Nickel Bond Dicing Blades

NEW GENERATION AND TECHNOLOGY

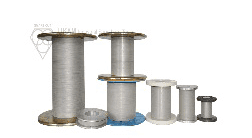

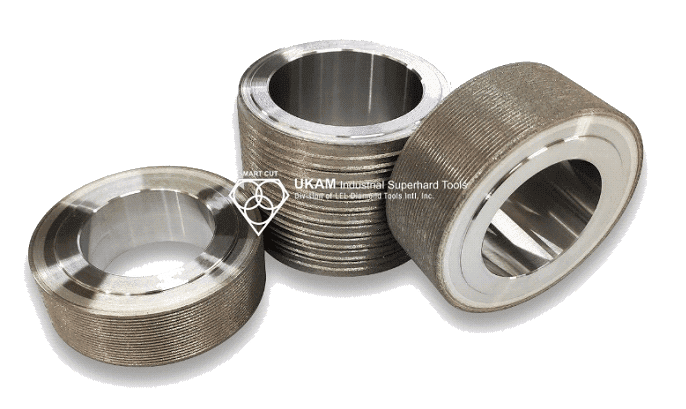

NICKEL BOND HUBLESS

SMART CUT® Series (SCN) DIAMOND & CBN DICING BLADES

Maintain excellent form & sharpness. Providing lower wear rate, longer life, and minimum level of chipping on wide variety materials.

SMART CUT® Nickel Bond Hubless series New Generation & Technology Dicing Blades, have a high diamond concentration and give a freer, faster cutting action with minimum heat generation. Diamonds have higher protrusion ratio, staying on the surface of the cut allowing for fast material removal. Hubless Nickel Bond dicing blades are capable of maintaining excellent form & sharpness. Widely used for cutting wafers and thin substrates.

SMART CUT® Hubless are produces in highly ontrolled, clean room environment under the Highest Quality Standards. Only the highest quality raw materials are used in manufacturing process. Utilizing world class quality control, inspection, and measurement equipment.

Highly Experienced Engineers and chemists constantly monitor and control all material input & output at all stages of manufacturing process. Insuring product consistency for use in demanding & sensitive applications such Nano Technology, MEMS, etc. This process allows for blades to be produced with very tight tolerances, and optimize kerf shape, geometry, diamond size, and bond hardness to fit your particular application/requirements

- Superior Wear Resistance (Hard Bond)

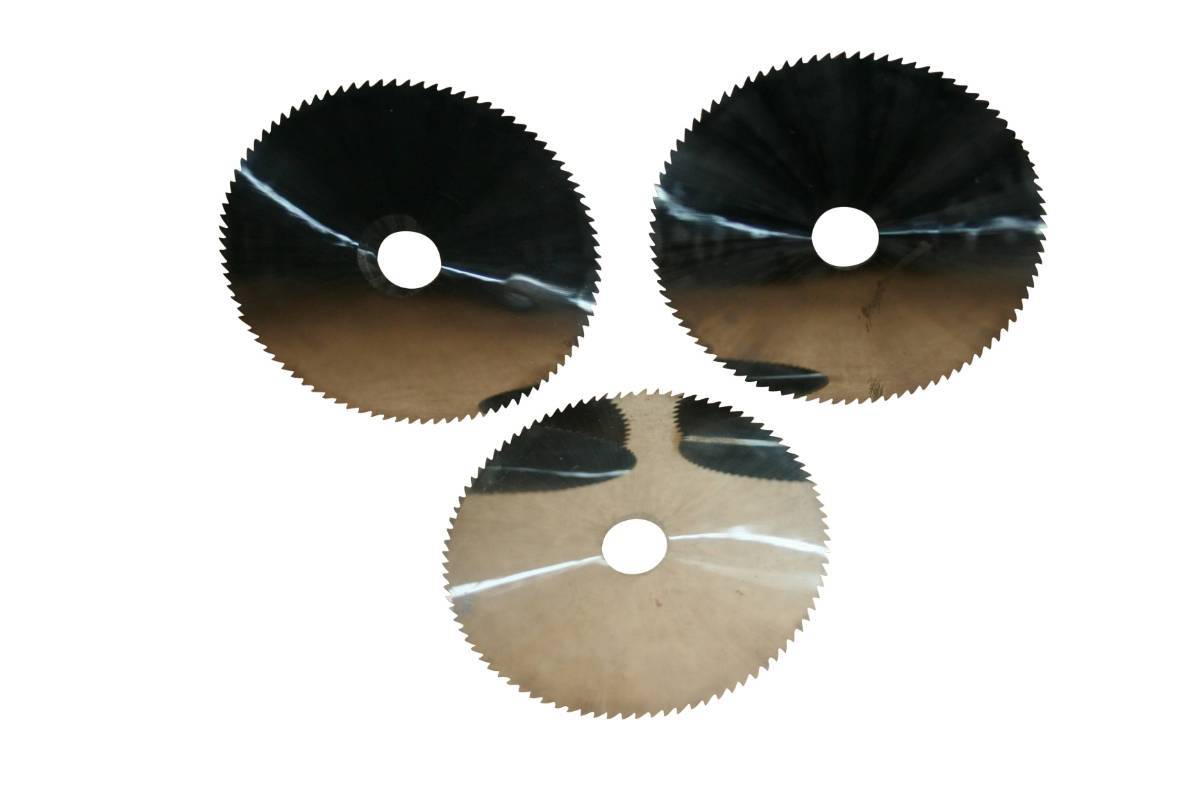

- Ultra Thin Kerf (thinnest blades available (down to .0008”)

- Excellent rigidity for higher exposure

- Exceptionally long blade life

- Maintains good edge geometry

- Excellent on applications requiring high accuracy

About Nickel (Plated) Bond

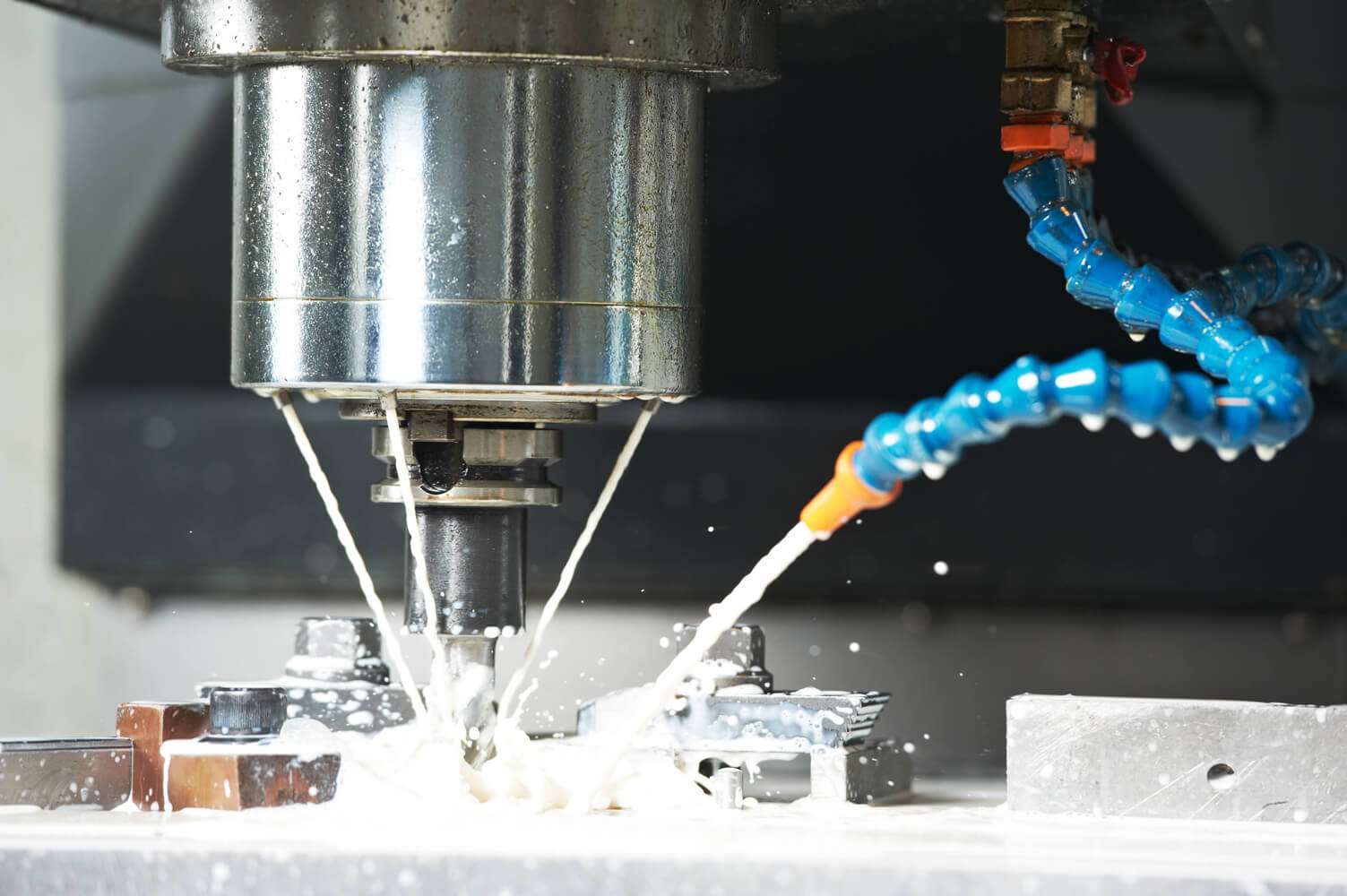

Electroplated (nickel bond) diamond products usually have a single layer of diamonds, held by a tough, durable nickel alloy. Nickel is frequently used as a base for plating diamond. Because of its excellent strength, toughness and flexibility during the plating process, electroplated diamonds are able to retain their original shape and dimensions throughout their working life. Unlike sintered) metal bond or resin bond diamond products, where diamond particles are buried in bond and held together by metal or resin binder deep inside. Electroplating allows diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.

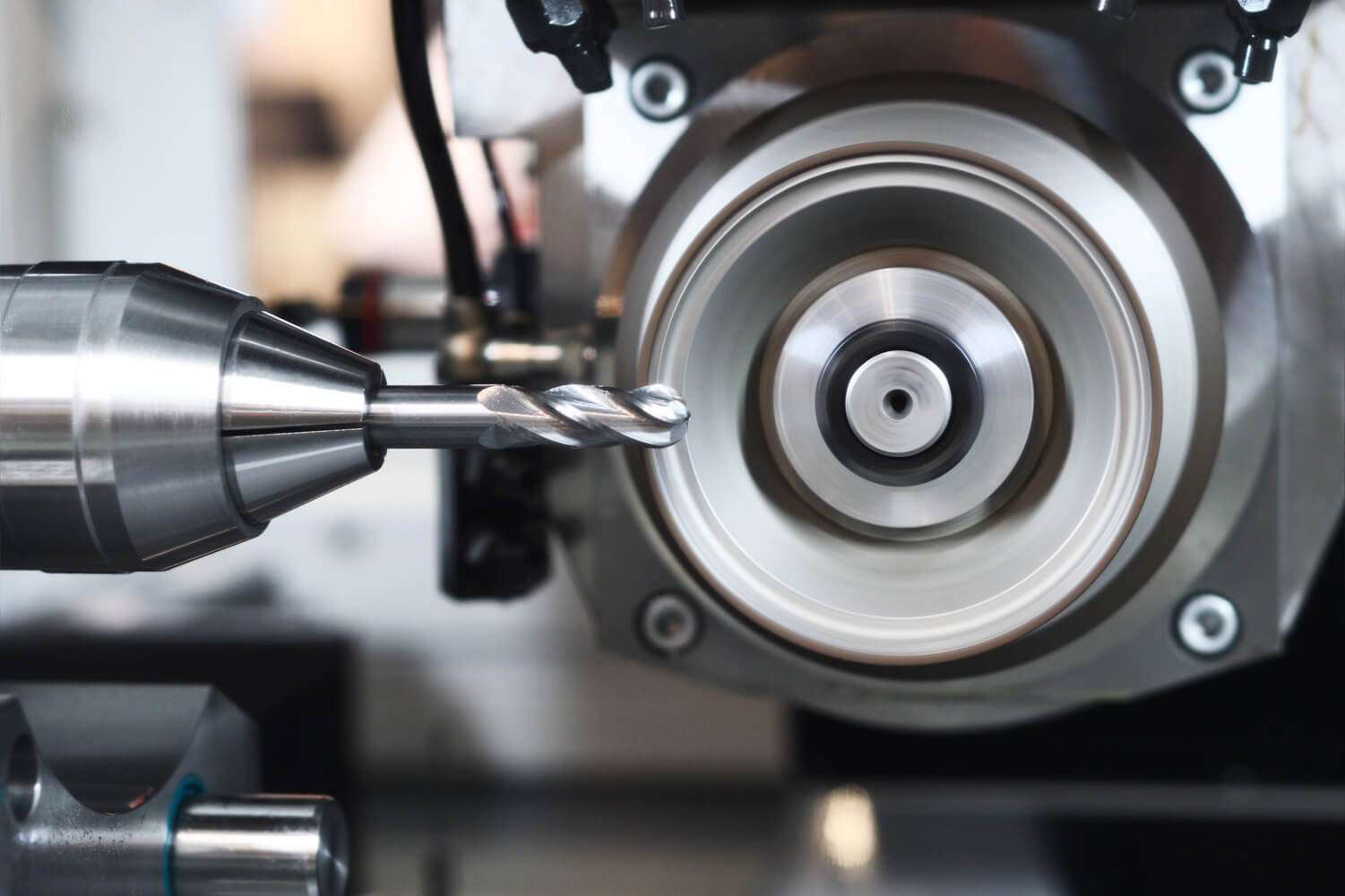

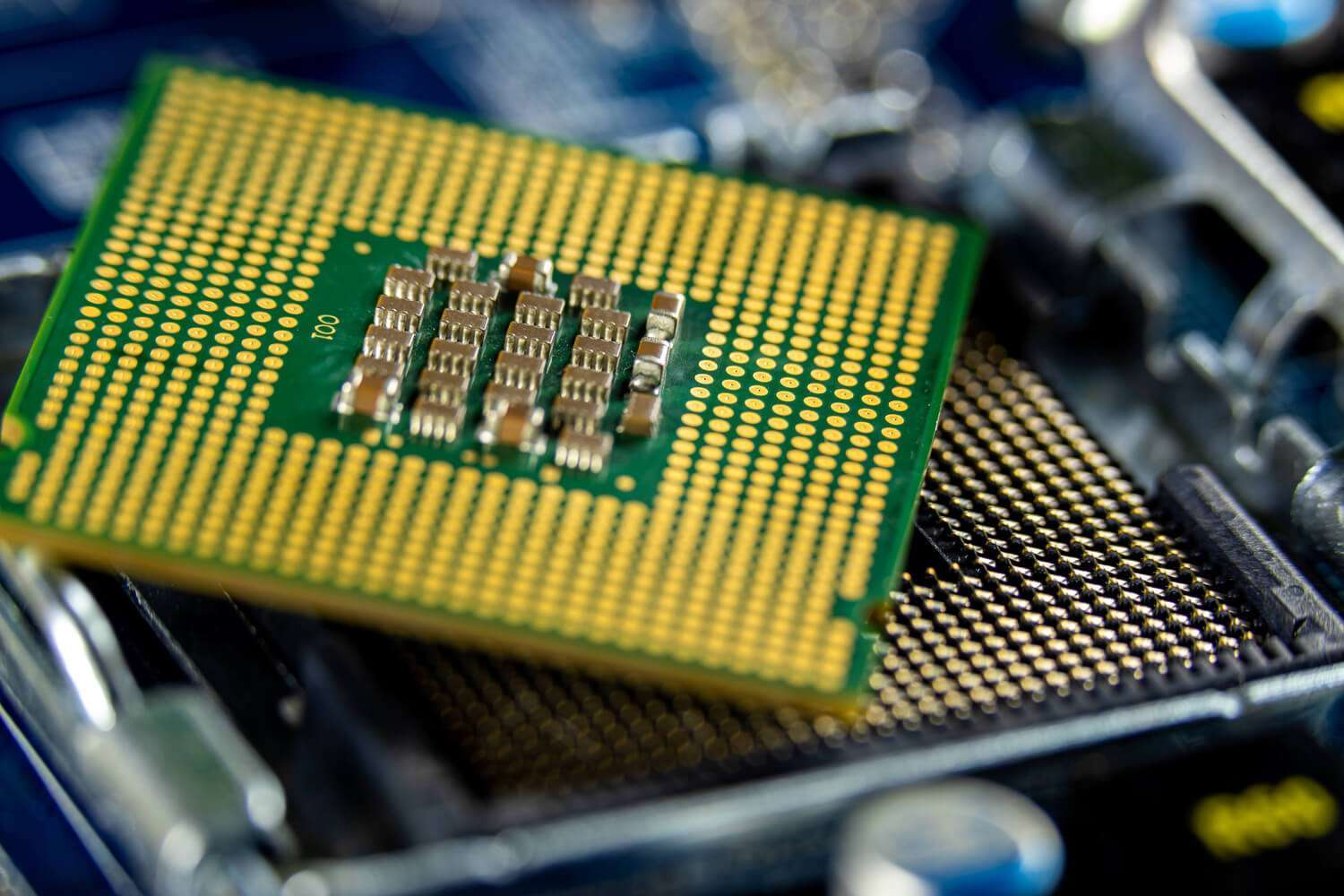

Silicon wafer dicing is usually done with the plated diamond blade (hubbed or hubbless) which has proven most effective for this application. The Kerfs are typically in the 1-3 mil. range using a nominal spindle speed of 30,000 RPM with feed rates as high as 8 inch per sec.

Features

- Excellent form & corner holding characteristics

- Best tolerances in the industry

- Superior Cut Quality

- Unmatched Consistency

- Universal Application

- Requires Minimal Dressing

Benefits

- Increases Blade Life

- Reduce Chipping

- Reduce Blade Wear

- Increase Process Consistency

- Maintain Consistent Cutting Speed

- Minimum Loss of Material

- Reduce Cost

Advantages

- Maximum cutting performance

- No glazing

- Faster cutting action

- Improved surface finish quality

- Better coolant retention

- No Material Deformation

- Faster Cutting Speed

How SMART CUT® Nickel Bond Works?

The sharpest and finest quality diamonds or CBN crystals that go into a SMART CUT® Nickel Bond, immediately penetrate into the material, grinding and polishing as they cut.

- Different Product

- Different Technology

- Different Company

Expect MORE from your tools

How SMART CUT ® Bond Works?

Sharpest And Finest Quality Diamonds

The sharpest and finest quality diamonds or CBN crystals that go into a SMART CUT ® Diamond Bond, immediately penetrate into the material, grinding and polishing as they cut.

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT ® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

Diamonds or CBN Crystals

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

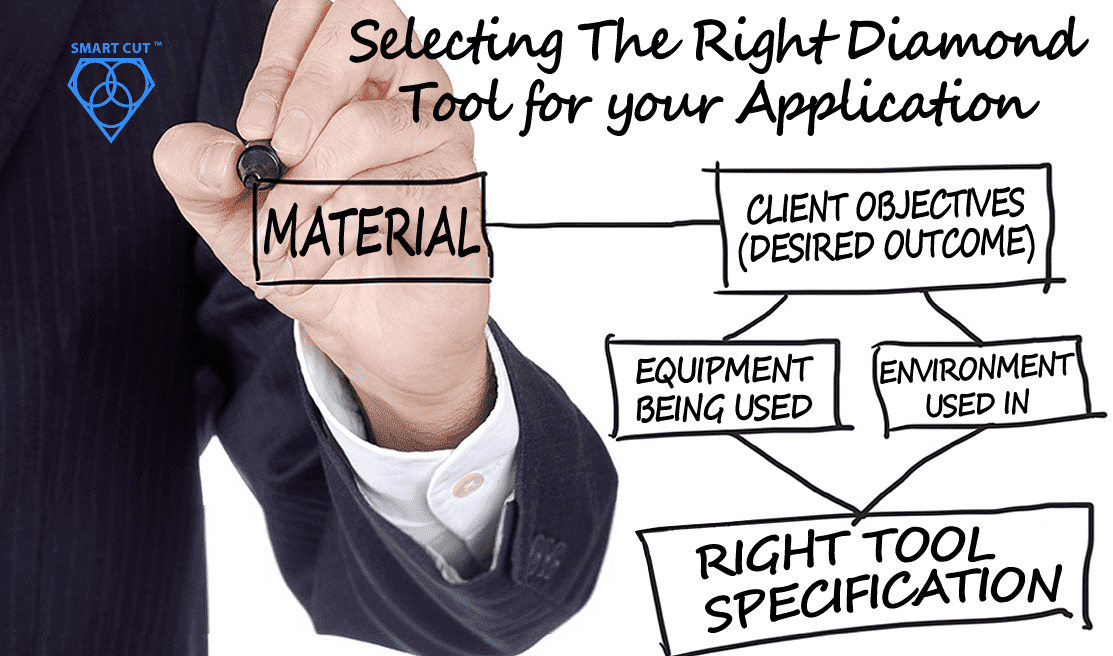

Contact Us for FREE Quote & Recommendation

We will work with you to determine your needs, and recommend the right parameters for your specific material/application.

SMART CUT® Series SCN

Hybrid bond Specifications

Size Designation: D X TE X H, Where: D-Outside Blade Diameter, TE –Blade Thickness, H- Blade Inside Diameter.

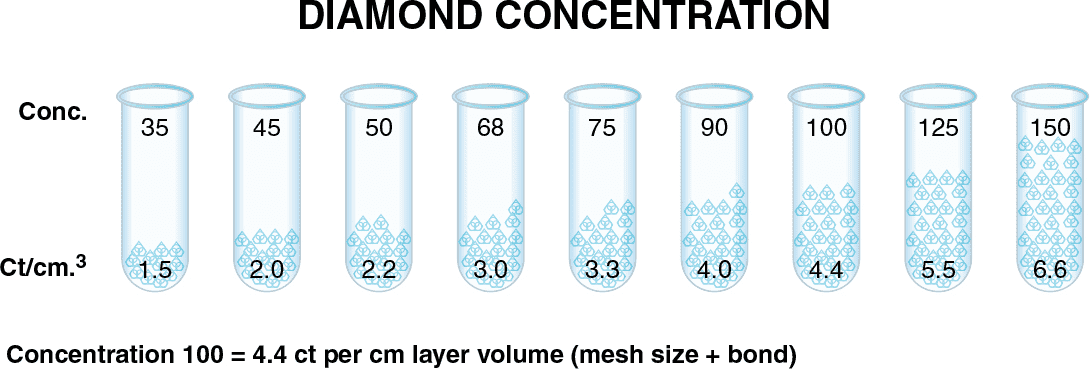

Below is a guide to help you select the right Diamond Size for your Nickel Bond Hubless Dicing Blades for your application

** Letter Abbreviations: D-FOR DIAMOND, B -FOR CBN.

Usage Recommendations

Handling

Please note that nickel bond dicing blades are not 100% resilient, that is if a blade is deformed through mishandling it will allays retain a certain amount of that deformation. Though that some mishandling may not have noticeable impart on the cut quality (this would depend on parameters required and the amount of damage done). Nevertheless, proper handling procedure is important to the safe use, and overall robustness of any precision grinding process.

- Always inventory the blades in the original package as packaged from us. This will not only protect the blades, but allow the necessary blade information to be available on hand.

- Store the package away from obvious hazards such as water, hear and dust.

- Clean hands and clean bench is required for any inspection or inventory purposes.

- Handle the blades using the inside diameter hole whenever possible.

Cleaning

- A careful and through cleaning is an important step to a reliable diamond glade cutting process. Below are some guideless.

- All cleaning should be done in an area that is as particulate free as possible, a clean room is optimal, but not absolutely required.

- Use a residue free cleaning solvent, isopropyl alcohol is recommend, but acetone is also acceptable.

- Use clean, laboratory grade lint free wipes.

- Always visually inspect for any debris or particulate that might be imbedded or otherwise requires special or added treatment to remove.

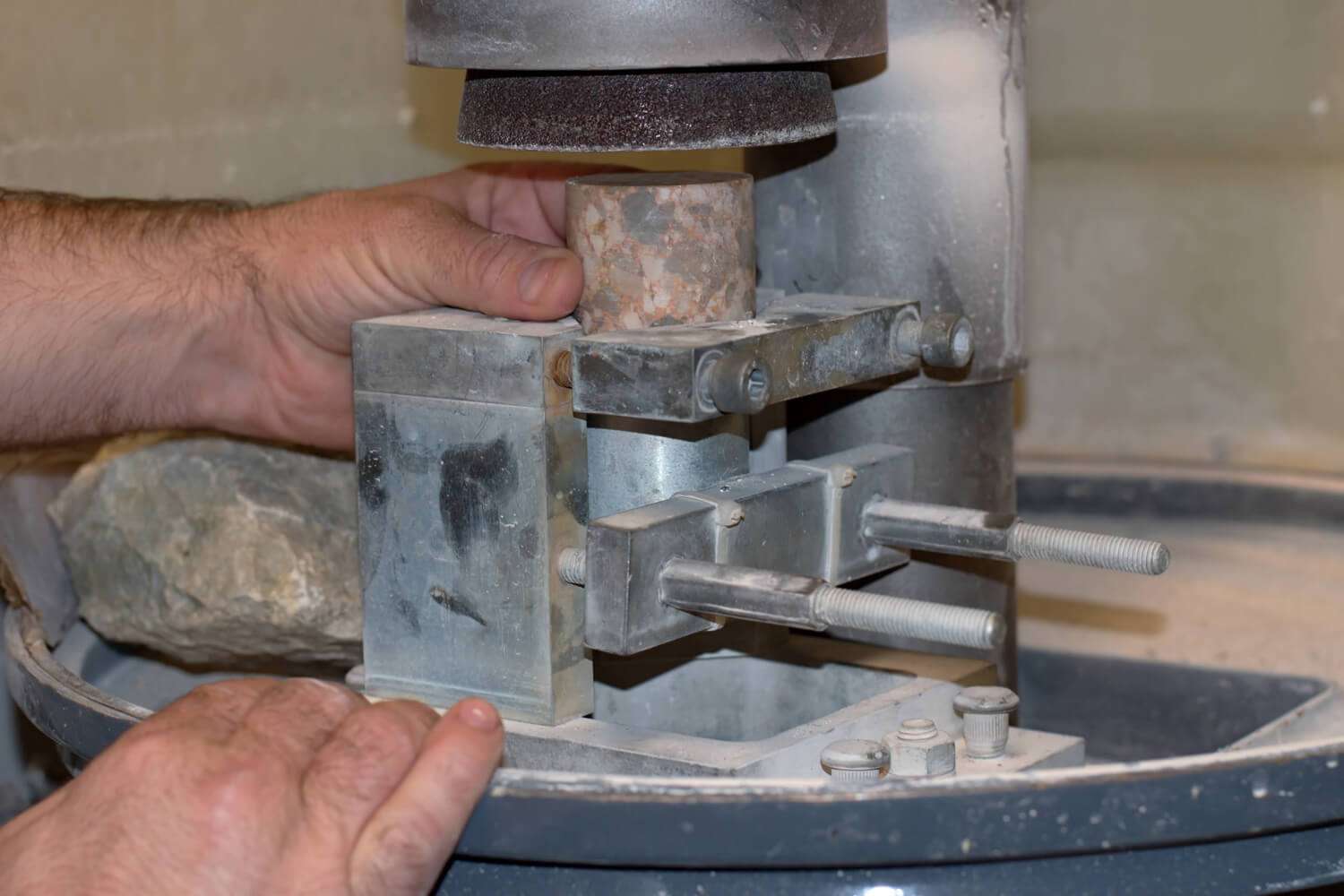

Mounting (Stacking)

There a re numerous mounting systems (Arbor, Hub, Flange) each requiring slightly different components and procedures. Below are some recommendation:

- The mounting hardware (arbor, hub, flange) and the stacking components (Spacers, Blades) must be clean of any debris.

- A through visual inspection for burrs dings dents or other damage.

- Mechanically inspect the mounting hardware for axial and radial run out to verify that all is within specification.

- Assemble and inspect per manufacturer instructions.

Truing

The truing of a diamond blade is an important step towards a repeatable and robust cutting process. Without this step the blade or the material can become damaged due to the “hammering” caused by excessive radial run out of the blades. This damage can lead to inconsistent blade performance and cut quality, and in extreme circumstances blade failure.

Dressing

Blade dressing is an important part of precision cutting process. With an optimized dressing system and intervals the cutting forces will be stable and predictable

Use the blade recommend dressing system (stick, plate or board) and process. This will optimize the diamond protrusion for maximum blade life and cut quality. Deviations from those recommendations should be used with considerable causation.

There are many variables involved with the selection of a suitable blade dressing systems. Including bond type, bond hardness & bond structure. Abrasive size and type, abrasive concentration, the blade form and size.

Generally speaking the size of abrasive particles used in the dressing system (whether stick, plate or board) should be slightly larger than the abrasive size of nickel bonded dicing blade being dressed.

Why Work With Us?

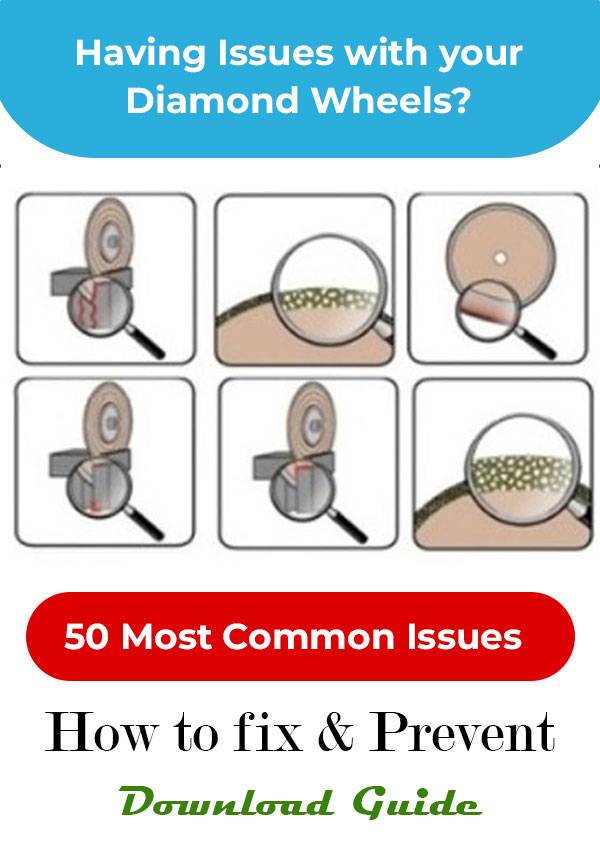

Comprehensive Source Of Information On Dicing Blades

We understand that your success depends on select the right dicing blade, and optimizing your dicing parameters to best fit your applications/needs. The more you understand about what we can do for you, the better our partnership will be. On our website you will find the Most Comprehensive Source of Information on Everything you wanted to know about diamond dicing blades & industrial diamond tools.

Large Inventory & Custom Manufacturing

Largest Inventory of Precision & Ultra Thin Diamond Dicing Blades in the U.S. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness's.

Experience Makes All The Difference

"ONE OF THE MOST EXPERIENCED COMPANIES IN THE INDUSTRY"

Over the years we have enjoyed working with all types if clients, regardless of size. Proprietary dicing blade chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect blade life, quality of cut, surface finish. Reducing and often eliminating additional steps often required after cutting.

Umatched Technical Support

We Are a Partner In Your Success

Developing close ties with our customers is the foundation of our business. At the core of our company is a team of world class engineers, knowledgeable customer service personnel here to serve you. Whether is designing or manufacturing a special solution. We will go out of our way to optimizing your process to ultimate level of efficiency.

Advanced

Technology

American Manufacturer As one of the few remaining independent U.S.Diamond Tool & machine builders. We have the experience & tradition to help you remain at frontier of technology Our experience has been further enhanced by acquiring assets and processes from some of the oldest American tool manufacturers, along with their decades of experience and R& D. This has positioned us as one of the most experienced companies in the industry.

Superior Quality &

Consistency

Our unique bond formulations, tool designs, stringent requirements, and utilization of exceptionally high-quality diamonds and raw materials ensure top-notch products that adhere to strict ISO 9000 standards.

Our proprietary technology allow us to control and regulate the dozens of variable that affect toolife, quality, & consistency.

Expect More From Your Tools