Don’t Buy a Diamond Core Drill Until You Read This Guide

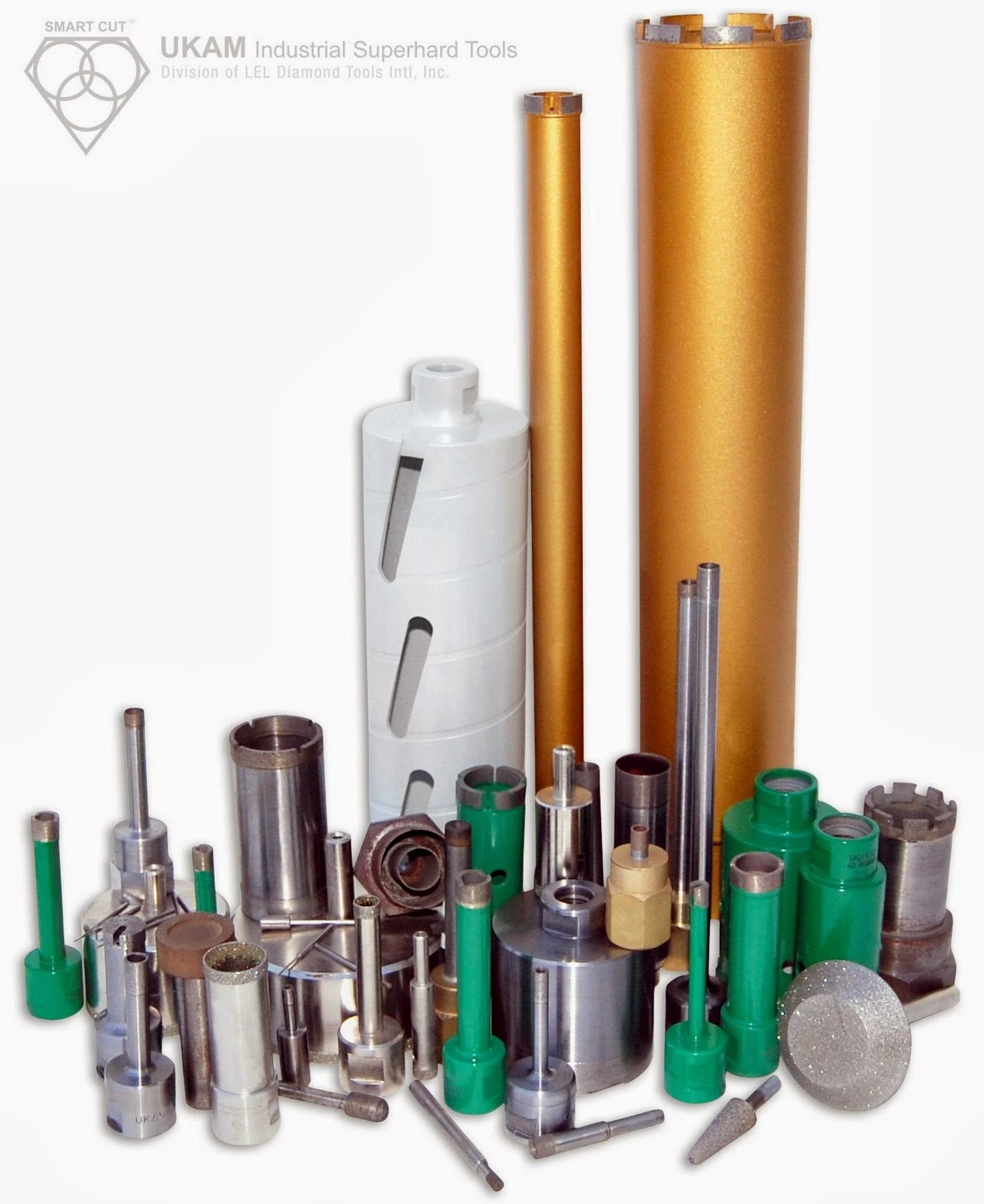

Diamond core drills are essential tools for cutting precise circular holes in concrete, masonry, tile, stone, and other dense materials. Whether you’re a contractor, installer, plumber, electrician, or an advanced DIY user, choosing the wrong tool can lead to slow drilling, damaged segments, overheating, or expensive replacements. Before you invest in a core drill, it’s important to understand the features, specifications, and safety considerations that truly matter.

This guide covers everything you should know before buying—so you can avoid costly mistakes and choose a tool that delivers clean, accurate, and efficient performance.

What a Diamond Core Drill Is Designed To Do

A diamond core drill removes a cylindrical section of material by using a rotating barrel lined with diamond-infused segments, allowing it to cut cleanly into hard surfaces without grinding across a flat plane like a traditional blade. Instead, the bit drills downward to produce a precise, smooth, round opening, making it ideal for applications such as plumbing penetrations, electrical conduit installation, HVAC openings, concrete sampling, stone and tile hole cutting, and structural anchoring. Since these tasks demand accurate hole sizes and clean edges, selecting the right tool is essential for achieving optimal cut quality, speed, and overall efficiency.

Wet vs. Dry Core Drills

Which One Do You Need?

Wet core drills are the preferred choice for heavy-duty drilling applications where heat buildup and dust control are critical. By using water as a coolant and lubricant, these drills operate at lower temperatures, extend bit life, and enable deeper penetration into tough materials such as concrete, reinforced concrete, brick, and large-diameter holes. In contrast, dry core drills are designed with special segment geometry that disperses heat and expels debris without requiring water, making them ideal for environments where water use is impractical—such as indoor installations, occupied spaces, or overhead drilling. They perform best on masonry, block, soft to medium concrete, and other light-duty tasks where speed and convenience are key.

Handheld vs. Rig-Mounted Core Drills

Not all cutting tasks require the same rim design. Three of the most common styles are:

Handheld Drills

Smaller, portable, and best for holes up to 4″–6″. They’re ideal for electricians, plumbers, and remodelers working in tight or elevated spaces.

Choose handheld if:

- You drill small to medium holes

- Mobility matters

- Jobsite changes frequently

Rig-Mounted Drills

Used for larger diameters, deeper penetrations, or highly reinforced concrete. The drill attaches to a stand for stability and accuracy.

Choose a rig-mounted drill if:

- You drill large holes (6”–14”)

- Precision is essentia

- You’re working with heavy reinforced concrete

- You conduct recurring or professional drilling tasks

Rig-mounted systems also reduce user fatigue and improve safety.

Core Bit Size and Compatibility Matters

Choosing the right bit size is essential, but compatibility is equally important. Ensure the core drill matches:

- Diameter capacity

- Connection type (e.g., 1-1/4″-7 UNC, 5/8″-11)

- RPM range

- Power requirements

A bit that spins too fast will overheat, while one spinning too slow will drill inefficiently. Always match RPM to bit size:

- Small bits (1″–3″): higher RPM

- Medium bits (4″–8″): moderate RPM

- Large bits (10″+): lower RPM, high torque

Power: Electric, Hydraulic, or Pneumatic?

Electric Core Drills

The most common type, available as handheld or rig-mounted options.

Great for indoor and outdoor use.

Hydraulic Core Drills

Used in industrial environments, underwater applications, and situations requiring extremely high power.

Pneumatic Core Drills

Best for hazardous environments where electricity is not allowed.

They deliver strong performance with excellent safety.

Choose power type based on jobsite conditions, material hardness, and whether dust or sparks are a concern.

Segment Types and Bond Hardness

The diamond segments on the core bit determine cutting speed and lifespan. The bond—the material holding the diamonds—controls how quickly they wear away.

Bond Rule of Thumb

- Diameter capacity

- Soft materials → hard bond (prevents premature wear)

Segment Shapes

- Standard segments: everyday drilling in concrete and masonry

- Turbo segments: faster penetration and improved cooling

- Roof-top segments: reduce friction and prevent binding when starting the hole

- Drop segments: prevent jamming when hitting reba

Selecting the correct segment shape and bond ensures smooth, safe drilling.

Motor Power and Speed Control

Power determines how efficiently you can cut through dense materials. Look for:

- High torque for large-diameter bits

- Variable speed settings

- Soft-start technology

- Overload protection

- Integrated clutch for safety

Underpowered drills bog down, overheat, and wear out bits quickly

Safety Considerations You Shouldn’t Ignore

- Always use PPE

- Anchor or brace rig-mounted drills

- Keep cords and hoses away from rotating parts

- Let bits cool during dry drilling

- Avoid side pressure—drills must stay perfectly aligned

- Use GFCI-protected outlets for electric drills

Many accidents happen when operators try to force the bit through material or let the drill bind unexpectedly.

Common Mistakes Buyers Make

Before purchasing, avoid these common errors:

- Choosing a handheld drill for holes that require rig stability

- Ignoring the required RPM for the bit size

- Using dry bits for wet-only applications

- Choosing the wrong bond hardness

- Underestimating power needs for reinforced concrete

Not accounting for dust control requirements Knowing what NOT to do saves money and frustration.

Frequently Asked Questions

A diamond core drill is used to create precise circular holes in concrete, masonry, tile, stone, asphalt, and other dense materials. It’s commonly used in plumbing, electrical, HVAC, and construction applications.

Choose a wet core drill for reinforced concrete, deeper holes, or heavy-duty tasks. Choose a dry core drill when water cannot be used, such as indoor work or small masonry jobs.

Handheld drills are portable and used for smaller holes. Rig-mounted drills are attached to a stand for stability and are used for larger diameters, deeper cuts, or drilling reinforced concrete.

Match the bit size to your job’s hole diameter requirements and check that your drill supports the bit’s RPM, arbor connection, and torque needs. Larger bits require lower speed and higher torque.

No. Wet-only bits require water to cool the segments. Using them dry can cause overheating, glazing, or segment failure.

Conclusion

A diamond core drill is a highly specialized tool, and choosing the right one requires more than simply selecting a size or price point. You must consider whether you need wet or dry drilling, handheld or rig-mounted equipment, the appropriate bond and segment type, and a motor with sufficient power and torque for your applications. When chosen correctly, a high-quality core drill delivers clean, precise holes, longer tool life, and a safer, more efficient working experience.