Menu

-

0 items in quote

No products in the Quote Basket.

9 am to 6 pm PST time

No products in the Quote Basket.

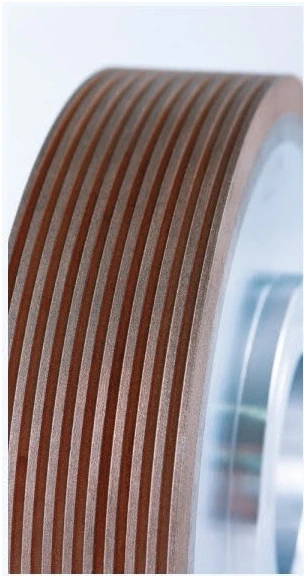

SMART CUT® Diamond Edge Grinding Wheels are engineered to deliver exceptional performance for precision grinding applications, providing superior results in both rough and fine grinding. These wheels are ideal for use in industries that require highly accurate EDM processing and consistent wafer-to-wafer results. Manufactured with synthetic diamond grit, SMART CUT® wheels offer improved surface roughness and extended tool life due to their tightly controlled diamond distribution and uniform bond structure.

SMART CUT® Diamond Edge Grinding Wheels are designed for superior performance in high-precision grinding applications, especially when working with hard and brittle materials. These wheels are engineered to provide exceptional edge grinding efficiency, increased productivity, and extended tool life. Featuring multi-layer electroplated technology, SMART CUT® wheels offer more than twice the lifetime and productivity improvement compared to single-layer electroplated products.

Available in Single & Multi-Layer electroplated technology, SMART CUT® wheels offer more than twice the lifetime and productivity improvement compared to single-layer electroplated products.

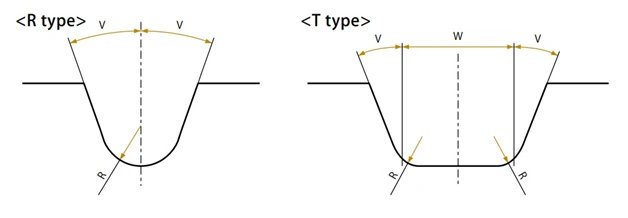

Groove Profiles: SMART CUT® wheels are available with a variety of groove profiles, including V and W shapes, ensuring versatility for different grinding tasks.

Tolerances: We are capable of manufacturing with highly precise tolerances that meet or exceed customer specifications. These include radius tolerances of +0.02mm (0.0008″), half angle tolerances of ±0.5 degrees, and groove depth tolerances of ±0.004” (0.102mm).

Our edge grinding wheels feature a circular runout of less than 0.005” (0.127mm), side runout of less than 0.0001” (0.0025mm), flatness within 0.0002” (0.0051mm), and shaft perpendicularity within 0.0005” (0.0127mm).

For high-precision, long-lasting edge grinding solutions, SMART CUT® Diamond Edge Grinding Wheels are the ideal choice for advanced materials and tough applications.

SMART CUT Diamond Edge Grinding Wheels are ideal for use on hard and brittle materials, including:

⦁ Ceramics

⦁ Gallium Arsenide

⦁ Gallium Nitride

⦁ Glass

⦁ Germanium

⦁ Sapphire

⦁ Silicon

⦁ Silicon Carbide

Multi-layer electroplated SMART CUT wheels offer more than twice the lifetime and productivity improvement compared to single-layer electroplated products. This makes them highly efficient for high material yield and throughput when grinding hard and brittle materials.

The uniform diamond size and distribution throughout the wheel ensure a consistent grinding process, resulting in superior surface finishes with minimal edge chipping and subsurface damage. This helps improve the overall quality of your workpieces.

SMART CUT Diamond Edge Grinding Wheels are available with grit sizes ranging from 400 to 3,000 JIS, making them suitable for both rough and fine grind applications

SMART CUT wheels can accommodate up to 10 grooves per wheel, and they are available with two grit types: rough and fine.

Each groove on SMART CUT wheels is precisely machined using the Electrical Discharge Machining (EDM) process, ensuring strict geometric tolerance control for consistent profile accuracy.

Yes, SMART CUT Diamond Edge Grinding Wheels can be tailored to your specific groove dimensions, offering V, R, or custom profiles to suit your grinding needs.

SMART CUT wheels can be optimized by adjusting the diamond bond hardness and other characteristics to ensure optimal performance for your specific grinding process.

We provide onsite application support and process fine-tuning to help you achieve the best results with your SMART CUT Diamond Edge Grinding Wheels. Our team can assist in optimizing the wheel’s performance for your specific grinding needs.

SMART CUT wheels, thanks to their multi-layer electroplated design and uniform diamond distribution, offer extended lifespans compared to single-layer products, providing longer operational use and reduced frequency of replacements.

SMART CUT wheels are suitable for both rough and fine grinding applications, providing versatility across different industries and material types.

Yes, SMART CUT wheels are engineered for wafer-to-wafer grinding applications, offering consistent performance and high material yield.

SMART CUT Diamond Edge Grinding Wheels are specifically designed for high-precision edge grinding of hard and brittle materials. Unlike traditional grinding wheels, they offer superior performance, longer tool life, and minimal edge chipping due to their uniform diamond distribution, multi-layer electroplated structure, and engineered diamond exposure ratio.

The uniform diamond distribution and engineered diamond exposure ratio help ensure that the cutting action is consistent and controlled, resulting in smooth grinding and reducing the risk of edge chipping. Additionally, the multi-layer electroplated construction contributes to less wear and damage during the grinding process.

SMART CUT wheels are available in two standard wheel diameters: 102 mm and 202 mm. Custom diameters can be manufactured upon request for specific applications.

The Electrical Discharge Machining (EDM) process is used to precisely machine the grooves of SMART CUT wheels. This ensures strict control over the geometric tolerance of each groove, leading to accurate and consistent edge grind profiles, which is crucial for industries requiring high precision.

SMART CUT Diamond Edge Grinding Wheels are versatile and can be used in both wet and dry grinding applications. For wet grinding, we recommend using the appropriate coolant to extend tool life and improve performance.

While SMART CUT wheels can be used without coolant for dry grinding, we recommend using a high-quality coolant for wet grinding applications. The use of the correct coolant helps reduce heat build-up, improves surface finish, and prolongs the life of the grinding wheel.

SMART CUT wheels use a metal bond, available in both standard and hard options. The metal bond provides excellent diamond retention, making the wheel more durable and resistant to wear, which is essential for grinding hard and brittle materials.

Yes, SMART CUT wheels are designed to handle thin and delicate materials, delivering accurate grinding results without causing significant edge damage or warping. Their precision design makes them well-suited for wafer and other thin material applications.

SMART CUT wheels are engineered to optimize material yield, ensuring that the maximum amount of material is utilized while minimizing waste. This makes them an excellent choice for industries where maximizing material yield is critical.

Yes, SMART CUT wheels can be tailored to meet your specific grinding needs. Custom options include adjusting the grit size, bond hardness, groove profile, and other parameters to suit the unique requirements of your grinding application.

SMART CUT wheels typically require a short break-in period to optimize diamond exposure. The exact time will depend on the specific application and grinding parameters, but generally, the wheel will reach peak performance after a brief initial use.

SMART CUT wheels are ideal for high-precision edge grinding of hard and brittle materials with minimal edge chipping and high material yield. If you require a durable, consistent, and high-performance grinding solution for tough materials, SMART CUT is the right choice. We also offer expert advice and support to help you determine the best product for your needs.

To maximize the lifespan of your SMART CUT wheels, ensure proper maintenance such as regular dressing, appropriate grinding speeds, and using the correct coolant for wet grinding. Following recommended operating parameters and performing periodic maintenance will help preserve wheel life and performance.

Yes, SMART CUT wheels are available in different bond strengths (standard or hard). The choice of bond strength will depend on the material being ground and the desired performance characteristics. We can help you select the appropriate bond strength for your specific application.

SMART CUT wheels offer superior part quality due to their uniform diamond distribution, engineered diamond exposure ratio, and multi-layer electroplating. These features ensure a consistent profile, high material yield, and superior surface finishes, all while minimizing edge chipping and subsurface damage.

The multi-layer electroplating of SMART CUT wheels enhances their durability, providing a higher diamond concentration and extended tool life. This layer ensures optimal diamond exposure, which translates into more consistent and efficient grinding over time, particularly in demanding edge grinding applications.

Yes, SMART CUT wheels are specifically designed for high-precision wafer grinding. Their uniform diamond distribution and ability to handle thin, delicate materials make them ideal for applications such as semiconductor wafer edge grinding and other wafer-to-wafer processes.

SMART CUT wheels can be tailored for both rough and fine grinding, depending on the grit size chosen. The flexibility to accommodate different grinding finishes ensures that SMART CUT wheels are adaptable to a wide range of applications, from initial material removal to fine edge finishes.

The use of SMART CUT wheels improves the overall grinding process by increasing throughput, reducing grinding time, and enhancing the surface finish quality. With their extended lifespan and consistent performance, these wheels help improve production efficiency and minimize downtime due to tool changes.

Yes, SMART CUT wheels are compatible with automated grinding systems. Their durability, uniformity, and customizable profiles make them ideal for integration into automated processes where precision, speed, and consistency are essential.

No, SMART CUT wheels can be used with standard grinding equipment. However, for optimal performance, it’s recommended to use equipment that can handle the precise speed and pressure requirements specific to your application. Additionally, the use of proper coolants may be required for wet grinding applications.

Choosing the right grit size depends on the material you’re grinding and the desired finish. For rough grinding, larger grits (such as 400-800) are typically used, while finer grits (such as 1,000-3,000) are ideal for achieving smooth finishes. Our technical team can assist in recommending the optimal grit size for your specific application.

The EDM process ensures extremely tight tolerances on groove dimensions, allowing for highly accurate groove profiles. This is essential for applications requiring precise edge grinding and dimensional consistency. It also helps extend the wheel’s lifespan by reducing the likelihood of groove wear during use.

In high-throughput environments, SMART CUT wheels help reduce cycle times by maintaining consistent performance across multiple grinding sessions. The increased diamond exposure and longer lifespan contribute to higher productivity without compromising surface finish quality.

While SMART CUT wheels are optimized for grinding, they can also be used for certain polishing applications, especially when a fine finish is required. For polishing tasks that require a higher degree of smoothness, additional polishing tools or finer grit sizes may be recommended.

Yes, SMART CUT wheels are versatile and can be used in various industries beyond semiconductors, such as optics, automotive, aerospace, and precision manufacturing, where hard and brittle materials require high-precision grinding.

Customization options for SMART CUT wheels include groove profiles (V, R, or custom), grit sizes (ranging from 400 to 3,000 JIS), bond hardness (standard or hard), and even the number of grooves per wheel. We can also tailor the bond characteristics to match your specific material and process needs.

SMART CUT wheels are engineered for high material yield, allowing you to grind with greater precision while minimizing material loss. Their consistent grinding process ensures that parts are ground efficiently without unnecessary waste, making them a cost-effective solution for high-precision applications.

To maintain the performance and longevity of SMART CUT wheels, store them in a clean, dry environment away from excessive heat or moisture. Ensure that the wheels are kept free from any contaminants, which could affect their performance when used.

Yes, SMART CUT wheels are ideal for grinding fragile and thin materials, including delicate wafers or ceramics. Their precision design helps ensure minimal damage to the edges and surfaces, making them perfect for industries where part integrity is critical.

You should consider replacing your SMART CUT wheel when you notice a decrease in grinding efficiency, surface finish quality, or when the wheel starts to show signs of significant wear. Regular maintenance, including dressing the wheel, can help extend its life, but eventual replacement is necessary to maintain optimal performance.

SMART CUT wheels are designed with durability and longevity in mind, helping to reduce waste and the need for frequent wheel replacements. Using these wheels can help lower the overall environmental impact by reducing material consumption and improving the efficiency of the grinding process.

Tab Content

Tab Content

Tab Content

SMART CUT® Diamond Edge Grinding Wheels are suitable for use with a variety of materials, including:

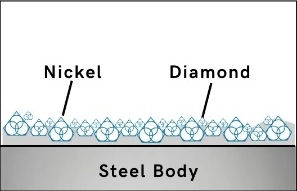

Electroplated (nickel bond) diamond products usually have a single layer of diamonds, held by a tough durable nickel alloy. Nickel is frequently used as a base for plating diamond. Because of its excellent strength, toughness and flexibility during the plating process. Electroplated diamond products are able to retain their original shape and dimensions thought their working life. Unlike sintered (meal bond) or resin bond diamond products, where diamond particles are buried in bond and held together by metal or resin binder deep inside.

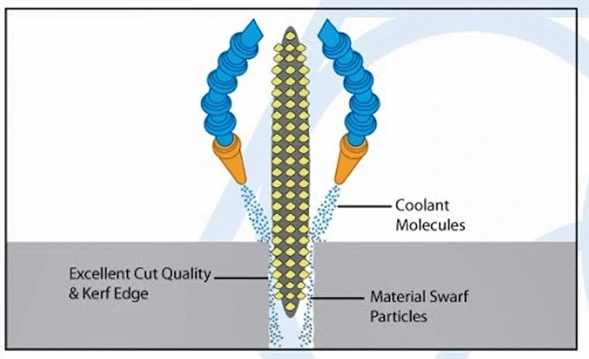

Electroplating allows diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.

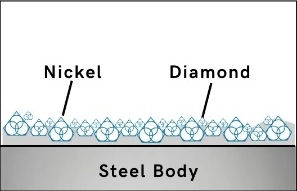

They have several layers of diamonds, held by a tough durable nickel alloy. Providing high diamond concentration, better diamond crystal retention and maximum diamond particle (grit) exposure/protrusion ratio. This provides freer, faster cutting action with minimum heat generation. Advantages of this type of technology include: longer tool life, more uniformity in performance, less stress to material being worked on, minimum material deformation, and better preservation of true material micro structure. This is specially important for more delicate, sensitive applications such as: glass, crystals, silicon wafers, carbon composites, sapphire, etc.

Electroplating is the only bond that allows different diamond crystal protrusion/exposure through use of different coating thicknesses. Usually the exposure ratio is based on the application (materials to be cut) The final specification depends primarily on the machining task and the associated necessary chip clearance space. For high-speed grinding the coating thickness should be about 30 to 40% of the grit particle diameter, when grinding or cutting glass fibre-reinforced plastics 30 to 50%, when machining ceramic material and cemented carbide 60 to 70%, and when machining stone up to 100%.

The sharpest and finest quality diamonds or CBN crystals that go into a SMART CUT® Diamond Bond, immediately penetrate into the material, grinding and polishing as they cut.

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

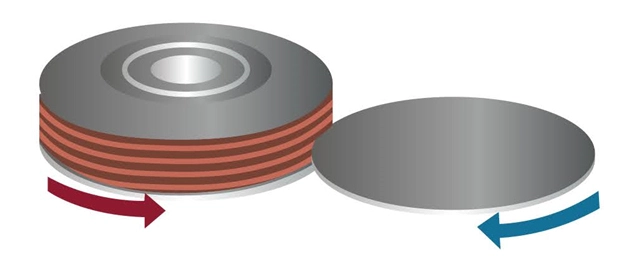

Once the peripheral dimensions of the silicon wafers are established through peripheral grinding, attention turns to surface and edge grinding. This stage is crucial for achieving the necessary flatness and surface quality for semiconductor fabrication, which involves intricate processes like photolithography and various deposition techniques.

Surface and edge grinding play several key roles. Firstly, surface grinding ensures the wafers are perfectly flat, which is vital for the success of subsequent photolithographic processes where any deviation can cause focus issues and pattern distortions.Secondly, edge grinding targets the wafer’s outer rim to remove microscopic cracks or chips that could propagate during processing and potentially lead to wafer breakage. Lastly, both grinding methods enhance the smoothness of the wafer's surface, essential for the uniform deposition of thin films and other materials in later stages.

These grinding processes use specialized machines equipped with fine-grit, diamond-coated grinding wheels, performing under tightly controlled conditions. The selection of the grinding wheel is critical; wheels with finer abrasive particles are chosen for a smoother finish, while coarser grits are used for rapid material removal. Key grinding parameters such as wheel speed, feed rate, and depth of cut are carefully optimized to balance the removal rate with surface quality, and these parameters often vary depending on the type of silicon wafer and its intended application.

Coolants play an essential role in surface and edge grinding, minimizing thermal stress and flushing away silicon particles from the grinding interface. This prevents overheating and reduces the risk of surface contamination and damage. An excellent coolant for this application.

SMART CUT® HD-2 is a synthetic coolant specifically designed for the cutting of semiconductor materials, including sapphire, silicon, germanium, single-crystal SiC, and II-VI crystals. This coolant offers excellent cut rates and imparts outstanding surface finishes with reduced warp and total thickness variation (TTV). It is ideal for diamond abrasive cropping, squaring, and wafering of silicon ingots and wafers.

Despite being routine, surface and edge grinding present several challenges. Maintaining uniform thickness across a single wafer and from one wafer to another is particularly challenging as wafer diameters increase. Grinding can also introduce sub-surface damage like micro-cracks and stresses, which must be minimized to ensure the mechanical and functional integrity of the wafers. Achieving the right balance in material removal is crucial; too much removal can weaken a wafer, while insufficient grinding may leave defects.

The quality of surface and edge grinding directly impacts the subsequent steps of semiconductor device fabrication. Imperfections in flatness or surface quality can adversely affect the lithography process,potentially leading to defective circuit patterns. Moreover, the integrity of the wafer's edges is critical to prevent breakage during handling, especially as wafers become larger and thinner.

Diamond edge grinding wheels are essential tools for high-precision grinding applications, particularly when working with hard and brittle materials such as ceramics, glass, and semiconductor wafers. These wheels are available in two main types: electroplated and sintered (metal bond), each offering distinct advantages depending on the specific grinding requirements. Below, we explore the differences between these two types of diamond edge grinding wheels, helping you choose the right one for your application.

Electroplated diamond wheels are made by electroplating diamond particles onto a metal core using an electrochemical process. This bonding technique results in a high concentration of diamond particles exposed at the surface of the wheel. The primary feature of electroplated wheels is their fast cutting ability, making them ideal for applications where quick material removal is necessary.

Sintered diamond wheels, also known as metal bond wheels, are manufactured by embedding diamond particles into a metal matrix, which is then heated and compressed to form a solid bond. This bond type is known for its durability and gradual wear characteristics, offering consistent performance over extended periods.

|

Attribute |

Sintered Metal Bond Edge Grinding Wheels |

Plated (Electroplated) Edge Grinding Wheels |

|---|---|---|

|

Bond Type |

Metal bond (sintered) |

Electroplated (diamond particles directly bonded to the core) |

|

Cutting Speed |

Slower cutting speed, controlled and consistent material removal |

Faster cutting speed, ideal for rapid material removal |

|

Tool Life |

Longer lifespan, gradual diamond exposure, consistent performance |

Shorter lifespan, diamonds wear out quickly, more frequent replacement |

|

Durability |

High durability for heavy-duty grinding |

Less durable under heavy grinding, more prone to wear |

|

Surface Finish Quality |

High-quality finish, minimal edge chipping, consistent results |

May cause more edge chipping and surface inconsistencies, lower finish quality |

|

Subsurface Damage |

Lower subsurface damage due to controlled diamond release |

Generally lower subsurface damage but can vary depending on wear |

|

Chipping & Cracking |

Minimal edge chipping, excellent for precision grinding of brittle materials |

Higher risk of edge chipping due to faster wear and less controlled cutting |

|

Precision & Consistency |

Excellent for high-precision grinding with consistent results |

May show more variation in performance over time |

|

Grinding Efficiency |

Moderate material removal rate, suitable for controlled, precise grinding |

High material removal rate, efficient for quick grinding |

|

Suitability for Hard Materials |

Excellent for hard, brittle materials (e.g., ceramics, sapphire, glass) |

Better suited for softer or thin materials (e.g., thin wafers, soft ceramics) |

|

Risk of Edge Chipping |

Low risk, ideal for delicate edge grinding |

Higher risk, especially on brittle materials |

|

Cost |

Higher upfront cost but cost-effective in the long run due to longer lifespan |

Lower initial cost but higher long-term replacement costs |

|

Maintenance Requirements |

Requires more frequent dressing to maintain optimal performance |

Requires less frequent dressing, but needs more frequent replacement |

|

Suitability for Fine Finishes |

Ideal for high-precision, fine finishes with minimal edge chipping |

Suitable for rough or medium finishes, less precise for fine work |

|

Grinding Applications |

Precision edge grinding, wafer processing, ceramics, hard materials |

High-throughput grinding, thin materials, rapid material removal |

|

Customization Options |

Can be tailored with different grit sizes, bond strengths, and profiles |

Can be customized in terms of grit size and profile but with limitations on bond strength |

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2025. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales