Precision & Micro Carbide Tools

Ultra Thin, High

Ultra Thin, High Precision & Micro Carbide Tools

UKAM Industrial offers larger variety of tungsten carbide micro drills, micro tools and ultra thin and high precision cutting blades from stock and custom manufactured to fit your requirements.

- Ultra Thin & High Precision Carbide Blades for Slicing, Dicing, Slotting, & Grooving - available as thin as .004" and diameters from 50mm to 500mm

- Micro Carbide Drills & Tooling - available from small as 20 microns - products include drills, routers, end mills, and specialized cutting tools ranging from 0.05mm to 6.70mm diameters (0.0020" - 0.2638")

- Specialized Coatings such as Diamond Like Carbon and CVD (chemical vapor deposition) are available to extend the life of these tools

MATERIALS USED ON / APPLICATION:

- Electronics

- PCB Manufacturing

- Medical

- Dental

- Aerospace

- Automotive

- Microelectronics

- MEMS

- Jewelry

- Mold & Die Making

Why Technical Teams Trust Us:

Ultra Thin & High Precision Carbide Blades

For low speed saws

Used On: All Low Speed Wafering Saws, Sectioning Saws, Such as Buehler, Struers, Leco, & many others.

Ultra thin, fine teeth tungsten Carbide blades are available from 3” (75mm) to 8” (200mm) OD, thickneness from from .004” (100 microns). Standard arbor is ½”, but can be made any size. Ttypically used on low speed cutting machine. Typical application are materials where diamond cannot be effective used such as green ceramics, PC Board substrates, fiberglass, laminates, MLP/QFN, soft and gummy materials and similar applications.

Ultra Thin & High Precision Carbide Blades

For Slicing, Slitting & Dicing

Tungsten carbide dicing / slitting blades are typically used in slow speed cutting machine. The typically rotate at low RPM’s (mostly below 1,000 RPM). Typical application for tungsten carbide saw blades are green ceramics, PC Board substrates, fiberglass, laminates, MLP/QFN, and similar materials. Diameters from 50mm to 500mm, starting .004” (0.1mm) kerf thickness. These blade are made to order based on each individual requirement.

Carbide Micro Drills

We offer large variety of standard stock & custom micro drills from 0.05mm diameter to 6mm. with 3mm and 3.2mm shanks, and various heald lengths, and flute specifications. Used are used for drilling

- Low carbon steel

- High carbon steel

- Stainless steels

- Nickel alloys

- Cast iron

- Aluminum

- Copper – brass alloys

- Plastics

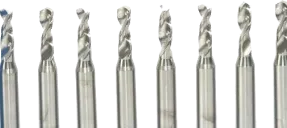

Carbide Micro Tools & End Mills

Carbide Micro Tools & End Mills are available in various sizes, geometries, flute designs, head lengths, shank diameters and coatings to fit your specific requirements

Micro end mills are used to create complex geometries, drill small holes, and achieve tight tolerances

machining small features, such as small pockets, ribs, and channels.

Small Carbide Routers & Tooling

Small carbide routers and tooling are commonly used for routing operations, which involve removing material from a workpiece to create grooves, channels, or profiles. These tools are used in wide variety of industries where intricate designs and precise cuts are necessary.

Why Work With Us?

Comprehensive Source Of Information On Diamond Tools

The more you understand about what we can do for you the better our partnership will be. Here you will find most comprehensive source of information and optimizing and improving your cutting, drilling, grinding and polishing on the web. Find everything you ever wanted to know about diamond tools.

Large Inventory & Custom Manufacturing

We have the largest variety of diamond tools available in stock. we regularly produce custom diamond tools to better fit customers specific needs & specifications. Just about any diamond tool can be designed and manufactured per customer drawing or specifications.

Umatched Technical Support

WE ARE A PARTNER IN YOUR SUCCESS

Developing close ties with our customers is the foundation of our business. At the core of

our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced

Technology

AMERICAN MANUFACTURER

As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool

manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality & Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards. Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency EXPECT MORE FROM YOUR TOOLS

Experience Makes All The Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

With a team of highly knowledgeable and experienced engineers, we possess a deep understanding of the challenges you encounter when cutting, drilling, grinding and polishing. This expertise is gained from decades of experience manufacturing sophisticated and high precision tools and equipment for advanced industries and complex applications. Unlike other companies that exclusively focus on tools for the stone and construction industries, we offer unique solutions that surpass their capabilities and expertise.

Best Value For

The Money

We are always looking for partners to work with in expanding the market reach. We produce and offer highest quality products at very attractive pricing. While we may not be the lowest cost solution provider. Our products offer one of the best Return on Investment available & quality, that you cant find anywhere. We offer amazing discounts based on quantity. Lets us develop a win, win relationship.

Unmatched Performance & Quality

Our standard and custom products offer the best performance and value for your money.

count on us to provide higher level of performance compared to what is typically available in the market. While standard tools for stone may be sufficient in many cases, they often fall short when dealing with tougher materials and challenging applications.

Don't struggle with inferior tools - DEMAND THE BEST!

Time, Money, & Material - you will save will more than pay for these TOOLS in short period of time