Menu

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

SMART CUT® 6050 A precision section saw designed for cutting all types of materials with ease. Low-Speed Precision cutter is applicable to accurate cutting of hard materials, especially to high-value fragile artificial crystal. The Spindle has high accuracy of operation, the horizontal feed position of the processed work piece can slightly be adjusted, and the machine can be power-off automatically after cutting is finished.

SMART CUT® 6050 precision section saw represents a state-of-the-art solution for cutting a broad spectrum of materials, tailored especially for applications requiring high precision and careful handling of hard, high-value materials such as fragile artificial crystals. This machine is not only adept at maintaining operational accuracy but also emphasizes user safety and operational convenience.

SMART CUT® 6050 saw features a robust construction with an aluminum base and stainless steel door, ensuring durability and reliability in various industrial environments. It is equipped with a precision spindle that offers exceptional accuracy, enabling slight adjustments in the horizontal feed position of the workpiece for optimal cutting precision. The machine’s design includes an automatic power-off function that activates once cutting is complete, which adds an extra layer of safety while also conserving energy.

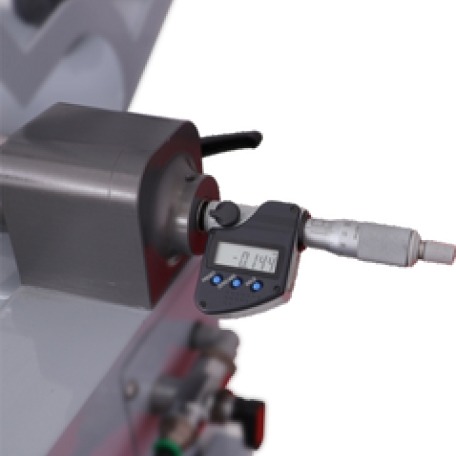

Key operational features include a micrometer for precise cross-feed adjustments up to 25mm and a down-feed facility capable of accommodating different weights up to 400 grams, allowing for versatile handling of various materials and sizes. SMART CUT® 6050 operates over a speed range of 60 to 1000 RPM, adjustable to suit specific material requirements and cutting conditions.

For fluid management, the saw integrates a recirculating tank and a built-in, easily movable stainless steel coolant tray, complemented by a transparent coolant splash guard that enhances visibility and safety. The control interface of the machine is a color touch screen HMI, which simplifies the operation and increases the interactivity for the operator.

With its compact dimensions of 30″ x 19″ x 18″ and weighing 121 lbs, the SMART CUT® 6050 is designed for efficient use of workspace while providing the capabilities needed for precise, safe, and efficient cutting operations. SMART CUT® 6050 is an invaluable asset in settings that demand precision and reliability in the cutting of delicate and valuable materials.

Tab Content

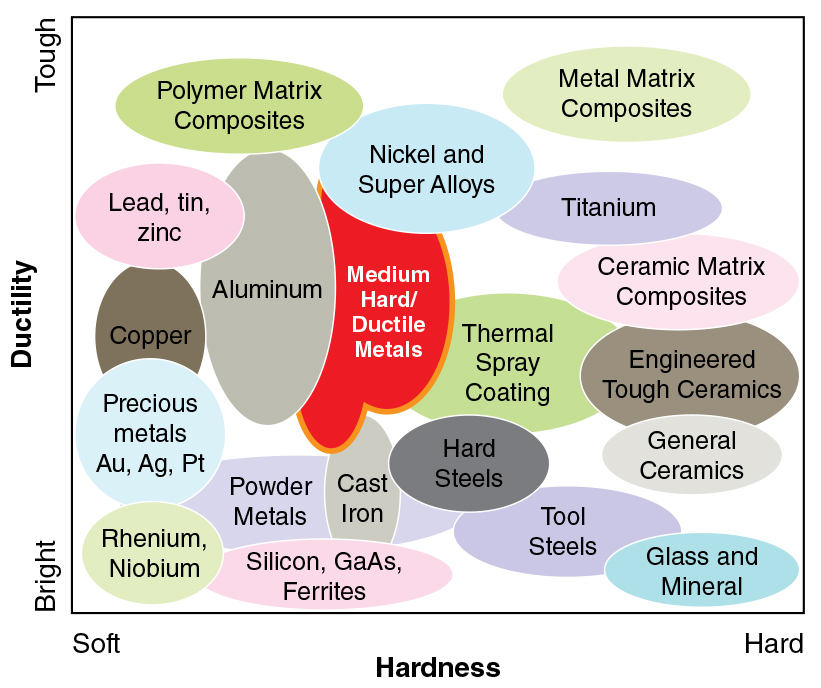

INDUSTRIES USED IN:

Ferrous & Non-Ferrous Metals:

Tab Content

Tab Content

Tab Content

Your choice of one (1) quart of SMART CUT® Water Soluble Coolant or Mineral Oil is included with machine. SMART CUT® Water Soluble Coolant Reduces material thermal stress, edge damage, and internal cracking, increases blade life, provides better cut quality, preserves material micro structure

Hence, assuring long-term integrity of material being sectioned. Since SMART CUT coolant is both a coolant and lubricant, both the wafering blade and material benefit. Mix ratio is 1:20 (1 part coolant, 20 parts water) on very hard and dense materials and 1:40 (1 part coolant, 40 parts water) on softer materials. Depending on mix ratio 1 quart will produce 5.7 to 9 gallons of coolant when mixed with water. As a coolant, SMART CUT KOOL reduces heat caused by friction. As a lubricant, SMART CUT KOOL lowers friction and surface tension, which increases swarf dispersion.

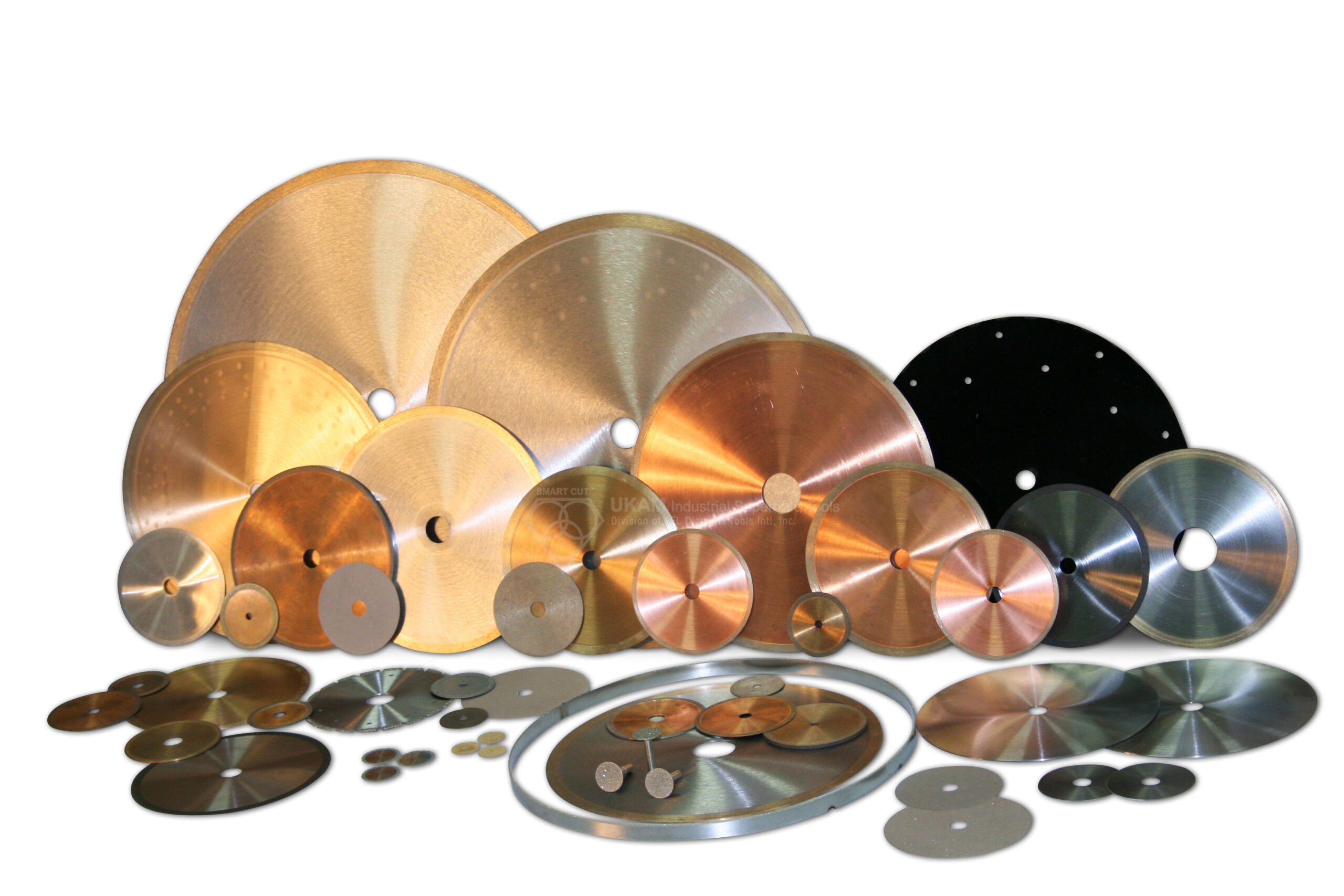

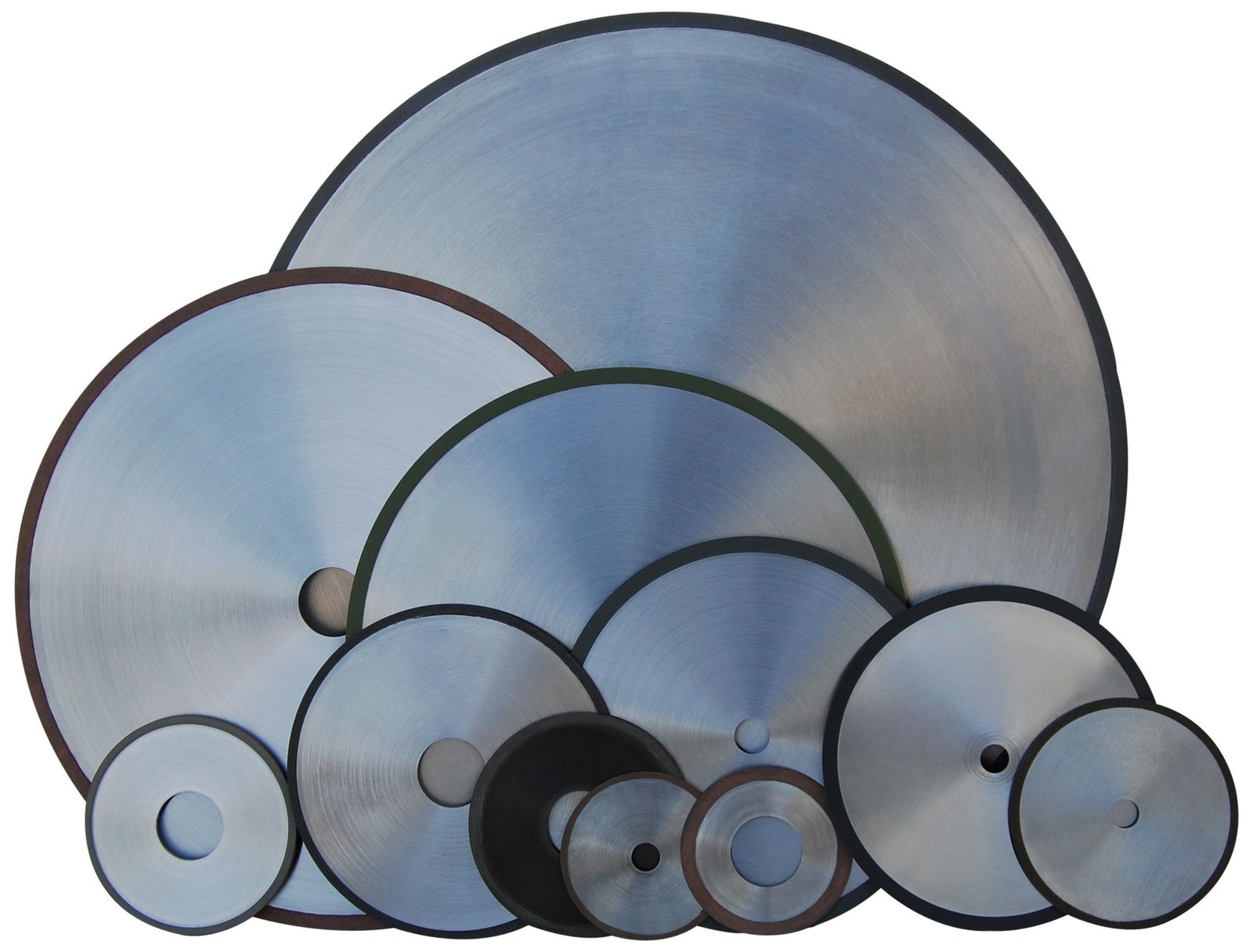

one (1) diamond wafering blade any specification is included FREE OF CHARGE with purchase of any machine (any specification). we have almost unlimited number of diamond & CBN wafering blade specifications in stock available for immediate delivery. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness’s. With several thousand unique blade specification in stock not listed on our standard stock program. This insures you will receive the best blade specification possible for your specific application.

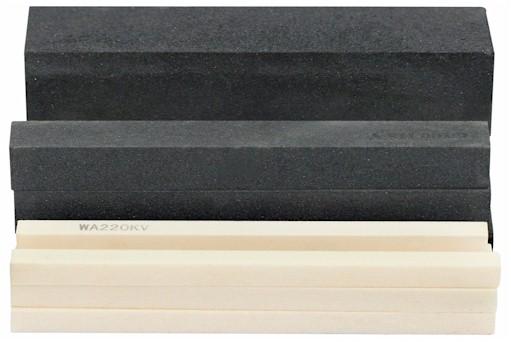

One (1) dressing stick is included with the purchase of any machine free of charge. The dressing stick we supply is similar to the diamond size of the wafering blade you have chosen (or we recommended) for your application. Wafering Blades must be diamonds particles/crystals exposed properly through frequent dressing. Otherwise, the diamond tool will glaze over. They will begin to tear rather than grind which is very destructive. Tearing caused from unexposed diamonds creates friction. This causes uneven wear and/or heat cracks in the wafering blade and/or material being cut. Resulting in premature blade wear, blade tensioning problems, and will eventually destroy the blade. The more frequently the blade is dressed the freer and cooler it will cut with lot more consistency.

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales