-

0 items in quote

No products in the Quote Basket.

Diamond Wire Loops

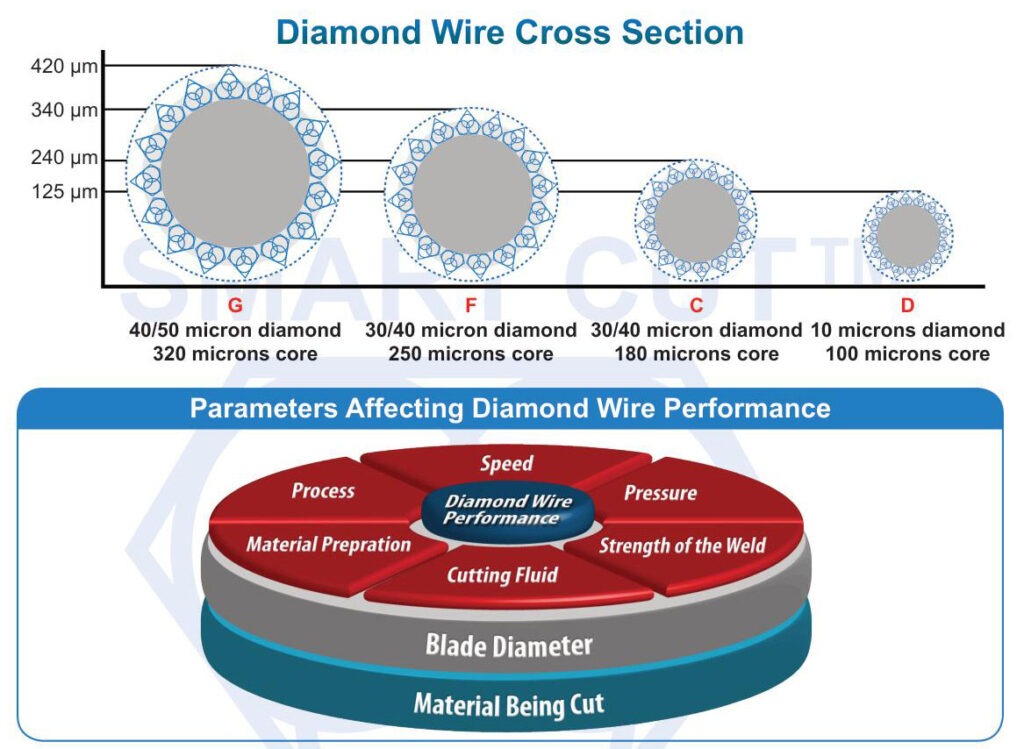

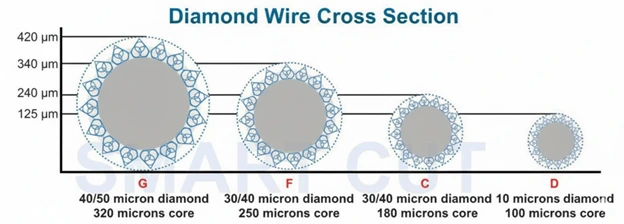

SMART CUT® Diamond Wire Loops are closed-loop precision tools mounted on pulleys and designed for high-accuracy cutting of wafers, optics, and crystals. Unlike spool-based systems, loop wires maintain stable and consistent tension across the entire loop, ensuring repeatable performance, minimal vibration, and extremely clean cuts. This makes them the preferred choice in laboratories, research facilities, and advanced production environments where tolerances are tight and surface quality is critical. They are manufactured with wire diameters ranging from 80 to 350 µm, using core materials such as high-tensile steel, tungsten, molybdenum, and NiTi alloys.

DESCRIPTION

SPECIFICATIONS

FREQUENTLY ASKED QUESTIONS

INDUSTRIES USED IN

ACCESSORIES

USAGE RECOMMENDATION

DESCRIPTION

Diamond grit sizes from 5 to 50 µm and bond options including electroplated nickel, resin, and multi-layer designs allow customization for specific applications. Loop lengths typically range from 600 to 1500 mm, with larger formats available for production. With tensile strengths of 2000 to 4000 MPa and wire speed ranges from 0.5 to 20 m/s, these loops are engineered for both stability and durability. Diamond Wire Loops are widely applied in the semiconductor industry for wafer slicing, in optics and photonics for quartz and sapphire processing, and in research and development environments where consistency is essential. Their closed-loop design ensures a long service life through even wear, the ability to achieve ultra-thin kerf widths as small as 10–25 µm, and extremely stable cutting with minimal vibration. Variations include continuous diamond wire for uniform cutting and smooth surfaces, segmented diamond wire with gaps for chip clearance and reduced cutting temperature, and multi-layer or spiral-coated diamond wire that balances speed, finish, and tool life. Together these configurations make Diamond Wire Loops one of the most precise and versatile solutions available for advanced material processing.

SPECIFICATIONS

Wire Diameter: 80–350 µm

Core Material: High-tensile steel, tungsten, molybdenum, NiTi alloys

Diamond Grit Size: 5–50 µm

Bond Type: Electroplated (nickel)

Loop Length: 600–1500 mm (larger available for production)

Tensile Strength: 2000–4000 MPa

Wire Speed Range: 0.5–20 m/s

FREQUENTLY ASKED QUESTIONS

Tab Content

INDUSTRIES USED IN

Tab Content

ACCESSORIES

Tab Content

USAGE RECOMMENDATION

Tab Content

Advantages

- Long service life due to even wear

- High stability, minimal vibration

- Improve Return on Investment - less initial capital required

- Preferred in laboratory and production environments requiring repeatability

Applications

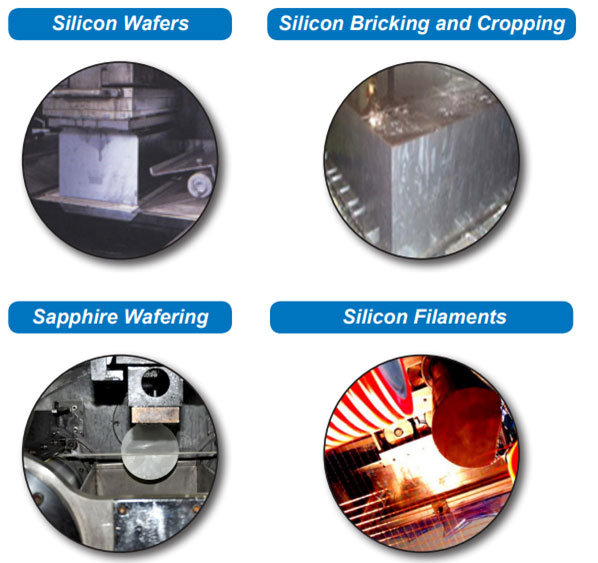

- Semiconductor wafers

- Sapphire

- Quartz

- Advanced Optics

- R&D

Continuous Diamond Wire

SMART CUT® Continuous diamond wire is manufactured by coating the entire length of the wire with diamond abrasives, leaving no gaps or uncoated areas. This uninterrupted design ensures that every portion of the wire contributes to the cutting process, which results in uniform engagement between the abrasive and the material. The continuous contact reduces fluctuations in cutting pressure, leading to a stable process with predictable results.

Because the cutting edge is always in contact with the workpiece, continuous diamond wire is known for producing exceptionally smooth surfaces and narrow kerf widths. This reduces material waste, increases yield, and minimizes the need for secondary finishing steps such as grinding or polishing. In delicate materials such as semiconductor wafers, sapphire, quartz, and advanced ceramics, continuous wire helps avoid micro-cracks, thermal stress, and subsurface damage that could compromise part performance.

Another advantage is its compatibility with precision cutting machines that operate at controlled speeds and feed rates. Continuous wires are less prone to vibration compared to segmented wires, which translates into greater accuracy and longer tool life when used under proper operating conditions. This makes them the preferred choice in industries where tight tolerances, repeatability, and surface quality are critical, such as microelectronics, photonics, and optics.

However, continuous wires do have trade-offs. Because the diamond abrasive layer covers the entire wire, chip clearance and coolant flow can be more limited compared to segmented designs. This means operators must use optimized coolant delivery systems and controlled feed rates to avoid clogging and maintain efficient cutting. For large block cutting or highly abrasive materials, continuous wire may not be as efficient as segmented wire, but for precision applications, it remains the industry standard.

Advantages:

- Uniform cutting action

- Consistent engagement

- Exceptionally smooth surfaces and narrow kerf widths

- Minimized need for secondary finishing

- Lower risk of micro-cracks, thermal stress, and subsurface damage

- Less prone to vibration

- Compatible with precision cutting

- Preferred choice in industries requiring tight tolerances, repeatability, and surface quality

Segmented Diamond Wire

SMART CUT® Segmented (interval-coated) diamond wire is engineered with abrasive zones separated by uncoated intervals. The purpose of this design is to give the wire built-in chip clearance pockets, which allow cutting debris, slurry, and coolant to circulate freely around the wire. This reduces the chance of clogging, lowers the cutting temperature, and keeps the diamonds exposed for longer periods. The result is a wire that can maintain performance even when cutting materials that tend to load or generate heavy swarf.

This configuration is especially valuable in semiconductor ingot slicing, advanced ceramics, composites, and other high-density or abrasive materials. In these cases, a fully coated wire might overheat or glaze because there is no room for the debris to escape. By spacing out the abrasive zones, segmented wire maintains cutting efficiency without the same risk of overheating.

The trade-off is that segmented wire does not always achieve the ultra-smooth surfaces or the finest kerf control that continuous wire can provide. Instead, it prioritizes cooler operation, stable cutting speeds, and longer effective wire life. For example, in silicon or SiC ingot processing, segmented wire allows higher throughput while still producing wafers with acceptable surface quality for subsequent polishing. In ceramic and composite processing, it minimizes breakage and extends tool life compared to fully coated wires.

It is important to distinguish segmented (interval-coated) wire from beaded diamond wire used in stone cutting. Beaded wire is built with discrete diamond-impregnated beads strung on a steel cable, intended for quarrying or cutting massive stone blocks. In contrast, interval-coated segmented wire is a precision cutting tool developed for electronics, optics, and advanced materials, where the focus is on controlled chip evacuation and improved reliability rather than rough shaping.

When applied with proper tension, coolant delivery, and feed rates, segmented diamond wire provides a strong balance of cutting efficiency, durability, and cost-effectiveness, particularly in industries where productivity and throughput are as important as precision.

Advantages:

- Built-in chip clearance pockets

- Reduced risk of clogging

- Lower cutting temperature

- Extended exposure of diamonds

- Stable cutting speeds

- Higher throughput

- Minimized breakage

- Longer effective wire life

- Cost-effective solution

Multi-Layer or Spiral-Coated Diamond Wire

SMART CUT® Multi-layer or spiral-coated diamond wire is designed to combine the benefits of speed, surface finish, and tool life. Instead of relying on a single uniform coating, these wires are built with several layers of diamond abrasive or a spiral arrangement along the wire’s length. This design places more cutting points in contact with the material, which improves efficiency while keeping the cutting action stable. The spiral spacing also creates natural channels for debris and coolant evacuation, reducing the chance of clogging and helping the wire stay cooler during operation.

Because multiple layers of abrasive are present, new cutting edges are exposed as the outer diamonds wear away. This extends tool life beyond what is possible with single-layer electroplated wires. At the same time, the wire maintains a sharper and more consistent cutting action than resin bond wires, which typically cut more slowly. The result is a balanced performance, offering faster cutting than resin systems and smoother surfaces than aggressive electroplated wires.

These qualities make multi-layer or spiral-coated wires well suited for mid-range applications where both throughput and surface quality are important. They are widely applied in photovoltaic silicon wafer slicing, advanced ceramics, composites, and specialty glasses. In these areas, they provide reliable performance without sacrificing finish quality or generating excessive heat. They are also valued in research and prototyping, where one versatile wire may be required to handle different materials efficiently.

The main limitation of spiral-coated wires is that they are not optimized for extremes. Electroplated wires remain superior for maximum cutting speed, while resin bond wires are better for ultra-delicate substrates where minimizing chipping and microcracking is critical. Cost can also be a factor, since producing spiral or multi-layer wires is more complex. Even so, for many industrial users, the balance of speed, finish, and longevity makes them a cost-effective solution for demanding but versatile cutting requirements.

Advantages:

- Multiple cutting points in contact

- Natural channels for debris and coolant evacuation,

- Extended tool life

- Sharper and more consistent cutting action

- Balanced performance

- Reliable results in mid-range applications

- Versatile across materials

- Valued in research and prototyping,

Hybrid Diamond Wire

Hybrid diamond wires are designed to combine the strengths of multiple abrasive configurations into a single tool. Instead of relying on one coating strategy, these wires may use a mix of continuous and segmented zones or even integrate different bond types such as electroplated, resin, or multi-layer coatings. This allows the wire to deliver greater versatility and adapt to a wider range of cutting conditions without frequent tool changes.

A major benefit of hybrid wires is their ability to cut mixed-material assemblies or multi-layered components. In these situations, a continuous section of the wire ensures smooth surfaces and precise dimensional accuracy, while the segmented or spiral-coated zones promote better debris evacuation and cooler operation. This balance makes them suitable for applications such as advanced composites, ceramic–glass hybrids, and semiconductor devices where both speed and surface integrity matter.

Hybrid configurations also perform well when cutting parameters vary. They can tolerate changes in feed rate, wire tension, and coolant flow better than single-purpose wires, which reduces downtime and provides consistent performance. This stability is highly valued in industries such as aerospace, photonics, and microelectronics, where small variations in cut quality can lead to expensive rework or rejected parts.

Why Use Diamond Wire

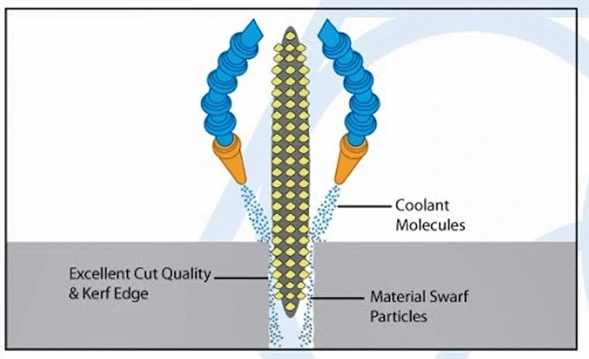

Diamond wire is used because it offers a highly controlled and efficient method of cutting hard and brittle materials while maintaining accuracy and surface integrity. Unlike traditional cutting tools, diamond wire distributes force evenly along its length, which reduces stress, vibration, and heat on the material.

This makes it possible to achieve thin kerf widths, often less than 25 microns, and produce smooth surfaces with minimal chipping or microcracking. The process generates very little heat, typically less than a 10°F rise, which prevents thermal damage, warping, or subsurface fractures in sensitive materials such as semiconductors, sapphire, quartz, and ceramics. Diamond wire is also versatile, capable of cutting both delicate samples and large blocks, depending on the wire type and machine configuration.

It reduces material waste, often eliminates the need for secondary finishing, and offers longer tool life with the proper bond selection, making it a cost-effective and reliable choice for industries that demand precision, repeatability, and clean cutting results.

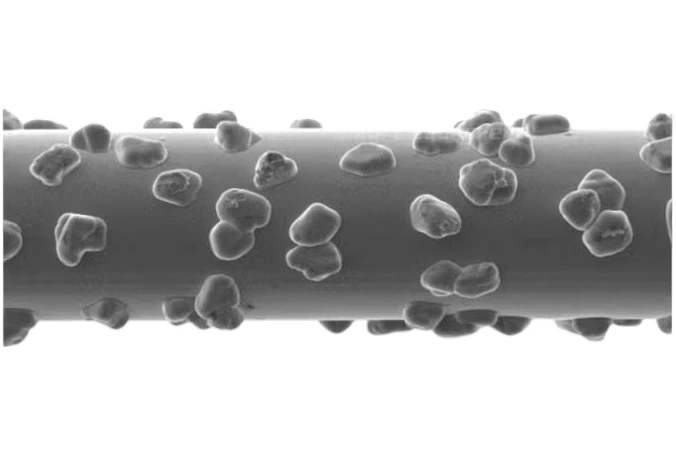

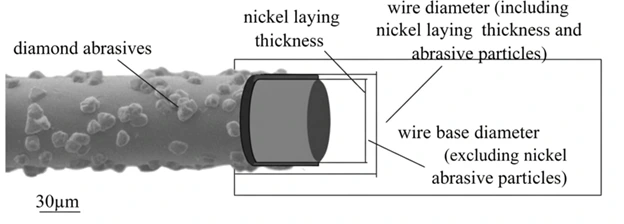

Electroplated Diamond Wire

Electroplated diamond wire is made with a single layer of diamond particles bonded with nickel plating, providing very sharp cutting edges, aggressive performance, and high throughput. It is widely used for semiconductor wafers, sapphire, optical crystals, and glass substrates, where speed and precision are essential. The design ensures consistent sharpness and fast material removal

Advantages:

- Provides the fastest cutting speeds

- Consistent sharpness throughout its short life cycle

- Ideal for high-volume wafer slicing and precision industries

- Excellent for materials that require aggressive, efficient cutting

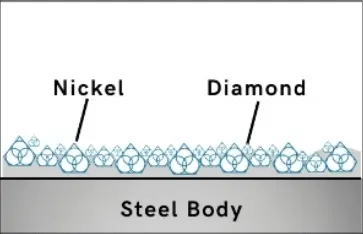

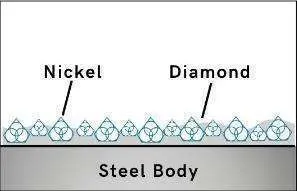

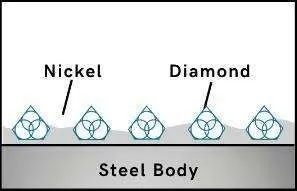

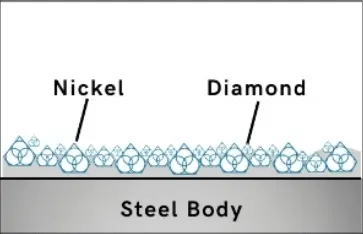

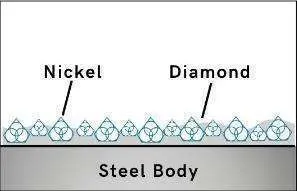

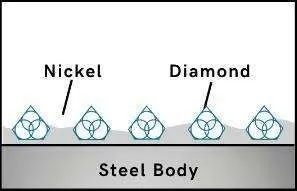

About Nickel Bond (Electroplated) Tools

Electroplated (nickel bond) diamond products usually have a single layer of diamonds, held by a tough durable nickel alloy. Nickel is frequently used as a base for plating diamond. Because of its excellent strength, toughness and flexibility during the plating process. Electroplated diamond products are able to retain their original shape and dimensions thought their working life. Unlike sintered (meal bond) or resin bond diamond products, where diamond particles are buried in bond and held together by metal or resin binder deep inside. Electroplating allows diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.

How SMART CUT ® Bond Works?

Step 1

Sharpest And Finest Quality Diamonds

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Bond Diamond Bond makes sure every diamond is in the right place. and at the right time, working where you need it most.

Step 2

Diamonds or CBN Crystals

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Step 3

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast

cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

How SMART CUT ® Bond Works?

Step 1

Sharpest And Finest Quality Diamonds

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Bond Diamond Bond makes sure every diamond is in the right place. and at the right time, working where you need it most.

Step 2

Diamonds or CBN Crystals

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Step 3

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast

cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

SMART CUT® HD-2B

Synthetic Low IFT Coolant / Lubricant for Wire Saws

SMART CUT® is a synthetic coolant specifically designed for the cutting of semiconductor materials, including sapphire, silicon, germanium, single-crystal SiC, and II-VI crystals. This coolant offers excellent cut rates and imparts outstanding surface finishes with reduced warp and total thickness variation (TTV). It is ideal for diamond abrasive cropping, squaring, and wafering of silicon ingots using ID, band, and wire saws. SMART CUT® HD-2B can also be used as a non-re-circulating edge grinding coolant or lubricant for silicon wafers and ingots.

SMART CUT® HD-2B Coolant enhances cutting performance by providing exceptional cooling and lubrication. The coolant's molecules interact with the cutting area, efficiently absorbing heat to prevent overheating.

While SMART CUT® HD-2B is not specifically designed to be mixed with water, its advanced formula works effectively in "once-through" systems, where it helps maintain optimal cutting conditions by reducing friction. This results in improved tool life, superior material quality, and smoother cuts. By dissipating heat effectively, SMART CUT® HD-2B minimizes tool wear, improves cut quality, and enables faster, more efficient cutting, all while ensuring a cleaner, more environmentally friendly process.

SMART CUT® HD-2B 2B acts as both a coolant and lubricant, effectively reducing heat generated by friction and minimizing surface tension. As a lubricant, it enhances the dispersion of material swarf, ensuring that swarf particles are effectively moved away from the diamond tool and cutting zone, preventing buildup within the kerf. The coolant's advanced formula works by bonding with the cutting area, helping to penetrate the kerf and flush out material debris, preventing chipping and internal cracking. Additionally, because SMART CUT® HD-2B keeps the cutting area clean and free from debris, it minimizes the need for secondary material processing and cleaning operations, enhancing overall efficiency and reducing maintenance requirements.

Related Products

SMART CUT® Diamond Cylindrical Grinding Wheels

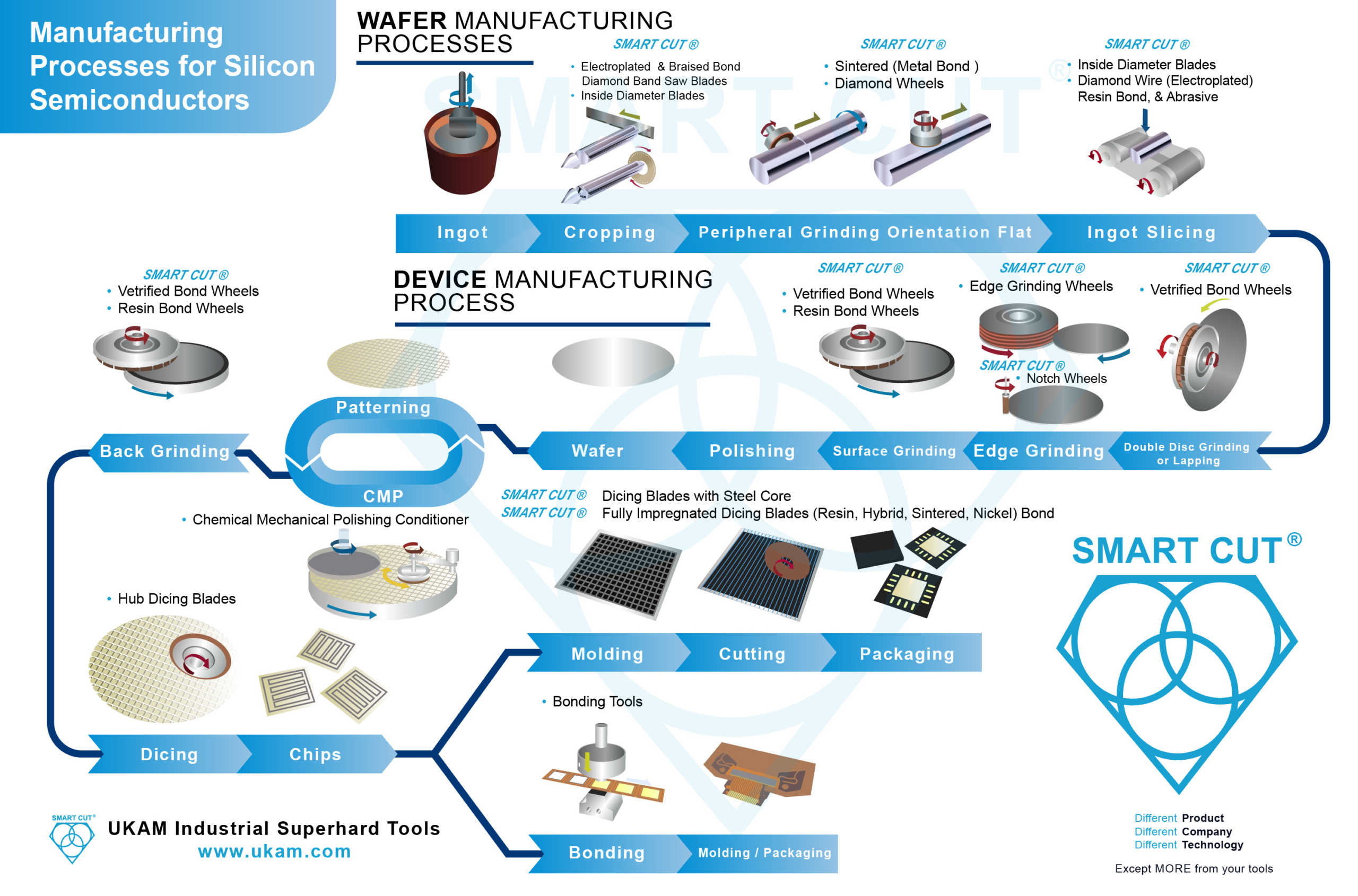

SMART CUT® Diamond Cylindrical Grinding Wheels are engineered for the precise peripheral grinding of silicon ingots, making them an ideal choice for industries such as semiconductors, electronics, automotive, and photovoltaics. These high-performance grinding wheels are designed to process the outer surfaces of silicon ingots, ensuring accurate orientation flats are created, which are essential for subsequent processing steps. The addition of the orientation flat, a marked edge indicating the crystallographic plane of the wafer, is crucial for the wafer's alignment in future manufacturing processes.

During the post-slicing phase, wafers undergo shaping and smoothing through peripheral grinding.

SMART CUT® Diamond Notch

SMART CUT® Diamond Notch Grinding Wheels in Single & Multi Layered electroplated nickel bond & sintered (metal bond) are construction are developed for high precision notch formation on semiconductor wafers. These wheels support performance requirements for Silicon, Silicon Carbide, Gallium Arsenide, and Sapphire. The electroplated structure holds diamond particles firmly on the surface, producing accurate geometry, clean edges, and stable performance during continuous wafer processing. You receive predictable grinding behavior, long wheel life, and consistent notch dimensions under demanding production conditions.

SMART CUT® Diamond Edge Grinding Wheels (Electroplated)

SMART CUT® Diamond Edge Grinding Wheels are engineered to deliver exceptional performance for precision grinding applications, providing superior results in both rough and fine grinding. These wheels are ideal for use in industries that require highly accurate EDM processing and consistent wafer-to-wafer results. Manufactured with synthetic diamond grit, SMART CUT® wheels offer improved surface roughness and extended tool life due to their tightly controlled diamond distribution and uniform bond structure.

Electroplated (Nickel Bond) Diamond Band Saw Blades

SMART CUT® Braised Bond Diamond Band Saw Blades

ID blades

SMART CUT® HD Synthetic Low IFT Coolant/Lubricant For Diamond Wire Sawing Silicon

SMART CUT® is a synthetic coolant specifically designed for the cutting of semiconductor materials, including sapphire, silicon, germanium, single-crystal SiC, and II-VI crystals. This coolant offers excellent cut rates and imparts outstanding surface finishes with reduced warp and total thickness variation (TTV). It is ideal for diamond abrasive cropping, squaring, and wafering of silicon ingots using ID, band, and wire saws. SMART CUT® HD-2B can also be used as a non-re-circulating edge grinding coolant or lubricant for silicon wafers and ingots.

DIAMOND BACKGRINDING WHEELS

SMART CUT® Diamond Backgrinding Wheels are designed for precision thinning and flattening of silicon wafers, glass, and ceramic substrates. These high-performance wheels are used on backgrinding machines, including models from Disco, Okamoto, Strasbaugh, and other leading manufacturers. Available in sizes ranging from 8” to 14” O.D., they are engineered to handle a wide range of materials and applications, from semiconductor wafers to microelectronic packages.

Recently Viewed Products

ARE YOU USING DIAMOND WIRE

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR DIAMOND WIRE?

Knowledge Center

08

Jul

Share this Article with Friend or Colleague

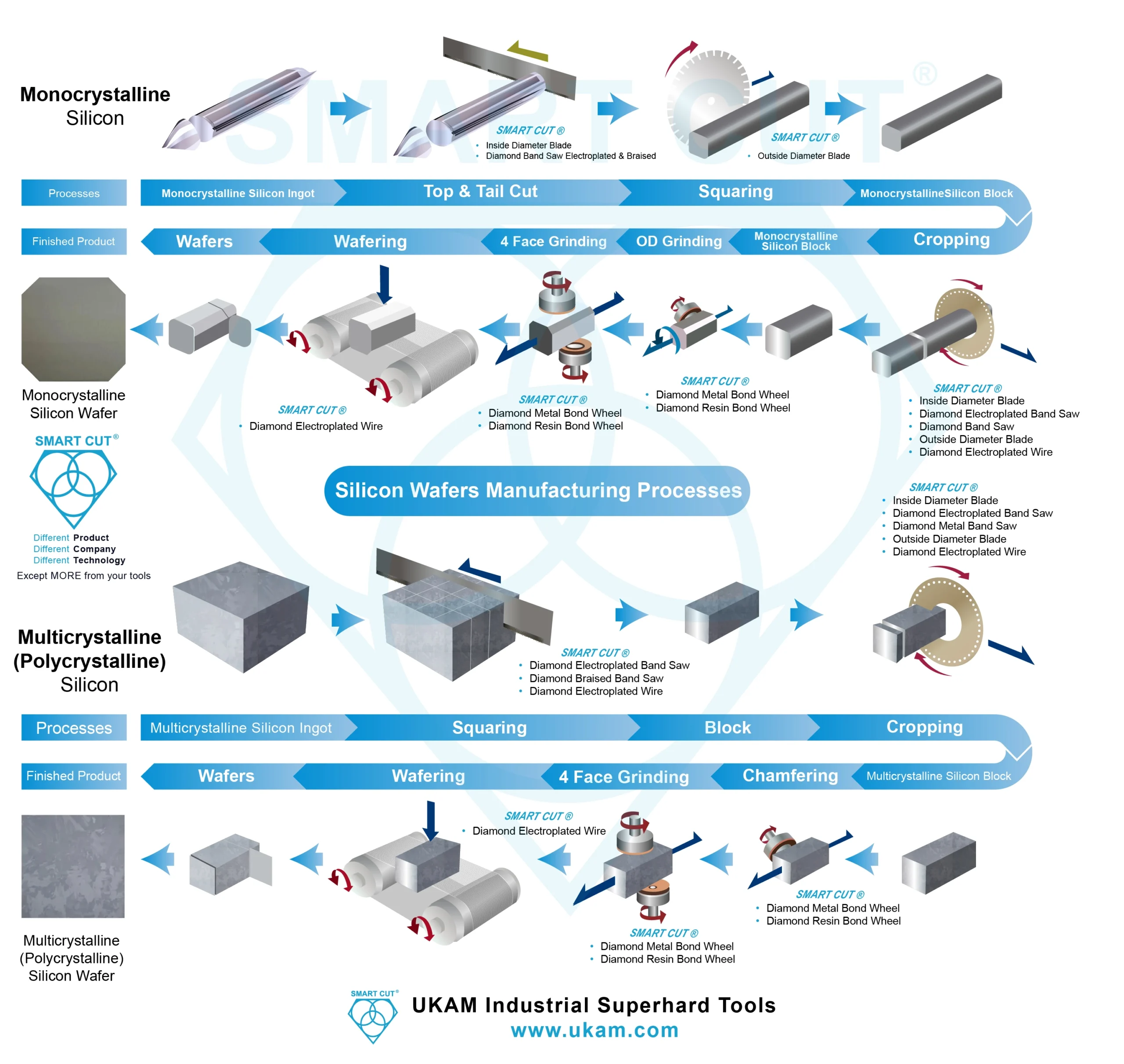

1. Ingot Production

The journey begins with the creation of silicon ingots, which are pure silicon cylinders produced through methods like the Czochralski process. Once formed, these ingots undergo a...

08

Jul

The Comprehensive Guide to the Processes of Silicon Wafers Production

Share this Article with Friend or Colleague

The production of silicon wafers, an essential component in semiconductor manufacturing, involves several intricate steps to ensure precision and quality. This article explores the detailed processes depicted in...

04

Aug

Diamond Wire vs band saw blades and circular blades

Diamond wire, band saw blades, and circular blades are all cutting tools used in various industries for different purposes. Each tool has its advantages and applications

For cutting ultra hard...

02

Jun

Comparing Two Different Cutting Methods (Low Speed Saw vs. Wire Saw)

Share this Article with Friend or Colleague

For metallography, sample preparation, materials research and working with large variety of materials, selecting the optimal cutting technology is crucial for achieving high-quality results across various materials and...

02

Nov

Guide to Diamond Wire Sawing: Technologies, Wire Types, and Machine Designs

Share this Article with Friend or Colleague

Diamond wire saws provide one of the most precise and reliable methods for sectioning both hard and fragile materials. The principle behind the process is simple yet highly...