-

0 items in quote

No products in the Quote Basket.

Diamond Band Saw Blades

Diamond Band Saw Blades

All diamond band saw blades are custom manufactured to fit your exact material, needs and application requirements. We will work with you to determine your needs, and recommend the right parameters for your specific material / application.

Diamond Band Saw Blades Made to your Specifications

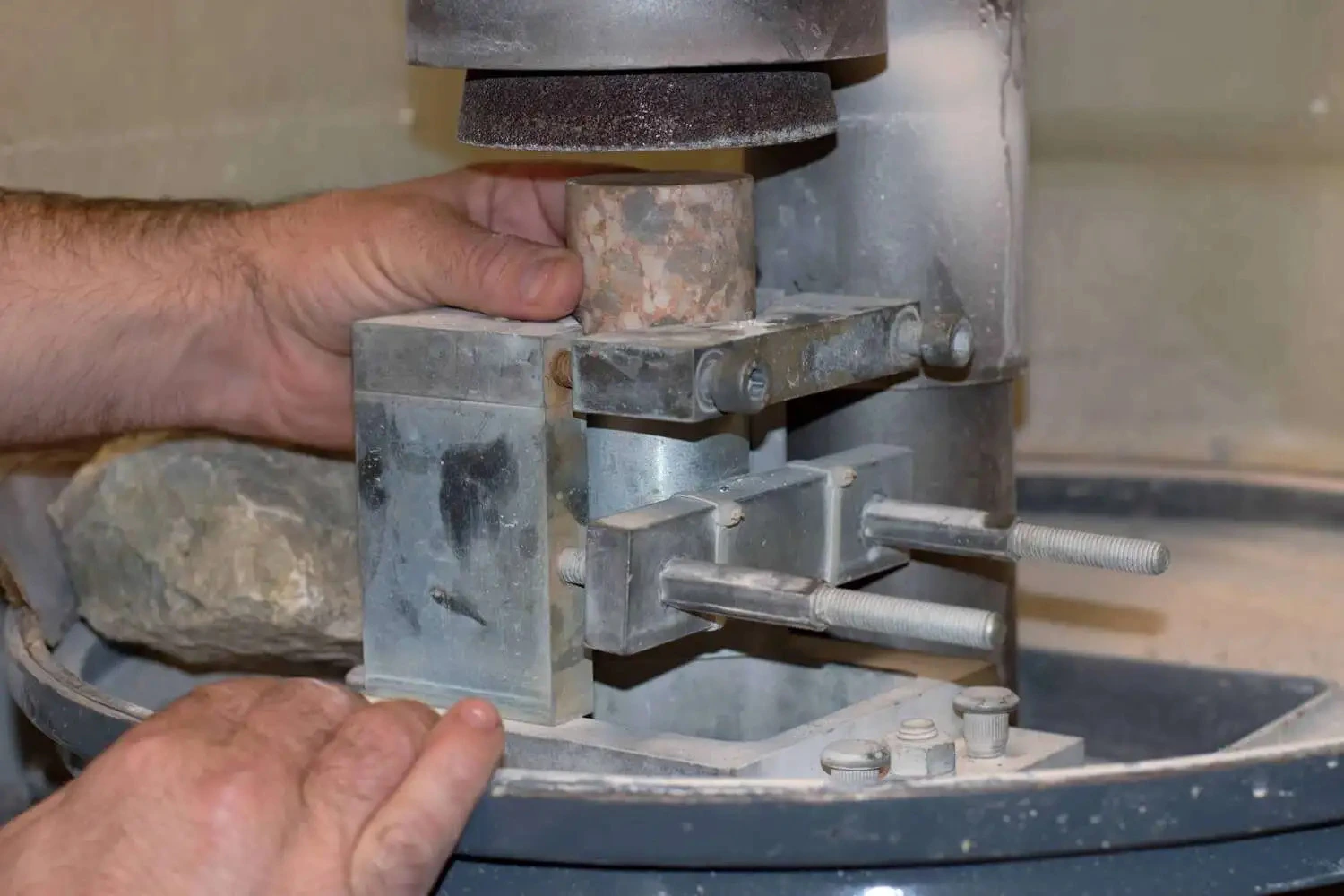

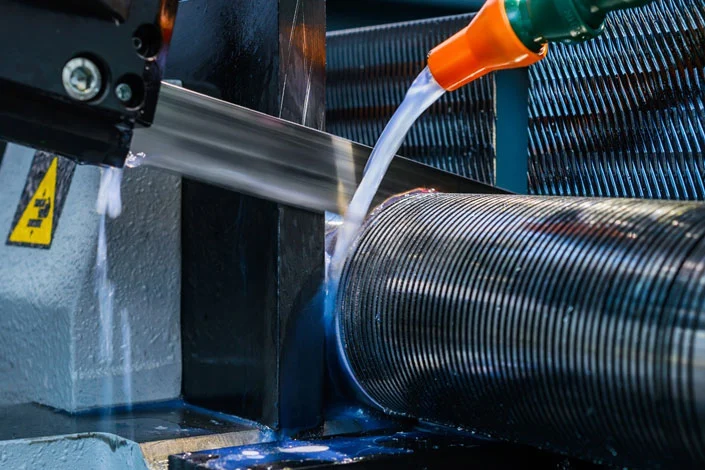

Diamond Band Saw Blades have proven the be an effective diamond machining tools on a large variety of materials and applications. With diamonds firmly attached to ultra thin metal body, Diamond Band Saw Blades remain the tool of choice for many diamond cutting and machining jobs. Perfect Solution for cutting large variety of ultra hand and brittle materials such as: quartz, glass, carbon, silicon, ceramics or composites. Large variety of diamond band saw blade specifications are available to fit any application. Blades are cut and welded to clients specification, weld is guaranteed for the life of the blade. Only the highest quality raw materials are used in the manufacturing process is carefully controlled, matching your application with the right bond type, grit size, bond hardness and composition.

Electroplated Diamond Band Saw Blades

SMART CUT® Electroplated Diamond Band Saw Blades are premium cutting tools designed for precision and durability in challenging applications. These blades feature a robust steel core, coated with a generous layer of electroplated diamond grit. The electroplating process ensures an even distribution of diamond particles, offering a consistent and smooth cutting experience. Ideal for cutting through hard materials like ceramic, glass, stone, and composite materials

Braised Bond Diamond Band Saw Blades

SMART CUT® Braised Bond diamond band saw blades are crafted through a metallurgical bonding process that securely attaches diamonds to high-grade steel edges. This innovative technique ensures our blades are not only reliable and long-lasting but also resistant to brittleness, setting them apart as a superior choice compared to both traditional toothed and electroplated diamond saw blades.

Tungsten Carbide Band Saw Blades

SMART CUT® Tungsten Carbide Band Saw Blades offer significant improvements in performance and durability over traditional toothed blades. The unique cutting action and inherent toughness of Tungsten Carbide Grit band saws enables users to effectively and economically work difficult, hard, snaggy, abrasive and brittle materials that defeat even the sharpest and most advanced toothed alternatives.

Why Choose Us?

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price

Why Work With Us?

Comprehensive Source of Information on Diamond & CBN Blades

We understand that your success depends on select the right diamond & CBN blade, and optimizing your parameters to best fit your applications/needs.

The more you understand about what we can do for you, the better our partnership will be.

On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond & CBN blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Diamond Drills & Tools in the U.S Available in different diameters, wall thicknesses, angles, radiuses, drill depths, mounting types, bond types, diamond mesh sizes, concentrations, bond hardness, tolerances. Custom Manufacturing to fit your particular requirements is available with short lead times and no minimum order quantities.

Experience makes all the Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary drill chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect drill life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after drilling.

Umatched Technical Support

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced Technology

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality &

Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency

Expect More From Your Tools

ARE YOU USING RIGHT DIAMOND BAND SAW BLADES

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DIAMOND BAND SAW BLADES?

Knowledge Center

07

Oct

Selecting the right diamond band saw blade is important for getting the best results in your cutting process. The right blade can help you achieve clean cuts, reduce material waste, and make your blades last...

17

Sep

Diamond Band Saw Blades Usage Recommendations & Best Practices

Diamond band saw blades are used for cutting large variety of materials from ultra hard ceramics to glass and composite materials. This article covers all critical usage recommendations and best practices for diamond band saw...

04

Aug

Diamond Wire vs band saw blades and circular blades

Diamond wire, band saw blades, and circular blades are all cutting tools used in various industries for different purposes. Each tool has its advantages and applications

For cutting ultra hard...

08

Jul

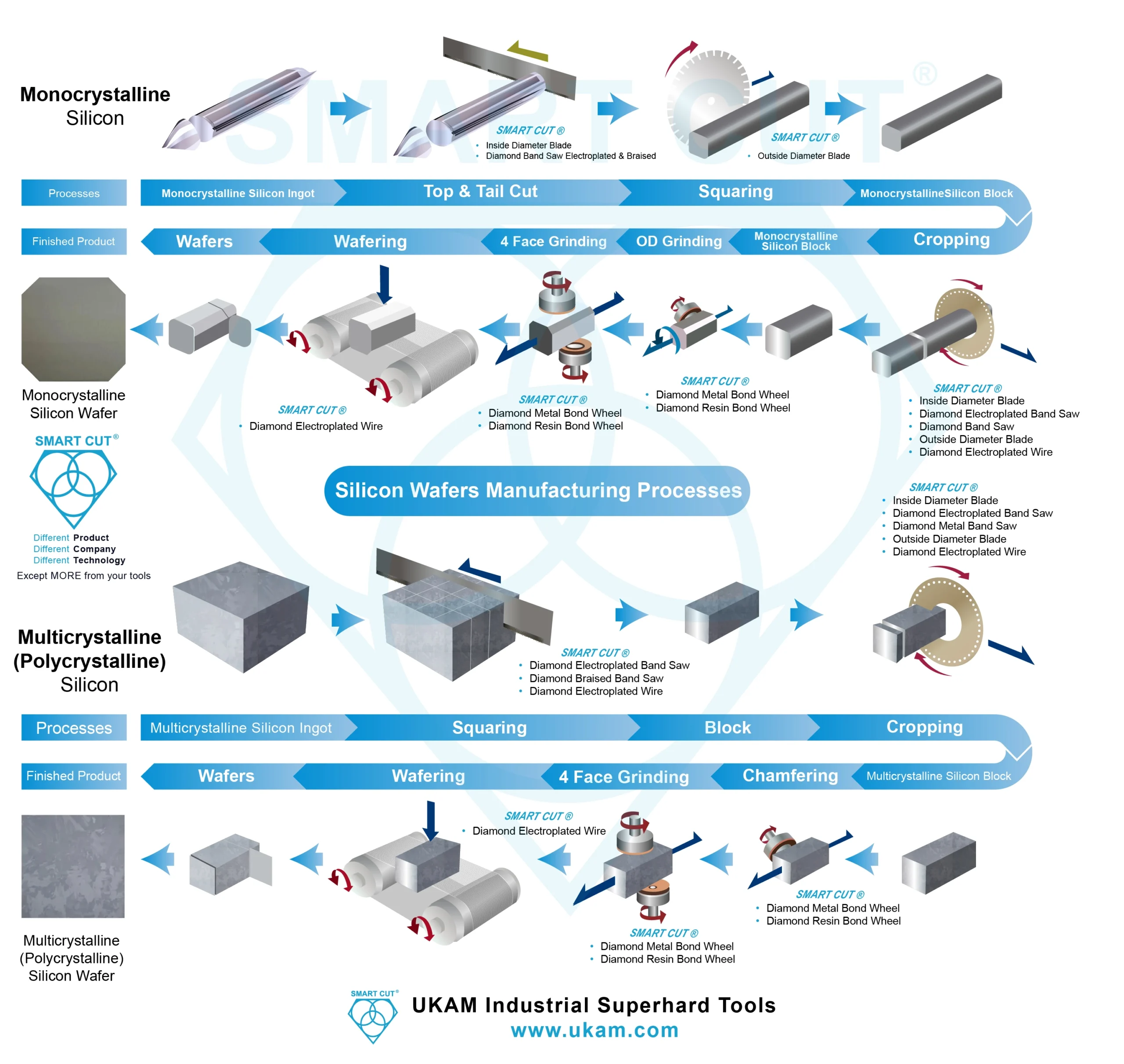

The Comprehensive Guide to the Processes of Silicon Wafers Production

Share this Article with Friend or Colleague

The production of silicon wafers, an essential component in semiconductor manufacturing, involves several intricate steps to ensure precision and quality. This article explores the detailed processes depicted in...

08

Jul

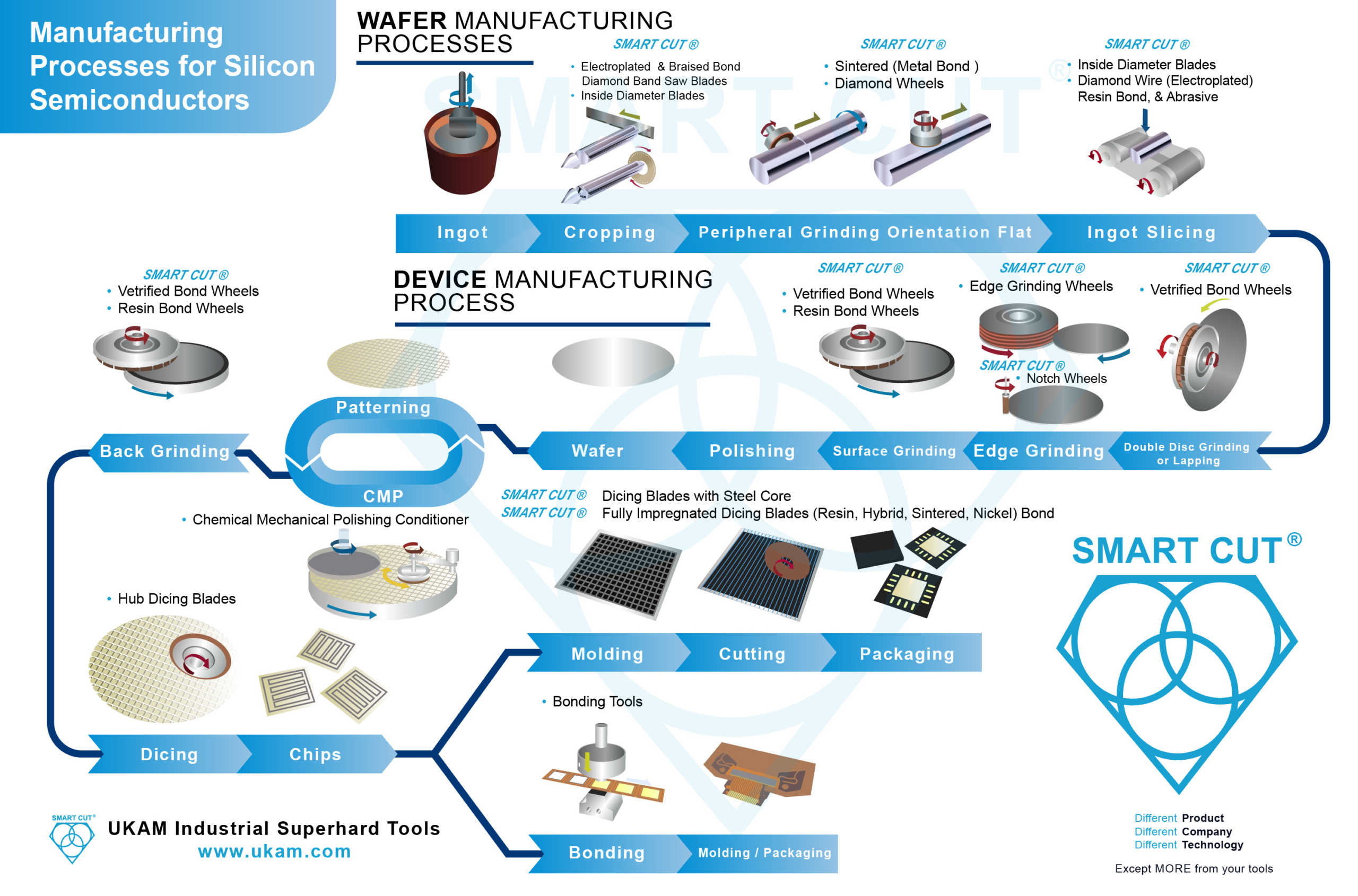

Manufacturing Processes for Silicon Semiconductors From Ingot to Integrated Circuit

Share this Article with Friend or Colleague

1. Ingot Production

The journey begins with the creation of silicon ingots, which are pure silicon cylinders produced through methods like the Czochralski process. Once formed, these ingots undergo a...