-

0 items in quote

No products in the Quote Basket.

SMART CUT®

Tungsten Carbide Band Saw Blades

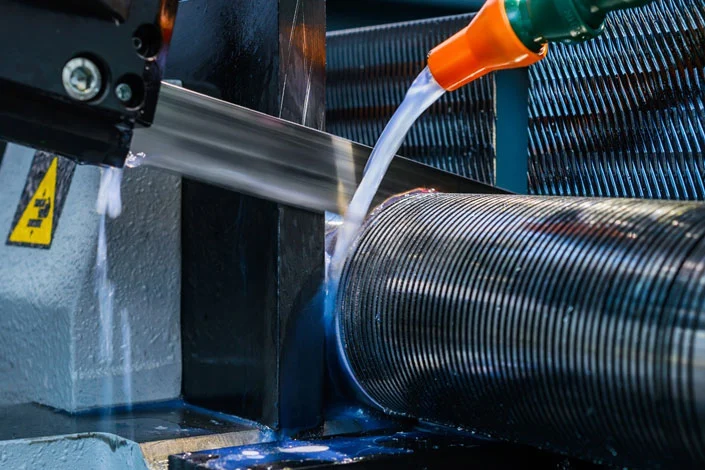

SMART CUT® Tungsten carbide band saw blades deliver exceptional durability and cutting performance for demanding industrial applications. Featuring high-quality tungsten carbide tips, these blades offer superior hardness, wear resistance, and extended life. Precision-ground edges ensure clean, accurate cuts with minimal burring, ideal for applications requiring a high-quality surface finish.

DESCRIPTION

SPECIFICATIONS

ADVANTAGES

FEATURES

INDUSTRIES USED IN

FAQ

ACCESSORIES

DESCRIPTION

SMART CUT® tungsten carbide grit band saw blades, designed for cutting the toughest materials. Tungsten carbide grit, one of the hardest materials known, is metallurgically bonded to a steel base, forming permanent cutting edges instead of teeth. These blades outperform traditional toothed blades in durability and effectiveness, enabling efficient, economical cutting of hard, abrasive, and brittle materials.

Our range includes blade widths from 1/4” to 2” and two styles: continuous blades for brittle or thin materials and gulleted blades for larger sections. Continuous edge blades are ideal for materials under 1/4” thick or prone to cracking, while gulleted blades handle more robust materials effectively.

With faster cutting speeds, longer life, and unmatched precision, tungsten carbide band saw blades enhance productivity and lower operating costs.

SMART CUT® tungsten carbide band saw blades come in two styles: continuous and gulleted. Each style comes in either medium or coarse grit, depending on width. Coarse removes more material, Medium leaves a better finish.

Continuous Blades – Ideal for cutting materials such as aircraft sheet stainless steel, fiberglass honeycomb, glass and glass blocks, nickel alloys, and titanium.

Gulleted Blades – Designed for applications including aircraft flooring and interiors (composites), aluminum oxide, carbon/graphite, cast iron, industrial ceramics, composites, concrete building panels, laminates, stone and minerals, as well as tires and wire-reinforced rubber.

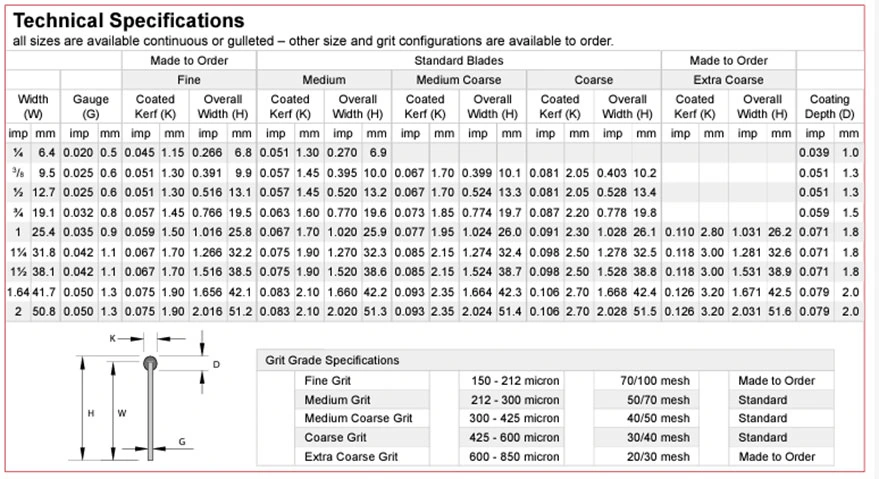

SPECIFICATIONS

Tab Content

ADVANTAGES

Tab Content

FEATURES

Tab Content

INDUSTRIES USED IN

Tab Content

FAQ

Tab Content

ACCESSORIES

Tab Content

Features

- Operates Safer - Designed for stability, these blades minimize vibration and virtually eliminate snagging, ensuring a safer and more controlled cutting experience.

- Performs Better - Tungsten carbide blades handle various materials with ease and precision, enabling seamless curve shaping and preventing breakouts or surface damage.

- Works Faster - The grinding mechanism allows for quicker, more efficient material removal while maintaining precise control for intricate tasks.

- More Universal Application - Capable of processing a wide range of challenging materials, tungsten carbide blades are ideal for addressing unique cutting requirements.

- Saves Money - With extended life, high performance, and consistent quality, these blades provide a superior return on investment over conventional alternatives.

- Lasts Longer - Tungsten carbide grit edge blades retain their sharpness significantly longer than traditional toothed blades, offering extended durability. The ability to reverse the blades further enhances their lifespan.

- Handles Tougher Jobs - Engineered for resilience, tungsten carbide grit blades endure heavy use and deliver exceptional performance even in the most demanding conditions.

- Produces Smoother Results - With thousands of micro-cutting edges, these blades utilize a grinding action instead of the aggressive tearing motion of toothed blades. This reduces the risk of breaking brittle materials and leaves smooth, chip-free edges that often need no further finishing.

Recommended Band Speeds

|

Material |

SFPM |

Coolant |

|---|---|---|

|

Aircraft Tooling |

200–1000 |

|

|

Beryllium |

150–600 |

Yes |

|

Cable and Wire Rope |

1200–3000 |

Yes |

|

Carbon and Graphite |

1000–4000 |

|

|

Cement Lined Pipe |

120–500 |

|

|

Compressed Perlite Moldings |

400–1600 |

|

|

Fiber Reinforced |

800–1500 |

|

|

Fiberglass Honeycomb |

4000–6000 |

|

|

Fiberglass Reinforced Plastics, Melamine, Phenolic |

1000–3000 |

|

|

Foamglas |

1000–3000 |

|

|

Friction Materials |

1000–3000 |

|

|

Glass |

500–1000 |

Yes |

|

Graphite Composites |

1500–3000 |

|

|

Green Unfired Ceramics |

200–1200 |

|

|

Grey Cast Iron |

150–300 |

|

|

Hastelloys |

120–300 |

Yes |

|

High-Temp Nickel Alloys and Super Alloys |

150–400 |

Yes |

|

Low Density Ceramics |

500–1500 |

|

|

Nitride Case Hardened and Induction Hardened Steels |

150–300 |

Yes |

|

Sintered Tungsten, Molybdenum |

125–700 |

Yes |

|

Soapstone, Chalk, Lava, Slate, Coal |

150-600 |

|

|

Syntactic Foam |

300–700 |

|

|

Titanium |

150–400 |

Yes |

|

Tool Steel Rc 42-65 |

150–200 |

Yes |

|

Welds and Met-Lab Specimens |

125–300 |

Yes |

|

White High Alloy Cast Iron |

150–350 |

|

|

Wire Reinforced Rubber |

1200–3000 |

Yes |

Related Products

Band Saw Blades

SMART CUT® Braised Bond Diamond Band Saw Blades

SMART CUT® LG Manual Metallurgical Grinder/Polisher with Single Wheel

SMART CUT® LP – 12” (300MM)

SMART CUT® LP – Grinding/Polishing Machine

Recently Viewed Products

ARE YOU USING RIGHT DIAMOND BAND SAW BLADES

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DIAMOND BAND SAW BLADES?

Knowledge Center

07

Oct

Selecting the right diamond band saw blade is important for getting the best results in your cutting process. The right blade can help you achieve clean cuts, reduce material waste, and make your blades last...

17

Sep

Diamond Band Saw Blades Usage Recommendations & Best Practices

Diamond band saw blades are used for cutting large variety of materials from ultra hard ceramics to glass and composite materials. This article covers all critical usage recommendations and best practices for diamond band saw...

04

Aug

Diamond Wire vs band saw blades and circular blades

Diamond wire, band saw blades, and circular blades are all cutting tools used in various industries for different purposes. Each tool has its advantages and applications

For cutting ultra hard...

08

Jul

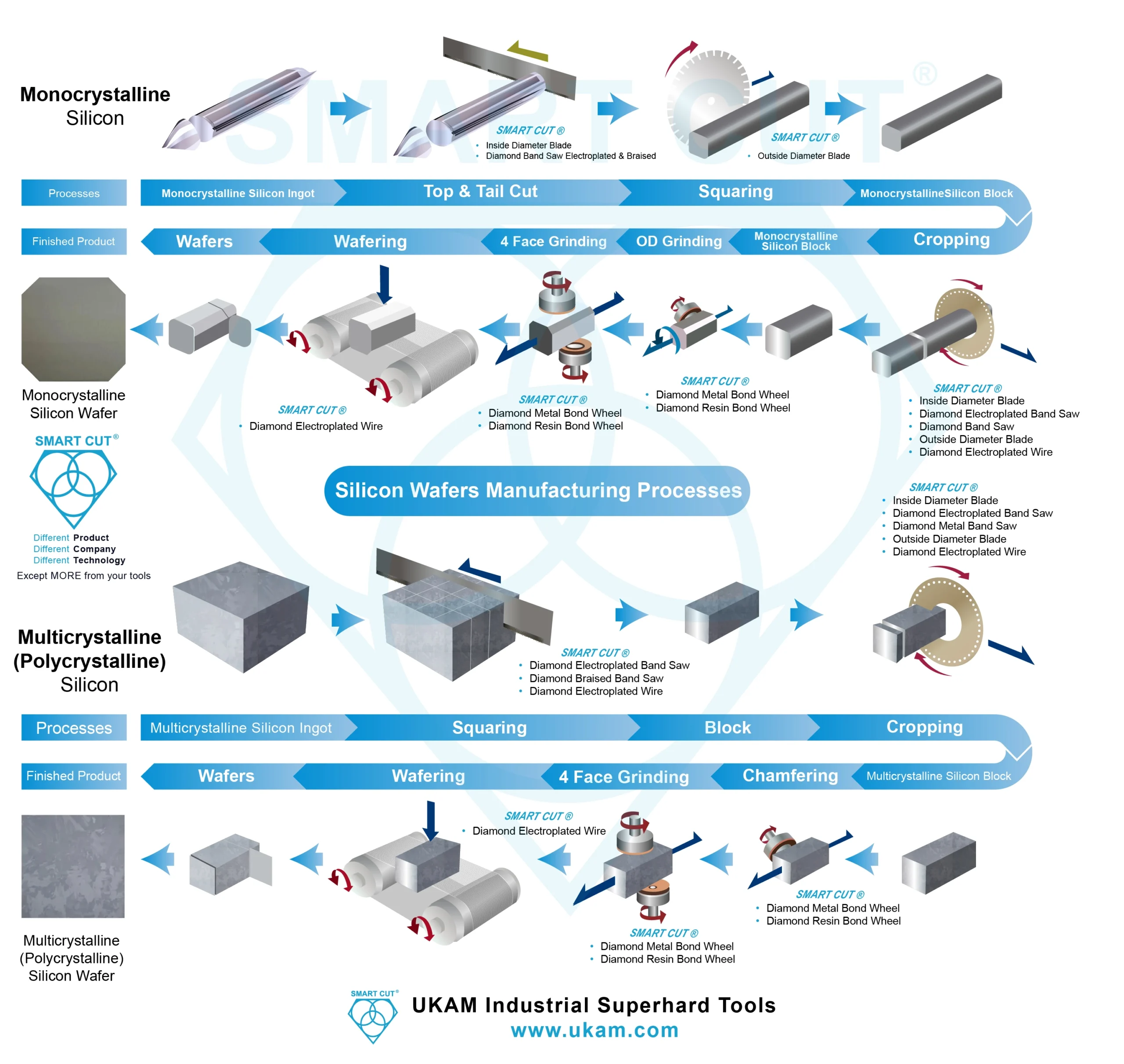

The Comprehensive Guide to the Processes of Silicon Wafers Production

Share this Article with Friend or Colleague

The production of silicon wafers, an essential component in semiconductor manufacturing, involves several intricate steps to ensure precision and quality. This article explores the detailed processes depicted in...

08

Jul

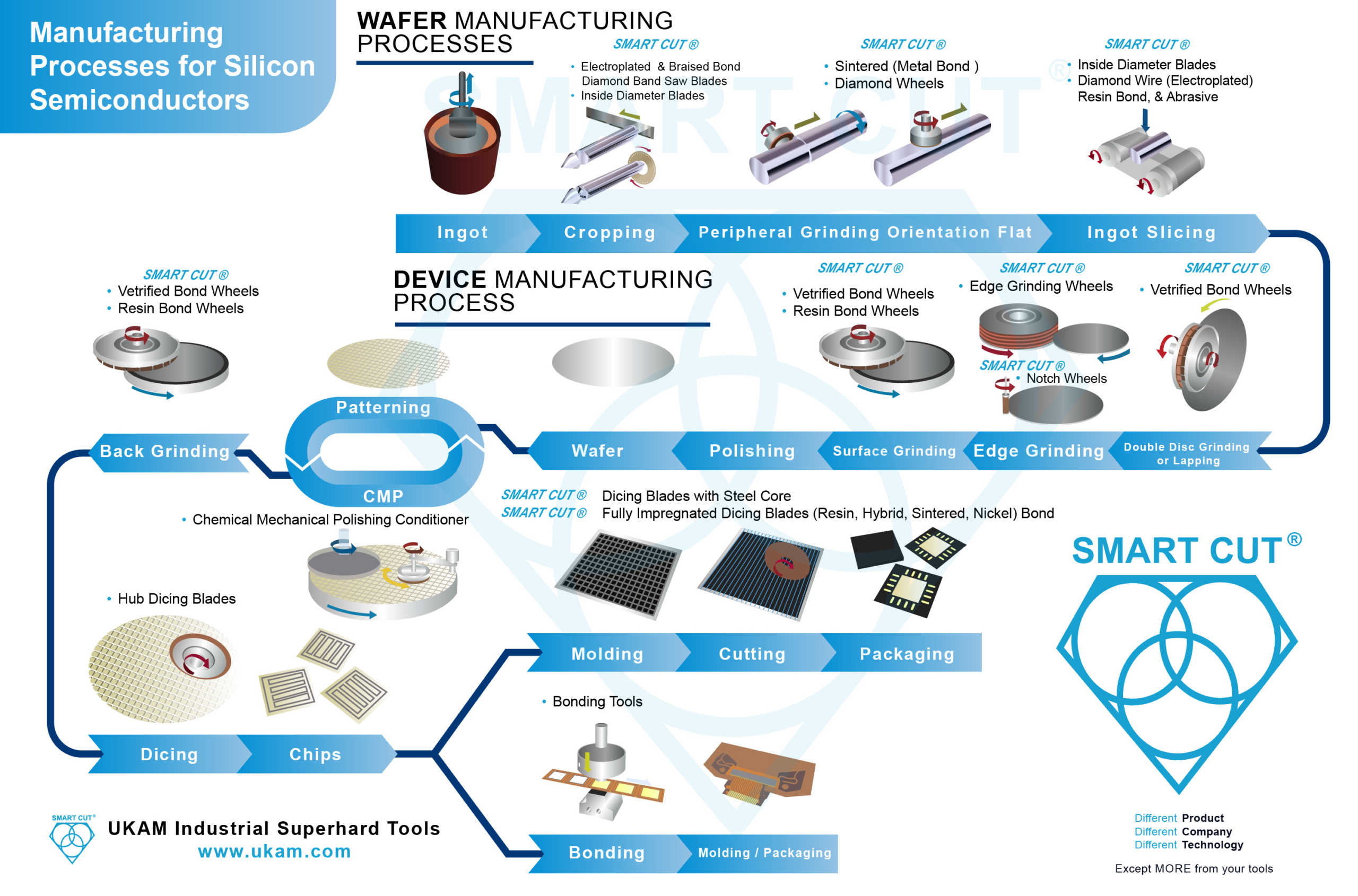

Manufacturing Processes for Silicon Semiconductors From Ingot to Integrated Circuit

Share this Article with Friend or Colleague

1. Ingot Production

The journey begins with the creation of silicon ingots, which are pure silicon cylinders produced through methods like the Czochralski process. Once formed, these ingots undergo a...

- Unmatched Selection For Many Applications

- Superior Quality & Consistency

- Immediate Worldwide Delivery

- Technical Support & Expertise

- American Based Manufacturer

- Different Product

- Different Technology

- Different Company

- Expect MORE from your tools

Let Us HELP You!

Subscribe To Our Newsletter

Signup for email offers, updates, and more

Contact Us

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin, high precision cutting blades, precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

- 25205 & 25201 Avenue Tibbits Valencia CA 91355 USA

-

Phone : (661) 257-2288

FAX : (661) 257 -3833 - lel@ukam.com

DIAMOND TOOLS BY BOND

EQUIPMENT

KNOWLEDGE CENTER

OUR PRODUCTS

COMPANY

CUSTOMER SERVICE

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use