How to select Right Diamond Tool for your Application

SELECTING THE RIGHT DIAMOND TOOL FOR YOUR APPLICATION

Guide for Selecting Diamond Tools

In order to help you select the right diamond tool for your application, our staff may ask you many questions about the material you wish to machine. These questions will specifically focus on:

-

Material being machined

Material being machined

-

How you plan to machine it

How you plan to machine it

-

Equipment you will be using

Equipment you will be using

-

RPM of that machine

RPM of that machine

-

Coolants used

Coolants used

-

Flange size or Accessories Being Used

Flange size or Accessories Being Used

5 Step Process Selecting Right Diamond Tools for your Application

You may wonder why we need to know this information? Each diamond tool is designed specifically for each application, and hence may react differently under different conditions. What worked for one application, may not work for another.

Key Variables in Diamond Tool Performance

Use the right diamond tool for your application

Provide as much information possible about your application and material being machined. We can help you better define your needs, so you can obtain the right tool for the job. Saving money and time.

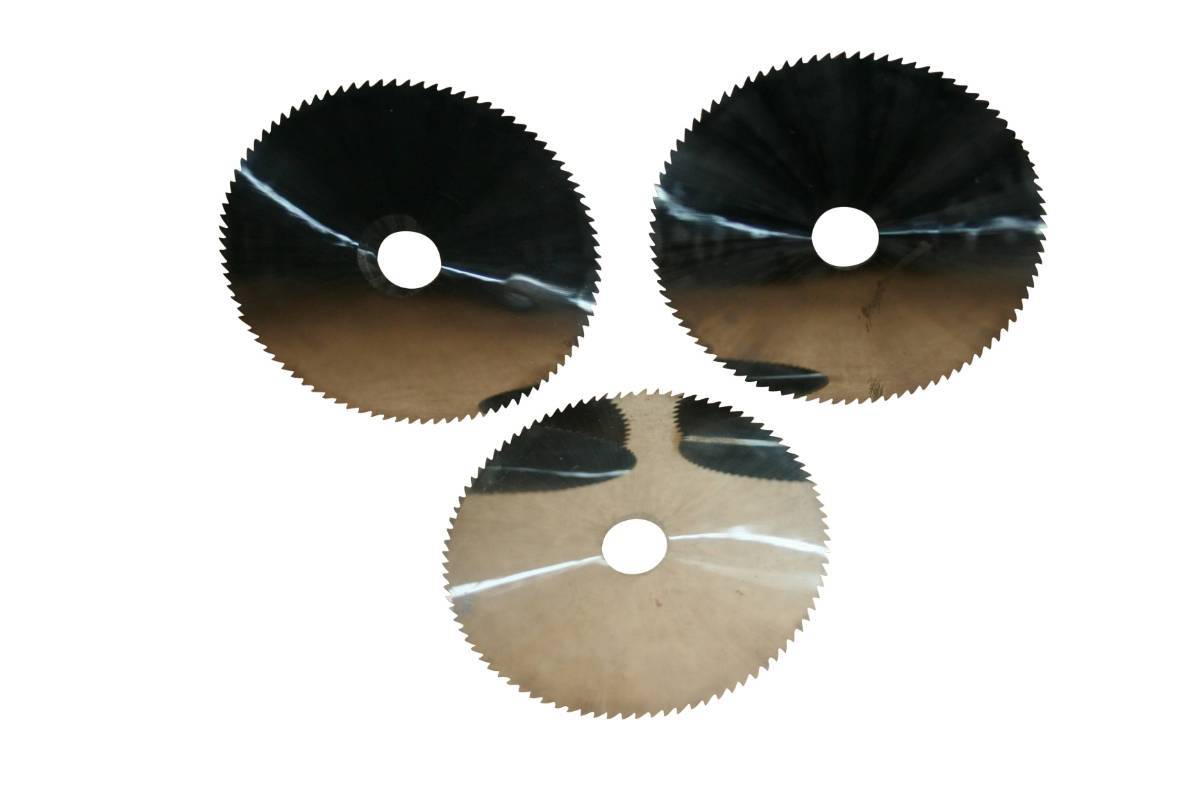

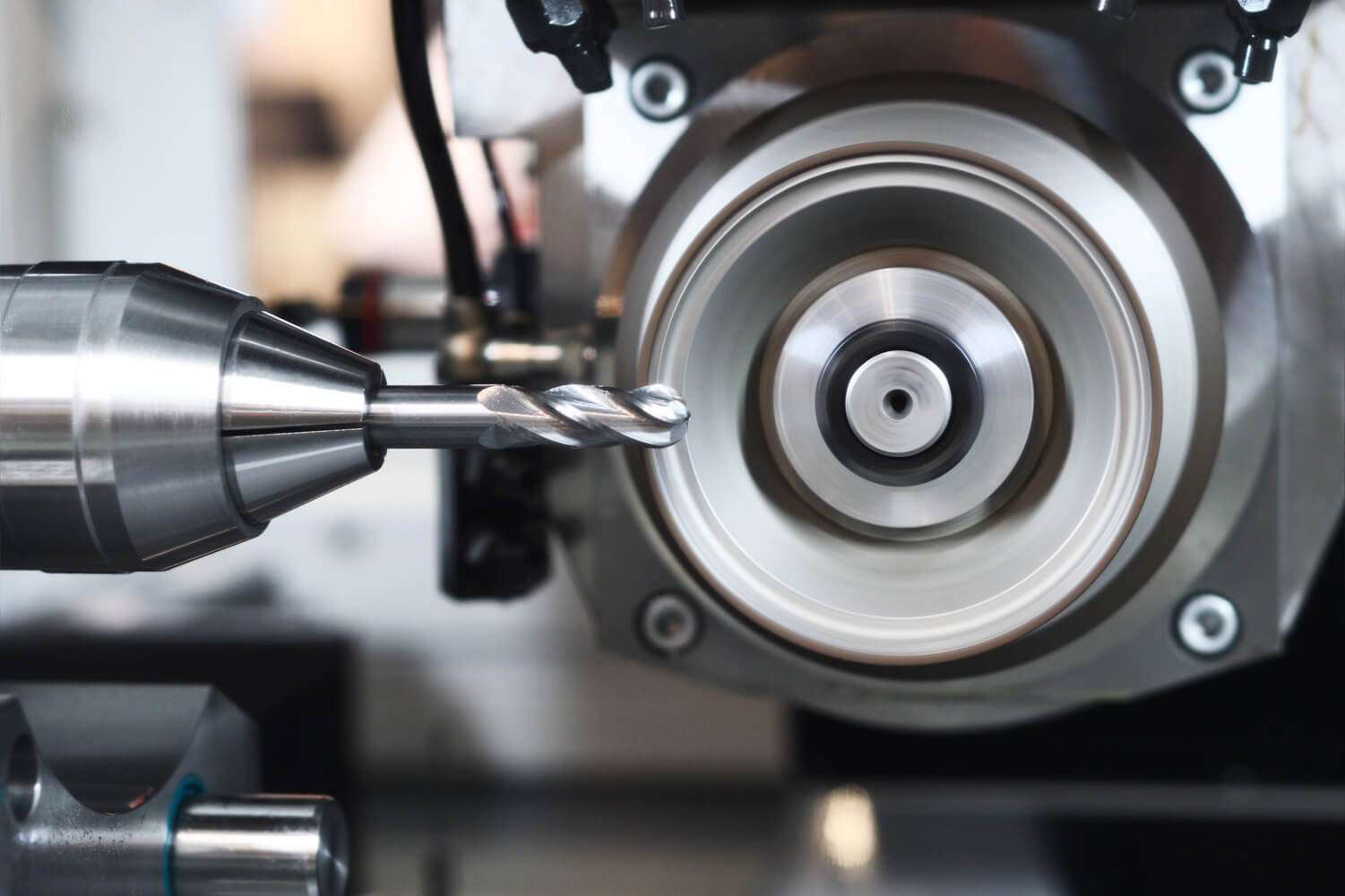

Precision Cutting Saws For Tubes & Rods

Using The Right RPM'S

One of the most critical factors in successful diamond tool usage is the right RPM's. If the diamond tool rotates to slow, it drags and creates heat. If it spins to fast, it causes friction and again generates heat. Possibly damaging your tool. Heat is the worst enemy for a diamond tool. Selecting the right RPM becomes a critical factor of success. Unfortunately, this can also be the most difficult aspect of your operation to correct. Diamond tools frequently require RPM's from 100 to 23,000. Charts provided in this manual will help you identify and select the right RPM's for your diamond tools. As well as provide suggestions on ways you can achieve it.

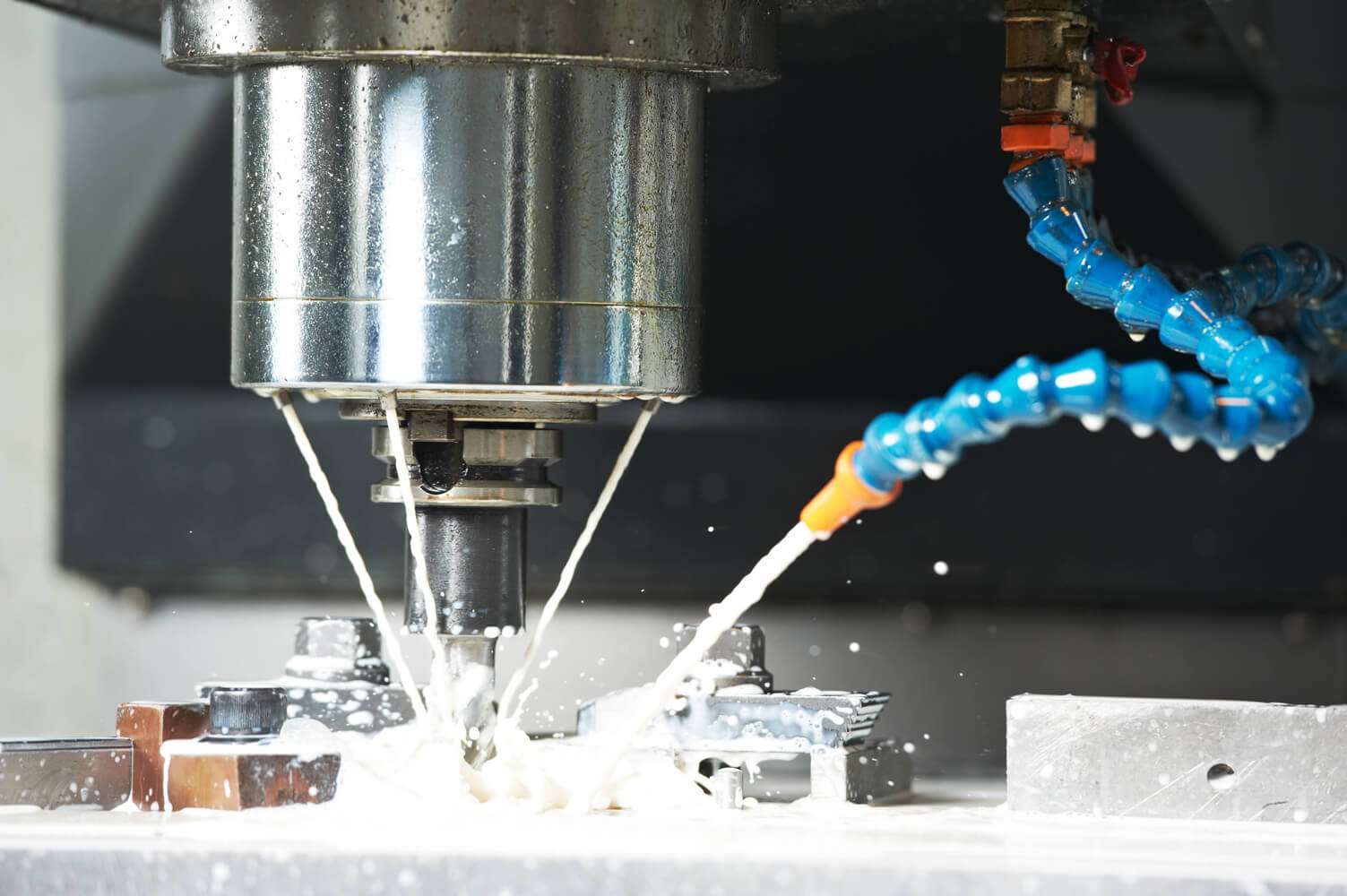

Using Right Coolant at Point of Contact

Depending on your application, there is a large variety of coolants you can select. Ranging from plain water, to water soluble coolants, to minerals and oils. Your specific application will be a determining factor in selecting a coolant. Not matter what coolant you decide to use, make sure it is used at the point of contact where material and tool intersect.

Properly Dressing Your Tools

Diamond tools must be both trued to and dressed on the machine on which it will be used. When your diamond tool is new, it should be dressed thoroughly by the operator. Never assume because the tool is new, that it does not require this operation. Using the correct, soft dressing stick, it is recommended that the tool is passed through the tick five to ten passes to expose the diamonds for optimum cutting performance.

Using Right Accessories

When cutting, use the right size flanges or wheel stiffener sets with all thin diamond blades to firmly hold it in place. This will help prevent the blade from "walking". Use Drill Head Assemblies (water swivel adapters) with core drills to provide coolant (water) through the center of the drill and on to drilling zone.

Operator Experience & Training

Many end users approach their diamond machining application uninformed of misled. Errors are made in the set up phase and critical steps are skipped. When problems do surface, most rush to treat a symptom rather than the cause. When encountering problems or variation in tool performance. Few stop to think about or carefully examine their process. Frustration leads them attribute their problems to diamond tool being used. what some clients some refer to as serious problem for example, may be resolved by following one of the principals above.

Operator

The operator of the machinery can either make or break the performance of the diamond tool. This is true whether the operation is manual or automatic. Some operators have the aptitude and experience to make almost any diamond tool perform to its optimum level of efficiency, while others may struggle and achieve only marginal results. Many end users approach their application uniformed or misled. Errors are made in the set up phase and critical steps are skipped. When problems do surface, most rush to treat a symptom rather than the cause, When encountering problems or variations in tool performance, few stop to think about or carefully examine their process. Frustration leas them to attribute their problems to diamond tool being used. What some clients refer to as serious problem for example, may be resolved in a simple step.

Find out more >>> (see our Trouble Shooting Guide on how to spot possible diamond tool issues, tips on resolving them, and suggestions on how to prevent these from happening in the first place)

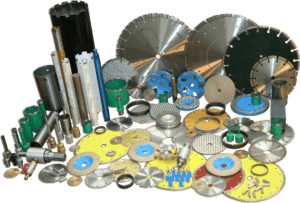

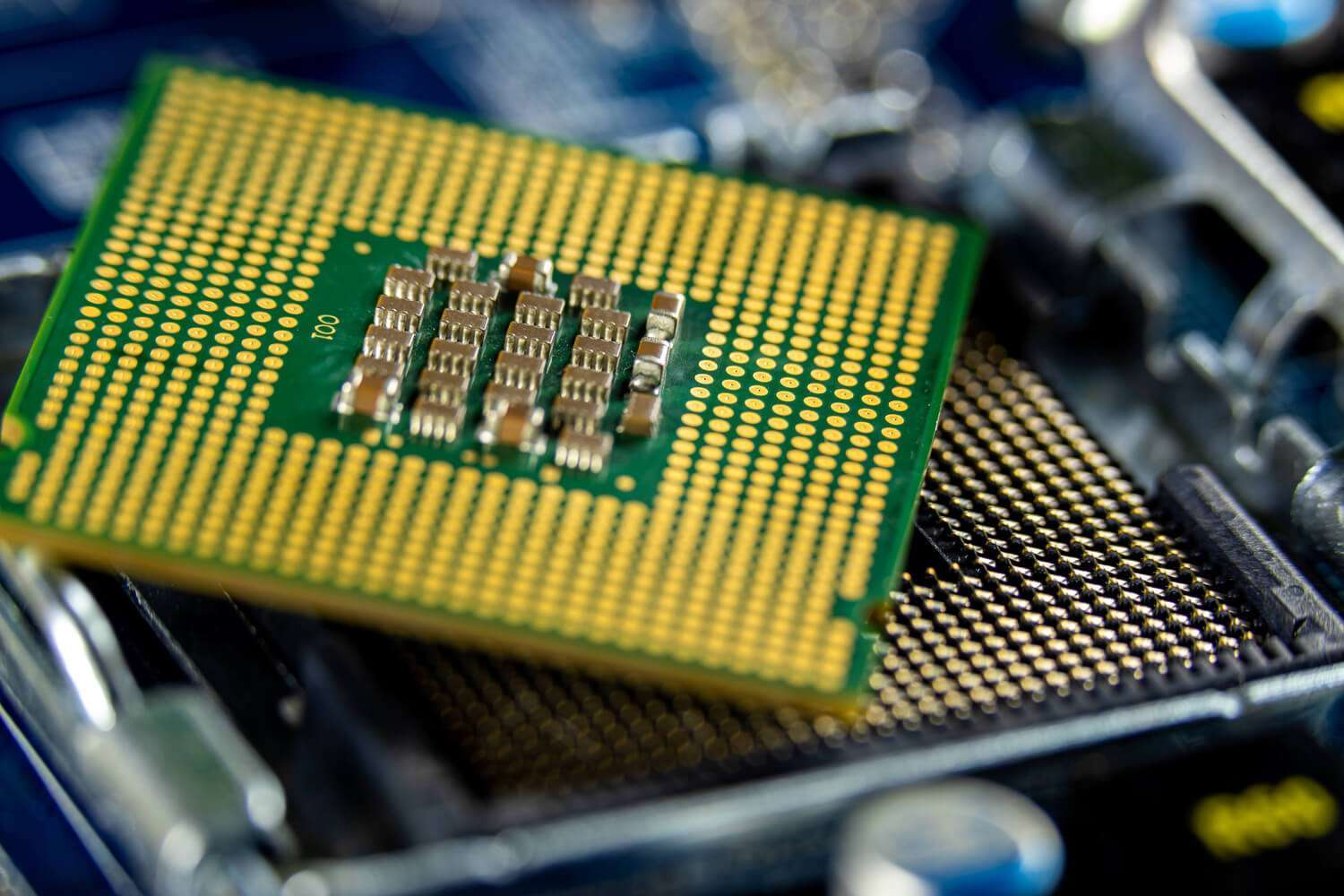

Material Being Cut

The material being cut and its variations is very influential on the life and performance of the diamond tool. Unfortunately, there is no universal diamond tool which will work optimally on thousands of different type of non metallic and hard and brittle materials efficiently , effectively, and economically. Therefore it is necessary to have different specifications for the different material types and / or material groups. Variables in Material Specification that play important role include hardness, Dimensions, Thickness, & Shape/Geometry.

Find out more >>> (see our Material Guide on understanding different material properties, their challenges and advice how to obtain best results for your application)

Feed Rate

Feed rate or speed at which the diamond tool moves through the material being cut has very strong affects on overall results. There is a strong correlation between feed rate and depth of cut, the structure and hardness of material being cut, and the tools specifications. Feed rate should be determined by your desired cut quality, material hardness, density, geometry, and thickness. The load to be applied to sample should be function of your desired cut quality and speed. Never force the tool beyond its cutting ability, this will only result in a glazed over diamond tool. Best practice to follow would be to start by applying light to medium pressure. Gradually feeding load arm into rotating blade, until it begins to cut at its own speed. If you can see dark “burn” marks around the diamond section, the cutting speed you are using is too fast or you are applying too much pressure. Load/Feed rate should never be so great that blade slows down.

Condition of the Machine

No two machines will provide identical results, It is highly important that the machine used be kept in good working condition at all times. A machine where regular maintenance is neglected will provide inconsistent results. Poor bearings, poor shaft conditions, loose rolling table, loose belts, dirty flanges or collets will cause poor surface finish, short tool life and many other undesirable results. Depending on the frequency of use, the machine should be checked on either daily or weekly basis and overhauled every 2 to 6 months or sooner if necessary.

Find out more >>> (see our Machine Buyers Guide on how to select the right cutting, drilling, grinding and polishing equipment for your application)

Driving Power

No two machines will provide identical results, It is highly important that the machine used be kept in good working condition at all times. A machine where regular maintenance is neglected will provide inconsistent results. Poor bearings, poor shaft conditions, loose rolling table, loose belts, dirty flanges or collets will cause poor surface finish, short tool life and many other undesirable results. Depending on the frequency of use, the machine should be checked on either daily or weekly basis and overhauled every 2 to 6 months or sooner if necessary.

Find out more >>> (see our Machine Buyers Guide on how to select the right cutting, drilling, grinding and polishing equipment for your application)

Driving Power

In order the diamond tool manufacturer to provide the proper tool specification, it is necessary to know the maximum horsepower of the machine. Diamond cutting tools require that pressure be applied for maximum performance. Sufficient pressure must be applied to maintain sharp cutting crystals. If too little pressure is applied, the diamond crystals are likely to become dull and polish. At the same time, too much pressure can also damage the diamond tool. For optimum performance the diamond tool speed should maintained through the cutting period. Since of the factors affecting life and performance of the tool is the SFPM (RPM'S) use. Any fluctuations during the cutting period must be eliminated or reduced to a minimum. Sufficient horse power must be supplied to the driving shaft to assure constant RPM.

Environment

The environment plays a major role in almost every facet of the diamond tool usage process. It influences surface finish, accuracy, cutting rate, overall cost and much more. Diamond Tool Specification and Process Usage Recommendation may greatly vary depending on the conditions under the work will be done. Requirements in High Volume Manufacturing facility producing hundreds and thousands of parts in terms of output, quality, and consistency. Will be greatly different from R & D laboratory conducting an analysis. Same principal holds true for hobbyists making crafts from their garage. There would be large contrast on the type of tools, equipment, RPM's, feed rates, material holding and coolant methods that would be applied among these three different groups. All of them have different needs and would require different approach to achieve their objectives.

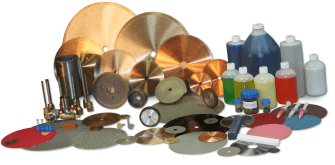

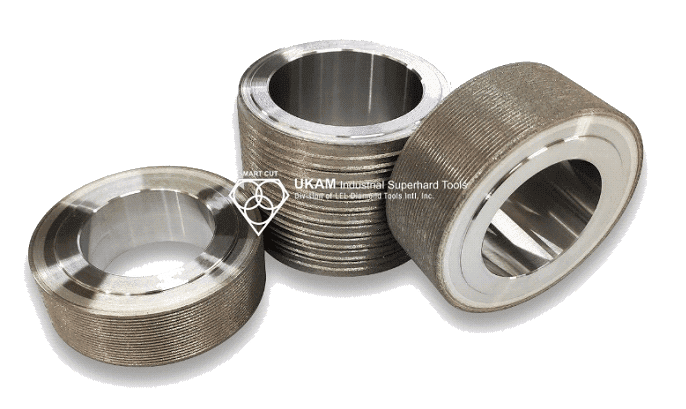

Use the Right Diamond Tool Accessories

Use of proper diamond tools accessories such as wheel stiffeners, flanges, water swivel adapters, etc can make a significant impact on the overall results. Unfortunately, this is something that is frequently overlooked by diamond tools users regardless of their background.

When cutting, use the right size flanges or wheel stiffener sets with all thin diamond wafering blades to firmly hold it in place. This will help prevent the blade from "walking". Use Drill Head Assemblies (water swivel adapters) with core drills to provide coolant (water) through the center of the drill and on to drilling zone.

Find out more >>> (see our Guide on Understanding Which Diamond Tools Accessories are Available and which ones to use for your application)

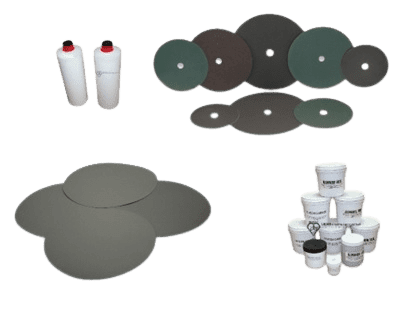

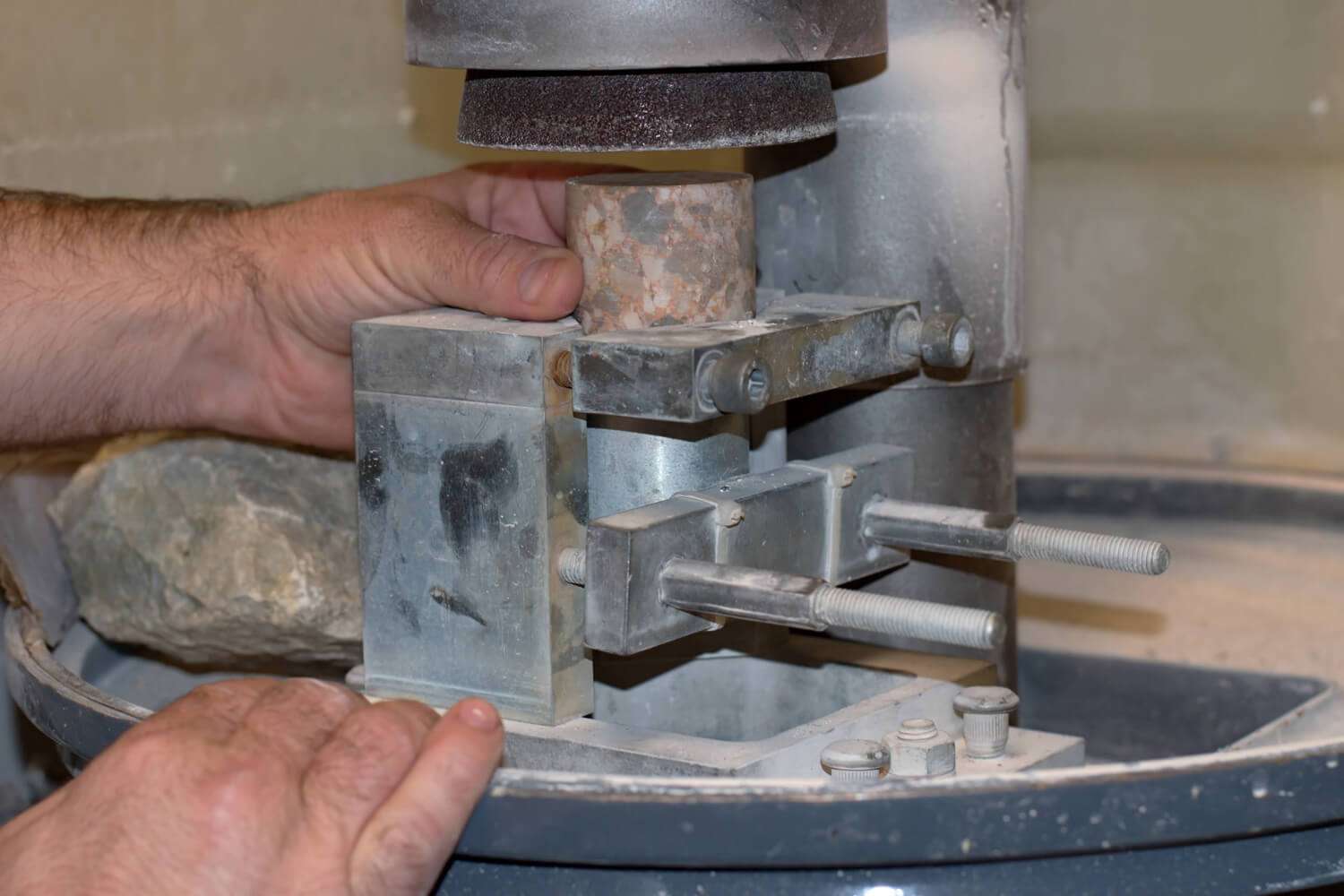

Dressing Diamond Tools

Dressing is the process of sharpening diamond particles in diamond bond matrix in order for the diamond particles to freely penetrate into the material, minimize loads, and provide good cut quality.

Diamond tools must be both trued to and dressed on the machine on which it will be used. When your diamond tool is new, it should be dressed thoroughly by the operator. Never assume because the tool is new, that it does not require this operation. Using the correct, soft dressing stick, it is recommended that the tool is passed through the tick five to ten passes to expose the diamonds for optimum cutting performance.

Find out more >>> (see our Guide on How to Dress, When to Dress, and How to select right dressing stick for your application)

Right Coolant at Point of Contact

Coolant provides cooling, lubrication, and material chip/swarf removal properties to the cutting zone. Possible coolants include water soluble lubricants, oils, and even plain water. Which coolant to use depends on the application. Plain water evaporates at 212 F. Often temperature in your cutting zone reaches as much as 500 degrees F. Often water evaporates, before it has a chance of affectively cooling the diamond tool and material. Resulting in shorter Tool Life, Material Damage or micro cracks associated with overheating. Water may cool your diamond tool, yet provide poor lubrication properties needed for optimum performance. Not matter which coolant is used, it should come in contact where the material and tool intersect. Optimum coolant nozzle orientation allows the most narrow angle of contact between the diamond tool and coolant. Coolant should have enough velocity to overcome the air barrier.

Find out more >>> (see our Guide on Why Use Coolant, Selecting the Right Coolant, How to Use to obtain best results)

Material Holding Method

Properly securing the material in place is one of most important steps in the application that frequently receives less attention then it deserves. The material holding fixture or method should keep the /material firmly in place, preventing it from moving. Various material holding fixtures & methods are available to accommodate all types of material shapes and geometries. Which method to use will depend on the beginning /material dimensions, desired cut depth, and material properties (hardness, brittleness, shape/geometry). Some challenges of mounting/fixturing is occasional chipping at bottom of material at the tool exit. Support is needed at the bottom of the material in order to help resolve this issue.

Find out more >>> (see our Guide on Different Material Holding/Clamping Methods, Which to Use to obtain best results for your application)

Material Geometry

MATERIAL TO BE CUT

Materials you are planning to cut will have a large impact in the types of diamond dicing blade you can use. If you are dicing ultra hard and brittle materials such as alumina or sapphire, it is generally recommended that you use a soft bond, thin kerf dicing blades such as Resin Bond. However, if you are cutting softer materials, material minimum thickness such as substrates and wafers. Nickel bond diamond dicing blade may be the best solution.

Material Thickness – will determine feed rate and RPM's to use type, diamond size and concentration to use.

Material Hardness is defined as the materials capability to resist deformation. All materials are classified by their scale of hardness. Material hardness is measured by many different hardness scales such as Mohs, Vickers, Knoop and other scales of hardness.

hard & brittle materials require a softer Bond Matrix, to cut faster and freer. While softer and abrasive materials require a harder bond blade bond matrix, to last longer. Harder bond matrixes hold diamond in place for very long time, providing longer tool life. This requires use of very hard diamond particles in order for the diamond tool to maintain its sharp edges for long periods of time.

The Right RPM'S

One of the most critical factors in successful diamond tool usage is the right RPM's. If the diamond tool rotates to slow, it drags and creates heat. If it spins to fast, it causes friction and again generates heat. Possibly damaging your tool. Heat is the worst enemy for a diamond tool. Selecting the right RPM becomes a critical factor of success. Unfortunately, this can also be the most difficult aspect of your operation to correct. Diamond tools frequently require RPM's from 100 to 23,00. Charts provided in this manual will help you identify and select the right RPM's for your diamond tools. As well as provide suggestions on ways you can achieve it.

Optimal Speeds/RPM's will vary depending on the tool OD (Outside Diameter). Using the right speed will help maximize tool life, prove performance, surface finish quality and reduce cost. Different material have different requirements for cutting speed. Material hardness, density, and spindle speed will affect both spindle speed and therefore cut quality.

Find out more >>> (see our Guide on Recommended RPM's for various types of diamond tools, materials, and applications)