-

0 items in quote

No products in the Quote Basket.

Band Saw Blades Electroplated (Nickel Bond)

SMART CUT® All diamond band saw blades are custom-manufactured to fit your exact material, needs, and application requirements. We will work with you to determine your needs and recommend the right parameters for your specific material/application.

SMART CUT® Diamond Band Saw Blades have proven the be an effective diamond machining tool on a large variety of materials and applications. With diamonds firmly attached to ultra thin metal body, Diamond Band Saw Blades remain the tool of choice for many diamond cutting and machining jobs. Perfect Solution for cutting a large variety of ultra hand and brittle materials such as quartz, glass, carbon, silicon, ceramics or composites. A large variety of diamond band saw blade specifications is available to fit any application.

DESCRIPTION

SPECIFICATIONS

INDUSTRIES USED IN

FAQ

ACCESSORIES

USAGE RECOMENDATION

DESCRIPTION

Blades are cut and welded to clients specification, weld is guaranteed for the life of the blade. Only the highest quality raw materials are used in the manufacturing process is carefully controlled, matching your application with the right bond type, grit size, bond hardness and composition.

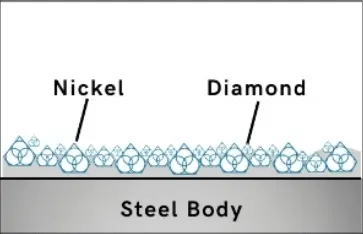

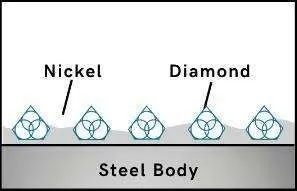

A band saw’s blade is diamond coated by electroplating, a process in which an electrical current deposits the coating onto the blade. This produces a hard, brittle Ni matrix that holds the diamonds in place and permits precise cutting on a variety of materials.

This process utilizes a flexible, toothed blade is welded into an endless band that rides on wheels driven by two pulleys and is guided through the work cut off or contour. Ideally Diamonds Band Saws Blades should be used on Band Saw Machines designed for this purpose. A friction saw is a special band saw capable of achieving band velocities of up to 15,000 sfpm or more.

SPECIFICATIONS

- Blade Thicknesses Available : 0.20″ to .035″

- Blade Widths Available : 1/4″ to 1.5″

- Grit sizes available : 35 to 120 mesh

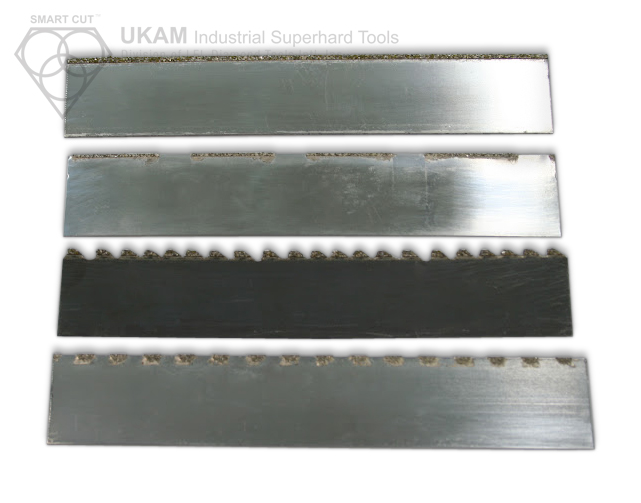

- Blade edge configurations available : continuous rim, segmented, gulleted, Scallop Segment

- Blade Backing Materials : Steel Alloy, Stainless Steel

- Coolant methods : Wet, Dry

- Average Band Saw Blade Life : 40 to 80 hours. Some has shown to last as long as 192 hours.

INDUSTRIES USED IN

Tab Content

FAQ

1. What materials can SMART CUT® Diamond Band Saw Blades cut?

SMART CUT® Diamond Band Saw Blades are suitable for cutting ultra-hard and brittle materials such as quartz, glass, carbon, silicon, ceramics, and composites.

2. Why are SMART CUT® Diamond Band Saw Blades effective for machining?

They use diamonds firmly attached to an ultra-thin metal body, making them highly effective for a wide variety of diamond machining and cutting applications.

3. Are different specifications of Diamond Band Saw Blades available?

Yes. A large variety of diamond band saw blade specifications are available to fit different machines and applications.

4. What industries commonly use Diamond Band Saw Blades?

They are widely used in industries that require precise cutting of hard and brittle materials, including diamond cutting, machining, and processing of advanced materials.

ACCESSORIES

Tab Content

USAGE RECOMENDATION

- Material Compatibility: Always ensure that the blade is suitable for the material you are cutting. Diamond blades are designed for specific materials and using them on incompatible substances can damage the blade or the material.

- Proper Installation: Ensure that the blade is correctly installed on the saw. The blade should be tensioned according to the manufacturer’s specifications to avoid slippage or breakage.

- Cutting Speed: Maintain an appropriate cutting speed. Too fast can overheat the blade and material, causing damage; too slow can reduce efficiency and cause unnecessary wear on the blade.

The recommended RPM (Revolutions Per Minute) for diamond band saw blades can vary significantly based on several factors including the type of material being cut, the diameter of the blade, the hardness of the material, and the specific design of the blade. Here are some general guidelines to consider:

- Material Type: Different materials require different cutting speeds. For example, softer materials like some types of ceramic or glass may be cut at higher speeds, while harder materials like quartz or granite require slower speeds.

- Blade Diameter: The larger the diameter of the blade, the slower the RPM should be. This is because a larger blade will have a higher cutting speed at the edge even with a lower RPM.

- Manufacturer’s Recommendations: Always check the manufacturer’s guidelines for the blade. These guidelines are based on extensive testing and are designed to optimize the blade’s performance and lifespan.

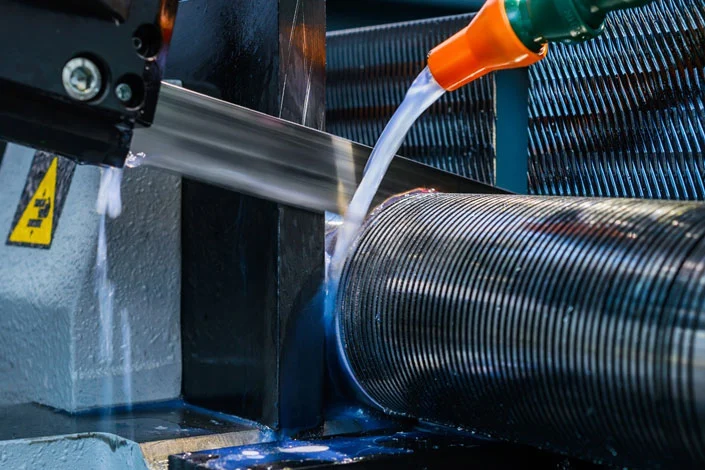

- Cooling Considerations: Higher speeds can generate more heat. If adequate cooling (like a water coolant system) is not in place, it’s advisable to use a lower RPM to prevent overheating the blade and the material.

- Type of Coolant: Water is often used as a coolant for diamond band saw blades, especially when cutting stone, glass, or tile. For some applications, especially in metal cutting, a water-soluble coolant or cutting oil is preferred to reduce friction and remove cuttings more effectively.

- Coolant Concentration: If you’re using a water-soluble coolant, ensure it’s mixed at the correct concentration. Too much water in the mixture can reduce its effectiveness, while too much concentrate can be wasteful and potentially harmful to the blade and workpiece.

- Continuous Flow: Ensure a continuous and adequate flow of coolant to the blade. The coolant should be applied directly where the cutting action is taking place to maximize its cooling and lubricating effects.

- Prevent Overheating: The primary purpose of the coolant is to keep the blade and the material being cut cool. Overheating can damage both the blade and the material and can also lead to dangerous situations.

- Coolant Cleanliness: Regularly clean and replace the coolant to prevent contamination. Dirty or contaminated coolant can reduce cutting efficiency and cause damage to the blade.

- Environmental Considerations: Be aware of the environmental and health implications of the coolant you choose. Some coolants may require special handling or disposal methods.

- Preventing Corrosion: If you’re using a water-based coolant, be mindful of the potential for rust and corrosion on your saw and blades. Consider adding a rust inhibitor to the coolant or regularly applying a rust preventative to your equipment.

- Coolant Distribution System: Maintain your coolant distribution system, ensuring that nozzles or hoses are not clogged and are positioned correctly to deliver coolant effectively to the blade.

- Avoiding Dry Cutting: Unless specifically designed for dry use, always use coolant with diamond band saw blades. Dry cutting can significantly reduce the life of the blade and degrade its performance.

- Coolant Temperature: In very hot conditions, the coolant itself can become warm. Consider ways to keep the coolant temperature down, as overheating can reduce its effectiveness.

- Safety and Health: Always use coolants in a well-ventilated area, and wear appropriate protective gear to avoid contact with skin and eyes. Some coolants may emit harmful vapors or be irritating to the skin.

- Recycling and Reuse: Some coolant systems allow for the recycling and filtration of the coolant for reuse. This can be both cost-effective and environmentally friendly.

- Compatibility with Materials: Ensure that the coolant is compatible with the material you are cutting. Some materials may react adversely with certain coolants.

- Coolant Pressure and Volume: Adjust the pressure and volume of the coolant to suit the cutting conditions. Different materials and cutting speeds may require different coolant pressures and volumes for optimal performance.

- Cutting Precision: For very precise cuts, a slower RPM may be beneficial as it allows for more control.

- Blade Wear and Tear: Using a higher RPM than recommended can lead to increased wear and a shorter lifespan for the blade. Conversely, a speed that is too low may result in inefficient cutting and unnecessary strain on the saw.

- Specific Applications: Some specialized applications may have unique RPM requirements. For instance, cutting very dense or abrasive materials often requires lower RPMs to minimize blade wear.

- Saw Capabilities: Ensure that the RPMs you choose are within the operational range of your saw. Operating a saw at an RPM it’s not designed for can be dangerous and damage the saw.

- Experience and Skill Level: Experienced users may be able to safely and effectively operate the saw at different RPMs based on their understanding of the material and the cutting process.

- Trial and Error: Sometimes, finding the optimal RPM requires a bit of experimentation, starting at a lower speed and gradually increasing it while monitoring the cutting performance and the condition of the blade.

- Lubrication and Cooling: Use an appropriate coolant or lubricant when cutting. This reduces heat build-up, prevents blade overheating, and extends the life of the blade.

- Safety Gear: Always wear appropriate safety gear including eye protection, ear protection, and gloves. Diamond cutting can produce small, sharp particles that pose a risk.

- Regular Inspections: Regularly inspect the blade for damage or wear. Look for missing or damaged diamonds and check the overall condition of the blade.

- Avoid Twisting: Keep the blade straight during cuts. Twisting or bending the blade can cause it to break.

- Feed Rate: Control the feed rate of the material into the blade. Forcing the material too quickly can overload and damage the blade.

- Blade Cleaning: Keep the blade clean from any build-up of material, which can affect its cutting efficiency.

- Storage: Store the blade in a dry, safe place where it won’t be damaged.

- Professional Advice: If unsure about the type of blade needed for a specific job, consult with a professional or refer to the manufacturer’s guidelines.

- Regular Maintenance: Ensure regular maintenance of the saw to keep it in good working condition, which also helps in extending the life of the blade.

Feed Rates

- Material Hardness: Softer materials can generally be cut at higher feed rates, while harder materials require a slower feed rate. For example, cutting marble will have a different optimal feed rate than cutting granite.

- Blade Specifications: The feed rate should match the specifications of the blade being used. Different blades are designed for different materials and cutting speeds. Always refer to the manufacturer’s guidelines.

- Thickness of the Material: Thicker materials require a slower feed rate to ensure an even and consistent cut. Pushing the blade too fast through a thick material can lead to blade deflection, uneven wear, or breakage.

- Type of Cut: Straight cuts can usually be made at a higher feed rate than curved or intricate cuts. For detailed work, a slower feed rate allows for greater precision.

- Blade Wear: A new blade can typically handle a faster feed rate. As the blade wears, you may need to adjust the feed rate to compensate for the reduced cutting efficiency.

- Cooling and Lubrication: Adequate cooling and lubrication can allow for slightly higher feed rates, as they help prevent blade overheating and material burning.

- Machine Capability: Ensure that the feed rate is within the capabilities of your cutting equipment. Overloading the machine can lead to poor cuts and potential damage to the machine or blade.

- Visual and Auditory Cues: Pay attention to the sound of the blade and the appearance of the cut. Chattering, excessive noise, or a rough cut surface can indicate that the feed rate is too high.

- Experience and Judgment: Operator experience plays a significant role in determining the right feed rate. Experienced operators can judge the optimal speed based on the cutting conditions and blade performance.

- Material Fracture Tendencies: Some materials are more prone to chipping or fracturing. A slower feed rate can reduce the risk of damaging these materials.

- Trial and Error: Sometimes finding the optimal feed rate requires experimentation. Start at a lower feed rate and gradually increase it while monitoring the cut quality and blade behavior.

- Safety Considerations: Always prioritize safety. A feed rate that is too high can be dangerous and may lead to loss of control or blade breakage.

- Consistency: Maintain a consistent feed rate throughout the cut for the best results. Inconsistent feeding can lead to blade wandering or irregular cuts.

- Feed Rate Units: Feed rates are typically measured in inches per minute (IPM) or millimeters per minute (mm/min). Ensure you are using the correct units and measurements.

- Blade Break-In: New diamond band saw blades often require a break-in period. Start with softer materials or less aggressive cutting to gradually expose new diamond grit. This can improve the overall performance and longevity of the blade.

- Avoid Overheating: Continuously monitor the blade temperature during use. Overheating can cause the metal to warp and the diamonds to lose their effectiveness. If the blade becomes too hot, pause cutting and allow it to cool down.

- Proper Tensioning: Maintain correct tension on the blade. Too much tension can lead to blade breakage, while too little can result in inaccurate cuts. Refer to the saw manufacturer’s guidelines for proper tensioning procedures.

- Use the Right Blade Width: Choose a blade width that is appropriate for the material and the type of cut you want to make. Wider blades are typically better for straight cuts, while narrower blades are ideal for cutting curves.

- Clean Cuts: Ensure that each cut is clean and straight. A wobbling or chattering blade can indicate a problem with the saw or the blade, and it can also lead to uneven wear or damage to the blade.

- Adjust for Blade Drift: Some band saws exhibit blade drift, where the blade does not cut in a perfectly straight line. Adjust the fence or your cutting technique to compensate for this drift to achieve accurate cuts.

- Use Variable Speed Saws When Possible: If your saw allows for speed adjustment, use this feature to match the speed to the hardness of the material. Harder materials often require slower speeds.

- Gradual Entry on Thick Materials: When starting a cut on a thick or dense material, begin slowly and increase the feed rate gradually. This approach helps in preventing blade shock and reduces the risk of chipping.

- Avoiding Blade Twist: When cutting curves, be mindful not to twist the blade excessively. Sharp turns can strain the blade and cause premature wear or breakage.

- Periodic Resting: Allow the blade to rest periodically during prolonged cutting sessions. This prevents continuous heat build-up and extends blade life.

- Disposal and Replacement: Once a blade becomes too worn or damaged, dispose of it properly and replace it with a new one. Continuing to use a damaged blade can be inefficient and unsafe.

- Training and Experience: If you’re new to using a diamond band saw, consider getting training or advice from experienced users. Understanding the nuances of these blades can greatly improve your cutting technique and safety.

- Blade Direction and Alignment: Ensure that the blade is mounted in the correct direction and is perfectly aligned with the band saw. Misalignment can cause uneven wear and poor cutting performance.

- Avoid Dry Cutting: Unless the blade is specifically designed for dry cutting, always use water or an appropriate coolant. Dry cutting with a blade meant for wet use can lead to overheating and premature wear.

- Regular Blade Cleaning: Over time, cutting residue can build up on the blade, affecting its performance. Regular cleaning helps maintain its cutting efficiency and prolongs its lifespan.

- Monitor Blade Wear: Be attentive to signs of wear such as reduced cutting performance, increased noise, or unusual vibrations. These signs can indicate that the blade needs to be replaced.

- Cutting Technique: For thicker materials, use a “step cutting” technique where you make a series of gradually deeper cuts. This approach can reduce the stress on the blade and improve the quality of the cut.

- Reduce Blade Fatigue: Alternate between different blades if you are making a large number of cuts. This allows each blade to rest and cool down, reducing the risk of fatigue and breakage.

- Avoid Impact or Shock: Never force the blade into the material. A smooth, steady approach is best. Impact or shock can cause diamond grit to dislodge or the blade to break.

- Correct Blade Storage: Store unused blades in a safe, dry place, ideally hanging or laid flat in a way that does not put stress on the blade. Avoid kinking or bending the blade.

- Manufacturer’s Instructions: Always follow the manufacturer’s instructions for use, maintenance, and safety. Different blades may have specific requirements or recommendations.

- Prevent Corrosion: After use, especially with water or coolant, dry the blade to prevent rust and corrosion. This is particularly important for the non-diamond parts of the blade.

- Blade Tracking: Regularly check and adjust the blade tracking. Proper tracking ensures that the blade runs smoothly on the wheels of the saw, reducing wear and the risk of blade deviation.

- Sharp Turns and Corners: When cutting sharp corners or intricate patterns, reduce the feed rate and carefully guide the material. Forcing the blade through tight turns can damage it.

- Understand Blade Specifications: Familiarize yourself with the blade’s specifications such as diamond grit size, concentration, and bond hardness. This information helps in selecting the right blade for a specific material and cutting requirement.

- Respect Load Capacity: Be mindful of the blade’s load capacity. Overloading can lead to blade deformation and potential breakage.

- Professional Maintenance: Consider having your blades professionally sharpened or re-tipped if they become dull. This can be more cost-effective than purchasing new blades.

- Safety First: Lastly, prioritize safety above all else. If you’re ever uncertain about a cutting task, seek professional advice or assistance to prevent accidents.

- Understand Blade Limits: Be aware of the maximum and minimum thicknesses and types of materials your blade is designed to cut. Using a blade outside of its intended range can lead to poor performance and potential blade damage.

- Controlled Feed Pressure: Apply a consistent and controlled feed pressure when cutting. Erratic pressure can cause blade deflection or breakage, and uneven wear.

- Avoid Blade Binding: Ensure that the material being cut does not pinch the blade. Blade binding can cause excessive wear and potential blade breakage.

- Material Stability: Secure the material being cut firmly. Movement during cutting can lead to inaccurate cuts and increase the risk of blade damage.

- Coolant Flow and Quality: Check the flow and quality of the coolant regularly. Ensure that the coolant is reaching the point of the cut and that it is not contaminated, as dirty coolant can harm the blade’s performance.

- Avoid Excessive Bending: When cutting curves, avoid bending the blade excessively as it can lead to metal fatigue and eventual failure.

- Use Appropriate Blade Speeds: Different materials require different blade speeds for optimal cutting. Consult the blade and material specifications for the recommended speeds.

- Blade Thickness Awareness: Be aware of the blade’s thickness and how it relates to the kerf (the width of the cut). This is important for precision cutting and avoiding material waste.

- Regular Breaks During Intensive Use: If using the blade intensively, give it and the saw regular breaks to prevent overheating.

- Blade Dressing: Periodically dress the blade to expose fresh diamond edges. This is especially important for blades that see a lot of use.

- Support Material Adequately: Ensure that larger or heavier materials are adequately supported to prevent blade pinching or deflection.

- Handle with Care: Diamond blades are robust in cutting but can be fragile if mishandled. Avoid dropping or striking the blade.

- Blade Path Clearance: Ensure that the path of the blade is clear of obstructions, including clamps, to prevent accidental contact and potential damage.

- Blade Compatibility with Saw: Ensure the blade is compatible with your particular band saw, considering factors like blade length, width, and tooth pitch.

- Avoid Reactive Materials: Be cautious when cutting materials that may react with water or coolants, such as certain metals, as this can cause damage or safety hazards.

- Record Keeping: Keep records of blade usage, including types of materials cut and hours of operation. This can help in scheduling maintenance and predicting blade life.

- Environmental Considerations: Be mindful of the environmental conditions in which you are working. Extreme temperatures and humidity can affect both the material being cut and the blade.

- User Training and Awareness: Ensure that all operators are adequately trained and aware of the proper usage and safety procedures for diamond band saw blades.

- Blade Disposal: Dispose of used or damaged blades properly, considering local regulations and safety practices.

- Stress Relief Cuts: When cutting large or thick materials, make relief cuts to reduce stress on the blade. This technique involves making additional cuts to remove material and prevent binding.

- Avoiding Side Pressure: Apply cutting pressure in a straight line. Side pressure can bend the blade and lead to uneven wear or breakage.

- Correct Blade Orientation: Make sure the blade’s direction of rotation is correct. A blade installed backwards will be ineffective and can be damaged.

- Material Clamping: Properly clamp or secure the material being cut to prevent movement. Unstable materials can cause irregular cuts and put extra stress on the blade.

- Regular Saw Maintenance: In addition to blade maintenance, ensure that the saw itself is in good condition. This includes checking the guide bearings, tension mechanism, and overall alignment.

- Blade Guide Adjustment: Adjust the blade guides correctly to support the blade close to the cut. This prevents blade deflection and ensures straighter cuts.

- Blade Teeth Per Inch (TPI) Selection: Choose the appropriate TPI for your blade based on the material’s thickness. Generally, a higher TPI is better for thinner materials, and a lower TPI for thicker materials.

- Avoiding Quick Stops and Starts: Avoid abrupt stops and starts during cutting, as this can jar the blade and potentially lead to damage.

- Using a Push Stick for Small Pieces: When cutting small pieces, use a push stick or other device to feed the material. This keeps hands away from the blade and minimizes the risk of injury.

- Cutting at a Consistent Angle: Maintain a consistent angle when feeding the material into the blade. Inconsistent angles can lead to irregular cuts and put uneven stress on the blade.

- Proper Saw Alignment: Ensure that the saw’s wheels, guides, and table are properly aligned according to the manufacturer’s specifications. Misalignment can cause the blade to wear unevenly or break.

- Blade Tension Monitoring: Regularly check the blade tension, as it can change with temperature fluctuations and use. Incorrect tension can lead to poor cutting performance or blade failure.

- Understanding Blade Life Expectancy: Be aware of the typical life expectancy of your blade under normal conditions and plan for replacement accordingly.

- Post-Use Inspection: After each use, inspect the blade for any signs of damage, including chips, cracks, or missing segments. Early detection of damage can prevent more serious issues.

- Avoiding Hazardous Materials: Do not cut materials that might be hazardous, such as materials containing asbestos or other harmful substances.

- Record Blade Performance Issues: Keep a log of any issues encountered during cutting. This can help in troubleshooting and identifying when a blade needs to be replaced or serviced.

- Environmental Cleanliness: Keep the work area clean and free of debris. A cluttered or dirty environment can lead to accidents and affect cutting accuracy.

- Proper Handling and Storage: Handle blades with care, avoiding any actions that could bend or twist them. Store them in a way that prevents physical damage.

- Regular Calibration of Equipment: Regularly calibrate your saw to ensure accurate cuts. Misalignment can lead to increased wear on the blade and poor quality cuts.

- Safety Checks: Perform routine safety checks on the saw and blade before each use. Ensure all safety guards are in place and functioning.

- Personal Protection Equipment (PPE): Always wear appropriate PPE, such as safety glasses, gloves, and hearing protection, when operating the saw.

- Avoid Cross-Contamination: Use different blades for cutting different materials to prevent cross-contamination, which can affect cutting performance and blade life.

- Gradual Increase in Cutting Load: When starting a cutting session, gradually increase the cutting load to allow the blade to warm up, which can prevent shock and wear.

- Regular Coolant Replacement: Change the coolant regularly to prevent contamination, which can affect the cutting process and potentially damage the blade.

- Inspect for Unusual Noises or Vibrations: Be alert to any unusual noises or vibrations during operation, as these can be early signs of blade or equipment issues.

- Use of Blade Stabilizers: Consider using blade stabilizers, if appropriate, to reduce blade vibration and enhance cutting precision.

- Proper Material Support: Ensure that the material is adequately supported both before and after the cut to prevent any unnecessary blade stress or deflection.

- Avoid Abrupt Force: Never apply abrupt force to the blade, either in the cutting direction or laterally. Gentle, consistent pressure is key.

- Maintain a Clean Blade Path: Regularly clean the path of the blade, including guides and wheels, to prevent buildup that can affect the blade’s performance.

- Periodic Professional Assessment: Have your equipment and blades periodically assessed by a professional to ensure they are in optimal condition.

- Educate on Emergency Procedures: Make sure all operators are aware of emergency procedures in case of blade breakage or equipment failure.

- Use the Right Machine for the Blade: Ensure that the saw machine used is suitable for the type of diamond band saw blade, considering factors like power, speed, and size.

- Monitor Blade Alignment During Use: Regularly check the alignment of the blade during use, as it can shift, especially when cutting tougher materials.

- Balanced Blade Wear: Rotate the blade usage if possible, to ensure even wear, which can extend the life of the blade.

- Avoid Twisting the Blade Off the Material: When finishing a cut, avoid twisting the blade off the material, as this can damage the blade.

- Proper Decommissioning of Blades: Decommission blades that are beyond their useful life in a responsible manner, respecting safety and environmental guidelines.

- Attention to Blade’s Running Direction: Ensure that the blade’s running direction matches the indicated direction on the saw. Reversed blades will underperform and can be damaged.

- Check for Material Defects: Before cutting, inspect the material for defects or foreign objects that might damage the blade.

- Lubrication of Moving Parts: Regularly lubricate all moving parts of the saw to ensure smooth operation and reduce wear on the blade.

- Use Blades with Suitable Diamond Grit: Choose a blade with a diamond grit size that is appropriate for the material being cut for optimal performance.

- Safety Training for New Operators: Provide comprehensive safety and operational training for new operators, including practical demonstrations and supervised practice sessions.

- Respect Maximum Depth of Cut: Do not exceed the blade’s maximum depth of cut. Overextending the blade can lead to damage and unsafe conditions.

- Environmental Factors: Consider the impact of environmental factors like humidity and temperature on both the material being cut and the blade.

- Preventive Maintenance Schedule: Establish and adhere to a regular preventive maintenance schedule for both the saw and the blades.

- Ensure Emergency Stop Accessibility: Make sure that the emergency stop button or feature on the saw is easily accessible during operation.

- Understanding Blade’s Limitations: Recognize that even the highest quality diamond band saw blades have limitations and are not indestructible.

Diamond Band Saw Trouble Shooting Guide

Problem

Possible Causes

Solutions

Blade Breakage

Excessive tension

Reduce blade tension

Improper blade size for machine

Ensure correct blade size is used

Excessive feed pressure

Adjust feed pressure to recommended level

Fatigue from repeated bending

Check and adjust blade tracking

Blade Dulling Quickly

Incorrect blade speed

Adjust to optimal speed for material

Inadequate coolant or wrong type

Check coolant flow and type; replace if necessary

Cutting material too hard for blade

Use a blade suitable for the material hardness

Overuse without rest

Allow intervals of rest for the blade

Inaccurate Cuts

Worn or damaged blade guides

Inspect and replace blade guides as needed

Blade misalignment

Align the blade correctly

Incorrect blade tension

Adjust blade tension to recommended level

Using a blade with incorrect tooth pitch

Use a blade with appropriate tooth pitch

Excessive Vibration

Worn bearings

Inspect and replace bearings if needed

Misaligned wheels

Align the saw wheels properly

Damaged blade

Replace the blade

Loose components in the machine

Tighten all loose parts and components

Difficulty in Starting the Cut

Dull blade

Replace or sharpen the blade

Incorrect blade for material type

Select the appropriate blade for the material

Insufficient coolant

Ensure adequate coolant flow

Improper technique

Review and adjust cutting technique

Excessive Noise

Blade hitting machine parts

Check and adjust blade tracking

Loose components

Tighten all loose parts and components

Worn or damaged blade

Inspect blade for damage and replace if necessary

Uneven Wear on Blade

Improper blade tension

Adjust blade tension to even out wear

Misaligned blade

Realign the blade

Uneven material surface

Ensure material is uniformly supported

Uneven Cut Surface

Worn or damaged blade teeth

Replace or sharpen the blade

Blade running at incorrect speed

Adjust blade speed according to material specifications

Improper blade tension

Adjust tension to recommended levels

Excessive Blade Wear

Continuous operation without breaks

Allow the blade to rest periodically

Cutting abrasive materials

Use blades designed for abrasive materials

Insufficient or inappropriate coolant

Use the correct coolant and ensure proper flow

Saw Not Cutting Straight

Blade guides misaligned

Realign the blade guides

Worn or damaged blade

Replace the blade

Machine components out of calibration

Calibrate machine components

Frequent Blade Slippage

Insufficient blade tension

Increase blade tension to proper level

Worn or damaged drive wheels

Replace or repair the drive wheels

Coolant on the blade or wheels

Clean the blade and wheels, ensure coolant is controlled

Coolant Issues

Clogged coolant nozzles

Clean or replace the nozzles

Insufficient coolant flow

Adjust the coolant system for better flow

Incorrect coolant mixture

Ensure the correct mixture and type of coolant

Increased Power Consumption

Blade binding in the cut

Check for proper blade alignment and tension

Dull blade increasing resistance

Replace or sharpen the blade

Motor or drive system issues

Inspect and service the motor and drive system

Difficulty in Blade Installation

Incorrect blade length or width

Use the correct size of blade for your saw

Tension mechanism issues

Inspect and repair the tension mechanism

Misalignment of blade path components

Align the components properly

Blade Deviates from Cut Line

Incorrect blade tension

Adjust tension to recommended levels

Worn or damaged blade teeth

Replace the blade

Misaligned blade guides

Adjust or replace blade guides

Rapid Tooth Strip Off

Excessively hard material

Use a blade designed for harder materials

Too high feed rate

Reduce feed rate

Insufficient blade tension

Adjust blade tension

Blade Binding

Misaligned workpiece

Ensure proper workpiece alignment

Inadequate support for workpiece

Use appropriate supports to stabilize workpiece

Blade worn or damaged

Replace the blade

Irregular Tooth Wear

Uneven material hardness

Check material consistency

Incorrect blade for material type

Select the appropriate blade for the material

Improper blade tension

Adjust tension to recommended levels

Slow Cutting Speed

Blade becoming dull

Replace or sharpen the blade

Incorrect blade speed for material

Adjust the blade speed according to material type

Inadequate power supply to saw

Check and ensure proper power supply

Noise or Chatter During Cutting

Loose components in the saw

Tighten all loose parts and components

Blade tension too low

Increase blade tension

Worn or damaged blade guides

Replace or adjust blade guides

Difficulty in Controlling Cut Direction

Blade too wide for the curve being cut

Use a narrower blade for tight curves

Inadequate blade tension

Adjust tension to recommended levels

Worn or damaged blade

Replace the blade

Excessive Coolant Spatter

High coolant pressure

Adjust the coolant pressure to a lower setting

Misaligned coolant nozzles

Adjust the nozzle alignment

Excessive blade speed

Reduce blade speed

Motor Overheating

Overloading the saw

Reduce feed rate and check for correct blade usage

Inadequate ventilation

Ensure proper ventilation around the motor

Electrical issues

Check and fix any electrical connections and components

Problem

Possible Causes

Solutions

Reduced Cutting Precision

Blade wear and tear

Replace the blade with a new one

Incorrect blade type for the task

Use a blade type more suited to the material

Machine calibration issues

Calibrate the saw according to manufacturer’s guide

Frequent Overheating of Blade or Saw

Continuous operation without adequate cooling

Ensure regular cooling intervals; check coolant system

Overfeeding the material

Reduce feed rate to decrease strain on the blade

Inefficient coolant system

Check and repair the coolant system

Increased Material Waste

Blade wandering off course

Check blade alignment and tension

Incorrect blade width for the material

Use a blade width appropriate for the material

Improper feed rate

Adjust the feed rate for more efficient cutting

Blade Becomes Stuck in Material

Insufficient blade tension

Increase blade tension

Debris build-up on the blade

Clean the blade regularly

Worn or damaged blade teeth

Replace the blade

Difficulty in Blade Tracking

Misalignment of wheels or guides

Adjust the alignment of wheels and guides

Worn or damaged tires on wheels

Replace tires on wheels

Blade not properly seated

Reinstall the blade correctly

Inconsistent Blade Life

Variation in material hardness

Use a blade suited for varying material hardness

Fluctuating feed rates

Stabilize feed rate

Inconsistent maintenance practices

Establish a regular maintenance routine

Excessive Noise During Start-up

Loose components or covers

Tighten all loose components and covers

Motor or belt issues

Inspect and repair/replace motor or belts

Dry or unlubricated moving parts

Lubricate moving parts according to guide

Difficulty in Adjusting Blade Tension

Faulty tension adjustment mechanism

Repair or replace the tension adjustment mechanism

Worn tension springs

Replace tension springs

Corrosion or debris in tensioning components

Clean and lubricate tensioning components

Problem

Possible Causes

Solutions

Frequent Resetting of Circuit Breaker

Electrical overload

Check electrical load and reduce if necessary

Short circuit in saw wiring

Inspect and repair any wiring issues

Faulty motor

Inspect and replace the motor if necessary

Blade Falling Off the Wheels

Insufficient blade tension

Adjust the blade tension

Worn or improperly aligned wheel tires

Replace or realign the wheel tires

Damaged or misaligned blade wheels

Repair or replace the blade wheels

Inefficient Cutting of Curves

Blade too wide for tight curves

Use a narrower blade for tighter curves

Incorrect blade tension

Adjust the blade tension

Improper saw speed

Adjust the saw speed to match the cutting requirement

Vibration in the Saw

Unbalanced wheels

Balance the wheels

Loose components in the saw

Tighten all loose parts and components

Worn bearings or drive belts

Replace worn bearings or drive belts

Difficulty in Maintaining Cut Line

Blunt blade teeth

Sharpen or replace the blade

Incorrect blade for the type of material

Use a blade that is suitable for the material

Misalignment of blade guides

Adjust or replace the blade guides

Excessive Dust and Debris Accumulation

Inadequate dust extraction system

Improve or install a proper dust extraction system

Blade not clearing debris

Check blade type and condition

effectively

replace if necessary

Overloading the saw with material

Reduce the volume of material processed at a time

Difficulty in Blade Alignment

Misaligned blade tracking

Adjust the blade tracking

Worn out blade tensioning components

Replace or repair tensioning components

Debris on blade path

Clean the blade path thoroughly

Blade Chipping or Cracking

Impact with hard or foreign objects in material

Inspect material for foreign objects before cutting

Excessive tension or feed pressure

Adjust tension and feed pressure

Use of blade beyond its lifespan

Replace the blade regularly

Blade Loses Tension During Cutting

Defective tension mechanism

Repair or replace the tension mechanism

Expansion of blade due to heat

Allow blade to cool; adjust tension as necessary

Worn tensioning components

Replace worn components

Material Burn Marks

Too slow cutting speed

Increase the cutting speed

Dull blade

Replace or sharpen the blade

Insufficient coolant

Increase coolant flow or check coolant quality

Blade Produces Rough Cut

Incorrect blade for the material

Use a blade suited for the material

Blade teeth are dull or damaged

Sharpen or replace the blade

Excessive feed pressure

Adjust feed pressure to recommended levels

Saw Struggles to Start Cutting

Low power supply

Check electrical supply and correct any issues

Blade not properly sharpened

Sharpen the blade or replace if necessary

Misalignment of blade or guides

Realign blade and guides as necessary

Inconsistent Blade Movement

Worn or loose drive belts

Replace or tighten the drive belts

Fluctuating power supply

Stabilize the power source or correct electrical issues

Damaged blade wheels

Inspect and replace damaged blade wheels

Difficulty in Changing Blades

Stiff blade tensioning system

Lubricate or repair tensioning system

Misaligned blade guides

Adjust or realign the blade guides

Corroded or jammed blade clamps

Clean, lubricate, or replace blade clamps

Excessive Wear on Blade Back

Blade rubbing against machine parts

Adjust blade tracking and guides

Improper blade tension

Adjust tension to the correct level

Worn blade guides

Replace or adjust the blade guides

Intermittent Cutting Issues

Intermittent electrical issues

Check and repair any electrical connections

Variable material density

Adjust cutting approach based on material density

Inconsistent blade tension

Regularly check and adjust blade tension

Saw Stops Mid-Cut

Overheating due to continuous use

Allow the saw to cool down; use intermittently

Electrical issues, like overheating or faulty wiring

Inspect and repair electrical components

Motor failure

Check the motor and replace if necessary

Blade Wandering During Cut

Blade tension too low

Adjust the blade tension

Worn or improper blade for the material

Replace the blade with a suitable type

Misalignment of blade guides or wheels

Adjust or replace the guides or wheels

Excessive Kerf Width

Blade width too wide for the application

Use a narrower blade

Blade wearing unevenly

Replace the blade; check machine alignment

Improper blade tension

Adjust the blade tension correctly

Coolant Leakage or Spillage

Loose or damaged coolant hoses

Tighten or replace coolant hoses

Overflow from the coolant reservoir

Check and adjust coolant levels

Incorrect coolant nozzle position

Reposition the coolant nozzles

Blade Corrosion or Rusting

Exposure to moisture or improper storage

Store blades in a dry environment; use rust inhibitors

Lack of proper blade maintenance

Clean and oil the blade regularly

Use of corrosive coolants

Switch to a non-corrosive coolant

Motor Vibration or Noise

Imbalanced motor rotor

Inspect and balance the motor rotor

Worn motor bearings

Replace motor bearings

Misalignment of motor with saw components

Realign the motor with the saw components

Difficulty in Maintaining Constant Speed

Variable power supply

Stabilize power source

Drive belt slippage or wear

Adjust or replace the drive belt

Malfunctioning speed control mechanism

Repair or replace the speed control

Blade Teeth Breaking Off

Hitting hard inclusions in the material

Inspect material for hardness variations before cutting

Excessive feed rate

Adjust the feed rate to be more gentle

Fatigue from repeated bending or twisting

Avoid twisting the blade; replace if it becomes fatigued

Table of comparision between plated and braised bond

Comparison Criteria

Electroplated Diamond Band Saw Blades

Brazed Bond Diamond Band Saw Blades

Bonding Process

Diamond particles are adhered to the blade surface through electroplating, involving a current-driven deposition from a diamond-containing solution.

Diamond particles are attached using a brazing process, where diamond grit is mixed with a brazing alloy and heated to bond the diamonds to the blade.

Durability

Generally, have a shorter lifespan due to easier detachment of diamond particles, and more prone to wear and tear.

Tend to be more durable due to stronger bonding, offering a longer lifespan and better performance under heavy-duty conditions.

Application

Best suited for lighter, precision cutting tasks. Often used for cutting softer materials or when a finer cut is needed.

Ideal for heavy-duty cutting and tougher materials. Suitable for demanding applications due to their durability and strength

Cost

Generally less expensive due to the simpler manufacturing process.

More costly owing to the complex brazing process and the blade’s longer lifespan.

Suitability for Specific Tasks

Better for delicate or precision work; suitable for materials like glass, ceramic, and thin stone.Generally less expensive due to the simpler manufacturing process.

Preferred for cutting harder materials such as thick stone, concrete, and reinforced materials, where durability and longevity are crucial.

Bonding Process

Uses electroplating to adhere diamond particles onto the blade surface.

Employs brazing, mixing diamond grit with a brazing alloy and heating to bond to the blade.

Durability

Shorter lifespan, more prone to wear and tear.

Longer lifespan, better performance under heavy-duty conditions.

Application

Ideal for lighter, precision tasks and softer materials.

Suited for heavy-duty cutting and tougher materials.

Cost

Generally less expensive.

Typically more costly

Suitability for Specific Tasks

Better for delicate, precision work; used for glass, ceramic, and thin stone.

Preferred for hard materials like thick stone, concrete, and reinforced materials.

Cutting Speed

Generally offers faster cutting speeds in softer materials.

May cut slower but more effectively through hard materials.

Precision

Provides finer cuts, suitable for detailed and precision work.

Less precise than electroplated but still effective for most applications.

Versatility

Limited to softer materials and precision tasks.

More versatile, can handle a range of materials and applications.

Maintenance Requirements

Lower maintenance due to simpler design, but may require more frequent replacement.

Higher initial durability reduces frequent maintenance but may require specialized care.

Environmental Impact

Lesser environmental impact in production but may contribute to more waste due to shorter lifespan.

Greater initial environmental impact due to brazing process but less waste over time.

Diamond band saw comparison electroplated vis braised bond

Comparison Criteria

Electroplated Diamond Band Saw Blades

Brazed Bond Diamond Band Saw Blades

Bonding Process

Electroplating bonds diamond particles onto the blade surface.

Brazing process mixes diamond grit with a brazing alloy, heating to bond to the blade.

Durability

Shorter lifespan, prone to wear and tear

Longer lifespan, performs better under heavy-duty conditions.

Application

Best for lighter tasks and softer materials.

Suited for heavy-duty cutting and tougher materials.

Cost

Generally less expensive.

Typically more costly.

Specific Task Suitability

Ideal for delicate, precision work; used for glass, ceramic, and thin stone.

Better for hard materials like thick stone, concrete, and reinforced materials.

Cutting Speed

Faster in softer materials.

Slower but more effective in hard materials.

Precision

Provides finer, more detailed cuts.

Less precise but effective for most applications.

Versatility

Limited to softer materials and precision tasks.

Handles a range of materials and applications.

Maintenance

Lower maintenance but may need frequent replacement.

Higher initial durability, may require specialized care.

Environmental Impact

Less impact in production but more waste due to shorter lifespan.

Greater initial impact, less waste over time.

Manufacturing Complexity

Simpler manufacturing process.

More complex manufacturing due to brazing.

Blade Thickness

Typically thinner, allowing for finer cuts

Generally thicker, providing strength for tougher materials.

Heat Resistance

Lower heat resistance, can be a limitation in some applications.

Higher heat resistance, beneficial for prolonged use and tough materials.

Reusability

Limited reuse potential due to wear and tear.

Higher reuse potential due to durability.

Ideal User Profile

Suitable for hobbyists or professionals needing precision in softer materials.

Ideal for industrial applications or professionals cutting tough materials regularly.

Bonding Process

Electroplating bonds diamond particles onto the blade surface.

Brazing process with a mixture of diamond grit and brazing alloy.

Durability

Shorter lifespan due to wear and tear.

Longer lifespan with better performance under heavy-duty conditions.

Application

Best for lighter, precision tasks in softer materials.

Suited for heavy-duty cutting in tougher materials.

Cost

Generally less expensive.

Typically more costly.

Specific Task Suitability

Ideal for delicate, precision work in materials like glass and ceramic.

Better for hard materials like stone and concrete

Cutting Speed

Faster in softer materials.

Slower but more effective in hard materials.

Precision

Provides finer, detailed cuts.

Effective but less precise.

Versatility

Limited to specific tasks in softer materials.

Versatile across a range of materials and applications.

Maintenance

Lower maintenance, frequent replacement needed.

Durable, may require specialized maintenance.

Environmental Impact

Less impact in production, more waste due to shorter lifespan.

Greater initial impact, less waste over time

Manufacturing Complexity

Simpler manufacturing process.

More complex due to the brazing process.

Blade Thickness

Thinner, allowing finer cuts.

Thicker, providing strength for tougher materials.

Heat Resistance

Lower, can be a limitation in some applications.

Higher, advantageous for prolonged use and tough materials.

Reusability

Limited due to wear and tear.

Higher due to durability

Ideal User Profile

Suitable for hobbyists or precision tasks in softer materials.

Ideal for industrial applications in tougher materials

Blade Life Extension

Limited options for extending blade life.

Longer blade life with potential for re-tipping or reconditioning.

Ease of Use

Generally easier to handle due to lighter construction.

May require more skill due to heavier and more robust construction.

Repairability

Limited repair options; often require replacement.

More repairable, especially if the blade body remains intact.

Initial Sharpness

Usually sharper initially, but loses sharpness quicker.

Less sharp initially but maintains sharpness longer.

Heat Generation

Can generate more heat in faster cutting, affecting blade life.

Generates less heat due to robust construction, benefiting longevity.

Description

Specifications

Frequently Asked Questions

Industries Used In

Accessories

Recommendations

Description

A band saw’s blade is diamond coated by electroplating, a process in which an electrical current deposits the coating onto the blade. This produces a hard, brittle Ni matrix that holds the diamonds in place and permits precise cutting on a variety of materials.

This process utilizes a flexible, toothed blade is welded into an endless band that rides on wheels driven by two pulleys and is guided through the work cut off or contour. Ideally Diamonds Band Saws Blades should be used on Band Saw Machines designed for this purpose. A friction saw is a special band saw capable of achieving band velocities of up to 15,000 sfpm or more.

Specifications

- Blade Thicknesses Available : 0.20″ to .035″

- Blade Widths Available : 1/4″ to 1.5″

- Grit sizes available : 35 to 120 mesh

- Blade edge configurations available : continuous rim, segmented, gulleted, Scallop Segment

- Blade Backing Materials : Steel Alloy, Stainless Steel

- Coolant methods : Wet, Dry

- Average Band Saw Blade Life : 40 to 80 hours. Some has shown to last as long as 192 hours.

Frequently Asked Questions

Industries Used In

Accessories

Recommendations

- Material Compatibility: Always ensure that the blade is suitable for the material you are cutting. Diamond blades are designed for specific materials and using them on incompatible substances can damage the blade or the material.

- Proper Installation: Ensure that the blade is correctly installed on the saw. The blade should be tensioned according to the manufacturer’s specifications to avoid slippage or breakage.

- Cutting Speed: Maintain an appropriate cutting speed. Too fast can overheat the blade and material, causing damage; too slow can reduce efficiency and cause unnecessary wear on the blade.

The recommended RPM (Revolutions Per Minute) for diamond band saw blades can vary significantly based on several factors including the type of material being cut, the diameter of the blade, the hardness of the material, and the specific design of the blade. Here are some general guidelines to consider:

- Material Type: Different materials require different cutting speeds. For example, softer materials like some types of ceramic or glass may be cut at higher speeds, while harder materials like quartz or granite require slower speeds.

- Blade Diameter: The larger the diameter of the blade, the slower the RPM should be. This is because a larger blade will have a higher cutting speed at the edge even with a lower RPM.

- Manufacturer’s Recommendations: Always check the manufacturer’s guidelines for the blade. These guidelines are based on extensive testing and are designed to optimize the blade’s performance and lifespan.

- Cooling Considerations: Higher speeds can generate more heat. If adequate cooling (like a water coolant system) is not in place, it’s advisable to use a lower RPM to prevent overheating the blade and the material.

- Type of Coolant: Water is often used as a coolant for diamond band saw blades, especially when cutting stone, glass, or tile. For some applications, especially in metal cutting, a water-soluble coolant or cutting oil is preferred to reduce friction and remove cuttings more effectively.

- Coolant Concentration: If you’re using a water-soluble coolant, ensure it’s mixed at the correct concentration. Too much water in the mixture can reduce its effectiveness, while too much concentrate can be wasteful and potentially harmful to the blade and workpiece.

- Continuous Flow: Ensure a continuous and adequate flow of coolant to the blade. The coolant should be applied directly where the cutting action is taking place to maximize its cooling and lubricating effects.

- Prevent Overheating: The primary purpose of the coolant is to keep the blade and the material being cut cool. Overheating can damage both the blade and the material and can also lead to dangerous situations.

- Coolant Cleanliness: Regularly clean and replace the coolant to prevent contamination. Dirty or contaminated coolant can reduce cutting efficiency and cause damage to the blade.

- Environmental Considerations: Be aware of the environmental and health implications of the coolant you choose. Some coolants may require special handling or disposal methods.

- Preventing Corrosion: If you’re using a water-based coolant, be mindful of the potential for rust and corrosion on your saw and blades. Consider adding a rust inhibitor to the coolant or regularly applying a rust preventative to your equipment.

- Coolant Distribution System: Maintain your coolant distribution system, ensuring that nozzles or hoses are not clogged and are positioned correctly to deliver coolant effectively to the blade.

- Avoiding Dry Cutting: Unless specifically designed for dry use, always use coolant with diamond band saw blades. Dry cutting can significantly reduce the life of the blade and degrade its performance.

- Coolant Temperature: In very hot conditions, the coolant itself can become warm. Consider ways to keep the coolant temperature down, as overheating can reduce its effectiveness.

- Safety and Health: Always use coolants in a well-ventilated area, and wear appropriate protective gear to avoid contact with skin and eyes. Some coolants may emit harmful vapors or be irritating to the skin.

- Recycling and Reuse: Some coolant systems allow for the recycling and filtration of the coolant for reuse. This can be both cost-effective and environmentally friendly.

- Compatibility with Materials: Ensure that the coolant is compatible with the material you are cutting. Some materials may react adversely with certain coolants.

- Coolant Pressure and Volume: Adjust the pressure and volume of the coolant to suit the cutting conditions. Different materials and cutting speeds may require different coolant pressures and volumes for optimal performance.

- Cutting Precision: For very precise cuts, a slower RPM may be beneficial as it allows for more control.

- Blade Wear and Tear: Using a higher RPM than recommended can lead to increased wear and a shorter lifespan for the blade. Conversely, a speed that is too low may result in inefficient cutting and unnecessary strain on the saw.

- Specific Applications: Some specialized applications may have unique RPM requirements. For instance, cutting very dense or abrasive materials often requires lower RPMs to minimize blade wear.

- Saw Capabilities: Ensure that the RPMs you choose are within the operational range of your saw. Operating a saw at an RPM it’s not designed for can be dangerous and damage the saw.

- Experience and Skill Level: Experienced users may be able to safely and effectively operate the saw at different RPMs based on their understanding of the material and the cutting process.

- Trial and Error: Sometimes, finding the optimal RPM requires a bit of experimentation, starting at a lower speed and gradually increasing it while monitoring the cutting performance and the condition of the blade.

- Lubrication and Cooling: Use an appropriate coolant or lubricant when cutting. This reduces heat build-up, prevents blade overheating, and extends the life of the blade.

- Safety Gear: Always wear appropriate safety gear including eye protection, ear protection, and gloves. Diamond cutting can produce small, sharp particles that pose a risk.

- Regular Inspections: Regularly inspect the blade for damage or wear. Look for missing or damaged diamonds and check the overall condition of the blade.

- Avoid Twisting: Keep the blade straight during cuts. Twisting or bending the blade can cause it to break.

- Feed Rate: Control the feed rate of the material into the blade. Forcing the material too quickly can overload and damage the blade.

- Blade Cleaning: Keep the blade clean from any build-up of material, which can affect its cutting efficiency.

- Storage: Store the blade in a dry, safe place where it won’t be damaged.

- Professional Advice: If unsure about the type of blade needed for a specific job, consult with a professional or refer to the manufacturer’s guidelines.

- Regular Maintenance: Ensure regular maintenance of the saw to keep it in good working condition, which also helps in extending the life of the blade.

Feed Rates

- Material Hardness: Softer materials can generally be cut at higher feed rates, while harder materials require a slower feed rate. For example, cutting marble will have a different optimal feed rate than cutting granite.

- Blade Specifications: The feed rate should match the specifications of the blade being used. Different blades are designed for different materials and cutting speeds. Always refer to the manufacturer’s guidelines.

- Thickness of the Material: Thicker materials require a slower feed rate to ensure an even and consistent cut. Pushing the blade too fast through a thick material can lead to blade deflection, uneven wear, or breakage.

- Type of Cut: Straight cuts can usually be made at a higher feed rate than curved or intricate cuts. For detailed work, a slower feed rate allows for greater precision.

- Blade Wear: A new blade can typically handle a faster feed rate. As the blade wears, you may need to adjust the feed rate to compensate for the reduced cutting efficiency.

- Cooling and Lubrication: Adequate cooling and lubrication can allow for slightly higher feed rates, as they help prevent blade overheating and material burning.

- Machine Capability: Ensure that the feed rate is within the capabilities of your cutting equipment. Overloading the machine can lead to poor cuts and potential damage to the machine or blade.

- Visual and Auditory Cues: Pay attention to the sound of the blade and the appearance of the cut. Chattering, excessive noise, or a rough cut surface can indicate that the feed rate is too high.

- Experience and Judgment: Operator experience plays a significant role in determining the right feed rate. Experienced operators can judge the optimal speed based on the cutting conditions and blade performance.

- Material Fracture Tendencies: Some materials are more prone to chipping or fracturing. A slower feed rate can reduce the risk of damaging these materials.

- Trial and Error: Sometimes finding the optimal feed rate requires experimentation. Start at a lower feed rate and gradually increase it while monitoring the cut quality and blade behavior.

- Safety Considerations: Always prioritize safety. A feed rate that is too high can be dangerous and may lead to loss of control or blade breakage.

- Consistency: Maintain a consistent feed rate throughout the cut for the best results. Inconsistent feeding can lead to blade wandering or irregular cuts.

- Feed Rate Units: Feed rates are typically measured in inches per minute (IPM) or millimeters per minute (mm/min). Ensure you are using the correct units and measurements.

- Blade Break-In: New diamond band saw blades often require a break-in period. Start with softer materials or less aggressive cutting to gradually expose new diamond grit. This can improve the overall performance and longevity of the blade.

- Avoid Overheating: Continuously monitor the blade temperature during use. Overheating can cause the metal to warp and the diamonds to lose their effectiveness. If the blade becomes too hot, pause cutting and allow it to cool down.

- Proper Tensioning: Maintain correct tension on the blade. Too much tension can lead to blade breakage, while too little can result in inaccurate cuts. Refer to the saw manufacturer’s guidelines for proper tensioning procedures.

- Use the Right Blade Width: Choose a blade width that is appropriate for the material and the type of cut you want to make. Wider blades are typically better for straight cuts, while narrower blades are ideal for cutting curves.

- Clean Cuts: Ensure that each cut is clean and straight. A wobbling or chattering blade can indicate a problem with the saw or the blade, and it can also lead to uneven wear or damage to the blade.

- Adjust for Blade Drift: Some band saws exhibit blade drift, where the blade does not cut in a perfectly straight line. Adjust the fence or your cutting technique to compensate for this drift to achieve accurate cuts.

- Use Variable Speed Saws When Possible: If your saw allows for speed adjustment, use this feature to match the speed to the hardness of the material. Harder materials often require slower speeds.

- Gradual Entry on Thick Materials: When starting a cut on a thick or dense material, begin slowly and increase the feed rate gradually. This approach helps in preventing blade shock and reduces the risk of chipping.

- Avoiding Blade Twist: When cutting curves, be mindful not to twist the blade excessively. Sharp turns can strain the blade and cause premature wear or breakage.

- Periodic Resting: Allow the blade to rest periodically during prolonged cutting sessions. This prevents continuous heat build-up and extends blade life.

- Disposal and Replacement: Once a blade becomes too worn or damaged, dispose of it properly and replace it with a new one. Continuing to use a damaged blade can be inefficient and unsafe.

- Training and Experience: If you’re new to using a diamond band saw, consider getting training or advice from experienced users. Understanding the nuances of these blades can greatly improve your cutting technique and safety.

- Blade Direction and Alignment: Ensure that the blade is mounted in the correct direction and is perfectly aligned with the band saw. Misalignment can cause uneven wear and poor cutting performance.

- Avoid Dry Cutting: Unless the blade is specifically designed for dry cutting, always use water or an appropriate coolant. Dry cutting with a blade meant for wet use can lead to overheating and premature wear.

- Regular Blade Cleaning: Over time, cutting residue can build up on the blade, affecting its performance. Regular cleaning helps maintain its cutting efficiency and prolongs its lifespan.

- Monitor Blade Wear: Be attentive to signs of wear such as reduced cutting performance, increased noise, or unusual vibrations. These signs can indicate that the blade needs to be replaced.

- Cutting Technique: For thicker materials, use a “step cutting” technique where you make a series of gradually deeper cuts. This approach can reduce the stress on the blade and improve the quality of the cut.

- Reduce Blade Fatigue: Alternate between different blades if you are making a large number of cuts. This allows each blade to rest and cool down, reducing the risk of fatigue and breakage.

- Avoid Impact or Shock: Never force the blade into the material. A smooth, steady approach is best. Impact or shock can cause diamond grit to dislodge or the blade to break.

- Correct Blade Storage: Store unused blades in a safe, dry place, ideally hanging or laid flat in a way that does not put stress on the blade. Avoid kinking or bending the blade.

- Manufacturer’s Instructions: Always follow the manufacturer’s instructions for use, maintenance, and safety. Different blades may have specific requirements or recommendations.

- Prevent Corrosion: After use, especially with water or coolant, dry the blade to prevent rust and corrosion. This is particularly important for the non-diamond parts of the blade.

- Blade Tracking: Regularly check and adjust the blade tracking. Proper tracking ensures that the blade runs smoothly on the wheels of the saw, reducing wear and the risk of blade deviation.

- Sharp Turns and Corners: When cutting sharp corners or intricate patterns, reduce the feed rate and carefully guide the material. Forcing the blade through tight turns can damage it.

- Understand Blade Specifications: Familiarize yourself with the blade’s specifications such as diamond grit size, concentration, and bond hardness. This information helps in selecting the right blade for a specific material and cutting requirement.

- Respect Load Capacity: Be mindful of the blade’s load capacity. Overloading can lead to blade deformation and potential breakage.

- Professional Maintenance: Consider having your blades professionally sharpened or re-tipped if they become dull. This can be more cost-effective than purchasing new blades.

- Safety First: Lastly, prioritize safety above all else. If you’re ever uncertain about a cutting task, seek professional advice or assistance to prevent accidents.

- Understand Blade Limits: Be aware of the maximum and minimum thicknesses and types of materials your blade is designed to cut. Using a blade outside of its intended range can lead to poor performance and potential blade damage.

- Controlled Feed Pressure: Apply a consistent and controlled feed pressure when cutting. Erratic pressure can cause blade deflection or breakage, and uneven wear.

- Avoid Blade Binding: Ensure that the material being cut does not pinch the blade. Blade binding can cause excessive wear and potential blade breakage.

- Material Stability: Secure the material being cut firmly. Movement during cutting can lead to inaccurate cuts and increase the risk of blade damage.

- Coolant Flow and Quality: Check the flow and quality of the coolant regularly. Ensure that the coolant is reaching the point of the cut and that it is not contaminated, as dirty coolant can harm the blade’s performance.

- Avoid Excessive Bending: When cutting curves, avoid bending the blade excessively as it can lead to metal fatigue and eventual failure.

- Use Appropriate Blade Speeds: Different materials require different blade speeds for optimal cutting. Consult the blade and material specifications for the recommended speeds.

- Blade Thickness Awareness: Be aware of the blade’s thickness and how it relates to the kerf (the width of the cut). This is important for precision cutting and avoiding material waste.

- Regular Breaks During Intensive Use: If using the blade intensively, give it and the saw regular breaks to prevent overheating.

- Blade Dressing: Periodically dress the blade to expose fresh diamond edges. This is especially important for blades that see a lot of use.

- Support Material Adequately: Ensure that larger or heavier materials are adequately supported to prevent blade pinching or deflection.

- Handle with Care: Diamond blades are robust in cutting but can be fragile if mishandled. Avoid dropping or striking the blade.

- Blade Path Clearance: Ensure that the path of the blade is clear of obstructions, including clamps, to prevent accidental contact and potential damage.

- Blade Compatibility with Saw: Ensure the blade is compatible with your particular band saw, considering factors like blade length, width, and tooth pitch.

- Avoid Reactive Materials: Be cautious when cutting materials that may react with water or coolants, such as certain metals, as this can cause damage or safety hazards.

- Record Keeping: Keep records of blade usage, including types of materials cut and hours of operation. This can help in scheduling maintenance and predicting blade life.

- Environmental Considerations: Be mindful of the environmental conditions in which you are working. Extreme temperatures and humidity can affect both the material being cut and the blade.

- User Training and Awareness: Ensure that all operators are adequately trained and aware of the proper usage and safety procedures for diamond band saw blades.

- Blade Disposal: Dispose of used or damaged blades properly, considering local regulations and safety practices.

- Stress Relief Cuts: When cutting large or thick materials, make relief cuts to reduce stress on the blade. This technique involves making additional cuts to remove material and prevent binding.

- Avoiding Side Pressure: Apply cutting pressure in a straight line. Side pressure can bend the blade and lead to uneven wear or breakage.

- Correct Blade Orientation: Make sure the blade’s direction of rotation is correct. A blade installed backwards will be ineffective and can be damaged.

- Material Clamping: Properly clamp or secure the material being cut to prevent movement. Unstable materials can cause irregular cuts and put extra stress on the blade.

- Regular Saw Maintenance: In addition to blade maintenance, ensure that the saw itself is in good condition. This includes checking the guide bearings, tension mechanism, and overall alignment.

- Blade Guide Adjustment: Adjust the blade guides correctly to support the blade close to the cut. This prevents blade deflection and ensures straighter cuts.

- Blade Teeth Per Inch (TPI) Selection: Choose the appropriate TPI for your blade based on the material’s thickness. Generally, a higher TPI is better for thinner materials, and a lower TPI for thicker materials.

- Avoiding Quick Stops and Starts: Avoid abrupt stops and starts during cutting, as this can jar the blade and potentially lead to damage.

- Using a Push Stick for Small Pieces: When cutting small pieces, use a push stick or other device to feed the material. This keeps hands away from the blade and minimizes the risk of injury.

- Cutting at a Consistent Angle: Maintain a consistent angle when feeding the material into the blade. Inconsistent angles can lead to irregular cuts and put uneven stress on the blade.

- Proper Saw Alignment: Ensure that the saw’s wheels, guides, and table are properly aligned according to the manufacturer’s specifications. Misalignment can cause the blade to wear unevenly or break.

- Blade Tension Monitoring: Regularly check the blade tension, as it can change with temperature fluctuations and use. Incorrect tension can lead to poor cutting performance or blade failure.

- Understanding Blade Life Expectancy: Be aware of the typical life expectancy of your blade under normal conditions and plan for replacement accordingly.

- Post-Use Inspection: After each use, inspect the blade for any signs of damage, including chips, cracks, or missing segments. Early detection of damage can prevent more serious issues.

- Avoiding Hazardous Materials: Do not cut materials that might be hazardous, such as materials containing asbestos or other harmful substances.

- Record Blade Performance Issues: Keep a log of any issues encountered during cutting. This can help in troubleshooting and identifying when a blade needs to be replaced or serviced.

- Environmental Cleanliness: Keep the work area clean and free of debris. A cluttered or dirty environment can lead to accidents and affect cutting accuracy.

- Proper Handling and Storage: Handle blades with care, avoiding any actions that could bend or twist them. Store them in a way that prevents physical damage.

- Regular Calibration of Equipment: Regularly calibrate your saw to ensure accurate cuts. Misalignment can lead to increased wear on the blade and poor quality cuts.

- Safety Checks: Perform routine safety checks on the saw and blade before each use. Ensure all safety guards are in place and functioning.

- Personal Protection Equipment (PPE): Always wear appropriate PPE, such as safety glasses, gloves, and hearing protection, when operating the saw.

- Avoid Cross-Contamination: Use different blades for cutting different materials to prevent cross-contamination, which can affect cutting performance and blade life.

- Gradual Increase in Cutting Load: When starting a cutting session, gradually increase the cutting load to allow the blade to warm up, which can prevent shock and wear.

- Regular Coolant Replacement: Change the coolant regularly to prevent contamination, which can affect the cutting process and potentially damage the blade.

- Inspect for Unusual Noises or Vibrations: Be alert to any unusual noises or vibrations during operation, as these can be early signs of blade or equipment issues.

- Use of Blade Stabilizers: Consider using blade stabilizers, if appropriate, to reduce blade vibration and enhance cutting precision.

- Proper Material Support: Ensure that the material is adequately supported both before and after the cut to prevent any unnecessary blade stress or deflection.

- Avoid Abrupt Force: Never apply abrupt force to the blade, either in the cutting direction or laterally. Gentle, consistent pressure is key.

- Maintain a Clean Blade Path: Regularly clean the path of the blade, including guides and wheels, to prevent buildup that can affect the blade’s performance.

- Periodic Professional Assessment: Have your equipment and blades periodically assessed by a professional to ensure they are in optimal condition.

- Educate on Emergency Procedures: Make sure all operators are aware of emergency procedures in case of blade breakage or equipment failure.

- Use the Right Machine for the Blade: Ensure that the saw machine used is suitable for the type of diamond band saw blade, considering factors like power, speed, and size.

- Monitor Blade Alignment During Use: Regularly check the alignment of the blade during use, as it can shift, especially when cutting tougher materials.

- Balanced Blade Wear: Rotate the blade usage if possible, to ensure even wear, which can extend the life of the blade.

- Avoid Twisting the Blade Off the Material: When finishing a cut, avoid twisting the blade off the material, as this can damage the blade.

- Proper Decommissioning of Blades: Decommission blades that are beyond their useful life in a responsible manner, respecting safety and environmental guidelines.

- Attention to Blade’s Running Direction: Ensure that the blade’s running direction matches the indicated direction on the saw. Reversed blades will underperform and can be damaged.

- Check for Material Defects: Before cutting, inspect the material for defects or foreign objects that might damage the blade.

- Lubrication of Moving Parts: Regularly lubricate all moving parts of the saw to ensure smooth operation and reduce wear on the blade.

- Use Blades with Suitable Diamond Grit: Choose a blade with a diamond grit size that is appropriate for the material being cut for optimal performance.