Diamond Blades: Everything You Need to Know Before Buying

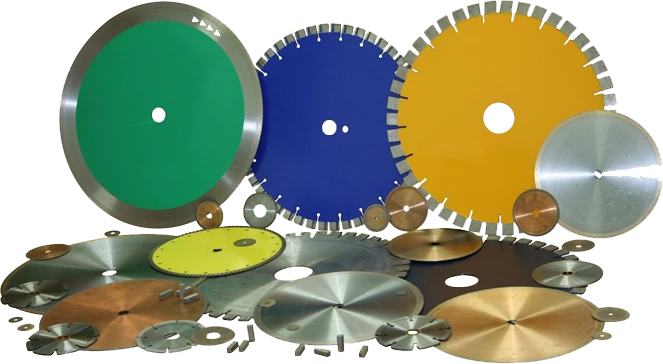

Cutting hard materials like concrete, tile, asphalt, or natural stone requires tools engineered for precision, durability, and efficiency. Among the most trusted options for contractors and serious DIYers are Diamond Blades, known for their ability to produce clean cuts and withstand demanding conditions. Before you invest in a new blade, it’s important to understand the design, materials, and features that determine performance and lifespan.

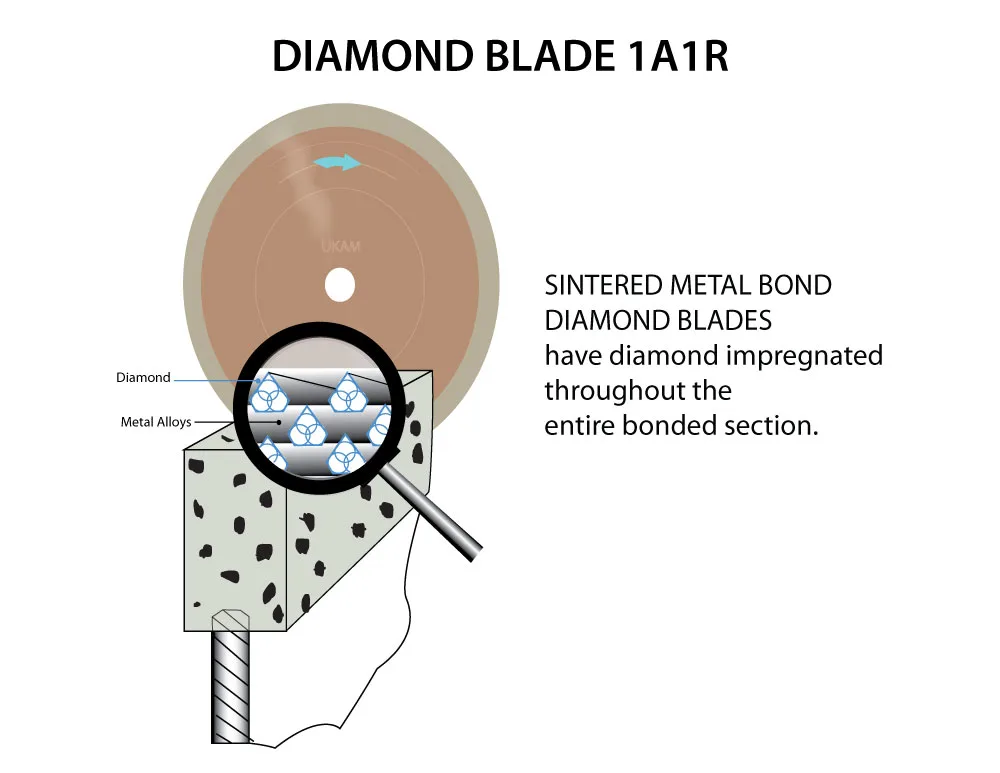

How These Blades Are Built

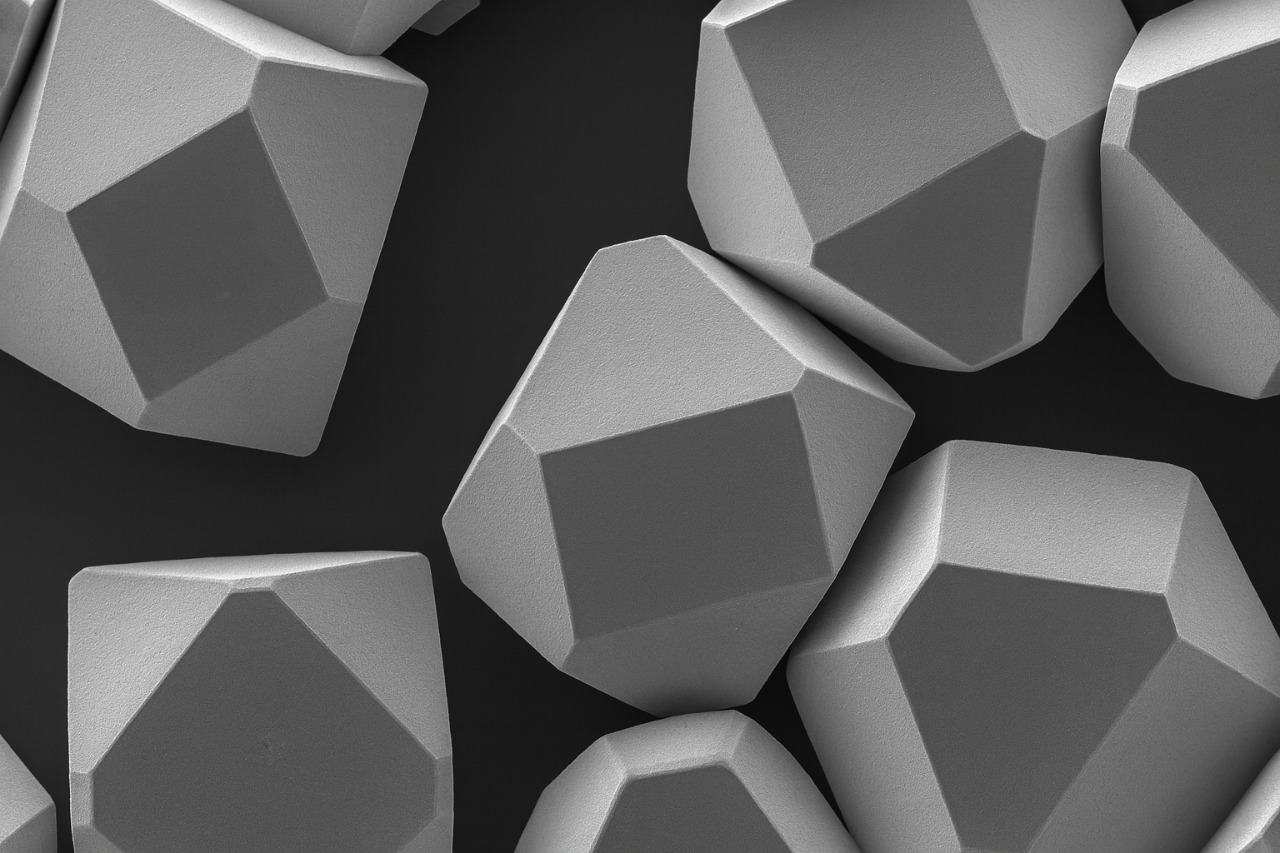

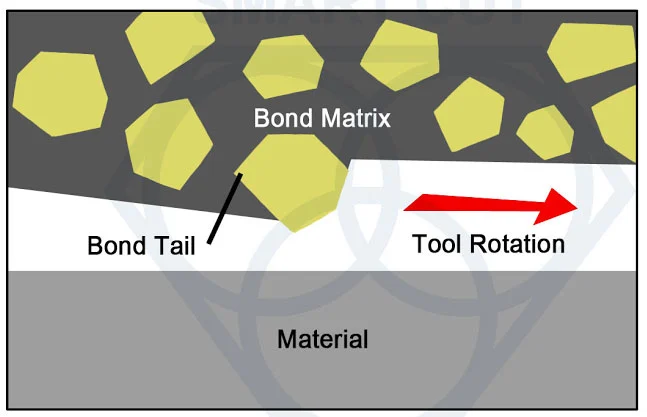

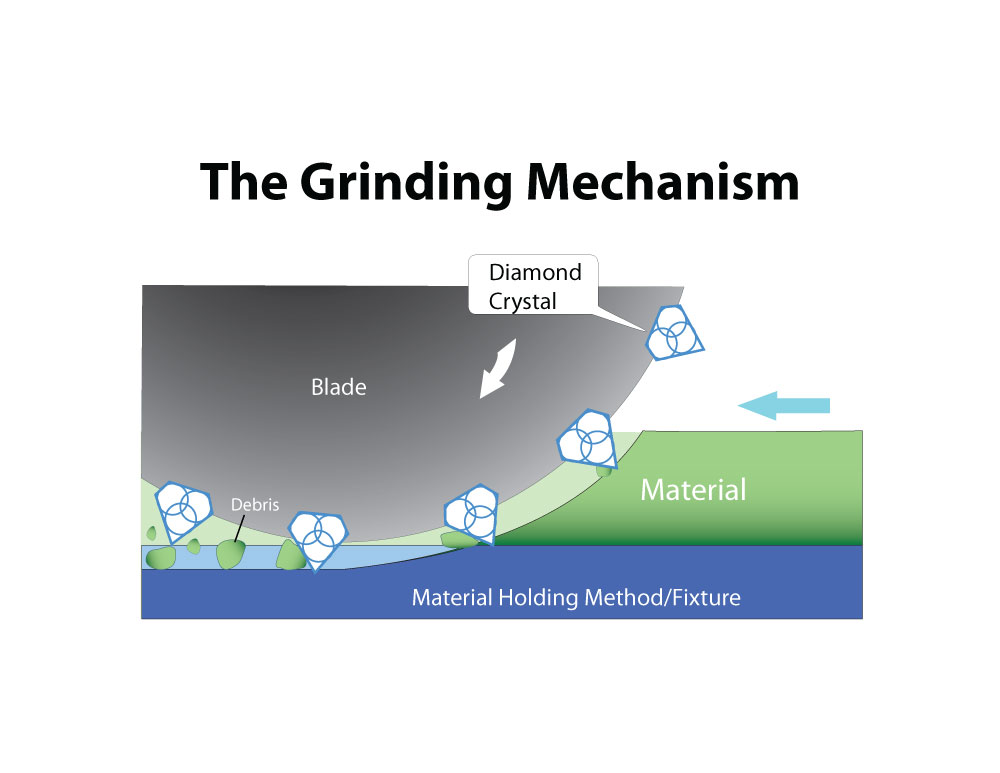

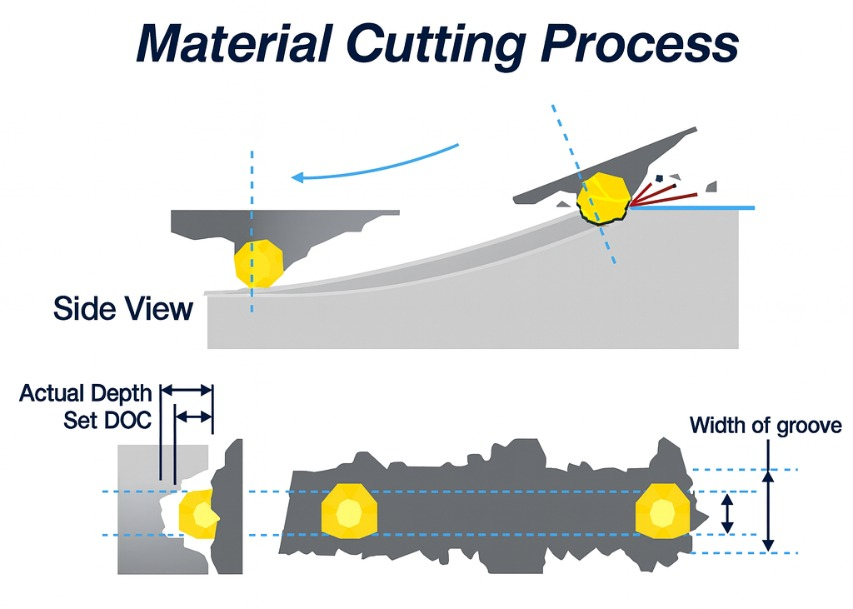

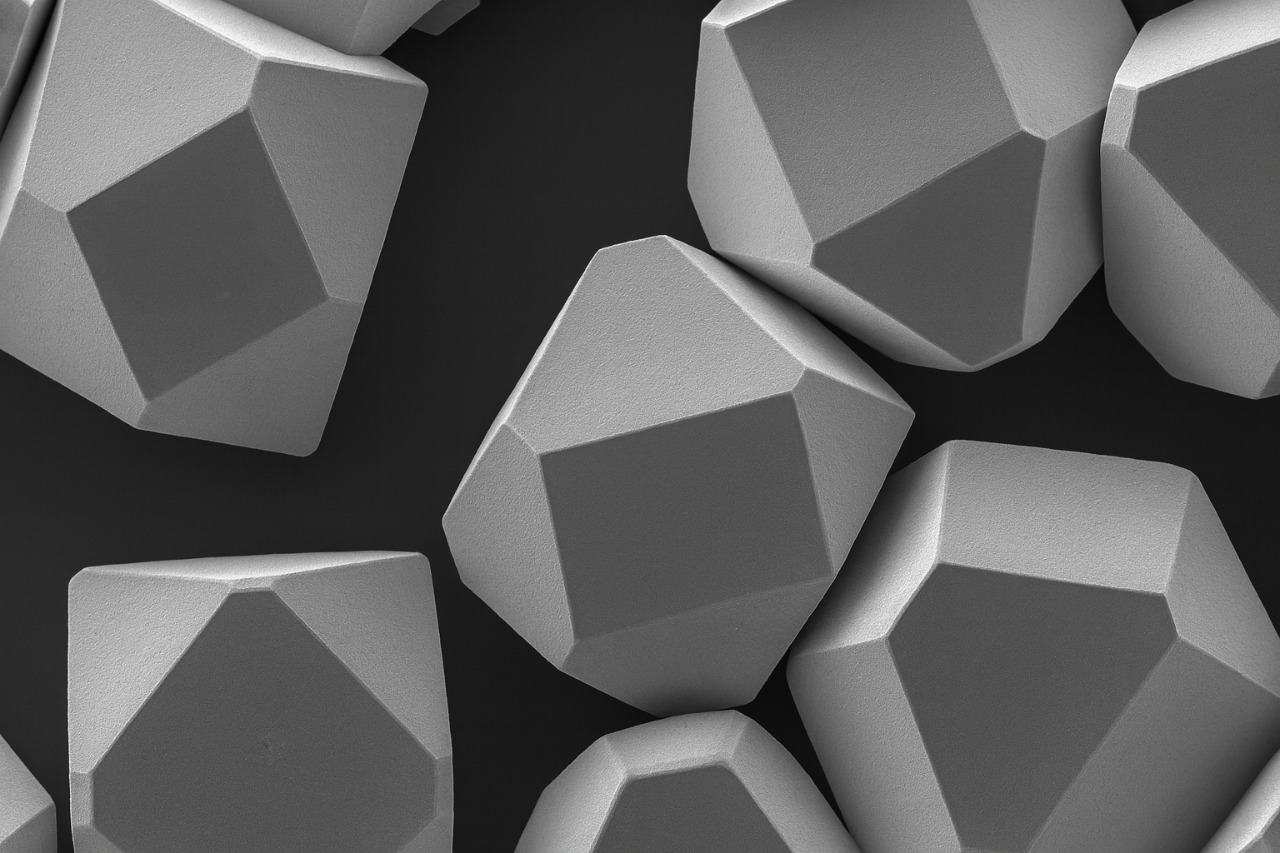

Modern cutting blades designed for stone and masonry operate through grinding rather than slicing. Instead of relying on friction alone, they use a steel core layered with a diamond-embedded rim. As the blade rotates, worn diamonds break away, allowing new particles to take their place. This controlled wear pattern is what gives the tool its cutting power and longer working life. When choosing Diamond Blades, understanding this engineered structure helps you make a more informed decision.

Why This Cutting

Technology Is Different

Traditional abrasive wheels often degrade quickly and lose cutting accuracy. The advantage of Diamond Blades lies in their consistency. The bond material that holds the diamonds in place is carefully formulated so that it releases particles at the correct rate. If the bond is too hard, the blade may glaze over; if it’s too soft, the blade wears down prematurely. Manufacturers engineer each blade type for specific materials, meaning the right match can dramatically improve cutting speed and quality.

Types of Rims and their Uses

Not all cutting tasks require the same rim design. Three of the most common styles are:

Continuous Rim

Not all cutting tasks require the same rim design. Three of the most common styles are:

Segmented Rim

Built for fast, aggressive cutting in concrete and masonry. The gaps between segments let air flow around the blade, making dry cutting possible for short periods.

Turbo Rim

A hybrid design with grooved edges that balance speed and smoother finishes. They’re popular for stone and general-purpose tasks.

Different materials demand different types of Diamond Blades, so choosing the correct rim style directly affects both performance and finish.

Matching the Blade to the Material

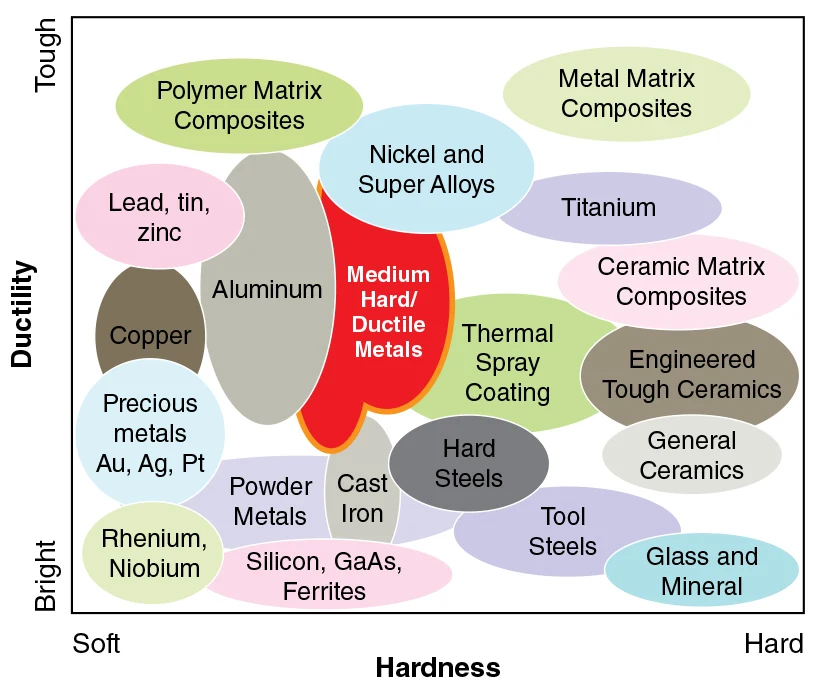

Every material has its own density and abrasiveness, and blade performance depends on selecting a bond hardness that complements the surface. Hard materials like granite or porcelain work best with a softer bond that exposes diamonds more easily. Softer materials like asphalt require a harder bond to prevent the blade from wearing too quickly. Understanding bond hardness helps prevent common problems like glazing, short lifespan, slow cutting speed, or chipping.

Wet vs. Dry Cutting

Cutting with coolant has several advantages: it keeps the blade cool, reduces dust, and extends lifespan. Wet cutting is common for tile saws, masonry saws, and larger stationary equipment. Dry cutting is suitable for quick fieldwork or job sites without water access. However, the blade should be allowed to rest between passes to avoid thermal damage. Checking manufacturer guidelines is essential—using a blade in the wrong setting can void warranties and reduce performance.

Blade Size and Compatibility

Traditional abrasive wheels often degrade quickly and lose cutting accuracy. The advantage of Diamond Blades lies in their consistency. The bond material that holds the diamonds in place is carefully formulated so that it releases particles at the correct rate. If the bond is too hard, the blade may glaze over; if it’s too soft, the blade wears down prematurely. Manufacturers engineer each blade type for specific materials, meaning the right match can dramatically improve cutting speed and quality.

Key Performance Factors Their Uses

Several technical specifications influence how a blade performs:

- Diamond concentration: Higher concentration improves longevity but raises the cost.

- Segment height: Taller segments generally indicate longer wear life.

- Core stiffness: A reinforced core minimizes wobble and noise.

- RPM rating: Your saw speed must be within the blade’s approved range.

Professionals rely on Diamond Blades because these engineered features give them predictable results even under tough job-site conditions.

Maintenance and Safe Usage

Proper handling and safety practices not only protect users but also extend the blade’s working life. Before each use, visually inspect the tool for cracks, missing segments, or distortions. Always use appropriate PPE, especially eye and respiratory protection. Avoid forcing the blade through material. Let the tool do the work, using smooth, steady pressure. Improper use of Diamond Blades can reduce lifespan, cause overheating, or lead to dangerous kickback.

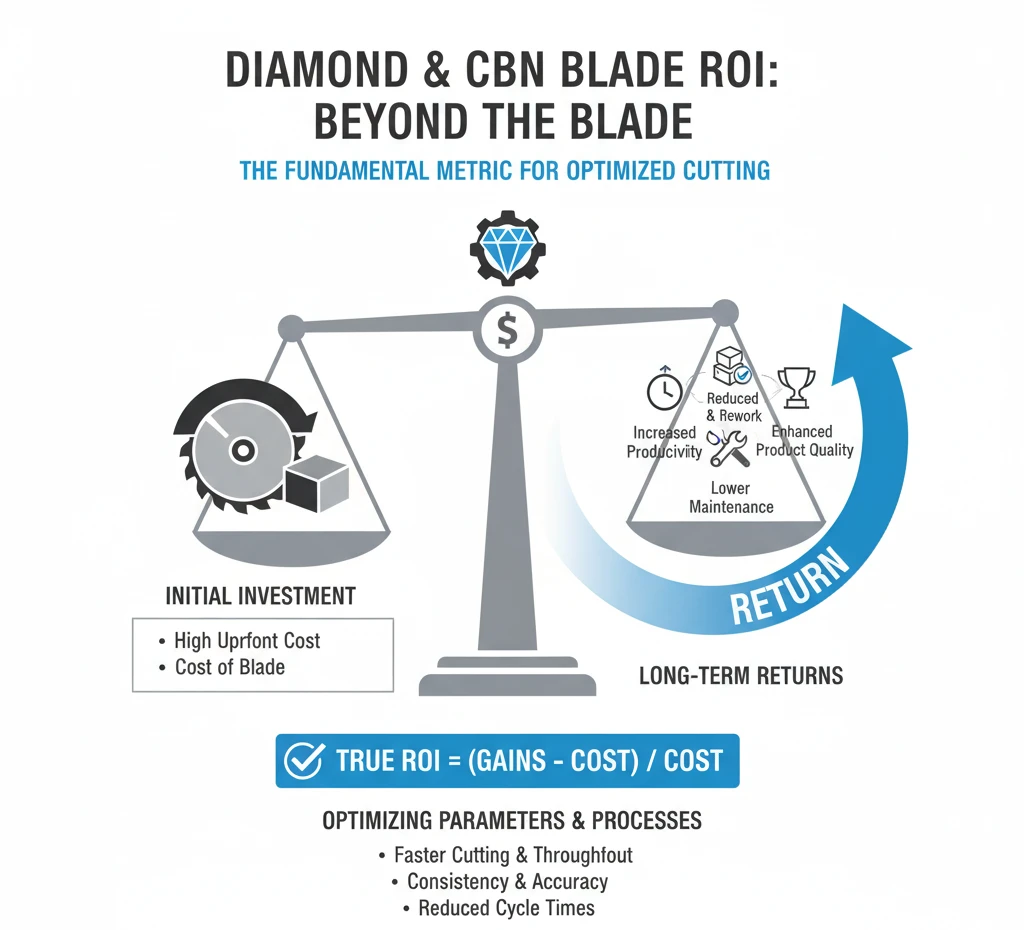

Cost vs. Value

Prices vary widely, but spending slightly more upfront often leads to better long-term returns. Premium blades cut faster, produce cleaner edges, and last significantly longer. For occasional home users, mid-range blades may provide the best value. For daily cutting tasks, high-end options deliver the consistency needed to avoid downtime. Evaluating price alongside expected usage ensures you choose the most economical option for your needs.

Frequently Asked Questions

They are primarily used to cut hard materials such as concrete, tile, granite, marble, brick, and asphalt with accuracy and durability.

Blade life depends on the material being cut, cutting speed, blade quality, and whether you use wet or dry cutting. High-quality blades typically last significantly longer when used appropriately.

Blade life depends on the material being cut, cutting speed, blade quality, and whether you use wet or dry cutting. High-quality blades typically last significantly longer when used appropriately.

Segmented blades offer fast cutting for concrete; turbo blades balance speed and smoothness; continuous rim blades are best for tile and delicate materials where chipping must be minimized.

Bond hardness determines how quickly diamonds are exposed. Hard bonds are used for soft, abrasive materials, while soft bonds are used for very hard materials.

Conclusion

Proper handling and safety practices not only protect users but also extend the blade’s working life. Before each use, visually inspect the tool for cracks, missing segments, or distortions. Always use appropriate PPE, especially eye and respiratory protection. Avoid forcing the blade through material. Let the tool do the work, using smooth, steady pressure. Improper use of Diamond Blades can reduce lifespan, cause overheating, or lead to dangerous kickback.