Selecting Right Drilling Equipment for your Application. What you features & functionality you should look for?

-

Posted by

Leon Meyer

Leon Meyer

Table of Contents

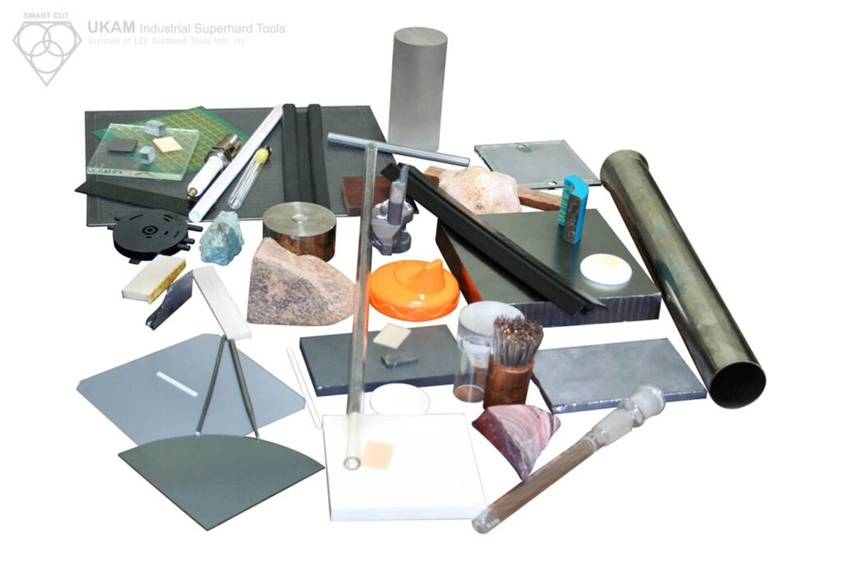

ToggleThere are hundreds or even thousands of different drilling equipment options. Selecting the right equipment for a specific application involves carefully considering several variables and attributes of the drilling equipment. Each attribute can significantly influence the effectiveness, efficiency, and outcome of the drilling process.

Its important to understand the different types available and what makes one piece of equipment a better option for your specific application, compared,. Whether you're doing a simple DIY project or handling very complex projects in industries like aerospace, advanced materials, composites, precision optics, semiconductor or something else. Using the right equipment can make all the difference in how efficiently and affectively the work is completed.

Using the right equipment will with your diamond core drills or other tools is an essential step towards how affectively you will be able to accomplish your goals. This guide will help you understand these key features and the different equipment variables available and how each one impacts your diamond drilling and related operations.

Drilling Equipment Feature Comparison Guide

Here is a list of the different drilling equipment available that can be used with diamond core drills, and other tools. As well as different features available

|

Equipment Type |

Typical Industries |

Horsepower (HP) |

RPM Range |

Feed Rate |

Spindle Travel |

Table Size & Adjustability |

Power Source |

Coolant System |

Control System |

Footprint & Portability |

Max Load Capacity |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

Handheld Drill |

DIY, Construction |

0.3 - 1.5 |

500 - 3,500 |

Manual |

Short |

N/A |

Electric, Battery |

None |

Manual |

Small, Portable |

Low |

|

Drill Press (Benchtop) |

Hobby |

0.5 - 2 |

200 - 4,000 |

Variable |

Medium |

Medium, Tilt & Rotate |

Electric |

Mist, Flood |

Manual, Some PLC |

Medium, Non-portable |

Medium |

|

Floor Drill Press |

Manufacturing, Hobby |

1 - 5 |

50 - 3,000 |

Variable |

Long |

Large, Tilt & Rotate |

Electric |

Flood, Through-spindle |

Manual, PLC |

Large, Non-portable |

High |

|

CNC Machine |

Manufacturing, Hobby |

5 - 20 |

100 - 10,000 |

Programmable |

Very Long |

Custom, Highly Adjustable |

|||||

|

Magnetic Drill Press |

Heavy Metal Fabrication |

1 - 3 |

300 - 3,000 |

Variable |

Medium |

Small, Fixed |

Electric, Pneumatic |

Mist, Flood |

Manual, Some PLC |

Medium, Portable |

Medium |

|

Radial Arm Drill |

Large Equipment |

5 - 15 |

40 - 2,000 |

Variable |

Very Long |

Large, Rotate & Tilt |

Electric |

Flood, Through-spindle |

Manual, PLC |

Large, Non-portable |

Very High |

|

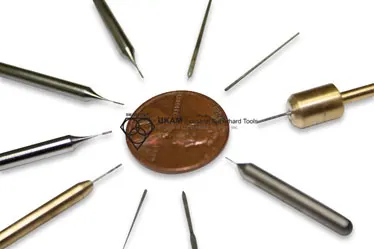

Micro Drill |

Electronics, Micro-engineering |

0.1 - 1 |

5,000 - 20,000 |

Precise |

Short |

Small, Fixed |

Electric |

None, Mist |

CNC, Manual |

Low |

Low |

|

Gantry Mill |

Shipbuilding, Large Structures |

15 - 50 |

100 - 2,500 |

Variable |

Long |

Very Large, Highly Adjustable |

Electric, Hydraulic |

Flood, Through-spindle |

CNC |

Very Large, Non-portable |

Extremely High |

|

Ultrasonic Drilling Machine |

Glass, Gemstone Processing |

0.5 - 2 |

20,000 - 40,000 |

Precise |

Short |

Small, Fixed |

Electric |

None, Mist |

CNC, Manual |

Small, Portable |

Low |

|

Core Drilling Rigs |

Mining, Construction |

10 - 50 |

200 - 1,200 |

Variable |

High |

Large, fixed |

Electric, Hydraulic |

High |

Manual, PLC |

Large, non-portable |

High |

|

Handheld Drills |

Construction, DIY |

0.3 - 1.5 |

500 - 3,500 |

Manual |

N/A |

N/A |

Battery, Electric |

Minimal |

Manual |

Highly portable |

Low |

|

Dremel Tools |

Crafts, Hobbyist |

0.1 - 0.5 |

5,000 - 35,000 |

Manual |

N/A |

Small, fixed |

Electric |

None |

Manual |

Highly portable |

Low |

|

Milling Machine |

Precision Engineering |

2 - 10 |

200 - 6,000 |

Variable |

Medium to high |

Medium, highly adjustable |

Electric |

High |

CNC, Manual |

Large, non-portable |

Medium to high |

|

Lathe |

Metalworking, Woodworking |

1 - 20 |

10 - 2,400 |

Variable |

N/A |

Large, adjustable |

Electric |

Medium |

Manual, CNC |

Large, non-portable |

High |

|

Equipment Type |

Safety Features |

Noise Level |

Dust Management |

Material Compatibility |

Torque |

Speed Adjustability |

Automatic Feed |

Operator Experience Level |

Cost of Ownership |

|---|---|---|---|---|---|---|---|---|---|

|

Handheld Drill |

Low |

Basic |

Moderate |

Minimal |

Wood, Light Metals, Plastic |

Moderate |

Fixed, some models variable |

No |

Low |

|

Drill Press (Benchtop) |

Advanced |

Moderate |

Optional |

Wood, Metals, Composites |

High |

Variable |

Optional |

Medium |

Moderate |

|

Floor Drill Press |

Enhanced |

Low |

Available |

Heavy Metals, Composites |

Very High |

Variable |

Yes |

High |

High |

|

Magnetic Drill Press |

Advanced, Magnetic Base |

Low to Moderate |

Optional |

Steel, Heavy Metals |

High |

Variable |

Yes |

Medium |

Moderate |

|

Radial Arm Drill |

Enhanced, Lockout/Tagout |

Moderate |

Available |

Large Metal Workpieces |

Very High |

Variable |

Yes |

High |

High |

|

Micro Drill |

Basic |

Low |

Minimal |

Electronics, Small Components | Moderate | Fully Programmable | Optional | High | Moderate |

|

Gantry Mill |

Comprehensive |

Low |

Advanced |

Large Structures, Metals |

Extreme |

Variable |

Yes |

High |

Very High |

|

Comprehensive |

Low |

Advanced |

Metals, Precision Components |

High |

Fully Programmable |

Yes |

High |

High |

|

|

Comprehensive |

Moderate |

Integral |

Metals, Stone, Composites |

N/A |

N/A |

N/A |

High |

Very High |

|

|

Advanced, Chemical Handling |

Low |

Required |

Hard, Conductive Materials |

Moderate |

Variable |

Yes |

High |

High |

|

|

Ultrasonic Drilling Machine |

Basic |

Low |

Minimal |

Glass, Gemstones, Hard Brittle Materials |

Low |

Variable |

No |

High |

Moderate |

|

Core Drilling Rigs |

Enhanced |

Moderate |

High |

Hard materials like concrete |

High |

Variable |

Yes |

High |

High |

|

Handheld Drills |

Basic |

Moderate |

Minimal |

Wood, light metals |

Moderate |

Fixed |

No |

Low |

Low |

|

Dremel Tools |

Basic |

Low |

Minimal |

Soft materials, crafts |

Low |

Highly variable |

No |

Low |

Moderate |

|

Milling Machine |

Comprehensive |

Moderate |

High |

Metals, plastics |

High |

Variable |

Optional |

High |

High |

|

Lathe |

Comprehensive |

Moderate |

High |

Metals, wood |

Very High |

Variable |

Optional |

Moderate to high |

Moderate to high |

Drilling Machine Horsepower

Horsepower of a drilling machine is a fundamental specification that determines its suitability for various applications. Higher horsepower not only facilitates the drilling of resistant materials but also contributes to better heat management, sustained performance under load, longer operational life, and greater economic efficiency. Therefore, when selecting a drilling machine, particularly for tasks that involve tough materials, significant consideration should be given to the horsepower rating to ensure it meets the demands of the job without compromising on performance or safety.

Horsepower is a crucial unit of measurement for power in drilling equipment, reflecting the motor's power output. It denotes the machine's capacity to manage varying drilling conditions and materials, with high horsepower crucial for tackling particularly tough or dense materials. Drills with greater horsepower can maintain high rotational speeds even under significant load, a key attribute for sustaining the cutting efficiency of diamond drills. This capability prevents the drill bit from stalling and minimizes wear and burnout.

When drilling, heat generated from the friction between the drill bit and the material can be intensive, especially with resistant materials. Equipment endowed with higher horsepower can effectively manage and dissipate this heat, facilitating the use of higher feed rates and speeds. These adjustments must be carefully balanced to avoid overheating, yet optimized to enhance drilling performance.

In industrial applications where consistent performance is crucial, the ability of a drill to operate continuously without overheating is essential for avoiding productivity losses. High-horsepower machines can endure longer operational periods, reducing the need for frequent breaks to cool down the equipment. This feature not only sustains performance but also extends the equipment's lifespan by mitigating the strain and wear on both the motor and its mechanical components.

Although machines with higher horsepower typically require more energy and involve higher initial costs, they compensate by offering greater economic and operational efficiency. These machines achieve faster drilling times and reduce labor costs, especially critical in large-scale or heavy-duty projects. The ability to swiftly drill through tough materials with fewer drill bit changes also curtails overall project expenses.

Moreover, high-horsepower drills boast considerable versatility, capable of accommodating a broad spectrum of materials and drilling tasks. Their speed can be adjusted to operate at lower velocities for hard materials and faster for softer materials, making them highly adaptable tools in environments involving multiple material types. This versatility ensures that high-horsepower drills are invaluable assets across various industrial settings, enhancing both productivity and adaptability.

High-horsepower drills not only deliver the raw power needed for tough jobs but also enhance the precision with which these jobs can be performed. The robust nature of these machines often supports better stability and vibration control, crucial for achieving clean, precise holes, especially in hard-to-drill materials. Precision is particularly important in industries where the quality of drilling impacts the structural integrity of the final product, such as in aerospace or precision engineering.

Organizations that invest in high-horsepower drilling equipment can scale their operations more effectively. These machines can handle a wider variety of jobs, from small-scale precision works to large-scale construction projects. This scalability prevents the need for multiple different machines and allows businesses to respond more flexibly to project demands. As a result, companies can take on a broader range of projects, enhancing their marketability and ability to grow.

While the initial purchase price of high-horsepower drilling equipment might be higher, the total cost of ownership can be lower over the machine's lifecycle. This reduction comes from the decreased need for replacements due to the equipment's enhanced durability and the lower frequency of repairs. Furthermore, the efficiency of high-horsepower drills can reduce the time spent on projects, thereby decreasing the labor costs and operational expenses associated with extended timelines.

High-horsepower machines are typically built to handle tough operating conditions, which include various safety enhancements to protect the operators. Features might include more sophisticated emergency stops, enhanced guards and shields, and advanced user interface controls that help prevent operator errors. These safety features are essential, as the powerful nature of the equipment can pose greater risks if not managed correctly.

Environmental Impact Considerations

With greater power comes greater responsibility, including managing the environmental impact. High-horsepower drills, particularly those powered by internal combustion engines or older electric models, might consume more energy and produce more emissions than their lower-powered counterparts. As such, businesses need to balance the power requirements with environmental sustainability goals. This balance might involve selecting equipment with the latest energy efficiency technologies or integrating renewable energy sources into operations.

RPM’s Range

RPM (revolutions per minute) indicates the speed at which the drill can operate. Different materials require different drilling speeds to optimize cutting efficiency and minimize tool wear. Understanding and selecting the appropriate RPM range for specific materials and drill types is fundamental in optimizing drilling performance. It affects everything from the basic integrity of the drilled holes to the more complex economics of operational efficiency and maintenance costs. For industries that rely on precise and efficient drilling outcomes, paying close attention to RPM recommendations and adjusting them based on material hardness and thickness is essential. This ensures that the diamond drills perform at their best, extending their useful life and delivering superior results.

Why is Using Diamond Drills at the right rpm’s settings for the diameter and material is important?

Minimum Heat Generating Managing heat is a primary consideration when selecting the correct RPM. Excessive heat during drilling can lead to premature wear on the drill bit, deformation of the material, and potential burn marks. By selecting an RPM within the ideal range for a specific material, operators can control the heat generated, which helps preserve the material's characteristics and the sharpness of the diamond drill bit.

More Efficient Drilling: The efficiency of drilling operations is also closely linked to the chosen RPM. Drilling at too low an RPM can unnecessarily prolong the drilling process, while too high an RPM may lead to frequent stops to allow for cooling and bit replacement. Thus, optimizing RPM not only saves time but also conserves resources, enhancing overall productivity.

Diamond Drill Wear and maintenance costs Furthermore, the RPM impacts tool wear and maintenance costs. Higher speeds may increase the rate at which a diamond drill bit wears out if not correctly matched with the material's hardness and abrasiveness. Selecting the proper RPM can significantly extend the life of the diamond drill reducing both the frequency of replacements and the associated costs.

Precision in drilling, required in industries such as advanced ceramics, composites, aerospace, precision optics and precision engineering, is influenced by RPM settings. The right RPM helps achieve cleaner, more accurate holes, crucial for high-specification environments where the quality of each hole could impact the final product's performance. Additionally, operating at an appropriate RPM can reduce the noise and vibration produced by drilling, minimizing inaccuracies and operator fatigue, and creating a safer, more comfortable work environment.

Advanced drilling techniques, such as peck drilling, which involves periodically retracting the drill bit to clear debris, also benefit from optimized RPM settings. These techniques require precise speed control to maximize their effectiveness and protect both the drill and the workpiece.

Lifecycle Cost Management: Proper RPM selection is integral to controlling the lifecycle costs of both the drilling equipment and the consumables like drill bits. Higher RPMs might lead to quicker completion times, which is advantageous for short-term productivity. However, if such speeds lead to frequent drill bit replacements or machine maintenance, the long-term costs could negate the initial gains. Therefore, balancing RPMs to suit the specific material and drill type can lead to more sustainable cost management.

Quality Assurance: In industries where precision is paramount, such as in medical device manufacturing or fine electronics, the RPM of drilling operations directly affects the quality assurance processes. Precise RPM settings help ensure that products meet stringent quality standards, reducing the risk of defects that could lead to failure in critical applications. This level of control helps in maintaining compliance with industry regulations and standards, which is vital for maintaining market credibility and avoiding costly recalls or repairs.

Energy Efficiency: Optimizing RPMs for specific drilling tasks can contribute significantly to energy efficiency. Drills operating at unnecessarily high RPMs consume more power, while those operating at lower than required RPMs may run longer than necessary. By optimizing the speed for each task, energy consumption can be minimized, contributing to greener operations and reduced operational costs.

Process Optimization: For complex or multi-step drilling operations, such as those involving different materials or drill bit sizes, the ability to adjust RPMs precisely is crucial. This flexibility allows operators to tailor their approach to each phase of the operation, optimizing the process for speed, accuracy, or material handling requirements.

Adaptability to Material Innovations: As new materials are developed, particularly composites or alloys with unique properties, having equipment capable of adjusting RPMs to suit these new materials becomes essential. This adaptability ensures that drilling operations can keep pace with innovations in material science, allowing businesses to expand their capabilities and take on new types of projects.

Reduction of Waste and Rework: Correct RPM settings reduce the likelihood of errors such as overheating, which can damage both the material and the drill bit. This precision reduces waste—material that is scrapped due to poor-quality holes—and rework, which is the need to redo work that did not meet specifications the first time. Reducing waste and rework not only saves materials and labor but also enhances the overall throughput of the manufacturing process.

Enhanced Operator Experience: Proper RPM settings make the drilling process smoother and less physically taxing for operators. This can lead to better job satisfaction and lower turnover. Additionally, when operators work with well-set equipment, the risk of accidents and injuries can decrease, leading to a safer workplace.

Feed Rate

Optimizing Material Removal - The feed rate determines the amount of material removed with each revolution of the drill bit. In diamond drilling, achieving the right balance in the feed rate is crucial for maximizing the efficiency of material removal. If the feed rate is too high, the drill may not remove enough material per cycle, leading to inefficient cutting and wasted effort. Conversely, too low a feed rate means the drill removes more material than necessary, which can overload the drill bit and lead to premature wear.

Heat Generation and Management - Feed rate significantly affects the amount of heat generated during the drilling process. High feed rates can cause excessive friction and heat buildup, which not only damages the diamond cutting edges but can also alter the properties of the material being drilled. Such heat accumulation can lead to thermal damage, affecting the integrity of both the drill bit and the workpiece. Proper management of feed rate helps maintain a balance where enough heat is generated to facilitate effective drilling without reaching detrimental levels.

Tool Life and Wear - The longevity of a diamond drill bit is closely tied to the feed rate. Excessive feed rates can lead to increased mechanical stress on the drill, accelerating wear and potentially leading to breakages. Each diamond-coated drill bit is designed to operate within certain feed rate ranges for optimal performance. Staying within these ranges ensures that the diamond grit is not stripped from the bit too quickly, thereby extending the tool’s life.

Surface Finish and Precision - Feed rate also impacts the surface finish of the drilled hole. A feed rate that is too high may result in rough, uneven finishes, with potential chipping or cracking in brittle materials like glass or ceramics. A carefully controlled feed rate ensures a smoother finish, with cleaner edges and more precise dimensional control, which is crucial for high-quality manufacturing processes.

Cost Efficiency - Managing the feed rate effectively can have direct implications for cost efficiency. Optimal feed rates minimize drill bit replacement costs and reduce the time taken for each drilling operation. This efficiency translates to lower overall project costs, as less time and fewer resources are expended in the completion of each task.

Safety Considerations - Safety in drilling operations can be enhanced by controlling the feed rate. Excessive speeds can lead to unexpected failures or breakages of the drill bit, creating hazardous conditions. By maintaining a controlled feed rate, the stability of the drilling process is improved, reducing the risk of accidents and ensuring safer operating conditions for workers.

The feed rate in diamond drilling is not merely a setting to be adjusted but a crucial factor that needs careful optimization based on the specific material characteristics and the desired outcomes of the drilling process. Proper management of the feed rate leads to improved efficiency, enhanced safety, longer tool life, and better-quality finishes, making it a key aspect of operational management in any drilling application. By understanding and controlling the feed rate, operators can ensure that their drilling processes are both cost-effective and capable of producing high-quality results.

Adjustability for Material Variability - Different materials respond uniquely under the same drilling conditions, necessitating adjustments in feed rate to accommodate their physical and chemical properties. Hard materials like granite or hardened steel may require slower feed rates to minimize wear on the diamond drill, whereas softer materials might be processed faster without significant tool damage. Adjusting feed rates appropriately for each material ensures efficient drilling without compromising tool integrity or the quality of the workpiece.

Impact on Drilling Cycles and Throughput - Feed rate directly influences the cycle time of each drilling operation. Optimizing feed rates can lead to significant improvements in throughput, particularly in high-volume production settings. Faster cycle times achieved through optimal feed rates can dramatically increase overall production output, providing a competitive edge in terms of both capacity and responsiveness to market demands.

Relationship with Other Drilling Parameters - Feed rate does not operate in isolation but interacts with other drilling parameters such as spindle speed, tool geometry, and coolant flow. For instance, an increase in feed rate might require adjustments in RPM or changes in coolant application to maintain optimal drilling conditions. Understanding these interactions is crucial for holistic process optimization, ensuring that changes in feed rate are harmoniously balanced with other factors.

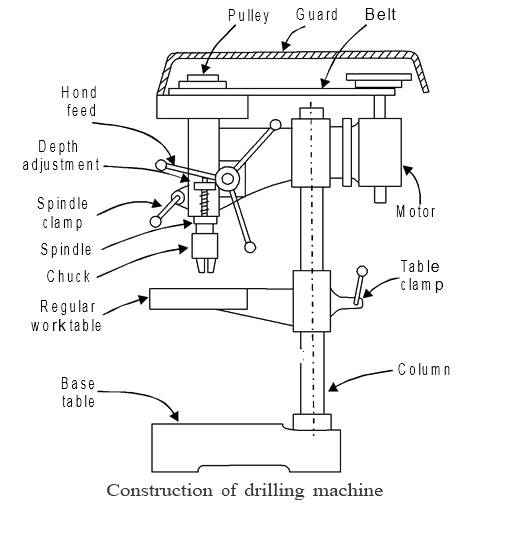

Spindle Travel

Spindle travel determines the maximum depth a drill can achieve. This is crucial when deep holes are required. Ensuring that the drilling equipment has sufficient spindle travel for your application is key to preventing the need for multiple setups and ensuring consistency across the depth of the drill.

Precision in Depth-Control - Spindle travel is critical for applications where the depth of the hole must be controlled with high precision. In industries such as aerospace and automotive, where components may have strict specifications for hole depth, having adjustable and precise spindle travel is essential. This precision ensures that each hole is drilled to the exact required depth, maintaining the structural integrity and functional specifications of the component.

Efficiency in Production - Equipment with sufficient spindle travel can drill to required depths in a single pass without the need for stopping, adjusting, or re-setting the drill bit. This capability significantly enhances production efficiency by reducing cycle times and minimizing labor input. It also reduces wear on the machine and the tool, as the process is streamlined and interruptions that can cause additional stress are eliminated.

Quality and Consistency - Consistent spindle travel across multiple uses ensures uniformity in the depth of holes across a batch of parts, which is crucial for mass production where parts must be interchangeable. Consistency in drilling also affects the assembly processes downstream, where variations in hole depth can lead to assembly issues, increased rejection rates, and non-compliance with quality standards.

Cost Management - Equipment with adjustable and reliable spindle travel can handle a variety of operations without the need for additional attachments or tools, which might be necessary to achieve the desired depth otherwise. This adaptability can lead to significant cost savings in terms of tool inventory and maintenance.

Safety and Stability - Adequate spindle travel contributes to the overall stability of the drilling process. When drills are operated within their optimal range of travel, there is less risk of overextending the equipment, which can lead to mechanical failures and safety hazards. Properly managed spindle travel helps in maintaining the balance and alignment of the drill, reducing the likelihood of accidents and ensuring a safer workplace.

Versatility Across Applications - Drills with a broad range of spindle travel can be used for multiple applications, from surface-level drilling to deep-hole applications. This versatility makes such equipment highly valuable in multi-functional workshops that handle diverse materials and project specifications. It allows companies to invest in fewer machines while maintaining the capability to undertake a wide range of drilling tasks.

Impact on Diamond Drill & Tool Design and Selection - The required spindle travel influences the design and selection of drill bits and tools. Longer drill bits are needed for deeper holes, which can introduce factors like bit flex and wander. Understanding the limits and capabilities of spindle travel helps in selecting the right tools that can perform effectively within those constraints.

Table Size & Adjustability

The size and adjustability of a drill table are crucial elements that significantly influence the versatility, efficiency, and safety of drilling operations. These features enable operators to handle a wide range of material types and sizes, achieve precise drilling specifications, and adapt to various production needs seamlessly. As such, when selecting drilling equipment, the capabilities of the drill table should be carefully considered to ensure they meet the specific requirements of the intended applications, particularly in environments where flexibility and precision is important

Accommodating Diverse Material Sizes and Shapes - The size of the drill table determines the maximum size of the material that can be securely placed and drilled. Larger tables can accommodate bigger or multiple pieces simultaneously, which is crucial for industrial applications where large-scale production or processing of sizable materials is common. This capability is particularly beneficial in sectors such as construction and large machinery manufacturing, where components can be exceptionally large and cumbersome.

Flexibility in Material Positioning - Adjustability in the drill table, such as the ability to tilt or rotate, allows operators to position materials at various angles without the need to reorient the piece manually. This flexibility is essential for creating complex geometrical features like angled holes, which are often required in custom manufacturing and specialized engineering applications. It allows for more complex designs and can significantly enhance the functionality of a component.

Enhancing Operational Efficiency - Adjustable tables can lead to greater efficiency in drilling operations. By reducing the need for additional setups or the use of supplementary jigs to achieve the desired angle or positioning, adjustable tables cut down on setup times and streamline the drilling process. This efficiency is crucial in high-volume or rapid production environments where time savings translate directly into cost savings.

Improving Quality and Precision - The ability to adjust the table for different angles and positions can directly impact the precision and quality of the drilling. Precise table adjustments ensure that the drilling angle and depth are consistently maintained according to specifications, which is critical for maintaining high-quality standards, especially in precision industries such as aerospace and automotive manufacturing.

Reducing Wear and Stress on Equipment - Using an adjustable table can also minimize the stress and wear on the drill itself. By allowing the material to be positioned optimally relative to the drill bit, less force is required to penetrate the material, and the drill can operate more efficiently. This proper alignment reduces the risk of drill bit breakage and wear, extending the lifespan of both the drill bits and the drilling equipment.

Safety Improvements - Safety in the workplace can be enhanced by tables that adjust easily and securely hold materials in place. Securely mounted materials and the ability to control the drilling angle from the table reduce the chances of slippage or movement during operation, which can lead to accidents. Moreover, ergonomic adjustments help prevent operator strain, particularly when handling large or heavy materials.

Customization and Special Applications - For specialized applications requiring non-standard drilling angles or unique material handling, an adjustable table is indispensable. It provides the necessary customization options for tackling unique project requirements without the need for extensive modifications to the setup or additional custom tooling, which can be costly and time-consuming.

Power Source

Selecting the appropriate power source for drilling equipment is crucial as it significantly affects the drill's operational capabilities, suitability for different environments, and overall mobility. Each power source—electric, pneumatic, hydraulic, or battery-powered—has distinct characteristics and offers unique advantages and limitations.

Electric drills are commonly used due to their simplicity and reliability. They only require access to an electrical outlet, making them suitable for steady, continuous operation in environments where electricity is readily available. Electric drills are also preferable for indoor use since they don’t produce emissions and operate quieter than their combustion-powered counterparts. However, their mobility is somewhat restricted by the length of their power cord and the necessity for nearby power outlets, which can be a disadvantage in remote or undeveloped areas.

Pneumatic drills, which operate on compressed air, offer robust power and are highly efficient for demanding drilling tasks. These drills depend on an air compressor, which limits their mobility but makes them particularly durable and suitable for harsh environments, including wet or dusty conditions. The lack of electrical components also makes pneumatic drills ideal for use in potentially explosive atmospheres, such as those found in the oil and gas industry.

Hydraulic drills provide exceptional power and are capable of handling the toughest drilling applications, often used in heavy construction and industrial settings. While they require additional equipment like hydraulic power packs, modern portable units have enhanced their usability even in more remote locations. However, hydraulic drills are generally heavier and more complex to set up than other types of drills, restricting their use to scenarios where their high power output is necessary.

Battery-powered drills are valued for their unmatched mobility. Free from cords and hoses, these drills can be used virtually anywhere, making them perfect for field work and locations lacking power infrastructure. Advances in battery technology have significantly improved their power and longevity, though they still may not sustain prolonged use on par with powered drills. While they are environmentally friendly in operation, the production and disposal of batteries present environmental and economic challenges that need consideration, particularly regarding sustainability and operational costs.

Coolant System

coolant systems in diamond drilling are not just an auxiliary feature; they are a crucial component that impacts the longevity of drilling equipment, the integrity and quality of the material being drilled, and the overall efficiency of the drilling process. Their benefits extend beyond mere temperature management, encompassing environmental and safety aspects as well, making them indispensable in any high-intensity drilling operation.

Continuous Operation and Productivity - In industrial settings where continuous operation is crucial, effective coolant systems are key. They enable prolonged drilling sessions by preventing overheating, which can lead to mandatory downtime needed for equipment to cool. This continuity is essential for maintaining high productivity rates, especially in sectors like mining, where delays can have cascading effects on subsequent processes.

Quality of Finish and Dimensional Accuracy - The presence of a coolant can greatly influence the finish quality of drilled holes. Coolants help to achieve a smoother finish by minimizing the occurrence of burrs and thermal damage to the material edges. This smoothness is critical when the holes are intended for precision fits, such as dowel pins in engineering assemblies or when cosmetic appearance is important in finished products. Furthermore, dimensional accuracy is better maintained as the coolant mitigates thermal expansion of the material during the drilling process, which can otherwise lead to size deviations.

Improved Diamond Drill & Tool Performance and Versatility - Coolants also enhance the performance of the drill bit itself. By reducing the thermal stress on diamond drills & tools, coolants help maintain the bit's sharpness and structural integrity, allowing it to perform optimally over a longer period. This extended tool life not only reduces the cost associated with tool replacement but also ensures consistent performance throughout the tool's lifespan. Additionally, the effectiveness of coolants in managing heat and debris extends the range of materials that can be efficiently drilled, from soft metals to hard ceramics and composites, thus enhancing the versatility of the drilling equipment.

Improved Operator Safety - From a safety perspective, coolants significantly reduce the risk of burns and fires, which are a concern when drilling into metallic and synthetic materials that can generate flammable debris or become extremely hot. The reduction of airborne dust and particles by the coolant also contributes to a healthier work environment, decreasing the risk of respiratory issues for workers involved in the drilling process.

Better for the Environment - Modern advancements in coolant technology have also focused on environmental impact. Biodegradable coolants and those with reduced harmful chemicals are becoming more prevalent, addressing the environmental and health concerns associated with the disposal and handling of traditional coolants. Additionally, systems that recycle and filter coolant for reuse not only reduce waste but also lower the operational costs associated with coolant replenishment.

Improved Overall Performance & Savings - While the installation and maintenance of coolant systems represent an initial investment and ongoing cost, the benefits they provide often outweigh these costs. The reduction in tool wear, decreased downtime, and improved product quality all contribute to a more economically efficient operation. Furthermore, by extending the life of drilling equipment and reducing the frequency of repairs and replacements, coolant systems can significantly impact the overall cost-efficiency of projects.

Control System

When selecting a control system for diamond drilling tools, consider the specific needs of your application. If precision and repeatability are crucial, an automated system like CNC might be the best choice. For smaller-scale or less precision-critical tasks, a manual system or PLC could provide the flexibility and cost-effectiveness needed. Each system offers different benefits, so aligning the choice with your production requirements, budget constraints, and long-term operational goals is essential for maximizing the effectiveness of your diamond drilling operations.

Using diamond drills and other specialized tools requires precise control to achieve the best results in terms of accuracy, efficiency, and cost. The control system of your drilling equipment plays a crucial role in how well you can manage these aspects. Here's how different control systems impact the use of diamond drills and tools:

Manual Control Systems

-

Direct Operator Control: Manual control systems need the operator to be actively involved, adjusting and guiding the drill. This is beneficial in settings where custom work is needed, and the operator's skill can make a significant difference, such as in crafting custom jewelry or other artisan products.

Direct Operator Control: Manual control systems need the operator to be actively involved, adjusting and guiding the drill. This is beneficial in settings where custom work is needed, and the operator's skill can make a significant difference, such as in crafting custom jewelry or other artisan products.

-

Limitations in Consistency: For diamond drilling, consistency is key, especially when working with materials like ceramics or precision components. Manual systems might not offer the repeatable accuracy that automated systems do, which could lead to variations in hole size or damage to sensitive materials.

Limitations in Consistency: For diamond drilling, consistency is key, especially when working with materials like ceramics or precision components. Manual systems might not offer the repeatable accuracy that automated systems do, which could lead to variations in hole size or damage to sensitive materials.

-

Cost Advantages: If your operations don't require high precision, manual systems are more budget-friendly both in initial cost and maintenance. They are ideal for simpler applications where the high precision of automated systems isn't critical.

Cost Advantages: If your operations don't require high precision, manual systems are more budget-friendly both in initial cost and maintenance. They are ideal for simpler applications where the high precision of automated systems isn't critical.

Programmable Logic Controllers (PLC)

-

Flexible Automation:PLCs provide a good mix of automation and adaptability. They are especially useful for diamond drilling where different materials or product designs might require slight adjustments in the drilling process. These systems allow you to program and adjust operations easily, adapting to different tasks without major hardware changes.

Flexible Automation:PLCs provide a good mix of automation and adaptability. They are especially useful for diamond drilling where different materials or product designs might require slight adjustments in the drilling process. These systems allow you to program and adjust operations easily, adapting to different tasks without major hardware changes.

-

Increased Production Consistency: The automated nature of PLCs helps ensure each drilling operation is consistent, which is crucial when using diamond drills to create uniformly precise cuts in materials like advanced ceramics or for applications in electronics where precision is paramount.

Increased Production Consistency: The automated nature of PLCs helps ensure each drilling operation is consistent, which is crucial when using diamond drills to create uniformly precise cuts in materials like advanced ceramics or for applications in electronics where precision is paramount.

-

Safety and Integration: PLCs enhance safety by incorporating automated checks that prevent the drill from operating under unsafe conditions. They can also be integrated with other systems for a more cohesive workflow, particularly in larger manufacturing settings where multiple processes need to be synchronized.

Safety and Integration: PLCs enhance safety by incorporating automated checks that prevent the drill from operating under unsafe conditions. They can also be integrated with other systems for a more cohesive workflow, particularly in larger manufacturing settings where multiple processes need to be synchronized.

CNC (Computer Numerical Control)

-

High Precision and Consistency: CNC control systems offer the highest level of precision and repeatability, which is essential for applications requiring meticulous detail, such as in aerospace or medical device manufacturing. Using CNC with diamond tools ensures that each cut is precise, minimizing material waste and enhancing the quality of the final product.

High Precision and Consistency: CNC control systems offer the highest level of precision and repeatability, which is essential for applications requiring meticulous detail, such as in aerospace or medical device manufacturing. Using CNC with diamond tools ensures that each cut is precise, minimizing material waste and enhancing the quality of the final product.

-

Complex and High-Volume Production: For complex designs or high-volume production runs, CNC systems can dramatically improve both efficiency and quality. They can be programmed for intricate cutting patterns that would be difficult or impossible to achieve manually.

Complex and High-Volume Production: For complex designs or high-volume production runs, CNC systems can dramatically improve both efficiency and quality. They can be programmed for intricate cutting patterns that would be difficult or impossible to achieve manually.

Footprint & Portability

The footprint and portability of drilling equipment play a pivotal role in determining its effectiveness and appropriateness for different operational contexts. Equipment choices should reflect not only the immediate needs of specific projects but also consider broader operational dynamics such as workspace flexibility, mobility requirements, and long-term scalability. Making informed decisions regarding the size and portability of drilling equipment can lead to more efficient, flexible, and cost-effective operations across a variety of industries.

Max Load Capacity

Max Load Capacity is the maximum weight and size of material that drilling equipment can safely and effectively handle. It's crucial to match the equipment's capacity with the dimensions of the material to ensure stability and safety during drilling. Exceeding the max load capacity can lead to equipment damage, safety hazards, and inefficient drilling performance. Adhering to manufacturer specifications and guidelines regarding load capacity is essential for maintaining a safe working environment. Operating within the specified load capacity ensures optimal performance and longevity of the equipment, while overloading can strain the equipment and lead to premature wear.

Understanding material properties and dimensions helps in selecting the appropriate drilling equipment with the necessary load capacity for the task. Regular inspection and maintenance of equipment are necessary to ensure it remains within its specified load capacity and operates safely and efficiently. Any signs of wear or damage should be addressed promptly to prevent equipment failure during drilling operations.

Safety Features

Safety features in drilling equipment are critical when using with sensitive tools diamond core drills and other diamond tools. These features help safeguard operators by reducing the risks associated with handling such tools and applications. Emergency stops are vital as they allow operators to quickly cease operations in emergencies. This is particularly important for diamond core drills, which can penetrate hard materials and may pose sudden operational challenges.

Safety guards act as protective barriers around the rotating parts of the drill, essential at the high speeds at which these drills operate. They prevent injuries from accidental contact and protect against debris ejected during drilling. Lockout/tagout (LOTO) capabilities ensure that drills are safely turned off and not accidentally restarted during maintenance, protecting against electrical shocks and other hazards.

Overload protection mechanisms are also crucial. They protect both the drill and the operator by shutting down the drill if the load becomes too great, a common risk given the hard materials often drilled. Noise reduction features, such as enclosures, are important too, as they mitigate the high noise levels produced during drilling, protecting operators' hearing and improving the work environment.

Safety interlock systems enhance safety by ensuring that all necessary protective measures are in place before the drill can operate. This prevents the drill from starting until it is completely safe to do so, significantly reducing the risk of accidents. Warning alarms and lights are particularly beneficial for diamond core drills. They provide visual and audible alerts about potential issues like overheating or malfunctions, allowing for timely corrective actions.

Finally, operator training is crucial. Proper training ensures that those using diamond core drills are fully aware of how to operate them safely and effectively, understanding potential risks and how to handle the equipment properly to prevent accidents and ensure smoother operations. Integrating these safety features not only protects operators but also enhances the efficiency and longevity of the equipment, ensuring that tasks are completed safely and effectively.

Noise Level

The noise level emitted by drilling equipment is a crucial consideration, particularly in environments with multiple personnel or in residential areas. Beyond being a nuisance, excessive noise poses risks to safety, health, and regulatory compliance.

Adhering to safety and health regulations is paramount in any workplace. Lowering noise levels helps companies comply with regulations aimed at protecting workers from noise-induced hearing loss and related health issues.

High noise levels can create discomfort and stress among personnel, leading to decreased productivity and job satisfaction. By reducing noise emissions, companies can foster a more comfortable work environment, promoting employee well-being and productivity.

In residential areas or urban environments, noise pollution from drilling can cause disturbances and complaints from nearby residents. Minimizing noise levels improves community relations and mitigates conflicts with local residents.

Excessive noise can also impact the environment, particularly in sensitive ecosystems or wildlife habitats. Lowering noise emissions helps minimize environmental disruption and protect wildlife populations from disturbances caused by industrial activities.

In noisy work environments, communication between personnel may be hindered, increasing the risk of accidents or errors. By reducing noise levels, companies can improve communication, enhancing overall safety and reducing workplace accidents.

High noise levels often indicate mechanical stress and vibration within drilling equipment, leading to premature equipment failure. Implementing noise reduction measures helps prolong the lifespan of drilling equipment by minimizing mechanical stress and vibration.

Dust Management

Effective management of dust generated during drilling operations is essential for maintaining a safe and healthy work environment, particularly when working with materials like concrete or stone. Dust poses significant health and safety risks to workers and the surrounding environment, making it imperative to implement proper dust management measures.

Airborne dust particles generated during drilling can lead to respiratory issues such as coughing, wheezing, and even more severe conditions like silicosis. Prolonged exposure to dust can have detrimental effects on workers' health, necessitating measures to minimize dust emissions and protect worker well-being.

In addition to health risks, airborne dust can also create safety hazards in the workplace, reducing visibility and increasing the risk of slips, trips, and falls. Dust accumulation on surfaces and equipment can impair performance and lead to premature wear and damage, affecting both worker safety and equipment reliability.

Implementing effective dust management systems helps maintain a clean and organized work environment, enhancing worker morale and productivity. It also ensures compliance with regulatory requirements governing dust exposure levels in the workplace, thereby avoiding potential fines or penalties for non-compliance.

Material Compatibility

Ensuring compatibility between drilling equipment, including diamond drill bits, and the material being drilled is essential for achieving optimal drilling outcomes and preventing damage to both the material and the tools involved.

Diamond Drill & Tool performance relies heavily on selecting equipment and diamond drills or tools tailored to the specific properties of the material. Different materials vary in hardness, abrasiveness, and structural integrity, directly impacting drilling effectiveness and efficiency. The use of appropriate diamond drills and tools ensures smoother, more precise drilling, reducing the risk of tool wear, breakage, or premature failure.

Quality of cut is directly influenced by material compatibility. Incorrect diamond drill or tool selection can result in chipping, cracking, or rough edges, compromising the integrity and appearance of the drilled surface. Diamond Drills & Tools designed for the material's properties deliver cleaner cuts with minimal surface damage, enhancing overall quality.

Safety considerations are paramount. Incompatible tools can lead to unpredictable drilling behavior, such as tool slippage or kickback, increasing the risk of accidents and injuries. Ensuring material compatibility creates a safer working environment for all involved.

Longevity of diamond drills and tools is prolonged with material-compatible equipment. Diamond Drills & Tools exposed to excessive stress or wear due to incompatibility are more prone to damage and failure, resulting in increased maintenance costs and downtime. Compatible tools optimize longevity and reduce the frequency of replacements.

Efficiency and productivity are enhanced with compatible tools. Smooth drilling operations with fewer interruptions allow operators to work more efficiently and meet project deadlines effectively. Moreover, compatible tools require less effort and energy, contributing to overall operational efficiency and productivity.

Torque

Torque plays a crucial role in determining a drill's ability to penetrate hard materials effectively. It directly influences the drilling process, particularly when dealing with tough materials that require greater force to cut through.

The driving force behind a drill bit's rotation, torque exerts pressure on the material being drilled. For hard materials like advanced ceramics, some metals, and natural stone, higher torque is essential to overcome resistance and achieve efficient penetration. Without adequate torque, progress may be slow, leading to potential stall-outs or failure to penetrate the material.

Torque requirements vary based on material hardness. Harder materials demand higher torque to initiate and sustain drilling progress, while softer materials may require less. Adjusting torque levels according to material hardness ensures optimal drilling performance and minimizes strain on equipment.

Adequate torque prevents stall-outs during drilling, particularly in challenging materials. Stall-outs occur when the drill encounters excessive resistance, causing the motor to stop rotating. Higher torque allows the drill to power through without stalling, ensuring continuous progress.

Proper torque management minimizes wear on diamond drills & tools and equipment. Insufficient torque can strain the diamond drill, leading to premature wear, chipping, or breakage. By delivering the necessary torque, operators prolong the drill bit's lifespan and maintain cutting performance.

Optimal torque enhances drilling efficiency by ensuring steady progress through the material. With sufficient torque, the drill maintains a consistent rotational speed, resulting in uniform cutting action and efficient material removal. This boosts drilling rates and overall productivity.

Torque management is crucial for operator safety. Inadequate torque can lead to sudden tool failures or kickbacks, posing hazards to operators and nearby personnel. Providing sufficient torque ensures safe and confident drilling operations, minimizing the risk of accidents.

Speed Adjustability

The ability to adjust drilling speed according to material hardness and drilling conditions is instrumental in optimizing tool life and ensuring high-quality cuts. This feature empowers operators to tailor drilling parameters to specific requirements, mitigating risks such as overheating and premature tool wear.

Customized drilling parameters tailored to material hardness and prevailing conditions are achievable through speed adjustability. Operators can fine-tune drilling speed to suit a broad spectrum of materials, from soft to hard, maximizing tool performance and yielding superior results.

Diamond drill and tool longevity benefits from matching drilling speed to material hardness, minimizing overheating and premature wear.

Excessive heat generation during high-speed drilling in hard materials can induce thermal stress, accelerating tool degradation. Speed adjustability maintains tools within safe temperature limits, extending their lifespan and reducing replacement frequency.

The ability to adjust drilling speed ensures precise and clean cuts, even in challenging materials. Optimization of drilling parameters minimizes tool deflection, vibration, and chatter, resulting in smoother surfaces and enhanced cut quality, crucial for precision applications like aerospace or automotive manufacturing.

Speed adjustability enhances the versatility and adaptability of drilling equipment across diverse tasks and materials. Operators can swiftly adjust drilling speed to accommodate changes in material properties or drilling conditions, ensuring consistent performance and optimal results across various applications.

Safety is improved through speed adjustability by preventing tool overload and reducing the risk of tool breakage or ejection. Operators can maintain better control over the drilling process, ensuring safe and efficient operation.

Operational efficiency and productivity receive a boost as drilling speed optimization minimizes rework and tool changes, streamlining the drilling process and maximizing throughput. This translates into cost savings and increased profitability for businesses.

Automatic Feed

Automatic feed mechanisms revolutionize drilling operations by ensuring consistent drilling pressure throughout the process. This innovation not only enhances borehole quality but also significantly reduces operator fatigue.

Consistent drilling pressure is crucial for achieving uniform surface finish quality, especially in materials with varying densities or hardness. By eliminating pressure fluctuations, automatic feed systems produce smoother, more precise boreholes with minimal imperfections. This is particularly vital in precision drilling applications where surface finish, chipping, and material deformation and overall part quality directly impacts component fit, assembly, or performance.

Moreover, automatic feed mechanisms alleviate the physical strain associated with manual drilling. By automating the feeding process, operators are relieved of the repetitive task of applying and adjusting drilling pressure manually.

This reduces the risk of operator fatigue, discomfort, or musculoskeletal injuries, thereby enhancing operator comfort and productivity during extended drilling sessions.

In terms of efficiency, automatic feed systems streamline the drilling process and reduce cycle times. The consistent application of drilling pressure ensures steady progress through the material, minimizing the need for frequent manual adjustments or interruptions. This results in faster drilling rates, increased throughput, and improved productivity, particularly in high-volume drilling applications or production environments.

Another advantage lies in the adaptability of automatic feed mechanisms to various materials and applications. Whether drilling through ceramic, glass, metal, or composites, automatic feed systems can adjust drilling pressure accordingly to optimize performance and borehole quality. This versatility makes automatic feed mechanisms suitable for diverse drilling tasks across different industries.

Furthermore, automatic feed mechanisms enhance safety during drilling operations. By automating the feeding process, the risk of operator errors or accidents caused by sudden changes in drilling pressure is minimized. This promotes a safer working environment and reduces the likelihood of injuries or incidents associated with manual drilling practices.

Operator Experience Level

The proficiency of the operator significantly impacts the efficient and safe operation of drilling equipment, thereby influencing training costs, potential for errors, and overall productivity and safety.

Efficient and productive operation relies heavily on the operator's skill level. Experienced operators can navigate drilling equipment adeptly, optimizing parameters and maximizing output. Their familiarity with controls, maintenance procedures, and troubleshooting techniques minimizes downtime and ensures optimal drilling outcomes. Conversely, inexperienced operators may struggle, leading to inefficiencies, delays, and reduced productivity.

Safety performance is directly linked to operator experience.

Experienced operators possess the knowledge and skills to identify and mitigate hazards, adhere to safety protocols, and respond to emergencies effectively. This reduces the likelihood of accidents caused by operator error. Conversely, inexperienced operators may lack the expertise to recognize and address safety risks adequately, increasing the potential for incidents.

Training costs vary depending on the skill level required for equipment operation. Training inexperienced operators may require extensive resources to impart necessary skills effectively. In contrast, experienced operators may need less intensive training, resulting in lower costs and faster onboarding. However, comprehensive training for all operators is essential to ensure safe and efficient operation.

The potential for operator error is influenced by experience. Experienced operators are less likely to make mistakes due to their familiarity with equipment and procedures. They can anticipate issues and address them promptly, reducing the risk of errors that could compromise safety or drilling quality. Inexperienced operators may struggle with decision-making, increasing the likelihood of errors.

Experienced operators contribute valuable insights for process optimization. Their firsthand knowledge enables them to identify areas for improvement and suggest innovative solutions. Leveraging their expertise drives continuous improvement, enhancing efficiency and maintaining competitiveness.

Cost of Ownership

The cost of ownership encompasses various factors, including initial purchase, maintenance, and operational expenses, all of which significantly impact the overall investment required for drilling equipment. Understanding these costs is essential for making informed decisions regarding equipment selection and budget allocation.

Initial purchase costs represent a substantial portion of the total cost of ownership. Factors such as equipment specifications, brand reputation, technological features, and market demand influence these upfront expenses. While higher-quality or technologically advanced equipment may command higher purchase prices, it often offers superior performance, durability, and reliability, potentially leading to long-term cost savings.

Maintenance expenses are a critical consideration, covering routine upkeep, repairs, and replacement of consumable parts. Regular maintenance helps extend equipment lifespan, prevent breakdowns, and maintain optimal performance.

Factors influencing maintenance costs include equipment complexity, frequency of use, environmental conditions, and availability of spare parts. Investing in preventive maintenance programs and quality components can help minimize maintenance costs and maximize equipment uptime.

Operational costs encompass the day-to-day expenses associated with equipment operation, such as fuel, electricity, consumables, and labor. Factors influencing operational costs include equipment efficiency, fuel consumption rates, energy efficiency, labor productivity, and material wastage. Investing in energy-efficient equipment, optimizing drilling processes, and training operators to maximize efficiency can help reduce operational costs over time.

Assessing the total cost of ownership (TCO) allows stakeholders to evaluate the long-term economic viability of investing in specific drilling equipment. While equipment with lower initial purchase costs may appear more affordable upfront, higher maintenance or operational expenses may result in a higher TCO over time. Conversely, investing in higher-quality equipment with higher initial costs may lead to lower maintenance and operational expenses, resulting in a lower TCO in the long run.

Understanding the cost of ownership is crucial for selecting suitable drilling equipment that aligns with budgetary constraints and performance requirements. By considering both upfront and ongoing costs, stakeholders can make informed decisions regarding equipment procurement, ensuring optimal value for investment. Factors such as equipment reliability, efficiency, and total lifecycle costs should be weighed against budget limitations and project needs to identify the most cost-effective solution.

Tolerances, Accuracy, and Repeatability

Tolerances, accuracy, and repeatability play crucial roles in selecting the right diamond drilling equipment for diamond core drills and diamond tools, as they directly impact the quality, precision, and consistency of the drilling process. Here's how these variables relate to equipment selection:

Tolerances: Tolerances define the allowable variation or deviation from a specified dimension or geometric feature. In drilling, tolerances specify the acceptable limits for hole diameter, depth, position, concentricity, and other dimensional characteristics. Tighter tolerances require greater precision in drilling operations and may necessitate advanced equipment, tooling, and machining techniques to achieve. Adhering to specified tolerances ensures that drilled features meet design requirements and functional specifications, facilitating proper assembly, mating, and functionality of components in the final product.

Accuracy: Accuracy refers to the degree of conformity between the actual drilled feature and the intended design or target dimension. It reflects the ability of the drilling equipment, tooling, and machining processes to consistently produce holes with minimal deviation from specified dimensions. Achieving high accuracy in drilling requires precise control of spindle speed, feed rate, tool geometry, cutting parameters, and machine dynamics. Additionally, factors such as tool wear, machine deflection, and environmental conditions can affect drilling accuracy and may require corrective measures to maintain dimensional integrity and quality throughout the drilling process.

Repeatability: Repeatability measures the consistency and reproducibility of drilling operations when performing multiple drilling cycles or producing identical features on different workpieces. It quantifies the ability of the drilling equipment and tooling to repeatedly achieve the same results within specified tolerances and accuracy limits. High repeatability ensures consistent hole quality, dimensional consistency, and interchangeability of parts in mass production or assembly applications. Achieving repeatability relies on stable machine performance, precise tool positioning, and consistent operating conditions, minimizing variability and deviations between successive drilling cycles.

Meeting Application Requirements: Diamond drilling equipment must meet specific application requirements, including dimensional tolerances for drilled holes and the accuracy of hole placement. When selecting diamond drilling equipment, manufacturers must consider the desired tolerances and accuracy levels to ensure that the equipment can consistently produce holes within the required specifications. Equipment with high precision and repeatability is essential for achieving tight tolerances and accurate hole placement, especially in applications where precision is critical, such as aerospace, automotive, or medical device manufacturing.

Optimizing Performance: The accuracy and repeatability of diamond drilling equipment directly impact its performance and efficiency. Equipment with higher accuracy and repeatability can produce more precise and consistent results, minimizing the need for rework or manual adjustments. This leads to improved productivity, reduced downtime, and enhanced overall efficiency in drilling operations. Manufacturers should prioritize equipment that offers superior precision and repeatability to optimize performance and maximize productivity in diamond drilling applications.

Ensuring Quality and Consistency: Tolerances, accuracy, and repeatability are essential for ensuring the quality and consistency of drilled holes and machined components. Equipment that can maintain tight tolerances and high accuracy levels throughout the drilling process helps produce parts with uniform dimensions, surface finishes, and geometric features. This is particularly important in industries where strict quality standards and regulatory requirements must be met, such as aerospace, defense, and medical device manufacturing. By selecting diamond drilling equipment with excellent tolerances, accuracy, and repeatability, manufacturers can achieve consistent quality and meet customer expectations for precision-engineered components.

Minimizing Waste and Rework: High levels of tolerances, accuracy, and repeatability in diamond drilling equipment help minimize waste and rework by reducing the likelihood of errors and deviations from specifications. Equipment that consistently produces accurate and repeatable results minimizes material wastage, scrap rates, and the need for rework or corrective actions. This not only improves operational efficiency but also reduces costs associated with material consumption, labor, and secondary machining operations. Manufacturers should invest in diamond drilling equipment that offers superior precision and reliability to minimize waste and optimize resource utilization in their operations.

Enhancing Productivity and Profitability: Ultimately, the selection of diamond drilling equipment with excellent tolerances, accuracy, and repeatability contributes to enhanced productivity and profitability in manufacturing operations. Equipment that can consistently meet tight tolerances and accuracy requirements enables manufacturers to produce high-quality parts efficiently, meet production deadlines, and satisfy customer demands. By investing in reliable and precise diamond drilling equipment, manufacturers can improve their competitiveness, drive operational excellence, and achieve long-term profitability in the diamond tooling industry.

Spindle Specifications

Spindle specifications are critical parameters that define the performance and capabilities of drilling equipment. These specifications encompass various aspects of the spindle, including its design, size, speed, power, and compatibility with different tooling systems. Understanding spindle specifications is essential for selecting the right equipment to meet specific drilling requirements and achieve desired outcomes.

-

Design and Construction: The design and construction of the spindle play a crucial role in determining its durability, stability, and precision during drilling operations. Spindles may feature different designs, such as belt-driven, gear-driven, or direct-drive configurations, each offering unique advantages in terms of power transmission, speed control, and reliability. Additionally, the material composition and manufacturing quality of the spindle components influence their ability to withstand high loads, resist vibration, and maintain accuracy over time.

Design and Construction: The design and construction of the spindle play a crucial role in determining its durability, stability, and precision during drilling operations. Spindles may feature different designs, such as belt-driven, gear-driven, or direct-drive configurations, each offering unique advantages in terms of power transmission, speed control, and reliability. Additionally, the material composition and manufacturing quality of the spindle components influence their ability to withstand high loads, resist vibration, and maintain accuracy over time.

-

Size and Capacity: Spindle size and capacity refer to the physical dimensions and load-bearing capabilities of the spindle assembly. The size of the spindle affects the maximum drilling depth, diameter, and weight capacity of the equipment, as well as its compatibility with different workpiece sizes and materials. Larger spindles can accommodate heavier loads and perform more robust drilling tasks, while smaller spindles are suitable for lighter-duty applications or precision drilling operations.

Size and Capacity: Spindle size and capacity refer to the physical dimensions and load-bearing capabilities of the spindle assembly. The size of the spindle affects the maximum drilling depth, diameter, and weight capacity of the equipment, as well as its compatibility with different workpiece sizes and materials. Larger spindles can accommodate heavier loads and perform more robust drilling tasks, while smaller spindles are suitable for lighter-duty applications or precision drilling operations.

-

Speed and Power: Spindle speed and power ratings are fundamental specifications that determine the drilling performance and efficiency of the equipment. Spindle speed, measured in revolutions per minute (RPM), influences cutting tool performance, material removal rates, and surface finish quality. Higher spindle speeds are advantageous for achieving faster drilling rates and smoother finishes, particularly in softer materials. Spindle power, typically measured in horsepower (HP) or kilowatts (kW), indicates the maximum torque and cutting force that the spindle can deliver, influencing its ability to penetrate hard materials and maintain stable drilling operations under varying loads.

Speed and Power: Spindle speed and power ratings are fundamental specifications that determine the drilling performance and efficiency of the equipment. Spindle speed, measured in revolutions per minute (RPM), influences cutting tool performance, material removal rates, and surface finish quality. Higher spindle speeds are advantageous for achieving faster drilling rates and smoother finishes, particularly in softer materials. Spindle power, typically measured in horsepower (HP) or kilowatts (kW), indicates the maximum torque and cutting force that the spindle can deliver, influencing its ability to penetrate hard materials and maintain stable drilling operations under varying loads.

-

Tooling Compatibility: Spindle specifications also include compatibility with different tooling systems, such as collet chucks, drill chucks, or quick-change adapters. The spindle interface must match the tooling system used to secure cutting tools or accessories, ensuring proper tool retention, concentricity, and alignment during drilling. Compatibility with standard tooling systems allows operators to interchange tools easily and adapt the equipment to various drilling applications without requiring specialized adapters or modifications.

Tooling Compatibility: Spindle specifications also include compatibility with different tooling systems, such as collet chucks, drill chucks, or quick-change adapters. The spindle interface must match the tooling system used to secure cutting tools or accessories, ensuring proper tool retention, concentricity, and alignment during drilling. Compatibility with standard tooling systems allows operators to interchange tools easily and adapt the equipment to various drilling applications without requiring specialized adapters or modifications.

-

Coolant and Chip Evacuation: Some spindle designs incorporate features for coolant delivery and chip evacuation to enhance drilling performance and prolong tool life. Through-spindle coolant systems provide lubrication and cooling directly to the cutting zone, reducing heat generation, tool wear, and chip buildup during drilling. Additionally, spindle designs with built-in chip evacuation channels or air blasts help remove chips and debris from the drilling area, preventing chip recutting, tool clogging, and surface damage.

Coolant and Chip Evacuation: Some spindle designs incorporate features for coolant delivery and chip evacuation to enhance drilling performance and prolong tool life. Through-spindle coolant systems provide lubrication and cooling directly to the cutting zone, reducing heat generation, tool wear, and chip buildup during drilling. Additionally, spindle designs with built-in chip evacuation channels or air blasts help remove chips and debris from the drilling area, preventing chip recutting, tool clogging, and surface damage.

-

Accuracy and Precision: Spindle specifications also influence the accuracy and precision of drilling operations, particularly in applications requiring tight tolerances or geometric complexity. High-quality spindles with low runout, minimal deflection, and precise speed control contribute to superior hole quality, dimensional accuracy, and surface finish, ensuring consistency and repeatability in drilled features. Precision spindle bearings, advanced motor control systems, and rigid spindle housings are essential elements for achieving high levels of drilling accuracy and precision.

Accuracy and Precision: Spindle specifications also influence the accuracy and precision of drilling operations, particularly in applications requiring tight tolerances or geometric complexity. High-quality spindles with low runout, minimal deflection, and precise speed control contribute to superior hole quality, dimensional accuracy, and surface finish, ensuring consistency and repeatability in drilled features. Precision spindle bearings, advanced motor control systems, and rigid spindle housings are essential elements for achieving high levels of drilling accuracy and precision.

Machine Reach and Structure

When selecting diamond drills for specific applications, the machine reach and structure are critical factors that significantly influence the choice of drills. These factors determine the feasibility of achieving the required depth and precision in drilling operations, particularly in challenging or specialized environments. Here's an in-depth exploration of how machine reach and structure affect diamond drill selection:

Machine reach refers to the ability of a drilling machine to access a certain depth or distance from its base or mounting point. This capability is crucial when dealing with workpieces of varying sizes or when operations require drilling at significant depths.

-

Depth Capability: The primary consideration for machine reach is the maximum depth the machine can handle. This is especially important in industries like geotechnical engineering, deep-hole drilling in oil and gas exploration, or in creating deep, narrow cavities in aerospace and automotive components. The reach must be sufficient to drill the entire depth without requiring repositioning of the workpiece or drill.