-

0 items in quote

No products in the Quote Basket.

Flanges for Diamond and CBN Cutting Blades

Standard & Custom Flanges for Laboratory and Industrial Cutting Machines

We manufacture a comprehensive selection of high-precision flanges compatible with virtually all precision cutting machines on the market. Each flange is meticulously produced using advanced CNC machining technologies to maintain tight tolerances, ensure perfect flatness, and provide consistent performance during the most demanding cutting operations. These flanges are engineered for optimal alignment and concentricity, helping extend blade life and enhance cut accuracy.

Using flanges is critical when operating with high-precision diamond and CBN cutting blades, especially in applications where consistent depth of cut, cut quality, and part integrity are essential.

DESCRIPTION

SPECIFICATIONS

FREQUENTLY ASKED QUESTIONS

INDUSTRIES USED IN

ACCESSORIES

USAGE RECOMMENDATION

DESCRIPTION

Flanges serve as reinforcement components that support both sides of the blade, distributing pressure evenly and maintaining the structural integrity of the blade throughout its rotation. This is particularly important in thin, high-performance blades used in semiconductor dicing, materials research, optics, composites, ceramics, and other advanced material applications.

By minimizing blade deflection and stabilizing the cutting edge, flanges play an essential role in reducing the risk of warping, blade tension loss, and flatness deviation. They help avoid slanted or irregular cuts, material edge chipping, and other defects that can compromise the part or the process. This translates into lower tool wear, fewer reworks, and better repeatability in production and R&D environments.

Our flanges are available in multiple sizes, thicknesses, and mounting configurations, and can be custom-fabricated to match specific machine or application requirements. Whether you’re using ultra-thin wafering blades, larger diameter cutoff wheels, or specialty dicing blades, properly matched and balanced flanges will help you achieve superior results. They are an essential component in any cutting system that values precision, consistency, and productivity.

SPECIFICATIONS

Tab Content

FREQUENTLY ASKED QUESTIONS

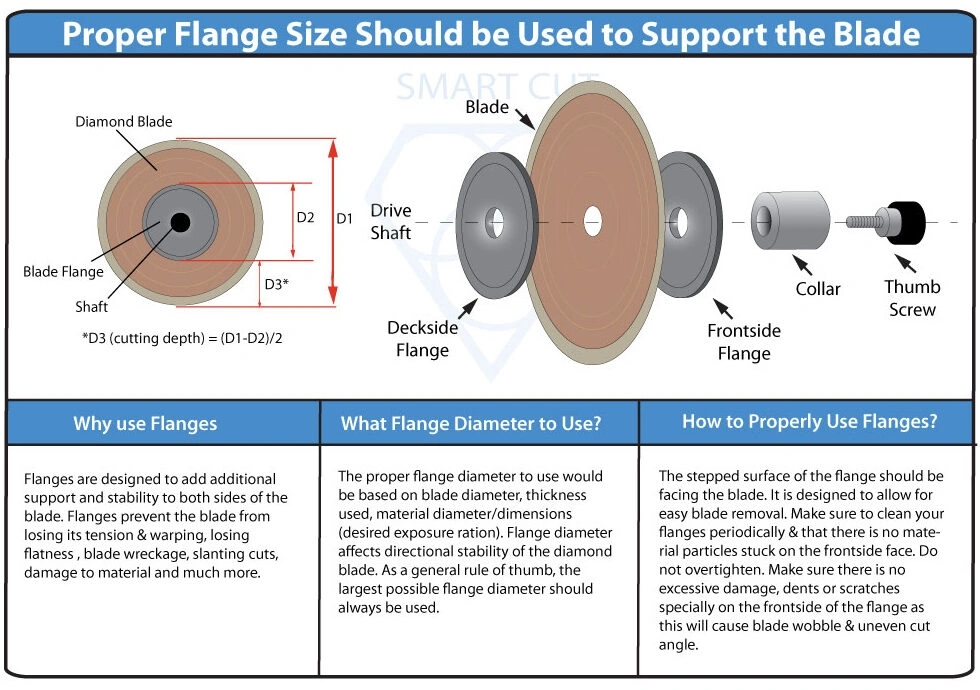

Flanges are essential for adding stability and support on both sides of the blade. They prevent the blade from:

- Losing tension

- Warping

- Losing flatness

- Blade wreckage

- Producing slanted cuts

- Damaging the material

Choosing the correct flange diameter requires considering:

- Blade diameter

- Thickness of the blade

- Diameter of the material being cut

- Material dimensions

- Desired blade exposure ratio

We offer a diverse range:

- 30mm flanges with 1/2″ and 5/8″ inside diameters

- 40mm flanges with 1/2″ and 5/8″ inside diameters

- 45mm flanges with 1/2″ and 5/8″ inside diameters Prices and other details can be viewed on our product listing page.

Yes, we produce a large variety of flanges designed to fit most dicing saws. These flanges cater to different blade diameters, kerf thicknesses, and inside diameters, ensuring precision with short lead times.

Certainly! We can manufacture flanges based on your drawings or specifications suitable for almost any cutting machine and application.

Using flanges correctly is vital for a successful cutting operation. Proper mounting ensures the blade remains stable during the cutting process, reducing risks associated with blade warping, damage, and other potential issues. Following recommended flange sizes based on blade and material dimensions ensures efficiency and safety.

For optimal directional stability, it is best to always use the largest possible flange diameter. However, for thinner and smaller diameter blades, a flange size equal to ¾ of the blade’s Outside Diameter is recommended. For larger and thicker blades, a flange diameter of about 1/3 of the blade’s outside diameter is advised.

Flanges should be kept free from rust and dirt. After tightening the flange nut, the blade should rotate without any wobble. It’s also essential to ensure that carriage alignment is accurate for deeper cuts to prevent the blade from bending. Any imperfections, such as scratches or nicks in the flange edge, can lead to issues during

Our flanges are:

- Precision machined on CNC machines to maintain exact tolerances.

- Available in an unmatched selection suitable for various applications.

Manufactured with a commitment to superior quality and consistency

Please Contact Us for a free quote tailored to your specific needs.

Routine inspection for rust, dirt, and any physical damage is essential. Clean them regularly with a soft cloth and a mild cleaner to remove any debris. If any damage is noticed, consider replacing the flange to ensure optimal blade performance

Our flanges are designed to fit most precision cutting machines. However, if you have specific models or brands in mind, please consult with us to ensure compatibility.

The longevity of a flange depends on the frequency of usage and the material being cut. Regularly inspect for wear and tear. If you notice any wobbling or inconsistency in your cuts, it might be time to replace your flanges.

For bulk order inquiries, please contact our sales team. We do offer special pricing for large volume purchases.

Our flanges are crafted from high-grade materials ensuring durability and precision. Specific material details can be provided upon request.

Our flanges are designed to withstand standard operating conditions of most precision cutting machines. However, if you have specific high-temperature requirements, please let us know so we can recommend the most suitable flange for your needs.

Always ensure that the flanges are properly installed and that the blade is securely mounted. Never operate the machine without the flanges in place. And always wear appropriate safety gear when operating any cutting machine.

Yes, we specialize in producing custom flanges based on your drawings or specifications. Please contact us with your requirements, and we’ll be happy to assist.

Signs of a worn-out flange include visible surface damage, wobbling during operation, or any alteration in the blade’s performance. It’s crucial to replace worn-out flanges to ensure safety and the machine’s optimal functionality.

Our flanges are versatile and can be used for both vertical and horizontal precision cutting machines. However, always refer to your machine’s manual or consult with our team to ensure proper compatibility.

Standard tools required for your specific precision cutting machine should suffice. However, always consult your machine’s manual for guidance on installation and removal of components.

Store unused flanges in a dry and cool place, away from direct sunlight. It’s also beneficial to keep them in their original packaging to prevent any potential damage or contamination.

Proper alignment is critical for precision cutting. Always refer to your machine’s manual for detailed instructions or consider seeking expert assistance for the initial setup.

The inside diameter refers to the central hole of the flange, which is crucial for mounting onto the machine. The outside diameter represents the overall size of the flange, which influences the blade’s stability and performance.

For custom branding or marking requests, please contact our sales team to discuss feasibility and any associated costs.

Our flanges are designed to support a wide range of material thicknesses. However, always ensure you select the correct flange based on the material’s dimensions and your machine’s specifications.

Yes, we offer discounts for bulk orders. Please contact our sales team to discuss volume discounts and any potential promotions.

The lifespan of a flange varies based on usage frequency and the materials being cut. Regularly inspect your flanges for signs of wear or damage and replace as needed to maintain optimal performance.

While our flanges are designed to fit most precision cutting machines, using them with non-original blades might alter performance. We recommend consulting with our technical team before pairing our flanges with blades from other manufacturers.

Yes, we ship our products globally. Please contact our sales team for shipping rates and estimated delivery times to your location.

Always turn off and disconnect the power to your cutting machine before installing or changing flanges. Ensure you’re wearing appropriate protective gear, such as gloves and safety glasses, during the installation process.

Absolutely! All our flanges go through rigorous quality checks to ensure they meet our high standards before they are shipped out.

Our flanges are precision machined from high-quality materials suitable for various cutting environments. For detailed specifications on the material composition, please refer to the product documentation or contact our team.

Cleaning and maintaining your flanges is essential for prolonging their lifespan. Wipe them down with a clean cloth after use and check for any signs of wear or debris. If necessary, use a mild detergent and warm water for cleaning, but ensure they are completely dry before reinstallation.

Our flanges are designed for a broad range of precision cutting machines. To determine compatibility with specific wet or dry machines, please refer to the product specifications or contact our technical team.

While our flanges are precision machined for durability, continuous exposure to extremely high temperatures may affect their performance. If your cutting operations involve high temperatures, please consult our technical team for recommendations.

Typically, no special tools are required for flange installation. However, always refer to your cutting machine’s manual and our product documentation to ensure a smooth installation process.

Our flanges are designed to provide optimal grip and stability, minimizing the risk of blade slippage. However, correct installation and regular maintenance are essential to ensure safety.

We pride ourselves on offering high-quality products at competitive prices. Our flanges are precision-machined with CNC machines to uphold the highest precision tolerances, ensuring consistent and reliable performance.

Yes, for bulk orders, we offer custom engraving or branding services. Please contact our sales team for more details.

Signs that flanges need replacement include visible wear, damage, or any changes in the performance of your cutting machine, such as increased vibration or inconsistent cuts.

For any issues or concerns, please reach out to our customer service team immediately. We’re committed to ensuring your satisfaction and will address any concerns promptly.

If there are more specific questions or deeper insights needed, our dedicated team is available to provide assistance and ensure you get the most out of our products.

more

Yes, for large volume orders, we offer bulk discounts. Please contact our sales team to discuss your requirements and get a customized quote.

Regular inspection after every use is recommended. However, for machines operating in heavy-duty environments, a more frequent check might be necessary to ensure the flanges remain in optimal condition.

Our flanges are made from high-quality, precision-engineered materials suitable for rigorous cutting applications. Specific material details can be provided upon request.

Yes, our flanges are treated to resist corrosion. However, as with all metal components, it’s essential to store them in a dry environment and clean them regularly to prevent any potential corrosion over time.

Refer to your machine’s user manual for specific torque guidelines. If you’re still unsure, our technical team can provide guidance.

INDUSTRIES USED IN

Tab Content

ACCESSORIES

Tab Content

USAGE RECOMMENDATION

Properly mounting the blade and flanges is key to any successful cutting operation. Flanges are designed to add additional support and stability to both sides of the blade. Flanges prevent the wafering blade from warping, blade wreckage, slanting cuts, damage to material/sample and much more. The proper flange diameter to use would be based on blade diameter, thickness used, material diameter/dimensions (desired exposure ration). Flange diameter affects directional stability of the diamond blade. As a general rule of thumb, the largest possible flange diameter should always be used. Flanges should provide sufficient clearance for sample so the cut may be completed without any interruption. For thinner and smaller diameter blades, recommended flange size is ¾ of the Outside Diameter of the wafering blade. Often extending right up to the diamond section. For larger and thicker blades the recommended flange diameter is approximately 1/3 the outside diameter of the blade. Flanges must be free of rust and dirt. Your blade should turn perfectly true after flange nut is tightened. Carriage alignment must be accurate for deeper cuts to prevent blade bending. Any small scratch or nick in flange edge can cause improper blade mounting. This can lead to slanted cuts, blades wobbling and wider cuts, more chipping, or even possible blade breakage.

Flange Usage Recommendations

Features:

-

CNC Machined Construction – Ensures high dimensional accuracy, flatness, and concentricity for optimal blade support.

CNC Machined Construction – Ensures high dimensional accuracy, flatness, and concentricity for optimal blade support.

-

Tight Tolerance Manufacturing – Guarantees consistent blade alignment and stability during high-speed operations.

Tight Tolerance Manufacturing – Guarantees consistent blade alignment and stability during high-speed operations.

-

Universal Compatibility – Available in multiple sizes and configurations to fit most precision cutting, dicing, and sectioning machines

Universal Compatibility – Available in multiple sizes and configurations to fit most precision cutting, dicing, and sectioning machines

-

Enhanced Blade Support – Reinforces both sides of the blade to prevent deflection, warping, and tension loss

Enhanced Blade Support – Reinforces both sides of the blade to prevent deflection, warping, and tension loss

-

Improved Cutting Accuracy – Reduces vibration and movement, resulting in cleaner, straighter cuts with minimal material damage.

Improved Cutting Accuracy – Reduces vibration and movement, resulting in cleaner, straighter cuts with minimal material damage.

-

Extended Blade Life – Minimizes uneven wear and heat buildup by evenly distributing pressure across the blade.

Extended Blade Life – Minimizes uneven wear and heat buildup by evenly distributing pressure across the blade.

-

Application-Specific Options – Can be custom-fabricated to match unique machine setups or specialized blade designs.

Application-Specific Options – Can be custom-fabricated to match unique machine setups or specialized blade designs.

-

Optimized for Ultra-Thin Blades – Ideal for wafering, dicing, and high-precision cutting of delicate and brittle materials.

Optimized for Ultra-Thin Blades – Ideal for wafering, dicing, and high-precision cutting of delicate and brittle materials.

-

Corrosion-Resistant Materials – Constructed from premium alloys to ensure durability and long-term performance.

Corrosion-Resistant Materials – Constructed from premium alloys to ensure durability and long-term performance.

We produce large variety of flanges to fit most precision cutting machines.

Flanges are precision machined on cnc machines to hold precision tolerances

Why use flanges?

Flanges are designed to add additional support and stability to both sides of the blade.

Flanges prevent the blade from:

-

losing tension

losing tension

-

warping

warping

-

losing flatness

losing flatness

-

blade wreckage

blade wreckage

-

slanting cuts

slanting cuts

-

damage to material

damage to material

How to Select Right Flange Diameter?

The proper flange diameter to use would be based on

-

blade diameter

blade diameter

-

thickness used

thickness used

-

material diameter

material diameter

-

material dimensions

material dimensions

-

desired blade exposure ratio

desired blade exposure ratio

Flanges for Diamond Blades

Showing 1 – -1 of 6 results Showing all 6 results Showing the single result No results found

Sort by Price low to high

Filters Sort results

Reset Apply

Picture | Item No | Diameter | Inside Diameter | Price | Quantity | Add to cart | |

|---|---|---|---|---|---|---|---|

30mm | 1/2" | Flanges for Diamond Blades | $70.00 | Max: Min: 1 Step: 1 | |||

30mm | 5/8" | Flanges for Diamond Blades | $70.00 | Max: Min: 1 Step: 1 | |||

40mm | 1/2" | Flanges for Diamond Blades | $75.00 | Max: Min: 1 Step: 1 | |||

40mm | 5/8" | Flanges for Diamond Blades | $75.00 | Max: Min: 1 Step: 1 | |||

45mm | 1/2" | Flanges for Diamond Blades | $80.00 | Max: Min: 1 Step: 1 | |||

45mm | 5/8" | Flanges for Diamond Blades | $80.00 | Max: Min: 1 Step: 1 |

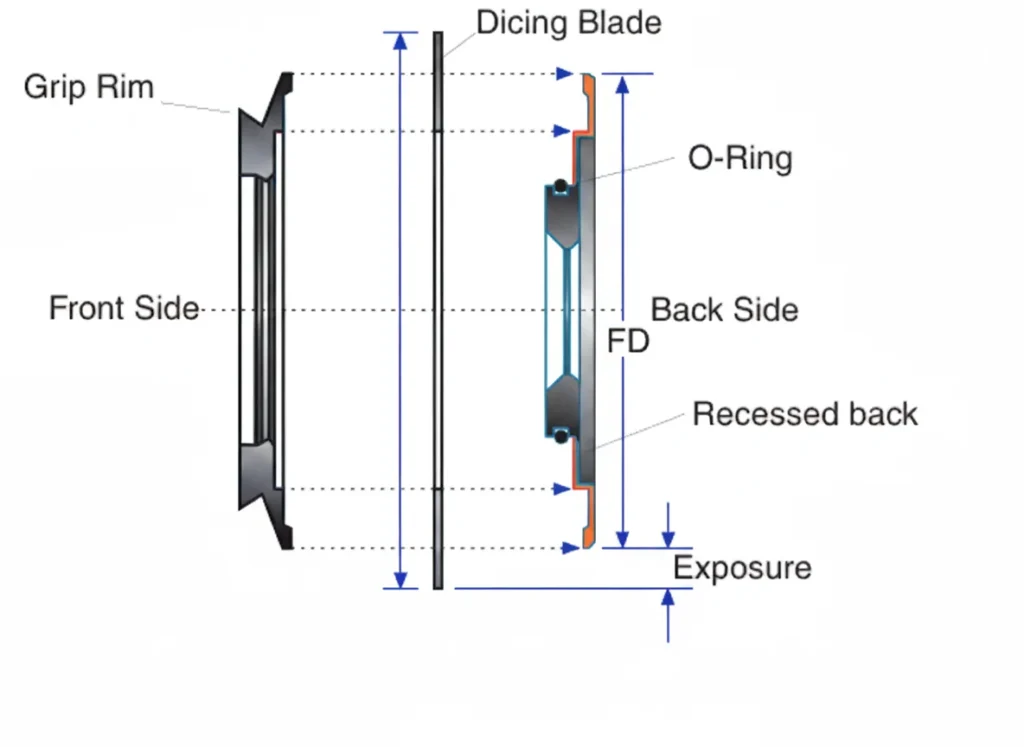

Flanges for Dicing Blades

Dicing blade flanges provide the secure and stable mounting needed for precision dicing operations. Manufactured to tight tolerances, they ensure concentricity and uniform clamping pressure, which reduces side run-out and improves cut quality. Made from durable stainless steel or aluminum alloys, these flanges resist wear, corrosion, and deformation during high-speed operation. Each flange is polished and balanced to prevent blade slippage and vibration, allowing the blade to perform at its highest potential.

We produce a large variety of flanges to fit most dicing saws, blade diameters, kerf thicknesses, and inside diameters with short lead times and high precision tolerances. Available in both standard and custom sizes, they are designed to fit most dicing saws including DISCO, Accretech, ADT K&S, and many others. Options such as special coatings or balancing holes can be added to meet specific cutting requirements.

Using high-quality flanges results in longer blade life, smoother cuts, and improved accuracy, especially when processing delicate materials like silicon wafers, sapphire, glass, and ceramics. By reducing stress on the blade and allowing higher spindle speeds and feed rates, precision flanges help you achieve greater throughput, better surface finish, and consistent cutting results across demanding applications in semiconductors, microelectronics, optics, ceramics, and research environments.

ADVANTAGES:

- Stable and secure mounting

- Reduced vibration

- Extended blade life

- Improved dimensional accuracy

- Minimized chipping

- Support for higher spindle speeds and feed rates

- Better surface finish

- Polished and balanced construction

- Compatibility with most dicing saws

- Wide variety of flange sizes

- Short lead times and high precision tolerances

Custom Flanges Manufacturing

We manufacture custom flanges to your drawing, specification, or sample for almost any cutting machine. Each flange is produced to tight tolerances for maximum stability and performance. They are available in different diameters, thicknesses, and mounting configurations, and made from materials selected for strength, balance, and long service life.

Using the right flange ensures improved blade stability, reduced vibration, and consistent cut quality with less chipping. It also helps extend tool life for both the blade and the machine. If you need a flange for a specialized application, provide your specifications and we will engineer a solution tailored to your process.

Related Products

Precision Arbors

SMART CUT® Mineral Oil

SMART CUT® Mineral Oil is recommended for cutting, drilling, grinding and machining larger variety of materials such as:

- Materials with High Metallic Content

- Advanced Ceramics

- Precious & Semi Precious Stone

- Many Other Ultra Hard Materials

SMART CUT® HD Synthetic Low IFT Coolant/Lubricant For Diamond Wire Sawing Silicon

SMART CUT® is a synthetic coolant specifically designed for the cutting of semiconductor materials, including sapphire, silicon, germanium, single-crystal SiC, and II-VI crystals. This coolant offers excellent cut rates and imparts outstanding surface finishes with reduced warp and total thickness variation (TTV). It is ideal for diamond abrasive cropping, squaring, and wafering of silicon ingots using ID, band, and wire saws. SMART CUT® HD-2B can also be used as a non-re-circulating edge grinding coolant or lubricant for silicon wafers and ingots.

SMART CUT® Water Soluble Dicing Coolant

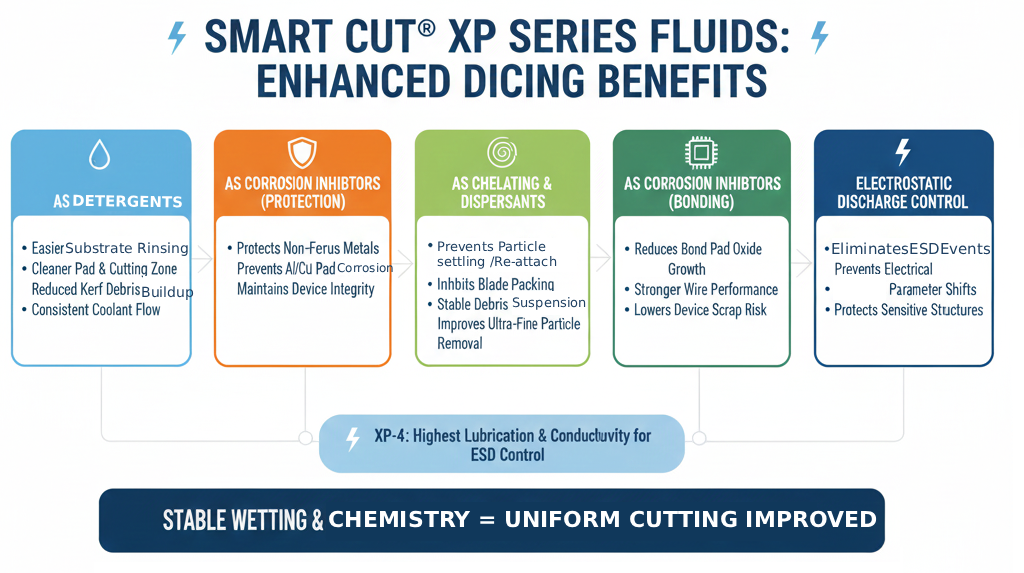

SMART CUT® XP Water Soluble Dicing Coolant added to deionized (DI) water reduces surface tension flowing from saws injection system and is carried directly of dicing blade.

This reduces material thermal stress, edge damage, and internal cracking, assuring long-term integrity of material being processed. Since SMART CUT® XP Dicing Coolant is a coolant and lubricant, and Surfactant both the dicing blade and substrate / wafer / package benefit.

SMART CUT® XP Dicing Coolant/Lubricant is a specially formulated low-foaming dicing and sawing coolant/lubricant designed for precision applications involving wafers with integrated circuits, MEMS devices, and IC packaging. This aqueous-based synthetic formulation enhances the dicing process by ensuring superior cleanliness of the die or package after dicing while preventing corrosion and oxidation on exposed metals. It eliminates electrostatic discharge, which can be generated during the rotation of the dicing blade, protecting delicate components from damage.

Recently Viewed Products

ARE YOU USING RIGHT DIAMOND & CBN TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT DIAMOND & CBN TOOLS?

Knowledge Center

02

Nov

Coolant is one of the most overlooked variables in the overall diamond or cbn tool machining process. Effective and proper use of coolant and recalculating coolant system will pay off in terms of improved surface...

29

Aug

Selecting the Right Coolant Method for your Diamond & CBN Tools

Coolant is one of the most important factors in CNC machining when using diamond and CBN tools. These tools are made to cut and grind very hard materials, which naturally produces high amounts of friction...

02

Jun

How to Selecting Right Diamond Tools for your application

Selecting the appropriate Diamond & CBN Tool specification is a crucial aspect of achieving your objectives. Opting for the ideal specification not only yields optimal results but also ensures the best return on investment. Conversely,...

02

Jun

How to properly use Diamond Tools

UKAM Industrial Superhard Tools manufactures precision diamond tools for a large variety of applications, materials, and industries.

Serving Global Manufacturers

Since 1990

American Based Manufacturer

Established in 1990

Expert technical support

Custom manufacturing

Thousands of Stock Products

Same day shipping

Share this Article...

02

Jun

Why use diamond

Serving Global Manufacturers

Since 1990

American Based Manufacturer

Established in 1990

Expert technical support

Custom manufacturing

Thousands of Stock Products

Same day shipping

Diamond is the hardest material known to man kind. When used on diamond/tools, diamond grinds away material...

02

Jun

Diamond vs CBN (cubic boron nitride) Tools

Cubic Boron Nitride (CBN) is a synthetic material that is renowned for its exceptional hardness and high thermal stability. It is composed of boron and nitrogen atoms arranged in a crystal lattice structure, similar to...

02

Jun

What is Diamond Mesh Size and how to select best one for your application

Diamond grit size can be defined as the size of the diamond particles used in the bond matrix. The larger the diamond particles (grit size) the faster the tool will cut.

Share this Article with Friend or...

02

Jun

What is Diamond Concentration and which to use for your application

Diamond concentration is measured based on the volume of diamond within a section of the tool. It is typically defined as Concentration 100, which equates to 4.4 carats per cubic centimeter of the diamond layer...

17

May

Choosing The Correct Diamond Bond Type

Selecting the appropriate diamond bond type for specific applications is crucial for several reasons. Diamond bond type directly affects the tool's performance, efficiency, and longevity. Different bond types determine how well a tool can withstand...

03

Jan

How to Properly Use Diamond Tools: A Complete Guide to Performance, Safety, and Tool Life

The use of diamond tools in the manufacturing and precision machining industries, as well as in construction, research, etc., is essential. They are used for a wide range of materials, including sharpening, cutting, grinding, and polishing...