How to Selecting Right Diamond Tools for your application

-

Posted by

Alexander Schneider

Alexander Schneider

Table of Contents

ToggleSelecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely, choosing an incorrect specification can lead to numerous problems and challenges.

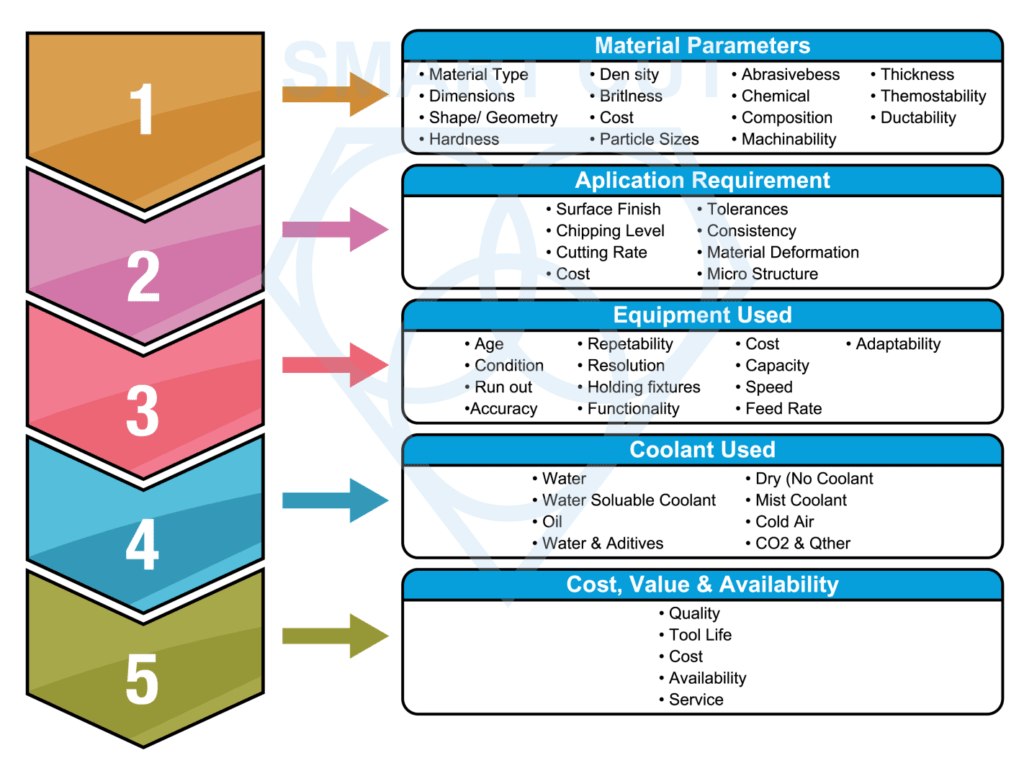

The process of selecting the right diamond or CBN tools for your application involves a series of strategic considerations that extend beyond just product selection. It requites a thorough understanding of the material characteristics, application requirements, equipment capabilities, coolant options, and overall cost-effectiveness. This guide presents a structured five-step approach to help you navigate these complex considerations.

Share this Article with Friend or Colleague

5 Step Guide of Selecting the Right Diamond or CBN Tool for your application

Each step is specifically designed to ensure that the chosen diamond tool or cbn not only meets the specific requirements of your material and application but also integrates seamlessly with your existing equipment, enhances operational efficiency, and aligns with your overall goals. By adopting this methodical approach, you can improve your optimize your application, increase the life of your tools, and insure maximum output.

When selecting the right diamond tool for your application, it is important to prioritize the factors that are most significant to your specific needs while recognizing the inherent trade-offs among these variables.

Let us explore these steps in detail to understand how to make the most informed and effective tool selection possible.

1. Understanding Material you are working with and its Parameters

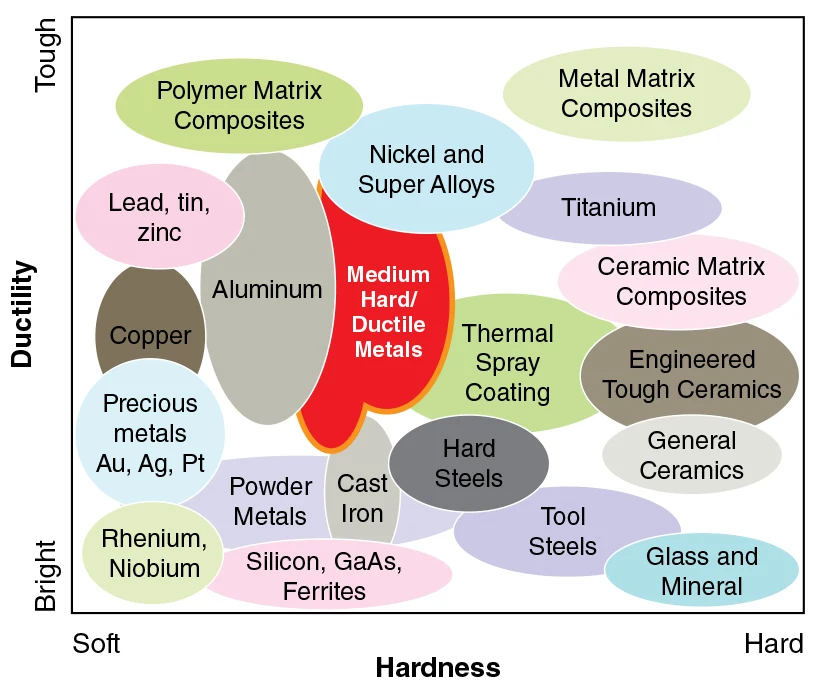

The First step in selecting the right diamond or cbn tools for your application is understanding the material characteristics and its parameters. This is one of the most important considerations and will set the stage for other steps in this process. This step is foundational as it ensures the selected tool will effectively interact with the material without causing damage or inefficiency. The following material parameters are essential to consider:

-

Material Type: Identify the material (e.g., metals, ceramics, composites) to determine the type of diamond tool needed based on the material’s properties.

Material Type: Identify the material (e.g., metals, ceramics, composites) to determine the type of diamond tool needed based on the material’s properties.

-

Dimensions: The size of the material influences the size of the tool and the type of machinery needed.

Dimensions: The size of the material influences the size of the tool and the type of machinery needed.

-

Shape/Geometry: Complex shapes may require specialized tools or adjustments in cutting technique.

Shape/Geometry: Complex shapes may require specialized tools or adjustments in cutting technique.

-

Hardness: The hardness of the material affects the choice of diamond grit and bond type in the tool to ensure effective cutting without excessive wear.

Hardness: The hardness of the material affects the choice of diamond grit and bond type in the tool to ensure effective cutting without excessive wear.

-

Density: Affects the cutting speed and the wear on the tool, as denser materials may require more force and cause quicker tool degradation.

Density: Affects the cutting speed and the wear on the tool, as denser materials may require more force and cause quicker tool degradation.

-

Brittleness: Brittle materials require tools that minimize chipping and cracking, possibly affecting the choice of cutting speed and coolant use.

Brittleness: Brittle materials require tools that minimize chipping and cracking, possibly affecting the choice of cutting speed and coolant use.

-

Cost: The cost of the material can influence the choice of cutting method and tools, balancing between efficiency and expense.

Cost: The cost of the material can influence the choice of cutting method and tools, balancing between efficiency and expense.

-

Particle Sizes: In materials composed of granular constituents, like some ceramics or composites, the size of the particles can influence the choice of diamond grit size to avoid dislodging particles or uneven cutting.

Particle Sizes: In materials composed of granular constituents, like some ceramics or composites, the size of the particles can influence the choice of diamond grit size to avoid dislodging particles or uneven cutting.

-

Abrasivebess: More abrasive materials will require diamond tools with specific properties, such as harder bond types to withstand wear.

Abrasivebess: More abrasive materials will require diamond tools with specific properties, such as harder bond types to withstand wear.

-

Chemical Composition: Some materials may chemically interact with certain types of coolants or cause excessive wear on specific types of diamond grit.

Chemical Composition: Some materials may chemically interact with certain types of coolants or cause excessive wear on specific types of diamond grit.

-

Thickness: The thickness of the material can affect the cutting technique and tool choice, as thicker materials may require different types of diamond tools or adjustments in cutting parameters.

Thickness: The thickness of the material can affect the cutting technique and tool choice, as thicker materials may require different types of diamond tools or adjustments in cutting parameters.

-

Thermostability: Materials sensitive to heat require tools and cutting conditions that minimize heat generation to prevent material degradation.

Thermostability: Materials sensitive to heat require tools and cutting conditions that minimize heat generation to prevent material degradation.

-

Ductability: Ductile materials may deform under cutting stress, requiring specific types of diamond tools that ensure clean cuts without material pull.

Ductability: Ductile materials may deform under cutting stress, requiring specific types of diamond tools that ensure clean cuts without material pull.

-

Microstructure: Understanding the microstructure of the material, such as grain size, phase distribution, and inclusion content, can influence the choice of diamond tool. For example, a heterogeneous microstructure might require a tool that can handle varying levels of hardness and abrasiveness across the material.

Microstructure: Understanding the microstructure of the material, such as grain size, phase distribution, and inclusion content, can influence the choice of diamond tool. For example, a heterogeneous microstructure might require a tool that can handle varying levels of hardness and abrasiveness across the material.

-

Elasticity and Modulus of Elasticity: These properties can affect how the material responds to the mechanical stress exerted during cutting. Materials with a high modulus of elasticity tend to be stiffer, which might necessitate different tool specifications to minimize the risk of deformation.

Elasticity and Modulus of Elasticity: These properties can affect how the material responds to the mechanical stress exerted during cutting. Materials with a high modulus of elasticity tend to be stiffer, which might necessitate different tool specifications to minimize the risk of deformation.

-

Thermal Conductivity: This parameter influences how quickly heat is conducted away from the cutting zone. Materials with low thermal conductivity might require enhanced cooling strategies during cutting to prevent thermal damage.

Thermal Conductivity: This parameter influences how quickly heat is conducted away from the cutting zone. Materials with low thermal conductivity might require enhanced cooling strategies during cutting to prevent thermal damage.

-

Fatigue Strength: For materials subjected to cyclic loads in their application, understanding their fatigue strength can help in selecting a tool that minimizes the introduction of fatigue stresses during cutting.

Fatigue Strength: For materials subjected to cyclic loads in their application, understanding their fatigue strength can help in selecting a tool that minimizes the introduction of fatigue stresses during cutting.

-

Corrosion Resistance: If the material is prone to corrosion, it’s crucial to consider how the cutting process and the environment in which the cutting occurs might accelerate such issues. This might influence the choice of coolant and tool handling procedures to mitigate corrosive effects.

Corrosion Resistance: If the material is prone to corrosion, it’s crucial to consider how the cutting process and the environment in which the cutting occurs might accelerate such issues. This might influence the choice of coolant and tool handling procedures to mitigate corrosive effects.

-

Reactivity to Coolants and Chemicals: Some materials may have adverse reactions to specific coolants or other chemicals used in the cutting process. It is important to select a coolant that does not chemically degrade or alter the material.

Reactivity to Coolants and Chemicals: Some materials may have adverse reactions to specific coolants or other chemicals used in the cutting process. It is important to select a coolant that does not chemically degrade or alter the material.

-

Optical Properties: For materials used in optical applications, maintaining the integrity of optical properties after cutting is crucial. This includes considering how the cutting process might affect the material's transparency or refractive index.

Optical Properties: For materials used in optical applications, maintaining the integrity of optical properties after cutting is crucial. This includes considering how the cutting process might affect the material's transparency or refractive index.

-

Environmental and Safety Concerns: Consider any environmental or safety regulations related to the material, such as toxicity or hazardous byproducts produced during machining. This might influence waste management and safety measures during the cutting process.

Environmental and Safety Concerns: Consider any environmental or safety regulations related to the material, such as toxicity or hazardous byproducts produced during machining. This might influence waste management and safety measures during the cutting process.

2. Application Requirements – (What is the end result you want to achieve?)

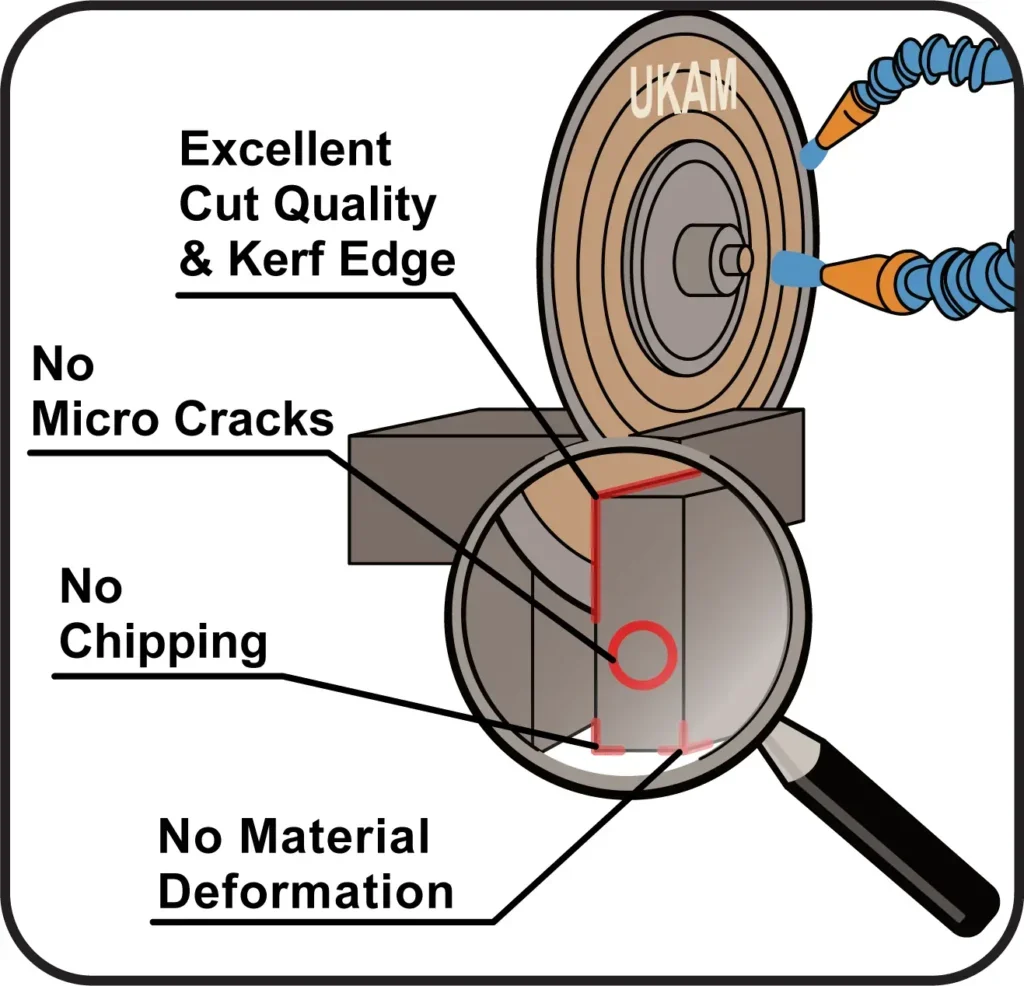

Your application's unique requirements and performance metrics will further refine the selection of diamond tools. Clearly understanding and defining your goals and objectives is an important step in selecting the right diamond or cbn tools for your application. This requires a deep understanding of your operational needs, quality requirements, and efficiency goals. Consider the following:

-

Surface Finish: The desired quality of the surface after cutting. Different applications may require varying levels of smoothness or specific surface characteristics.

Surface Finish: The desired quality of the surface after cutting. Different applications may require varying levels of smoothness or specific surface characteristics.

-

Chipping Level: Some applications cannot tolerate any chipping at the edges, while others may be more lenient. The choice of diamond tool must align with the acceptable level of chipping.

Chipping Level: Some applications cannot tolerate any chipping at the edges, while others may be more lenient. The choice of diamond tool must align with the acceptable level of chipping.

-

Cutting Speed/Rate: This refers to the speed at which the material can be cut. A higher cutting rate increases productivity but may impact the quality of the cut and tool wear.

Cutting Speed/Rate: This refers to the speed at which the material can be cut. A higher cutting rate increases productivity but may impact the quality of the cut and tool wear.

-

Cost: Budget constraints can influence tool choice, balancing cost with performance and longevity.

Cost: Budget constraints can influence tool choice, balancing cost with performance and longevity.

-

Tolerances: The degree of accuracy and precision required in the dimensions of the finished product. Tighter tolerances may require higher quality or specialized tools.

Tolerances: The degree of accuracy and precision required in the dimensions of the finished product. Tighter tolerances may require higher quality or specialized tools.

-

Consistency: The need for uniform performance and results across multiple cuts or batches.

Consistency: The need for uniform performance and results across multiple cuts or batches.

-

Material Deformation: The tool should minimize any unwanted deformation of the material, such as warping or structural changes due to heat or mechanical stress.

Material Deformation: The tool should minimize any unwanted deformation of the material, such as warping or structural changes due to heat or mechanical stress.

-

Micro Structure: It's essential to maintain the integrity of the material's microstructure after processing, which can be crucial for the material’s functional properties.

Micro Structure: It's essential to maintain the integrity of the material's microstructure after processing, which can be crucial for the material’s functional properties.

-

Edge Quality: Besides general surface finish, the quality of the edges after cutting is crucial for many precision applications, affecting both aesthetic and functional properties of the final product.

Edge Quality: Besides general surface finish, the quality of the edges after cutting is crucial for many precision applications, affecting both aesthetic and functional properties of the final product.

-

Heat Affected Zone (HAZ): Minimizing the heat-affected zone can be critical, especially for materials sensitive to thermal alterations. Selecting a tool that operates efficiently with minimal heat generation can be crucial.

Heat Affected Zone (HAZ): Minimizing the heat-affected zone can be critical, especially for materials sensitive to thermal alterations. Selecting a tool that operates efficiently with minimal heat generation can be crucial.

3. Equipment Compatibility

The equipment used in your application plays a crucial role in determining the feasible diamond tool or cbn specifications that can be used. Ensuring that these equipment parameters are taken into consideration guarantees that the selected diamond tool is compatible with your existing machinery and capable of executing the required tasks both effectively and efficiently. Additionally, the performance of these tools is significantly influenced by the equipment used. Key factors to evaluate include:

-

Repeatability: The ability of the equipment to consistently produce the same results under the same operating conditions. This is crucial for applications requiring precision and uniformity.

Repeatability: The ability of the equipment to consistently produce the same results under the same operating conditions. This is crucial for applications requiring precision and uniformity.

-

Resolution: The finest level of detail or the smallest measure of change that the equipment can detect or control during the cutting process.

Resolution: The finest level of detail or the smallest measure of change that the equipment can detect or control during the cutting process.

-

Holding Fixtures: The availability and suitability of fixtures used to hold the material securely during the cutting process. Proper fixtures are essential to prevent material movement and ensure accurate cuts.

Holding Fixtures: The availability and suitability of fixtures used to hold the material securely during the cutting process. Proper fixtures are essential to prevent material movement and ensure accurate cuts.

-

Functionality: The overall capabilities of the equipment, including its ability to perform the required cuts, accommodate various tool sizes, and adjust to different cutting conditions.

Functionality: The overall capabilities of the equipment, including its ability to perform the required cuts, accommodate various tool sizes, and adjust to different cutting conditions.

-

Cost: The cost of the equipment itself, which includes the initial purchase price, ongoing maintenance costs, and the cost of any necessary upgrades or accessories.

Cost: The cost of the equipment itself, which includes the initial purchase price, ongoing maintenance costs, and the cost of any necessary upgrades or accessories.

-

Adaptability: The ability of the equipment to be adjusted or configured to work with different types of tools and materials, which is essential for flexible manufacturing processes.

Adaptability: The ability of the equipment to be adjusted or configured to work with different types of tools and materials, which is essential for flexible manufacturing processes.

-

Capacity: Refers to the maximum size or volume of material that the equipment can handle, which must align with the dimensions of the materials to be cut.

Capacity: Refers to the maximum size or volume of material that the equipment can handle, which must align with the dimensions of the materials to be cut.

-

Speed:The operational speed of the equipment, which impacts the cutting rate and the overall efficiency of the cutting process.

Speed:The operational speed of the equipment, which impacts the cutting rate and the overall efficiency of the cutting process.

-

Feed Rate: The rate at which the material is fed into the cutting tool, which can influence the quality of the cut, tool wear, and the efficiency of material removal.

Feed Rate: The rate at which the material is fed into the cutting tool, which can influence the quality of the cut, tool wear, and the efficiency of material removal.

-

Coolant System Compatibility:Check if the equipment’s coolant system is adaptable to the types of coolants required for different materials and cutting conditions, especially if specialized coolants like mist or oil are necessary.

Coolant System Compatibility:Check if the equipment’s coolant system is adaptable to the types of coolants required for different materials and cutting conditions, especially if specialized coolants like mist or oil are necessary.

Identify Critical Performance Metrics:

Identify which of these goals are most important to you. Some of the most common performance metrics across many applications include:

-

Cutting Speed: If your operation prioritizes productivity, you might value tools that offer high cutting speeds to reduce cycle times. High-speed tools are particularly beneficial in high-volume production settings where time is a critical factor.

Cutting Speed: If your operation prioritizes productivity, you might value tools that offer high cutting speeds to reduce cycle times. High-speed tools are particularly beneficial in high-volume production settings where time is a critical factor.

-

Tool Life: For operations where frequent tool changes can lead to significant downtime or increased operational costs, choosing tools with longer life spans might be more cost-effective, even if they come with a higher upfront cost.

Tool Life: For operations where frequent tool changes can lead to significant downtime or increased operational costs, choosing tools with longer life spans might be more cost-effective, even if they come with a higher upfront cost.

-

Surface Finish: In applications where the quality of the finish is crucial, such as in decorative work or precision engineering, opting for a tool that achieves a superior finish might be essential, even if this means slower operation or higher costs.

Surface Finish: In applications where the quality of the finish is crucial, such as in decorative work or precision engineering, opting for a tool that achieves a superior finish might be essential, even if this means slower operation or higher costs.

-

Cost: For many businesses, especially startups or small-scale operations, initial cost and cost per cut are critical factors. In such cases, finding a balance between affordability and acceptable performance and longevity is necessary.

Cost: For many businesses, especially startups or small-scale operations, initial cost and cost per cut are critical factors. In such cases, finding a balance between affordability and acceptable performance and longevity is necessary.

Understanding Trade-offs:

Understand that there may be some trade offs involving sacrificing one objective over the other. Here’s a detailed look at how to balance these priorities and what to consider in the decision-making process:

-

Speed vs. Surface Finish: Tools designed for high-speed cutting may not always provide the best finish quality. High speeds can result in increased heat generation, which might affect the surface integrity of the material.

Speed vs. Surface Finish: Tools designed for high-speed cutting may not always provide the best finish quality. High speeds can result in increased heat generation, which might affect the surface integrity of the material.

-

Cost vs. Longevity: Lower-cost tools might seem economical but often come with shorter life spans or lower efficiency, leading to higher long-term costs due to replacements and downtime.

Cost vs. Longevity: Lower-cost tools might seem economical but often come with shorter life spans or lower efficiency, leading to higher long-term costs due to replacements and downtime.

-

Quality vs. Price: Higher-quality tools generally come at a higher price. The investment in premium tools can be justified if they produce superior results, reduce waste, or decrease the need for secondary finishing processes.

Quality vs. Price: Higher-quality tools generally come at a higher price. The investment in premium tools can be justified if they produce superior results, reduce waste, or decrease the need for secondary finishing processes.

4. Coolant Considerations

Selecting the appropriate coolant is a critical step in choosing your diamond or CBN tool. The coolant you use will significantly influence which tools are suitable for your application. Additionally, the coolant can greatly impact the cutting process, the lifespan of the tool, and the properties of the material being cut. Different types of coolants come with their own considerations in terms of effectiveness, environmental impact, cost, and compatibility with various materials and cutting conditions. The options include:

-

Water: A commonly used coolant due to its availability and effectiveness in heat dissipation. It's suitable for many general-purpose cutting operations but may require additives to prevent rust and enhance lubrication.

Water: A commonly used coolant due to its availability and effectiveness in heat dissipation. It's suitable for many general-purpose cutting operations but may require additives to prevent rust and enhance lubrication.

-

Water Soluble Coolant: These coolants are mixtures of water and oil or other additives, offering both cooling and lubrication. They are widely used due to their superior cooling properties and ability to reduce friction.

Water Soluble Coolant: These coolants are mixtures of water and oil or other additives, offering both cooling and lubrication. They are widely used due to their superior cooling properties and ability to reduce friction.

-

Oil: Provides excellent lubrication, which can lead to smoother cuts and extended tool life. However, oil coolants can be messier and may present disposal challenges. They are typically used for high-precision cutting operations where lubrication is more critical than cooling.

Oil: Provides excellent lubrication, which can lead to smoother cuts and extended tool life. However, oil coolants can be messier and may present disposal challenges. They are typically used for high-precision cutting operations where lubrication is more critical than cooling.

-

Mist Coolant: This type of coolant uses a misting mechanism to deliver a fine spray of coolant to the cutting area, reducing the amount of liquid coolant needed. It is useful in applications where minimal coolant use is preferred and can help keep the workpiece and tool cleaner.

Mist Coolant: This type of coolant uses a misting mechanism to deliver a fine spray of coolant to the cutting area, reducing the amount of liquid coolant needed. It is useful in applications where minimal coolant use is preferred and can help keep the workpiece and tool cleaner.

-

Cold Air: Utilizes chilled air to cool the cutting area. This method is particularly useful for materials sensitive to moisture or where liquid coolants could cause issues, such as with certain metals or composites.

Cold Air: Utilizes chilled air to cool the cutting area. This method is particularly useful for materials sensitive to moisture or where liquid coolants could cause issues, such as with certain metals or composites.

-

CO2 & Other: Advanced coolants like carbon dioxide can be used in a dry-ice form, providing cooling through sublimation which requires no cleanup. Other specialized coolants might include gases or cryogenic liquids, which are used for highly specific applications requiring extreme cooling.

CO2 & Other: Advanced coolants like carbon dioxide can be used in a dry-ice form, providing cooling through sublimation which requires no cleanup. Other specialized coolants might include gases or cryogenic liquids, which are used for highly specific applications requiring extreme cooling.

5. Cost, Value, and Availability

In the final step of selecting the right diamond or CBN tool, it's crucial to consider the overall cost-effectiveness. Assessing cost, value, and availability is essential to ensure that your selection not only fits your technical needs but also aligns with your budget and operational goals. This includes considering various factors that influence both the upfront and long-term costs associated with owning and operating the tool. Let's delve into these key elements to understand their impact on the overall cost-effectiveness of your tool choice.

-

Quality: Evaluates the overall quality of the diamond tool, including the precision of the cut, the durability of the tool, and its performance consistency. Higher quality tools generally offer better performance and longer lifespan, reducing the need for frequent replacements.

Quality: Evaluates the overall quality of the diamond tool, including the precision of the cut, the durability of the tool, and its performance consistency. Higher quality tools generally offer better performance and longer lifespan, reducing the need for frequent replacements.

-

Diamond or CBN Tool Life: Refers to the durability and operational lifespan of the tool under normal usage conditions. Tools with a longer life are generally more cost-effective over time, even if they come with a higher upfront cost.

Diamond or CBN Tool Life: Refers to the durability and operational lifespan of the tool under normal usage conditions. Tools with a longer life are generally more cost-effective over time, even if they come with a higher upfront cost.

-

Cost: The purchase cost of the tools, including any upfront investment needed for additional equipment or setup. This also includes the cost of operation, such as energy consumption, maintenance, and replacement of worn-out parts.

Cost: The purchase cost of the tools, including any upfront investment needed for additional equipment or setup. This also includes the cost of operation, such as energy consumption, maintenance, and replacement of worn-out parts.

-

Availability: The ease with which the tool or its replacement parts can be obtained. Availability is crucial for minimizing downtime; therefore, selecting a tool that is readily available or can be quickly supplied is important.

Availability: The ease with which the tool or its replacement parts can be obtained. Availability is crucial for minimizing downtime; therefore, selecting a tool that is readily available or can be quickly supplied is important.

-

Service: The level of customer service provided by the manufacturer or distributor, including their knowledge and technical support, maintenance services, and the availability of training for operators. Good service can significantly enhance the usability and lifespan of the tool.

Service: The level of customer service provided by the manufacturer or distributor, including their knowledge and technical support, maintenance services, and the availability of training for operators. Good service can significantly enhance the usability and lifespan of the tool.

-

Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the total cost of owning and operating the tool over its lifespan. This includes maintenance costs, operational costs (like energy and coolants), downtime costs, and eventual disposal or recycling costs.

Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the total cost of owning and operating the tool over its lifespan. This includes maintenance costs, operational costs (like energy and coolants), downtime costs, and eventual disposal or recycling costs.

-

Return on Investment (ROI): Calculate the expected return on investment for each tool option. Consider both direct returns, such as increased production capacity or reduced labor costs, and indirect returns, like improved product quality or enhanced customer satisfaction.

Return on Investment (ROI): Calculate the expected return on investment for each tool option. Consider both direct returns, such as increased production capacity or reduced labor costs, and indirect returns, like improved product quality or enhanced customer satisfaction.

Need Help Selecting the Right Diamond

or CBN Tool for Your Application?

Our applications engineers will review your material, machine, and cutting parameters and recommend the optimal

Diamond or CBN Tool specification/solution for your application

Free consultation. No obligation.

Need Help finding the right tool spec for your application

Our engineers can review your application and recommend the best diamond and CBN tool for your material, machine and cutting specs.

Our engineers can review your application and recommend the best diamond and CBN tool for your material, machine and cutting specs.

Trusted by Tens of Thousands of Manufacturers, Laboratories,

Research Institutions Worldwide Since 1990

Established in 1990

About the Author:

Alexander Schneider is a senior applications engineer with over 35 years of hands on experience in industrial diamond tooling. He specializes in the development, application, and optimization of ultra-thin and high-precision diamond blades, diamond core drills, and diamond and CBN grinding wheels for advanced materials.

His work spans ceramics, glass, composites, semiconductors, and high-performance metals. He supports research laboratories and manufacturing environments by optimizing tool design and cutting parameters to achieve high cut quality, long tool life, material integrity, and consistent process results.

ARE YOU USING RIGHT DIAMOND & CBN TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DIAMOND & CBN TOOLS?

Knowledge Center

Diamond Tool Coolants Why, How, When & Where to Use

Selecting the Right Coolant Method for your Diamond & CBN Tools

How to Selecting Right Diamond Tools for your application

How to properly use Diamond Tools

Why use diamond

Diamond vs CBN (cubic boron nitride) Tools

What is Diamond Mesh Size and how to select best one for your application

What is Diamond Concentration and which to use for your application

Choosing The Correct Diamond Bond Type

How to Properly Use Diamond Tools: A Complete Guide to Performance, Safety, and Tool Life

Alexander Schneider is a senior applications engineer with over 35 years of hands on experience in industrial diamond tooling. He specializes in the development, application, and optimization of ultra-thin and high-precision diamond blades, diamond core drills, and diamond and CBN grinding wheels for advanced materials.

His work spans ceramics, glass, composites, semiconductors, and high-performance metals. He supports research laboratories and manufacturing environments by optimizing tool design and cutting parameters to achieve high cut quality, long tool life, material integrity, and consistent process results.