clean, keeping surfaces free cutting and clean.

The matrix in which the diamond is contained is also lubricated and cleaned, allowing for consistent and sustainable cutting, while reducing maintenance and machine downtime. The product is odor-free, safe, and biodegradable, ensuring safer working conditions and a more environmentally friendly solution.

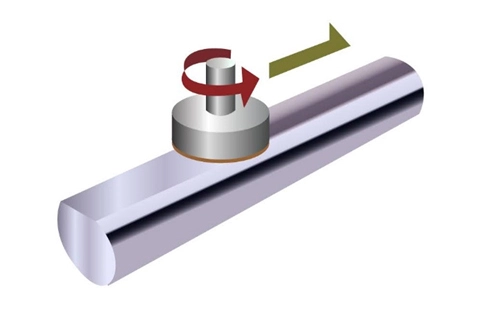

For producers of solar silicon wafers, SMART CUT® HD-2B is the recommended coolant for cropping and squaring silicon slabs and ingots. It allows for consistent and sustainable cutting at the higher speeds commonly used in diamond wire cropping and squaring saws. SMART CUT® HD-2B can also serve as a non-re-circulating coolant for edge grinding silicon ingots and wafers.

SMART CUT® HD-2B is specifically designed for use in “once-through” systems only. It provides extended blade and wire life, increased production, lower sub-surface damage, and reduced bow and warp. The product minimizes blade and wire deflection, eliminates exit chipping, and prevents substrate tear. It ensures cleaner machines and working conditions, while being non-staining, non-corrosive, and odor-free.

SPECIFICATIONS

Application:

- Designed for cutting semiconductor materials such as sapphire, silicon, germanium, single-crystal SiC, and II-VI crystals.

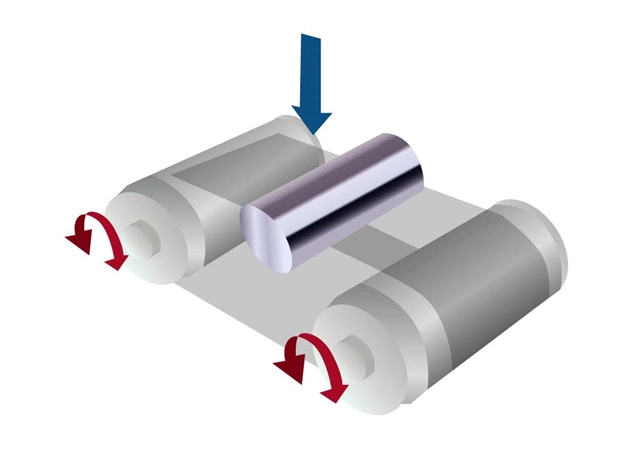

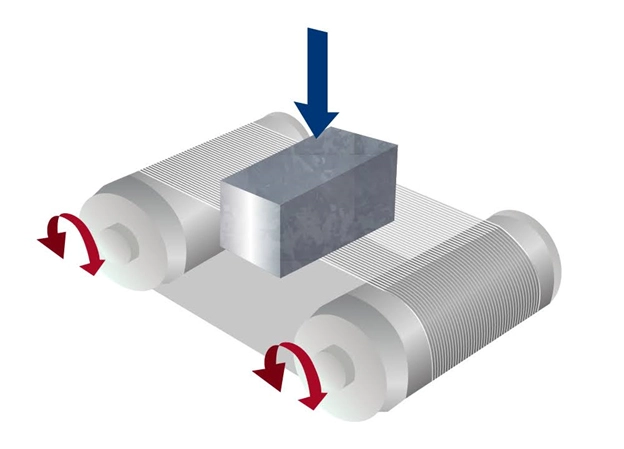

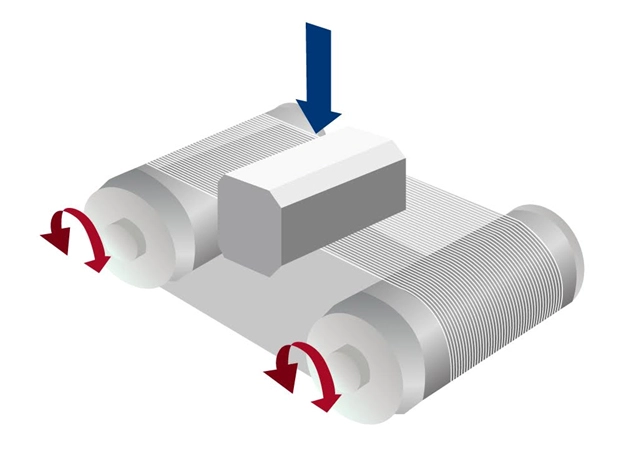

- Used for diamond abrasive cropping, squaring, and wafering of silicon ingots using ID, band, and wire saws.

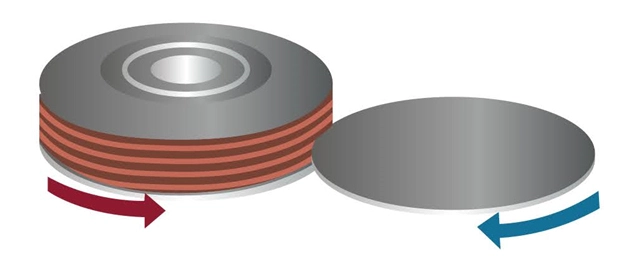

- Can be used as a non-re-circulating coolant for edge grinding silicon wafers and ingots.

Formulation:

- Synthetic coolant optimized for “once-through” systems using diamond blades or wires.

Physical Properties:

- Appearance: Clear liquid (may vary depending on the formulation)

- Viscosity: Low viscosity for efficient flow and minimal drag during cutting

- Density: Typically around 1.00 g/cm³ (may vary slightly based on formulation)

Available in:

- 5 Gallon

- 55 gallons

SMART CUT® HD-2B is designed for use at very high dilution ratios, typically evaluated at a ratio of 400 parts water to 1 part product (0.25%). Due to the high dilution, the quality of the water used is crucial to the performance of the fluid. Deionized (DI) water is the best choice as it eliminates ion interference with the surfactant base. However, softened or standard tap water can also be used effectively as long as its quality remains stable.

FREQUENTLY ASKED QUESTIONS

SMART CUT HD-2B is a synthetic wire slice coolant formulated for the cutting of semiconductor materials such as sapphire, silicon, germanium, single-crystal SiC, and II-VI crystals using fixed abrasive wires. It provides excellent cut rates, superior surface finishes, and extends the life of cutting tools.

SMART CUT HD-2B is designed for diamond abrasive cropping, squaring, and wafering of silicon ingots using ID, band, and wire saws. It is also used as a non-re-circulating edge grinding coolant for silicon wafers and ingots. It is ideal for “once-through” cutting systems.

SMART CUT HD-2B improves cutting performance by reducing tool wear, increasing cutting speed, and minimizing blade or wire deflection. It penetrates the kerf and wets the Si/Diamond/Nickel interface, which helps keep the debris soft and easier to clean, improving surface finish quality and reducing maintenance.

Yes, SMART CUT HD-2B is odor-free, non-toxic, and biodegradable, making it safe for use in a variety of cutting operations. It does not contain harmful chemicals and promotes safer working conditions.

SMART CUT HD-2B provides extended blade and wire life, increased production, minimal sub-surface damage, and reduced bow and warp. It also prevents exit chipping, substrate tear, and minimizes blade and wire deflection, ensuring consistent, high-quality cutting. Additionally, it maintains a cleaner machine and working environment due to its non-staining, non-corrosive properties.

By keeping the diamond interface clean and free-cutting, SMART CUT HD-2B reduces the need for frequent dressing and maintenance, minimizing machine downtime. It also keeps the matrix in which the diamond is contained lubricated and cleaned, ensuring consistent, sustainable cutting.

While SMART CUT HD-2B is primarily designed for cutting semiconductor materials such as silicon, sapphire, germanium, and II-VI crystals, it can also be used for similar materials that require high-speed, precision cutting with diamond abrasive tools.

SMART CUT HD-2B is designed for use in “once-through” systems. Simply add it to the cutting process to provide cooling and lubrication for diamond blades or wires. It is not intended for recirculation.

SMART CUT HD-2B helps to keep the debris generated during cutting soft and easier to clean, reducing the risk of clogging and maintaining a cleaner cutting area. This improves both the efficiency of the cutting process and the quality of the final product.

Yes, SMART CUT HD-2B is biodegradable, non-toxic, and free of harmful chemicals, making it an environmentally friendly choice for cutting operations. It contributes to safer and more sustainable working conditions.

Yes, SMART CUT HD-2B is compatible with both diamond wire and diamond blades. It is specifically designed for use in systems that employ diamond abrasive tools for cutting, ensuring optimal cooling, lubrication, and performance for both types of tools.

SMART CUT HD-2B enhances cutting speed by providing superior cooling and reducing friction, allowing diamond blades or wires to operate at higher speeds. This results in increased productivity and faster cycle times, all while maintaining cutting precision and tool life.

No special maintenance is required for SMART CUT HD-2B itself, but it is recommended to follow standard maintenance procedures for your cutting system to ensure optimal performance. The product helps reduce the frequency of tool dressing and keeps the cutting system clean, which in turn lowers maintenance requirements.

Yes, SMART CUT HD-2B is ideal for high-speed cutting operations. Its formulation is designed to withstand the higher cutting speeds common in diamond wire and blade cutting systems, making it an excellent choice for semiconductor material processing.

SMART CUT HD-2B provides superior heat transfer, which allows for better cooling of diamond blades and wires. It also has exceptional detergency, ensuring that the diamond interface remains clean and free-cutting, which increases cutting speed and reduces deflection. Unlike conventional coolants, it also keeps debris soft and easier to clean, reducing maintenance and downtime.

Yes, SMART CUT HD-2B is designed to handle high temperatures typically encountered in high-speed cutting applications. Its exceptional heat transfer properties help to rapidly cool the cutting tools, preventing excessive heat buildup and prolonging tool life.

SMART CUT HD-2B reduces the risk of thermal damage, substrate tear, and chipping by providing effective cooling and lubrication. It ensures that the material being cut maintains its structural integrity and high-quality surface finish, even during high-speed cutting operations.

SMART CUT HD-2B has a long shelf life when stored in proper conditions (cool, dry place, away from direct sunlight). However, it is always best to check the product’s expiration date and perform visual and physical inspections to ensure the product is in optimal condition before use.

Since SMART CUT HD-2B is biodegradable and non-toxic, it is environmentally friendly. However, you should still follow your local regulations for disposing of industrial coolants and liquids. Check with local authorities for specific disposal guidelines.

SMART CUT HD-2B is designed for use in “once-through” cutting systems with diamond blades or wires. If your system operates on a different type of cutting mechanism, it’s important to verify compatibility with your equipment manufacturer before use.

Yes, SMART CUT HD-2B is ideal for precision cutting applications, such as wafering and dicing of semiconductor materials. It maintains a clean and free-cutting interface, ensuring high precision with minimal defects, making it perfect for industries requiring tight tolerances and high-quality surface finishes.

Yes, SMART CUT HD-2B helps reduce the wear on diamond tools by providing excellent lubrication and cooling. It minimizes friction and heat buildup, both of which can contribute to premature tool wear. This extends the life of diamond blades and wires, improving the overall cost-effectiveness of your cutting operations.

SMART CUT HD-2B is especially beneficial in solar wafer production, where high-speed cutting is required. It helps maintain consistent cutting performance, reduces material waste, and minimizes defects, all of which contribute to a higher yield and more efficient production process. The product’s superior cooling properties also allow for faster cutting speeds, increasing overall throughput.

No, SMART CUT HD-2B is specifically designed for “once-through” systems and is not suitable for recirculating systems. It is formulated to work in environments where the coolant is not reused, ensuring optimal cooling and lubrication during the cutting process.

If SMART CUT HD-2B is used with a system not designed for “once-through” coolants, it may not provide optimal performance. The coolant could potentially lead to excess buildup or contamination in the system, reducing the effectiveness of the cutting process. Always verify compatibility with your equipment before use.

The amount of SMART CUT HD-2B required depends on the size and type of the cutting system being used. It is recommended to follow the guidelines provided by the equipment manufacturer and adjust based on the cutting speed and material being processed. Typically, you will need enough coolant to ensure proper cooling and lubrication during the cutting process.

Yes, SMART CUT HD-2B is designed for both low and high load cutting operations. It can handle a wide range of cutting pressures, providing effective cooling and lubrication even during high load cutting, while still offering efficient performance for lighter cutting tasks.

No, SMART CUT HD-2B is non-corrosive and safe for use with most cutting equipment. It is specifically formulated to protect and extend the life of your machinery by providing excellent lubrication and preventing excessive heat buildup. However, always follow proper maintenance procedures to ensure the longevity of your equipment.

SMART CUT HD-2B is primarily designed for use with materials like silicon, sapphire, germanium, single-crystal SiC, and II-VI crystals. If you are working with other types of semiconductor materials, it’s important to verify compatibility with your cutting system and the specific material before use.

SMART CUT HD-2B is biodegradable, non-toxic, and free of harmful chemicals, making it safer for both the environment and workers. Unlike many traditional coolants, it does not contain hazardous substances and is less likely to cause environmental damage when disposed of properly, contributing to more sustainable operations.

Yes, SMART CUT HD-2B can be used with both manual and automated cutting systems. Whether you are performing precision cutting by hand or using fully automated equipment, SMART CUT HD-2B ensures consistent performance, providing optimal cooling and lubrication for effective cutting.

SMART CUT HD-2B should be stored in a cool, dry place, away from direct sunlight and extreme temperatures. Proper storage helps maintain the product’s effectiveness and ensures it remains in good condition for use. Always store it in its original container and keep the lid tightly sealed to prevent contamination.

While SMART CUT HD-2B is formulated for cutting semiconductor materials, it may also be effective for hard materials such as ceramics. For specific applications, it’s recommended to test the product’s compatibility with the material being processed or consult with the manufacturer for more detailed guidance.

SMART CUT HD-2B should be replaced when it becomes visibly contaminated, loses its cooling properties, or when it no longer provides optimal lubrication. If you notice a decrease in cutting performance or an increase in maintenance requirements, it may be time to replace the coolant. Regular system checks and proper maintenance will help determine when replacement is necessary.

Yes, SMART CUT HD-2B is effective for both high and low RPM cutting applications. It is designed to provide efficient cooling and lubrication across a wide range of cutting speeds, ensuring optimal performance regardless of the RPM setting.

SMART CUT HD-2B offers several advantages over traditional cutting coolants, including superior heat transfer, better lubrication, and enhanced detergency. It provides a cleaner cutting interface, reduces wear on diamond tools, and extends tool life. Additionally, it is biodegradable and free of harmful chemicals, making it a more environmentally friendly choice compared to many conventional coolants.

SMART CUT HD-2B is designed to operate efficiently across a wide range of temperatures typically encountered in cutting applications. However, to maintain optimal performance, it should be used within the temperature range recommended by the equipment manufacturer. Avoid exposing the coolant to extreme temperatures, as this may affect its effectiveness.

No, SMART CUT HD-2B is designed to keep the cutting interface clean and free of residues. The coolant prevents debris buildup and ensures that the material being cut maintains a smooth surface finish. It also helps in keeping the machinery clean and reduces the need for excessive cleanup after each cutting session.

SMART CUT HD-2B helps improve sustainability by extending the life of cutting tools, reducing the frequency of tool replacements, and minimizing waste. Its biodegradable formulation ensures less environmental impact compared to conventional coolants. Additionally, its efficient performance reduces the need for excessive maintenance and lowers the consumption of coolant, making the overall process more sustainable.

It is not recommended to mix SMART CUT HD-2B with other coolants, as doing so could compromise its performance and effectiveness. For optimal results, use SMART CUT HD-2B as the sole coolant in the system, following the manufacturer’s guidelines for usage.

SMART CUT HD-2B helps ensure a high-quality, smooth cutting surface by providing consistent cooling and reducing friction. It prevents issues like substrate tear, exit chipping, and excessive heat buildup, all of which could compromise the quality of the material’s surface.

SMART CUT HD-2B is primarily designed for use with fixed abrasive wire saws, diamond blades, and other similar cutting tools. It works well with saws used for semiconductor material processing, including those used in high-speed and precision cutting applications. Always ensure that your cutting equipment is compatible with “once-through” coolants before use.

SMART CUT HD-2B contributes to reducing waste by maintaining a clean, efficient cutting process. It helps prevent material waste from excessive tool wear, chipping, and rough cutting. Additionally, by enhancing cutting performance and tool longevity, it minimizes the need for reprocessing, further reducing waste in the manufacturing process.

Yes, SMART CUT HD-2B is suitable for both high-volume and low-volume production environments. Its consistent performance across various cutting speeds and volumes ensures that it enhances productivity in high-volume operations while still providing precision and care in low-volume, specialized applications.

SMART CUT HD-2B helps reduce operational costs by extending the lifespan of diamond blades and wires, minimizing tool replacement and maintenance needs. It improves cutting efficiency, reducing cycle times and increasing throughput. Additionally, its superior cooling and cleaning properties reduce the need for frequent system cleanings and downtime, further contributing to cost savings.

SMART CUT HD-2B is a specialized coolant designed for semiconductor material cutting, and while it is optimized for “once-through” systems, it can be customized in some cases to meet specific needs. If you have a unique system or requirement, it’s best to consult with the manufacturer or a technical representative to confirm compatibility.

Yes, SMART CUT HD-2B is highly effective in preventing thermal damage during cutting. Its superior heat transfer properties rapidly dissipate heat, ensuring that delicate materials like silicon or sapphire remain free from heat-induced damage, such as warping or cracking, which is particularly crucial in semiconductor and solar wafer production.

To monitor the effectiveness of SMART CUT HD-2B, you can observe key indicators such as tool wear, cutting speed, surface finish quality, and the amount of debris generated. If there is an increase in tool wear or a decrease in cutting efficiency, it may be an indication that the coolant needs to be replaced or the system requires maintenance. Regular checks and maintenance of your equipment will help ensure SMART CUT HD-2B performs at its best.

The recommended flow rate for SMART CUT HD-2B will depend on the specific cutting system being used and the material being processed. Generally, the coolant should be provided at a flow rate that ensures consistent lubrication and cooling of the diamond tools.

SMART CUT HD-2B is a synthetic coolant that is specifically designed for use in “once-through” systems and is not intended to be mixed with water-based coolants. For optimal performance, use SMART CUT HD-2B on its own to achieve the best results in cutting operations.

While SMART CUT HD-2B is specifically formulated for semiconductor material cutting, it may be used in other precision cutting applications where diamond blades or wires are involved. However, for non-semiconductor materials, it is recommended to verify the product’s effectiveness with your specific material type to ensure compatibility and performance.

SMART CUT HD-2B helps prevent clogging by keeping the debris generated during cutting soft and easier to remove. The superior detergency properties of the coolant ensure that the diamond interface remains clean, allowing for continuous, uninterrupted cutting performance and reducing the risk of debris buildup.

SMART CUT HD-2B is specifically designed for “once-through” systems and is not intended for use in closed-loop or recirculating systems. Recycling the coolant in a closed-loop system may compromise its effectiveness, as the product is optimized for single-use applications. For systems requiring recirculating coolants, a different coolant formulation may be necessary.

SMART CUT HD-2B works effectively across a range of pressures typically used in diamond cutting operations. The coolant’s formulation allows it to perform well under both low and high-pressure cutting conditions. For optimal performance, consult your equipment’s specifications for the recommended pressure settings when using SMART CUT HD-2B.

Yes, SMART CUT HD-2B is well-suited for research and development (R&D) applications where precision cutting is critical. Its ability to provide consistent, high-quality cuts while minimizing tool wear and thermal damage makes it ideal for R&D settings, especially when working with semiconductor materials or other delicate substances.

SMART CUT HD-2B’s excellent lubricating properties and detergency keep the cutting interface clean and free from contaminants. This helps minimize surface contamination, ensuring that the material being cut maintains its integrity and quality. Additionally, the coolant’s formulation helps to prevent the accumulation of debris and residues on the workpiece, ensuring a smooth, clean surface finish.

SMART CUT HD-2B is primarily designed for semiconductor materials, but it may also be effective for cutting other materials in multi-material cutting applications, especially if diamond tools are involved. It is always recommended to test the product’s performance on different materials or consult with a technical expert to determine its suitability for specific multi-material applications.

If SMART CUT HD-2B comes into contact with skin or eyes, rinse immediately with plenty of water. Although the product is non-toxic and safe to use, it’s always a good practice to take appropriate precautions, including wearing gloves and protective eyewear when handling the coolant. If irritation persists, seek medical attention.

SMART CUT HD-2B improves the diamond wire or blade’s performance over time by reducing tool wear, minimizing deflection, and preventing thermal damage. Its cooling and lubricating properties ensure that the cutting tools stay sharper for longer, maintaining high cutting efficiency and prolonging their useful life.

INDUSTRIES USED IN

Semiconductor Materials

Sapphire

ACCESSORIES

Tab Content

USAGE RECOMMENDATION

Tab Content

Try SMART CUT® HD-2B Coolant Today

And see the difference it can make for your application

Advantage

-

Extended blade and wire life, reducing the need for frequent replacements and improving efficiency.

Extended blade and wire life, reducing the need for frequent replacements and improving efficiency.

-

Increased production due to faster and more consistent cutting, leading to higher throughput and reduced downtime.

Increased production due to faster and more consistent cutting, leading to higher throughput and reduced downtime.

-

Minimal sub-surface damage, preserving the material’s integrity and quality.

Minimal sub-surface damage, preserving the material’s integrity and quality.

-

Reduced bow and warp, ensuring precise dimensions and shapes.

Reduced bow and warp, ensuring precise dimensions and shapes.

-

Minimized blade and wire deflection, resulting in more accurate cuts and smoother surface finishes.

Minimized blade and wire deflection, resulting in more accurate cuts and smoother surface finishes.

-

Elimination of exit chipping and prevention of substrate tear, enhancing final product quality.

Elimination of exit chipping and prevention of substrate tear, enhancing final product quality.

-

Cleaner machines and working conditions, as the coolant is non-staining, non-corrosive, and odor-free.

Cleaner machines and working conditions, as the coolant is non-staining, non-corrosive, and odor-free.

-

Extended Blade and Wire Life: Reduces the frequency of tool replacements, improving cost-efficiency and minimizing downtime in the production process.

Extended Blade and Wire Life: Reduces the frequency of tool replacements, improving cost-efficiency and minimizing downtime in the production process.

-

Increased Cutting Speed: Enables faster cutting due to enhanced heat dissipation and a clean diamond interface, leading to higher productivity and reduced cycle times.

Increased Cutting Speed: Enables faster cutting due to enhanced heat dissipation and a clean diamond interface, leading to higher productivity and reduced cycle times.

-

Superior Surface Finish: Delivers smooth, high-quality cuts with minimal sub-surface damage, ensuring optimal material quality and reduced rework.

Superior Surface Finish: Delivers smooth, high-quality cuts with minimal sub-surface damage, ensuring optimal material quality and reduced rework.

-

Reduced Deflection: Minimizes blade and wire deflection, leading to more accurate cuts, consistent dimensional control, and improved surface flatness.

Reduced Deflection: Minimizes blade and wire deflection, leading to more accurate cuts, consistent dimensional control, and improved surface flatness.

-

Elimination of Chipping and Tear: Prevents exit chipping and substrate tear, ensuring the integrity of the material is maintained during cutting processes.

Elimination of Chipping and Tear: Prevents exit chipping and substrate tear, ensuring the integrity of the material is maintained during cutting processes.

-

Cleaner Machines and Work Environment: Non-staining, non-corrosive, and odor-free, making it easier to maintain equipment and creating safer, more pleasant working conditions.

Cleaner Machines and Work Environment: Non-staining, non-corrosive, and odor-free, making it easier to maintain equipment and creating safer, more pleasant working conditions.

-

Higher Production Yield: Supports higher cutting speeds and reduced tool wear, contributing to increased throughput and efficient production.

Higher Production Yield: Supports higher cutting speeds and reduced tool wear, contributing to increased throughput and efficient production.

-

Minimized Bow and Warp: Reduces distortion in materials, ensuring precise cuts and high-quality finished products.

Minimized Bow and Warp: Reduces distortion in materials, ensuring precise cuts and high-quality finished products.

-

Cost-Effective: By improving tool life and reducing maintenance requirements, it lowers overall operating costs and enhances profitability.

Cost-Effective: By improving tool life and reducing maintenance requirements, it lowers overall operating costs and enhances profitability.

-

Environmentally Friendly: Free of harmful chemicals, non-toxic, and biodegradable, contributing to a safer and more sustainable workplace.

Environmentally Friendly: Free of harmful chemicals, non-toxic, and biodegradable, contributing to a safer and more sustainable workplace.

Features

-

Specifically formulated for cutting semiconductor materials, including sapphire, silicon, germanium, single-crystal SiC, and II-VI crystals, using fixed abrasive wire.

Specifically formulated for cutting semiconductor materials, including sapphire, silicon, germanium, single-crystal SiC, and II-VI crystals, using fixed abrasive wire.

-

Designed for use in "once-through" systems with diamond blades or wires.

Designed for use in "once-through" systems with diamond blades or wires.

-

Exceptional heat transfer capabilities to quickly cool diamond blades or wires, extending tool life.

Exceptional heat transfer capabilities to quickly cool diamond blades or wires, extending tool life.

-

Superior detergency properties that keep the diamond interface clean, ensuring free cutting and increased cutting speed.

Superior detergency properties that keep the diamond interface clean, ensuring free cutting and increased cutting speed.

-

Enables consistent and sustainable cutting at high speeds typical of diamond wire cropping and squaring saws.

Enables consistent and sustainable cutting at high speeds typical of diamond wire cropping and squaring saws.

-

Can be used as a non-re-circulating coolant for edge grinding silicon ingots and wafers.

Can be used as a non-re-circulating coolant for edge grinding silicon ingots and wafers.

-

Non-staining, non-corrosive, and odor-free for cleaner machines and improved working conditions.

Non-staining, non-corrosive, and odor-free for cleaner machines and improved working conditions.

-

Optimized for use in diamond abrasive cropping, squaring, and wafering of silicon ingots with ID, band, and wire saws.

Optimized for use in diamond abrasive cropping, squaring, and wafering of silicon ingots with ID, band, and wire saws.

-

Provides reduced warp and total thickness variation (TTV) for superior material quality and surface finish.

Provides reduced warp and total thickness variation (TTV) for superior material quality and surface finish.

-

Ideal for use in high-performance environments where extended tool life and reduced maintenance are essential.

Ideal for use in high-performance environments where extended tool life and reduced maintenance are essential.

-

Supports high cutting speeds, allowing for increased productivity in semiconductor material processing.

Supports high cutting speeds, allowing for increased productivity in semiconductor material processing.

-

Offers a sustainable cutting solution that helps maintain a clean diamond interface for consistent performance.

Offers a sustainable cutting solution that helps maintain a clean diamond interface for consistent performance.

-

Compatible with a wide range of semiconductor materials, ensuring versatility in different applications.

Compatible with a wide range of semiconductor materials, ensuring versatility in different applications.

-

Enhances the overall reliability of cutting systems by reducing the risk of blade or wire deflection and improving cut accuracy.

Enhances the overall reliability of cutting systems by reducing the risk of blade or wire deflection and improving cut accuracy.

-

Helps maintain operational efficiency with its easy-to-use, once-through formulation, minimizing machine downtime and coolant management efforts.

Helps maintain operational efficiency with its easy-to-use, once-through formulation, minimizing machine downtime and coolant management efforts.

-

Specifically designed to prevent excessive heat buildup, maintaining optimal cutting conditions and reducing the risk of thermal damage to materials.

Specifically designed to prevent excessive heat buildup, maintaining optimal cutting conditions and reducing the risk of thermal damage to materials.

-

Provides excellent lubrication properties, ensuring smooth cutting and reducing friction between the diamond blade/wire and the material.

Provides excellent lubrication properties, ensuring smooth cutting and reducing friction between the diamond blade/wire and the material.

-

Increases cutting efficiency by improving the flushing of debris from the cutting area, preventing clogging and maintaining consistent performance.

Increases cutting efficiency by improving the flushing of debris from the cutting area, preventing clogging and maintaining consistent performance.

-

Reduces the frequency of tool dressing and maintenance, helping to lower overall operational costs.

Reduces the frequency of tool dressing and maintenance, helping to lower overall operational costs.

-

Optimizes the performance of high-speed cutting operations, contributing to faster cycle times and improved throughput.

Optimizes the performance of high-speed cutting operations, contributing to faster cycle times and improved throughput.

-

Excellent for use in precision applications where high surface quality, minimal defects, and tight tolerances are required.

Excellent for use in precision applications where high surface quality, minimal defects, and tight tolerances are required.

-

Formulated to provide effective cooling in high-load cutting processes, enhancing both the diamond tool and material lifespan.

Formulated to provide effective cooling in high-load cutting processes, enhancing both the diamond tool and material lifespan.

-

Reduces environmental impact by being non-toxic, biodegradable, and free of harmful chemicals, promoting safer working conditions.

Reduces environmental impact by being non-toxic, biodegradable, and free of harmful chemicals, promoting safer working conditions.

Green & Environmental Friedly Coolant

NOTE: contains no nitrides, phosphates, chromates, phenols, heavy metal salts, Petroleum oils, chlorine or phosphorus. Do not add inorganic nitrates, nitrites, or organic-nitro compounds.

How it Works

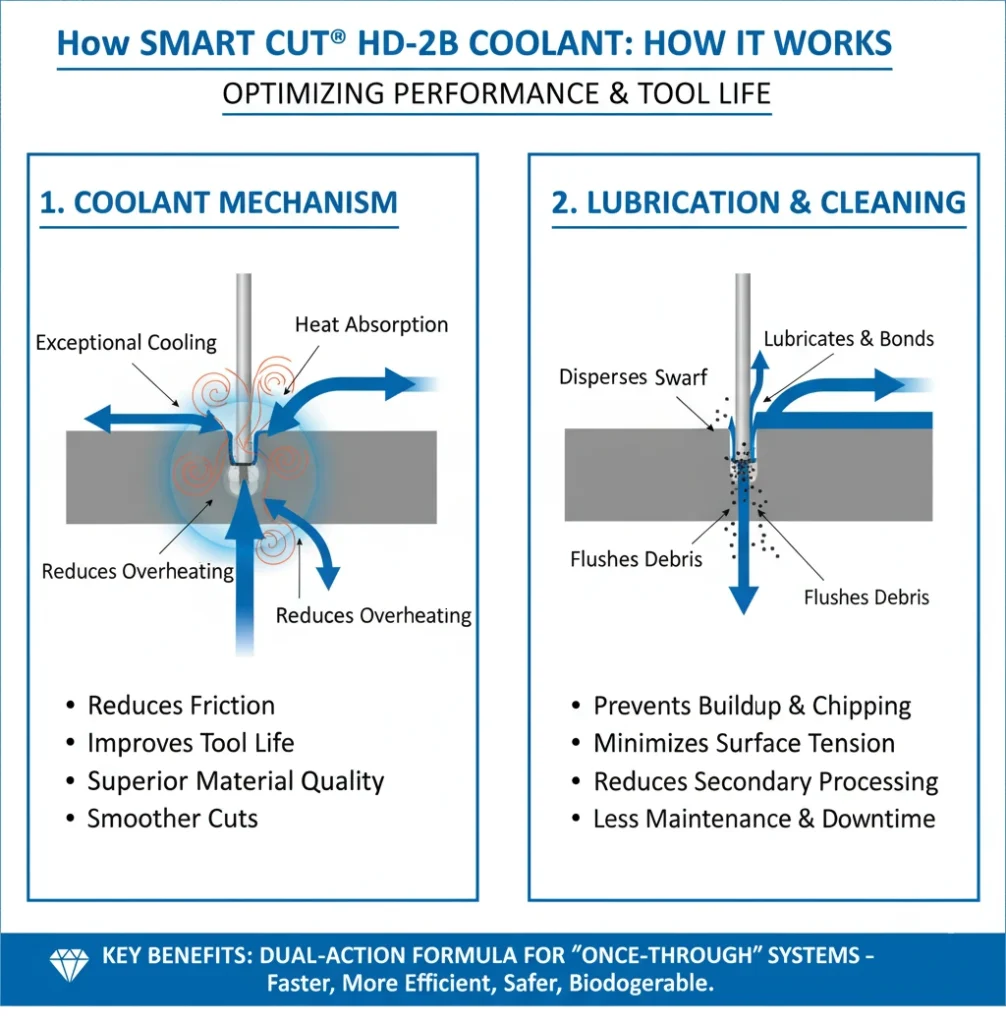

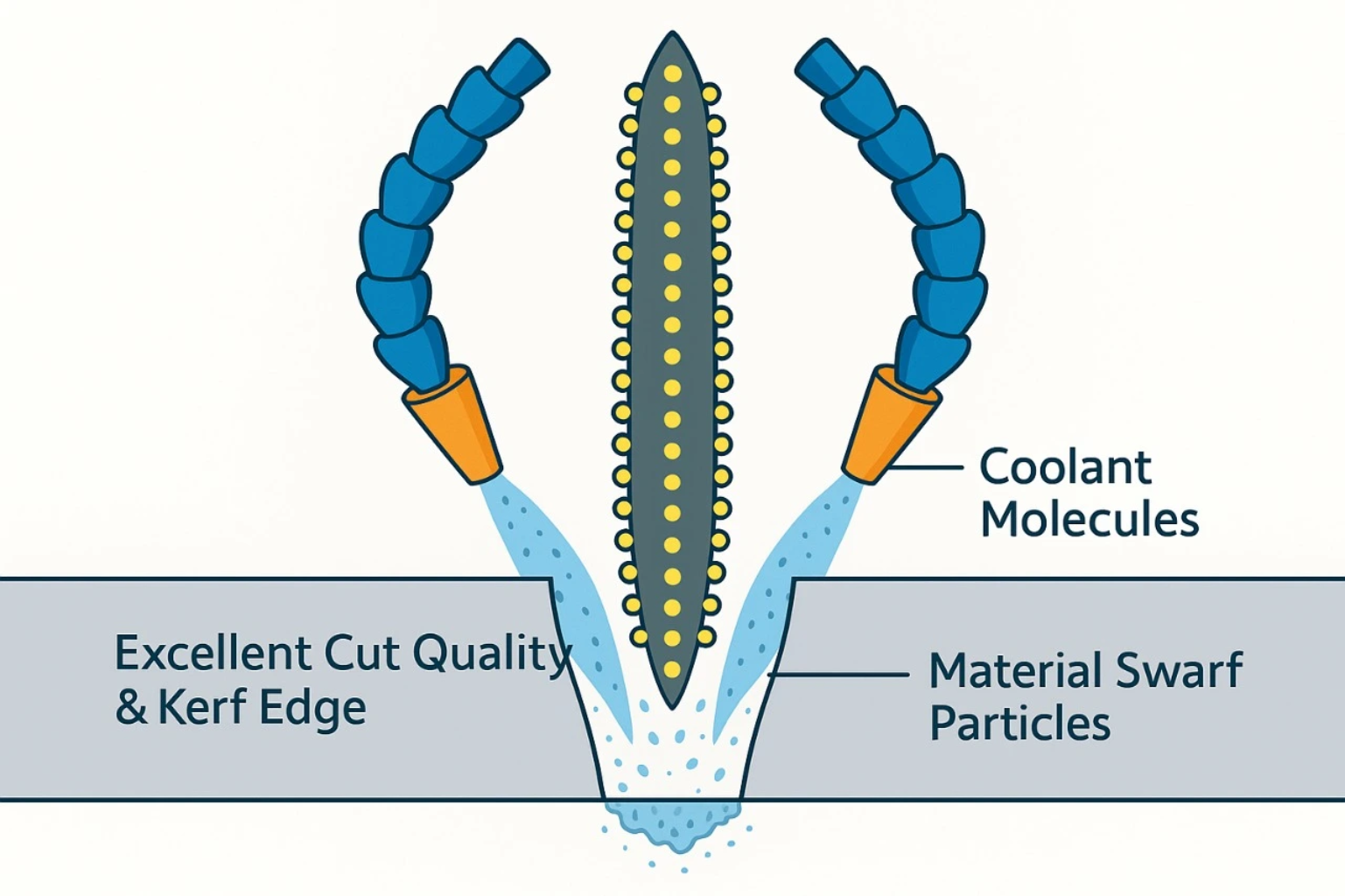

SMART CUT® HD-2B Coolant enhances cutting performance by providing exceptional cooling and lubrication. The coolant's molecules interact with the cutting area, efficiently absorbing heat to prevent overheating. While SMART CUT® HD-2B is not specifically designed to be mixed with water, its advanced formula works effectively in "once-through" systems, where it helps maintain optimal cutting conditions by reducing friction. This results in improved tool life, superior material quality, and smoother cuts. By dissipating heat effectively, SMART CUT® HD-2B minimizes tool wear, improves cut quality, and enables faster, more efficient cutting, all while ensuring a cleaner, more environmentally friendly process.

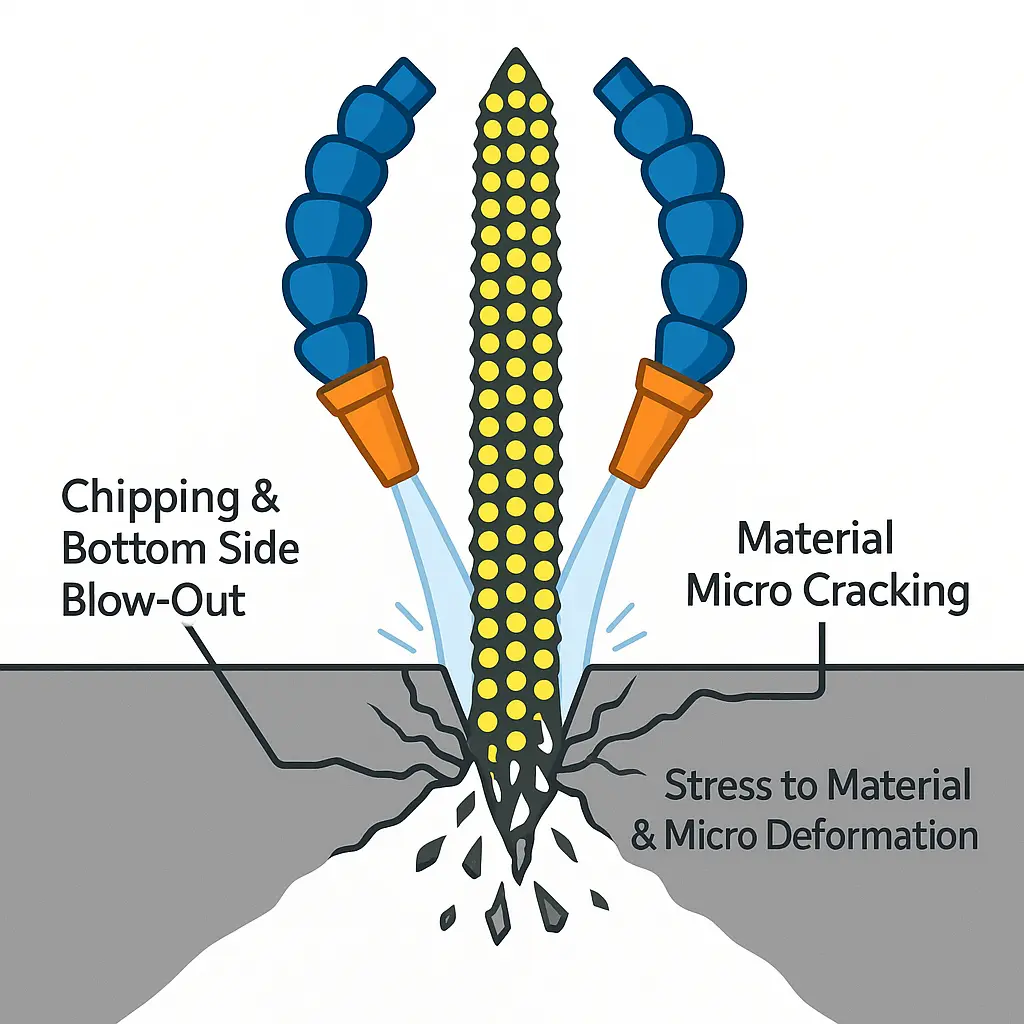

SMART CUT® HD-2B 2B acts as both a coolant and lubricant, effectively reducing heat generated by friction and minimizing surface tension. As a lubricant, it enhances the dispersion of material swarf, ensuring that swarf particles are effectively moved away from the diamond tool and cutting zone, preventing buildup within the kerf. The coolant's advanced formula works by bonding with the cutting area, helping to penetrate the kerf and flush out material debris, preventing chipping and internal cracking. Additionally, because SMART CUT® HD-2B keeps the cutting area clean and free from debris, it minimizes the need for secondary material processing and cleaning operations, enhancing overall efficiency and reducing maintenance requirements.

SMART CUT® Coolant vs Plain Water

SMART CUT® HD-2B Coolant enhances cutting performance by providing exceptional cooling and lubrication. The coolant's molecules interact with the cutting area, efficiently absorbing heat to prevent overheating. While SMART CUT® HD-2B is not specifically designed to be mixed with water, its advanced formula works effectively in "once-through" systems, where it helps maintain optimal cutting conditions by reducing friction. This results in improved tool life, superior material quality, and smoother cuts. By dissipating heat effectively, SMART CUT® HD-2B minimizes tool wear, improves cut quality, and enables faster, more efficient cutting, all while ensuring a cleaner, more environmentally friendly process.

SMART CUT® HD-2B 2B acts as both a coolant and lubricant, effectively reducing heat generated by friction and minimizing surface tension.

SMART CUT® Coolant

Plain water

As a lubricant, it enhances the dispersion of material swarf, ensuring that swarf particles are effectively moved away from the diamond tool and cutting zone, preventing buildup within the kerf. The coolant's advanced formula works by bonding with the cutting area, helping to penetrate the kerf and flush out material debris, preventing chipping and internal cracking. Additionally, because SMART CUT® HD-2B keeps the cutting area clean and free from debris, it minimizes the need for secondary material processing and cleaning operations, enhancing overall efficiency and reducing maintenance requirements.

Related Products

SMART CUT® Diamond Cylindrical Grinding Wheels

SMART CUT® Diamond Cylindrical Grinding Wheels are engineered for the precise peripheral grinding of silicon ingots, making them an ideal choice for industries such as semiconductors, electronics, automotive, and photovoltaics. These high-performance grinding wheels are designed to process the outer surfaces of silicon ingots, ensuring accurate orientation flats are created, which are essential for subsequent processing steps. The addition of the orientation flat, a marked edge indicating the crystallographic plane of the wafer, is crucial for the wafer's alignment in future manufacturing processes.

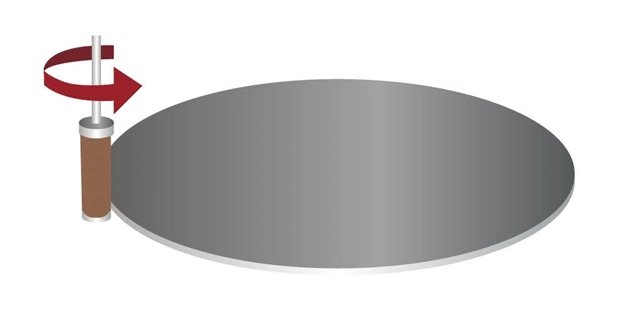

During the post-slicing phase, wafers undergo shaping and smoothing through peripheral grinding.

SMART CUT® Diamond Notch

SMART CUT® Diamond Notch Grinding Wheels in Single & Multi Layered electroplated nickel bond & sintered (metal bond) are construction are developed for high precision notch formation on semiconductor wafers. These wheels support performance requirements for Silicon, Silicon Carbide, Gallium Arsenide, and Sapphire. The electroplated structure holds diamond particles firmly on the surface, producing accurate geometry, clean edges, and stable performance during continuous wafer processing. You receive predictable grinding behavior, long wheel life, and consistent notch dimensions under demanding production conditions.

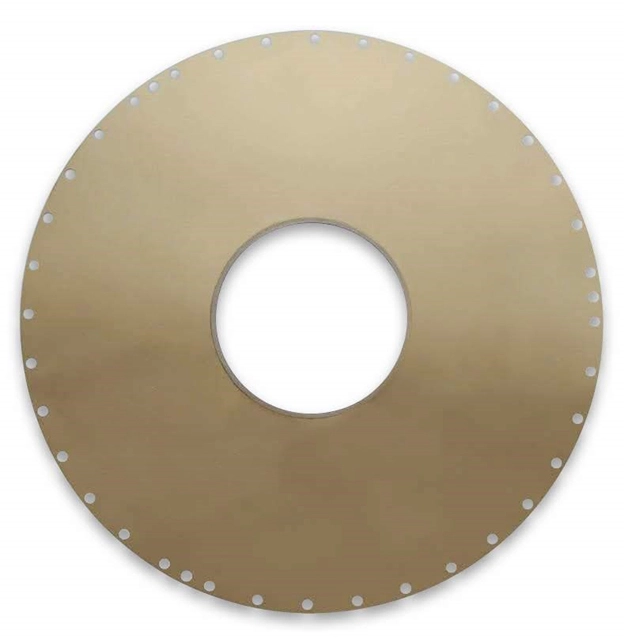

SMART CUT® Diamond Edge Grinding Wheels (Electroplated)

SMART CUT® Diamond Edge Grinding Wheels are engineered to deliver exceptional performance for precision grinding applications, providing superior results in both rough and fine grinding. These wheels are ideal for use in industries that require highly accurate EDM processing and consistent wafer-to-wafer results. Manufactured with synthetic diamond grit, SMART CUT® wheels offer improved surface roughness and extended tool life due to their tightly controlled diamond distribution and uniform bond structure.

Electroplated (Nickel Bond) Diamond Band Saw Blades

SMART CUT® Braised Bond Diamond Band Saw Blades

ID blades

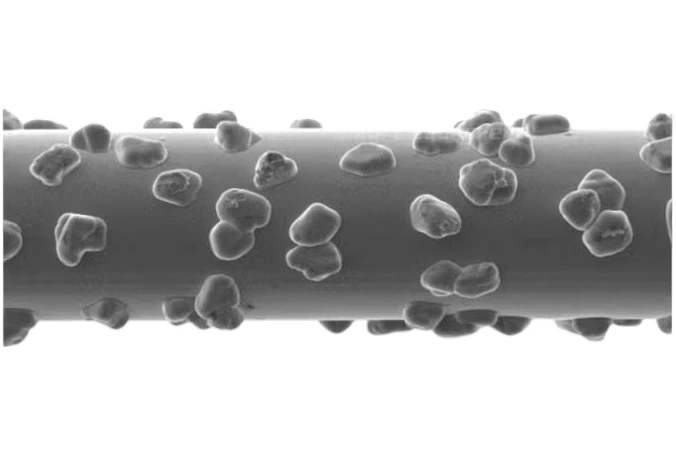

Diamond Wire

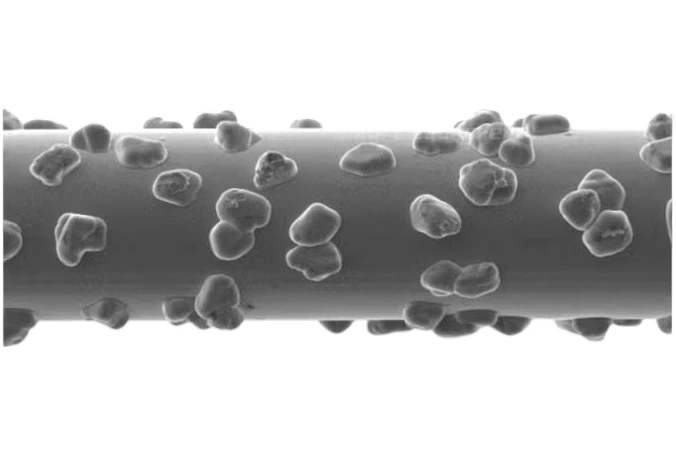

SMART CUT Diamond wire produces minimum kerf loss, less sub-surface damage, and contamination free coolant. Used for precision cutting of various types of artificial crystal, ceramic, quartz glass, monocrystalline silicon, polycrystalline silicon, sapphire and special metal materials. Diamond Wire cutting is an environmentally friendly cutting process as it eliminates slurry recycling and disposal issues.

It is widely used for slicing artificial crystals, ceramics, quartz glass, monocrystalline and polycrystalline silicon, sapphire, and specialty metals. The design provides high dimensional accuracy and smooth surfaces, often eliminating the need for extensive secondary processing.

DIAMOND BACKGRINDING WHEELS

SMART CUT® Diamond Backgrinding Wheels are designed for precision thinning and flattening of silicon wafers, glass, and ceramic substrates. These high-performance wheels are used on backgrinding machines, including models from Disco, Okamoto, Strasbaugh, and other leading manufacturers. Available in sizes ranging from 8” to 14” O.D., they are engineered to handle a wide range of materials and applications, from semiconductor wafers to microelectronic packages.

Recently Viewed Products

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Knowledge Center

02

Nov

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

29

Aug

Selecting the Right Coolant Method for your Diamond & CBN Tools

Coolant is one of the most important factors in CNC machining when using diamond and CBN tools. These tools are made to cut and grind very hard materials, which naturally produces high amounts of friction...

02

Jun

How to Selecting Right Diamond Tools for your application

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

17

May

Choosing The Correct Diamond Bond Type

Selecting the appropriate diamond bond type for specific applications is crucial for several reasons. Diamond bond type directly affects the tool's performance, efficiency, and longevity. Different bond types determine how well a tool can withstand...

03

Jan

How to Properly Use Diamond Tools: A Complete Guide to Performance, Safety, and Tool Life

The use of diamond tools in the manufacturing and precision machining industries, as well as in construction, research, etc., is essential. They are used for a wide range of materials, including sharpening, cutting, grinding, and polishing...