Cabbing Wheels

Cabbing Wheels

Diamond Cabbing Wheels

We offer large variety of diamond cabbing wheels from 6 to 8" diameter, thicknesses 1.5" to 2". Available in nickel bond (plated), resin bond and sintered (metal bond) with plastic and steel hub, diamond grit sizes from 30 to 8,000 mesh. Can be used on all conventional grinders made today. Such as Diamond Pacific, Barranca, Maxant, Graves, as well as other cabbing machines. All wheels have a 1" Diameter and include bushing to accommodate 3/4", 5/8", and 1/2'arbors.

DIAMOND LAPS

UKAM Industrial Superhard Tools manufactures & offers a large variety of diamond laps & polishing discs Below you will find informat...

SMART CUT® Diamond...

SMART CUT® Series Sintered (metal bond) Diamond Grinding Wheels are the longest lasting diamond wheels for cabbing...

Diamond Grinding Wheels...

The curved surface of our SMART CUT® 4″, 6″ and 8″ concave grinding wheels provide an excellent way to carve and grinding...

SMART CUT® RESIN BOND..

SMART CUT® Diamond Resin Wheels are an outstanding option to the Nova and Flex wheels. Diamond Resin Wheels are great...

SMART CUT® Diamond...

SMART CUT® Electroplated (Nickel Bonded) diamond grinding wheels, with steel hub. Made with highest quality diamonds for longer...

DIAMOND GRINDING...

SMART CUT® Electroplated (nickel bonded) diamond grinding wheels, with plastic center core. Made with the highest quality...

DIAMOND GRINDING...

SMART CUT® Electroplated Diamond Cabbing Wheels – Textured Steel Hub are engineered for lapidary, glass, ceramic professionals & hobbiests...

DIAMOND LAPS

UKAM Industrial Superhard Tools manufactures & offers a large variety of diamond laps & polishing discs. Below you will find information, specifications & prices on all laps & polishing discs

SMART CUT® Diamond Grinding Wheels – Sintered(Metal Bond)

SMART CUT® Series Sintered (metal bond) Diamond Grinding Wheels are the longest lasting diamond wheels for cabbing available today. When

Diamond Grinding Wheels (Electroplated) – Concave

SMART CUT® Electroplated Diamond Cabbing Grinding Wheels – Concave are precision-engineered tools designed specifically for carving, shaping, and

SMART CUT® RESIN BOND DIAMOND WHEELS

SMART CUT® Resin Bond Diamond Wheels offer a superior alternative to conventional Nova and Flex wheels, engineered specifically for cabbing, contour

DIAMOND GRINDING WHEELS (Electroplated) – Non Textured Steel Hub

SMART CUT® Electroplated (Nickel Bonded) Diamond Grinding Wheels with non-textured solid steel hubs are engineered for users who demand precision, durability,

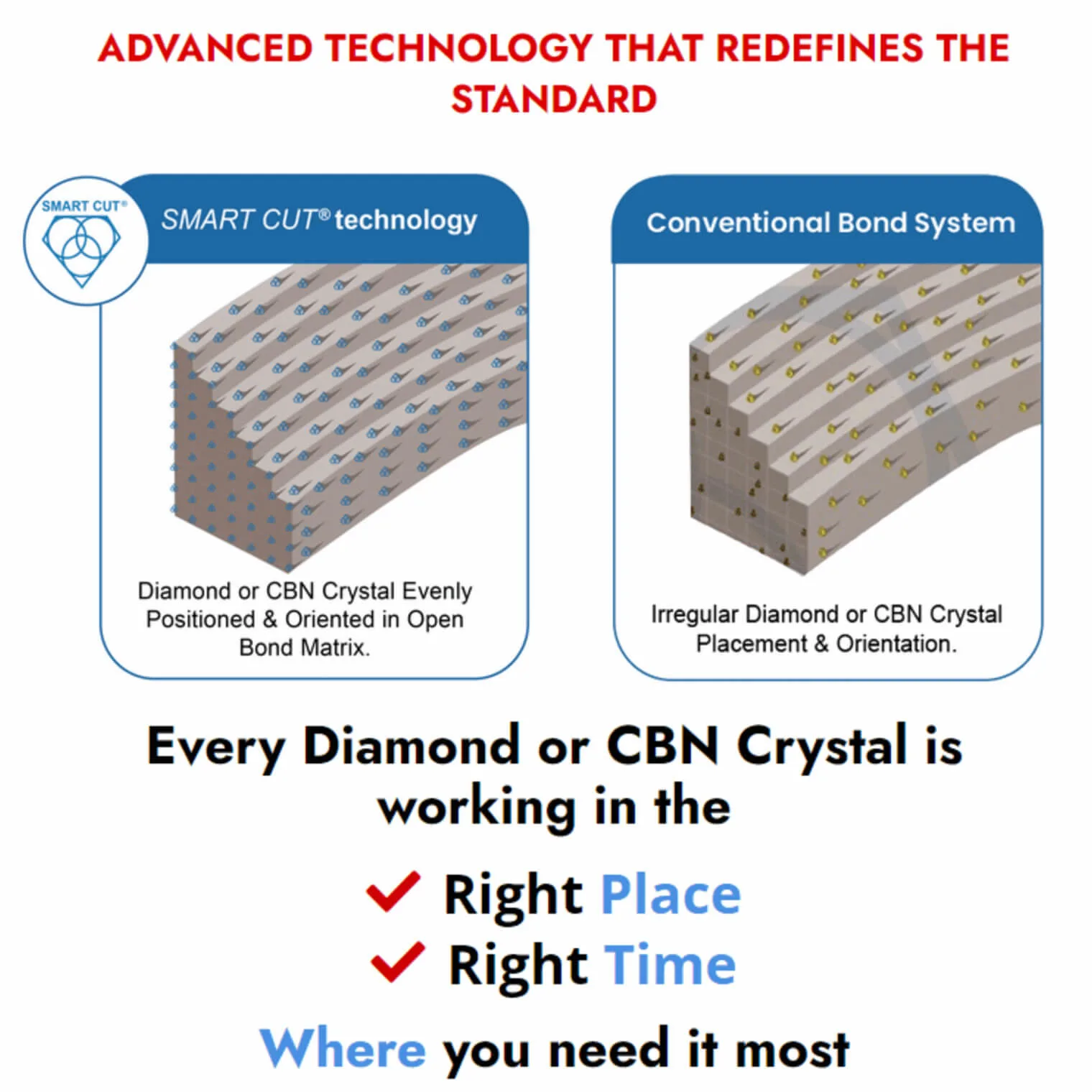

ITS WHAT YOU CANT SEE THAT MAKES ALL THE DIFFERENCE

SMART CUT® technology

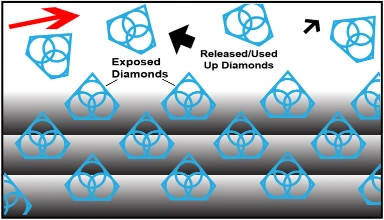

How SMART CUT ® Bond Works?

Sharpest And Finest Quality Diamonds

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT® Bond remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

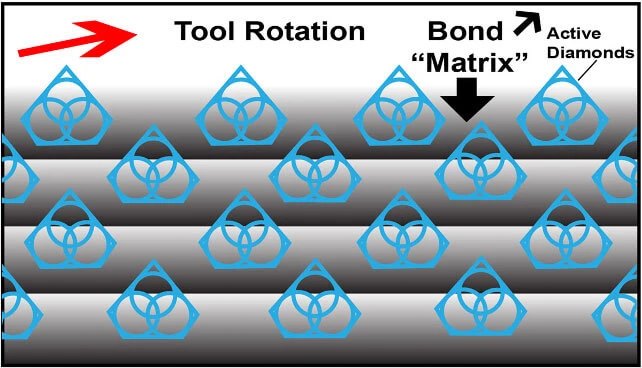

Diamonds or CBN Crystals

Diamonds or CBN Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT® Diamond Hybrid Bond makes sure every diamond is in the right place and at the right time, working where you need it most.

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Why Choose Us?

Optimize your application to ultimate level of efficiency

- Unmatched Selection For Many Applications

- Unmatched Technical Support & Expertise

- Superior Quality & Consistency

- Super Technology & innovation

- Immediate Worldwide Delivery

- American Based Manufacturer

-

Custom

Manufacturing - Better Value manufacturer Direct Price