-

0 items in quote

No products in the Quote Basket.

SMART CUT® 1022

CUTTING MACHINE

The SMART CUT® 1022 Precision Composite Plate Saw is built for precise cutting of composite materials for preparation of highly accurate composite test specimens.

The SMART CUT® 1022 features three standard models accommodating for the cutting of up to 2 foot by 2 foot (600mm by 600mm) or 4 foot by 4 foot (1250mm by 1250mm) composite sheets with maximum thickness of 2.16″ (~55 mm). Customized special order units can accommodate greater thickness and are custom designed to fit the application. All units include an easy to use computer based operator interface.

All units include an EZ-TSK (Touch Screen Keypad) for simple user operation.

DESCRIPTION

SPECIFICATIONS

ADVANTAGES

INDUSTRIES USED IN

FAQ

ACCESSORIES

OPERATING MANUALS

DESCRIPTION

Features

The main frame is designed for rigidity and high precision cutting. The stainless steel clad work-chamber is easy to clean. The cutting channel is designed to accommodate small pieces of material and specimens. The system is designed to cut the specified material size cleanly with the blade passing beyond the sheet. The system is designed to fully accommodate the size sheet and can cut up to the full width of the sheet. Larger sheets can be accommodated through a hinged flap. A standard 4” (100mm) port is built in the machine for optional dust or mist extraction operations. Custom tailored versions of the machine are possible.

- Fully enclosed frame

- Slatted work table

- Stainless steel work chamber

- Laser engraved position reference

- Precision fence mechanism for accurate cut

- Easy to use computer based control manual

- Automatic programmable feed

- Variable speed traverse

- Variable speed cutting head

- Recirculation coolant system with filtration

SPECIFICATIONS

High Accuracy Programmable Fence Mechanism

The electronic programmable fence has been designed for precision accuracy over the longest cut lengths. The system is designed to maintain parallelism better than 0.001”/L (0.020mm/L).

- Motorized and programmable allows system to automatically cut multiple specimens without user intervention

- High accuracy design guarantees parallelism

- Pneumatic fence clamps secure the sheet to the fence

Control Module Design

The Labcut® 5000 has an integrated computer control system. The operator interacts with the system via conversational CNC operations. Unlimited part programs and parameter combinations can be stored and recalled for repeat operations. Functions of the system can also be manually controlled.

- Computer controlled

- Easy to use Conversational CNC interface

- Unlimited stored programs

- Digital readout of machine parameters and settings

Safety & Environment

Our machines conform to strict CE European Safety standards meaning they have met EU consumer safety, health and environmental requirements. Safety features include:

- Emergency stop switch positioned for operator safety and machine shut down

- Canopy must be closed with safety interlock engaged in order to operate the machine

- Fully enclosed cutting environment for standard sized composite sheet

- Extraction port to fit optional dust or mist extraction systems

- Cutting carriage protected below table surface

- Wet cutting with recirculation filtration system

ADVANTAGES

INDUSTRIES USED IN

INDUSTRIES USED IN:

- Advanced Ceramics

- Composites

- Glass

- Geology

- Quartz

- Materials Research

- Medical Devices

- Metallography

- Photonics / Optics

- Semiconductor

Ferrous & Non-Ferrous Metals:

- Plain Carbon Steels

- Electronic Packages

- Stainless Steels Plastics

- Tool Steels Fasteners

- Aluminum Refractories

- Copper Base Alloys Integrated Circuits

- Magnesium Thermal Spray Coatings

- Titanium Metal Matrix Composites

- Biomedical Wafers

- Petrographic

- PCB.s Ceramics

FAQ

ACCESSORIES

OPERATING MANUALS

Pneumatic Sheet Clamps

For accurate sectioning the composite sheet needs to be firmly clamped during cutting. For this purpose pneumatic clamps are fitted to the worktable the entire length of the cutting head traverse during the cut. Additionally the sheet is also pneumatically clamped to the programmable precision fence. The clamping surfaces are rubberized for improved clamping of long sheets and reducing the possibility of damage introduced in the clamping process.

The integrated coolant tracking system works in conjunction with the clamps.

Cutting Carriage and Traverse

With the SMART CUT® 1022 Precision Composite Plate Saws the cutting carriage moves accurately along precision linear guides to ensure alignment of the cutting wheel to the material fence for accurate parallel sections.

The cutting carriage is powered by a 3.6Hp (2.7kW) motor. It is fully programmable and can raised or lowered to take account of thickness and depth of cut.

- Programmable Z axis adjustment to accommodate different cutting blades and material thicknesses

- Cutting carriage traverse on precision linear guides ensures accuracy

- Cutting motor power 3.6Hp (2.7kW)

- Programmable cutting wheel speed

- Programmable traverse (feed) rate

- Logical design integrated with coolant application location

- Wheel speed variation 2000-5000 RPM

Smart Cut® Coolants

Your choice of one (1) quart of SMART CUT™ Water Soluble Coolant or Mineral Oil is included with machine. SMART CUT™ Water Soluble Coolant Reduces material thermal stress, edge damage, and internal cracking, increases blade life, provides better cut quality, preserves material micro structure

Hence, assuring long-term integrity of material being sectioned. Since SMART CUT coolant is both a coolant and lubricant, both the wafering blade and material benefit. Mix ratio is 1:20 (1 part coolant, 20 parts water) on very hard and dense materials and 1:40 (1 part coolant, 40 parts water) on softer materials. Depending on mix ratio 1 quart will produce 5.7 to 9 gallons of coolant when mixed with water. As a coolant, SMART CUT KOOL reduces heat caused by friction. As a lubricant, SMART CUT KOOL lowers friction and surface tension, which increases swarf dispersion.

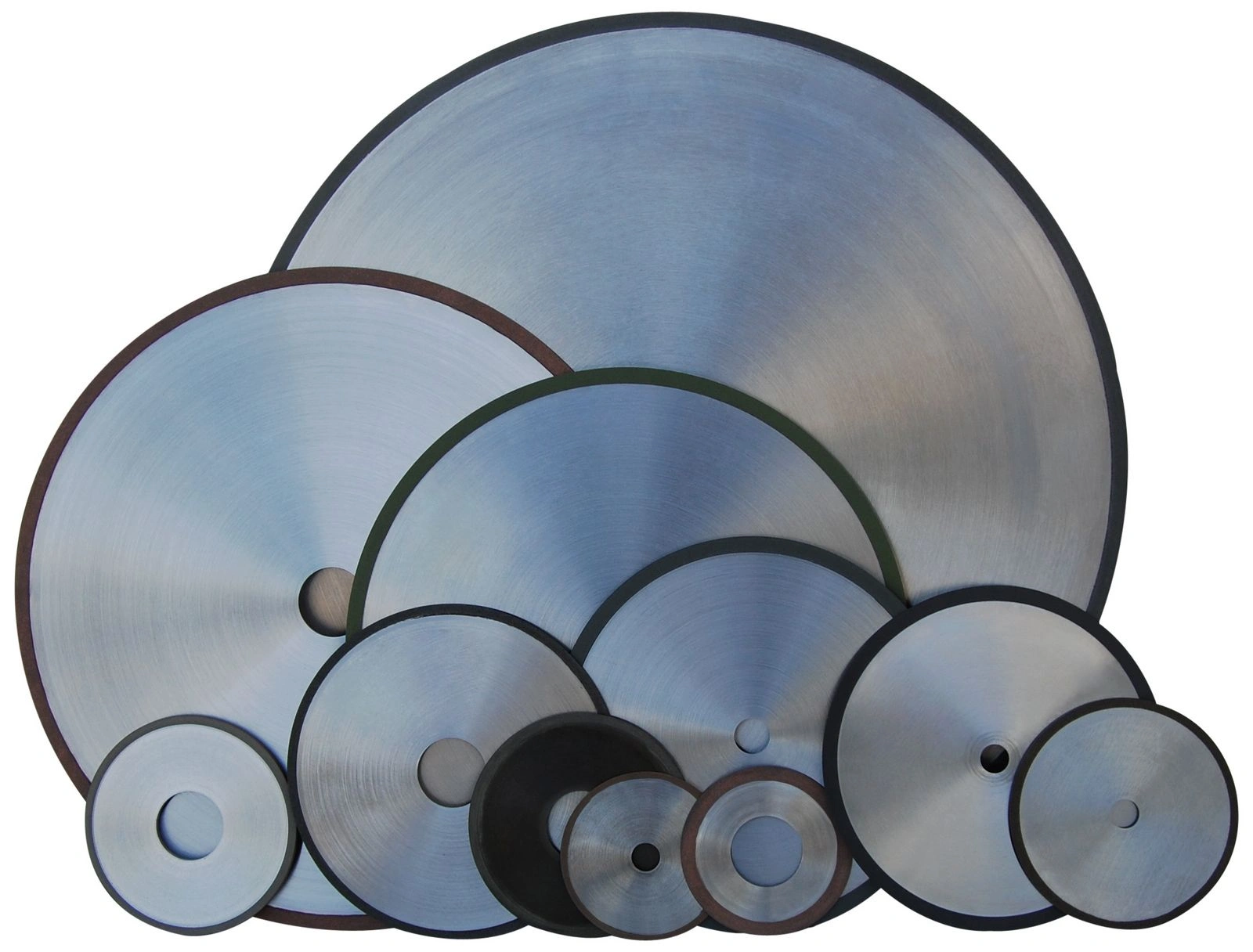

Largest Selecting of Diamond &

Cbn Wafering Blades Avaialble

one (1) diamond wafering blade any specification is included FREE OF CHARGE with purchase of any machine (any specification). we have almost unlimited number of diamond & CBN wafering blade specifications in stock available for immediate delivery. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness’s. With several thousand unique blade specification in stock not listed on our standard stock program. This insures you will receive the best blade specification possible for your specific application.

The Right Dressing Stick for Your Application

One (1) dressing stick is included with the purchase of any machine free of charge. The dressing stick we supply is similar to the diamond size of the wafering blade you have chosen (or we recommended) for your application. Wafering Blades must be diamonds particles/crystals exposed properly through frequent dressing. Otherwise, the diamond tool will glaze over. They will begin to tear rather than grind which is very destructive. Tearing caused from unexposed diamonds creates friction. This causes uneven wear and/or heat cracks in the wafering blade and/or material being cut. Resulting in premature blade wear, blade tensioning problems, and will eventually destroy the blade. The more frequently the blade is dressed the freer and cooler it will cut with lot more consistency.

Related Products

Item # UKAMLS01 SMART CUT® 4005 – Low Speed Saw

Item # UKAMLS02 SMART CUT® 6005 – Low Speed Saw

SMART CUT® 6040 – PRECISION CUTTING SAW

Recently Viewed Products

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

02

Nov

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

29

Aug

Selecting the Right Coolant Method for your Diamond & CBN Tools

Coolant is one of the most important factors in CNC machining when using diamond and CBN tools. These tools are made to cut and grind very hard materials, which naturally produces high amounts of friction...

02

Jun

How to Selecting Right Diamond Tools for your application

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Share this Article with Friend or Colleague

Metal Bonded Diamond Tools are “impregnated” with diamonds. This means that selected...

02

Jun

Why use diamond

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material on micro (nano) level. Due to its hardness Diamond will work all types of materials from...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

17

May

Choosing The Correct Diamond Bond Type

Selecting the appropriate diamond bond type for specific applications is crucial for several reasons. Diamond bond type directly affects the tool's performance, efficiency, and longevity. Different bond types determine how well a tool can withstand...

03

Jan

How to Properly Use Diamond Tools: A Complete Guide to Performance, Safety, and Tool Life

The use of diamond tools in the manufacturing and precision machining industries, as well as in construction, research, etc., is essential. They are used for a wide range of materials, including sharpening, cutting, grinding, and polishing...