Material Guide

-

Posted by

Ayan Sadyk

Ayan Sadyk

Table of Contents

ToggleUnderstanding the material you will be working with, their unique characteristics and properties is crucial for selecting the appropriate diamond or cbn cutting tools, machining parameters, and processes. Each material behaves differently under machining operations due to its physical, chemical, and mechanical properties. Here’s an overview of what you should know about machining a variety of materials, focusing on metals, composites ceramics, glass, optial glass, semiconductor materials, natural stone, semi precious and precious stone (lapidary), semiconductor materials.

Understanding the physical, chemical, and mechanical properties of materials is fundamental for selecting the appropriate machining strategies, tool materials, and operational parameters. Here’s a more detailed look at these properties:

Physical Properties

Physical properties are those that can be observed or measured without changing the composition of the material. In the context of machining, key physical properties include:

-

Density: The mass per unit volume of a material. It influences the material's weight and stiffness, affecting the choice of machining parameters and tooling requirements.

Density: The mass per unit volume of a material. It influences the material's weight and stiffness, affecting the choice of machining parameters and tooling requirements.

-

Thermal Conductivity: The ability of a material to conduct heat. High thermal conductivity materials (e.g., copper) dissipate heat more efficiently during machining, affecting tool wear and the need for cooling.

Thermal Conductivity: The ability of a material to conduct heat. High thermal conductivity materials (e.g., copper) dissipate heat more efficiently during machining, affecting tool wear and the need for cooling.

-

Thermal Expansion Coefficient: The rate at which a material expands with temperature. Materials with high thermal expansion coefficients (e.g., plastics) may require adjustments in machining tolerances for operations involving significant heat.

Thermal Expansion Coefficient: The rate at which a material expands with temperature. Materials with high thermal expansion coefficients (e.g., plastics) may require adjustments in machining tolerances for operations involving significant heat.

-

Electrical Conductivity: Relevant for processes such as electrical discharge machining (EDM), where the material must be conductive. Materials with low electrical conductivity (e.g., ceramics) are not suitable for EDM.

Electrical Conductivity: Relevant for processes such as electrical discharge machining (EDM), where the material must be conductive. Materials with low electrical conductivity (e.g., ceramics) are not suitable for EDM.

-

Melting Point: The temperature at which a material changes from solid to liquid. Materials with high melting points can withstand higher machining temperatures but may require specialized cutting tools that can operate effectively at elevated temperatures without losing hardness or strength.

Melting Point: The temperature at which a material changes from solid to liquid. Materials with high melting points can withstand higher machining temperatures but may require specialized cutting tools that can operate effectively at elevated temperatures without losing hardness or strength.

-

Specific Heat Capacity: This property indicates how much heat a material can absorb before its temperature rises. Materials with high specific heat capacities can absorb more heat during machining, potentially reducing thermal-induced stress and deformation but may also necessitate enhanced cooling strategies.

Specific Heat Capacity: This property indicates how much heat a material can absorb before its temperature rises. Materials with high specific heat capacities can absorb more heat during machining, potentially reducing thermal-induced stress and deformation but may also necessitate enhanced cooling strategies.

Chemical Properties

Chemical properties describe a material's reactivity with other substances, which can be critical for machining processes involving chemical interactions:

-

Corrosion Resistance: The ability to resist degradation due to reaction with environmental agents. This is crucial for selecting materials for tools and parts intended for corrosive environments.

Corrosion Resistance: The ability to resist degradation due to reaction with environmental agents. This is crucial for selecting materials for tools and parts intended for corrosive environments.

-

Oxidation Resistance: Important for high-temperature machining operations or applications where the material is exposed to oxygen at elevated temperatures, potentially affecting its integrity and the surface finish.

Oxidation Resistance: Important for high-temperature machining operations or applications where the material is exposed to oxygen at elevated temperatures, potentially affecting its integrity and the surface finish.

-

Chemical Stability: The resistance of a material to chemical change. In machining, chemical stability affects the choice of coolants and lubricants, as some materials may react adversely with specific chemical agents.

Chemical Stability: The resistance of a material to chemical change. In machining, chemical stability affects the choice of coolants and lubricants, as some materials may react adversely with specific chemical agents.

-

Reactivity with Coolants: Certain materials may react chemically with specific coolants or lubricants, leading to corrosion or material degradation. Selecting chemically compatible coolants is essential to prevent adverse reactions that can affect both the workpiece and the tool life.

Reactivity with Coolants: Certain materials may react chemically with specific coolants or lubricants, leading to corrosion or material degradation. Selecting chemically compatible coolants is essential to prevent adverse reactions that can affect both the workpiece and the tool life.

-

Surface Chemistry: The chemical composition of a material's surface can influence adhesion, friction, and wear characteristics during machining. For example, certain surface treatments or coatings may be applied to improve surface characteristics or to reduce the tendency for material to weld to the cutting tool.

Surface Chemistry: The chemical composition of a material's surface can influence adhesion, friction, and wear characteristics during machining. For example, certain surface treatments or coatings may be applied to improve surface characteristics or to reduce the tendency for material to weld to the cutting tool.

Mechanical Properties

Mechanical properties determine a material's behavior under various forces or loads. These properties are vital for predicting how materials will respond to machining forces:

-

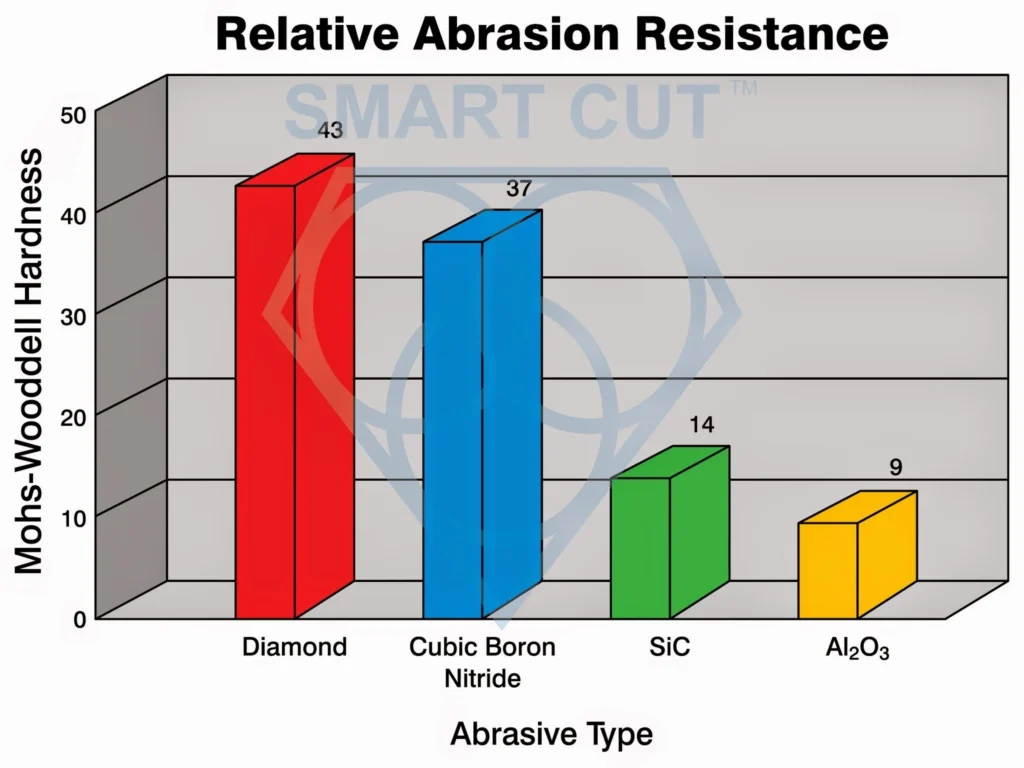

Hardness:The resistance of a material to deformation, typically measured by scales such as Rockwell, Brinell, and Vickers. Hard materials (e.g., hardened steel, ceramics) require harder cutting tools, such as those made from carbide or diamond.

Hardness:The resistance of a material to deformation, typically measured by scales such as Rockwell, Brinell, and Vickers. Hard materials (e.g., hardened steel, ceramics) require harder cutting tools, such as those made from carbide or diamond.

-

Tensile Strength: The maximum stress a material can withstand while being stretched or pulled before failing. High tensile strength materials are more resistant to cutting forces, demanding more robust machining strategies.

Tensile Strength: The maximum stress a material can withstand while being stretched or pulled before failing. High tensile strength materials are more resistant to cutting forces, demanding more robust machining strategies.

-

Yield Strength: The stress at which a material begins to deform plastically. Knowing the yield strength helps in avoiding excessive deformation during machining.

Yield Strength: The stress at which a material begins to deform plastically. Knowing the yield strength helps in avoiding excessive deformation during machining.

-

Elasticity and Plasticity: Elasticity is the ability of a material to return to its original shape after deformation, while plasticity is the degree to which it can undergo permanent deformation. Understanding these properties is essential for predicting material behavior under machining stresses.

Elasticity and Plasticity: Elasticity is the ability of a material to return to its original shape after deformation, while plasticity is the degree to which it can undergo permanent deformation. Understanding these properties is essential for predicting material behavior under machining stresses.

-

Toughness: The ability of a material to absorb energy and plastically deform without fracturing. Tough materials can withstand high-impact machining processes but may pose challenges in chip formation and control.

Toughness: The ability of a material to absorb energy and plastically deform without fracturing. Tough materials can withstand high-impact machining processes but may pose challenges in chip formation and control.

-

Wear Resistance: The ability to withstand abrasion and wear during machining. Materials with high wear resistance reduce tool wear but may require more aggressive machining parameters or specialized tool materials.

Wear Resistance: The ability to withstand abrasion and wear during machining. Materials with high wear resistance reduce tool wear but may require more aggressive machining parameters or specialized tool materials.

-

Fracture Toughness: This property measures a material's resistance to crack propagation. Materials with high fracture toughness are less likely to experience catastrophic failure or chipping during machining but may require specific tool geometries to manage chip formation and removal effectively.

Fracture Toughness: This property measures a material's resistance to crack propagation. Materials with high fracture toughness are less likely to experience catastrophic failure or chipping during machining but may require specific tool geometries to manage chip formation and removal effectively.

-

Ductility: Ductile materials can deform significantly before breaking, allowing for more aggressive machining conditions but also posing challenges in terms of maintaining dimensional accuracy and surface finish. Controlling machining parameters and tool paths is critical for machining ductile materials.

Ductility: Ductile materials can deform significantly before breaking, allowing for more aggressive machining conditions but also posing challenges in terms of maintaining dimensional accuracy and surface finish. Controlling machining parameters and tool paths is critical for machining ductile materials.

-

Fatigue Strength: The ability of a material to withstand repeated loading and unloading cycles without failing. Understanding the fatigue strength is crucial for parts subjected to cyclic stresses in their operational life. Machining strategies that minimize surface defects can help improve the fatigue strength of the finished part.

Fatigue Strength: The ability of a material to withstand repeated loading and unloading cycles without failing. Understanding the fatigue strength is crucial for parts subjected to cyclic stresses in their operational life. Machining strategies that minimize surface defects can help improve the fatigue strength of the finished part.

-

Modulus of Elasticity (Young’s Modulus): This property measures the stiffness of a material, or its resistance to elastic deformation under load. Materials with a high modulus of elasticity are stiffer, which can influence the selection of machining parameters to prevent deflection or distortion during the cutting process.

Modulus of Elasticity (Young’s Modulus): This property measures the stiffness of a material, or its resistance to elastic deformation under load. Materials with a high modulus of elasticity are stiffer, which can influence the selection of machining parameters to prevent deflection or distortion during the cutting process.

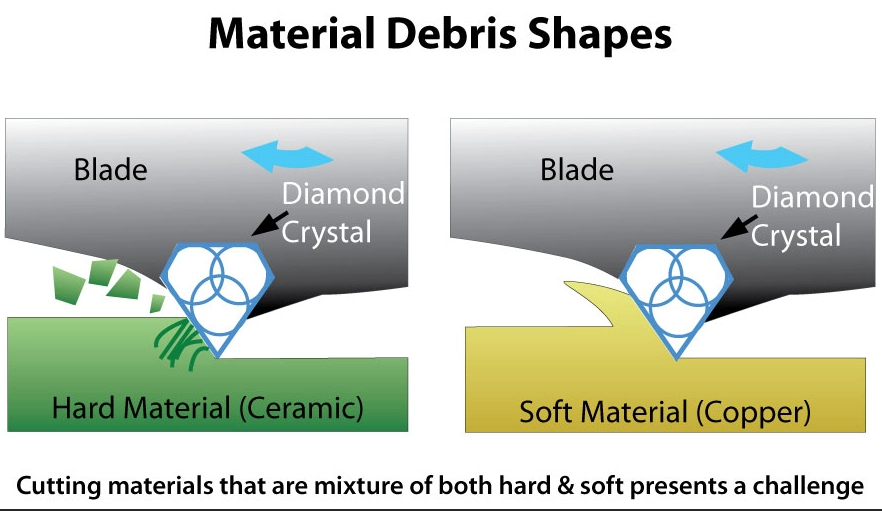

Material Debris / Chipping Type

The shape of material debris, or chips, generated during machining operations is significantly influenced by the material properties of the workpiece, as well as the machining parameters such as tool geometry, cutting speed, feed rate, and depth of cut. Understanding the relationship between material properties and chip formation can provide valuable insights into the machinability of the material, the efficiency of the machining process, and the quality of the finished product. Here's how material properties affect chip shapes and what those shapes can indicate about the machining process:

1. Ductility

-

Materials with High Ductility (e.g., most aluminum alloys, mild steels): These materials tend to produce long, continuous chips. Continuous chips are indicative of smooth cutting but can pose problems with chip evacuation and may lead to a wrapped chip around the tool or workpiece, potentially damaging both.

Materials with High Ductility (e.g., most aluminum alloys, mild steels): These materials tend to produce long, continuous chips. Continuous chips are indicative of smooth cutting but can pose problems with chip evacuation and may lead to a wrapped chip around the tool or workpiece, potentially damaging both.

-

Optimization Strategy: Chip breakers, high-pressure coolant systems, or specific tool geometries can be used to control chip formation and facilitate chip breaking or evacuation.

Optimization Strategy: Chip breakers, high-pressure coolant systems, or specific tool geometries can be used to control chip formation and facilitate chip breaking or evacuation.

2. Hardness

-

Hard Materials (e.g., hardened steels, titanium alloys, ceramics): Hard materials often result in short, brittle chips. These chips indicate that the material is fracturing ahead of the tool edge rather than undergoing plastic deformation.

Hard Materials (e.g., hardened steels, titanium alloys, ceramics): Hard materials often result in short, brittle chips. These chips indicate that the material is fracturing ahead of the tool edge rather than undergoing plastic deformation.

-

Optimization Strategy: Adjustments in tool material (e.g., polycrystalline diamond or cubic boron nitride) and cutting parameters can help manage tool wear and surface finish when working with hard materials.

Optimization Strategy: Adjustments in tool material (e.g., polycrystalline diamond or cubic boron nitride) and cutting parameters can help manage tool wear and surface finish when working with hard materials.

3. Toughness

-

Tough Materials (e.g., nickel-based superalloys, some stainless steels): Tough materials can produce segmented (serrated) chips, which result from a cyclical process of crack initiation, propagation, and fracture due to the material's resistance to shear deformation.

Tough Materials (e.g., nickel-based superalloys, some stainless steels): Tough materials can produce segmented (serrated) chips, which result from a cyclical process of crack initiation, propagation, and fracture due to the material's resistance to shear deformation.

-

Optimization Strategy: Optimizing cutting speed and feed rate, and using tools with reinforced cutting edges can help manage the machining of tough materials.

Optimization Strategy: Optimizing cutting speed and feed rate, and using tools with reinforced cutting edges can help manage the machining of tough materials.

4. Thermal Conductivity

-

Materials with Low Thermal Conductivity (e.g., titanium, Inconel): These materials tend to retain heat in the cutting zone, affecting chip shape and potentially leading to work-hardening of the surface being machined. Chips may be more difficult to predict but can range from segmented to continuous, depending on the specific conditions.

Materials with Low Thermal Conductivity (e.g., titanium, Inconel): These materials tend to retain heat in the cutting zone, affecting chip shape and potentially leading to work-hardening of the surface being machined. Chips may be more difficult to predict but can range from segmented to continuous, depending on the specific conditions.

-

Optimization Strategy: Using coolants effectively to manage temperature and selecting tool materials that can withstand high temperatures can help improve chip formation and surface quality.

Optimization Strategy: Using coolants effectively to manage temperature and selecting tool materials that can withstand high temperatures can help improve chip formation and surface quality.

5. Brittleness

-

Brittle Materials (e.g., cast iron, some ceramics): Brittle materials typically produce powdery chips or small, fragmented pieces due to their inability to undergo significant plastic deformation before fracturing.

Brittle Materials (e.g., cast iron, some ceramics): Brittle materials typically produce powdery chips or small, fragmented pieces due to their inability to undergo significant plastic deformation before fracturing.

-

Optimization Strategy: Using sharp tools and controlling vibration can help minimize surface damage and improve the quality of the machining process for brittle materials.

Optimization Strategy: Using sharp tools and controlling vibration can help minimize surface damage and improve the quality of the machining process for brittle materials.

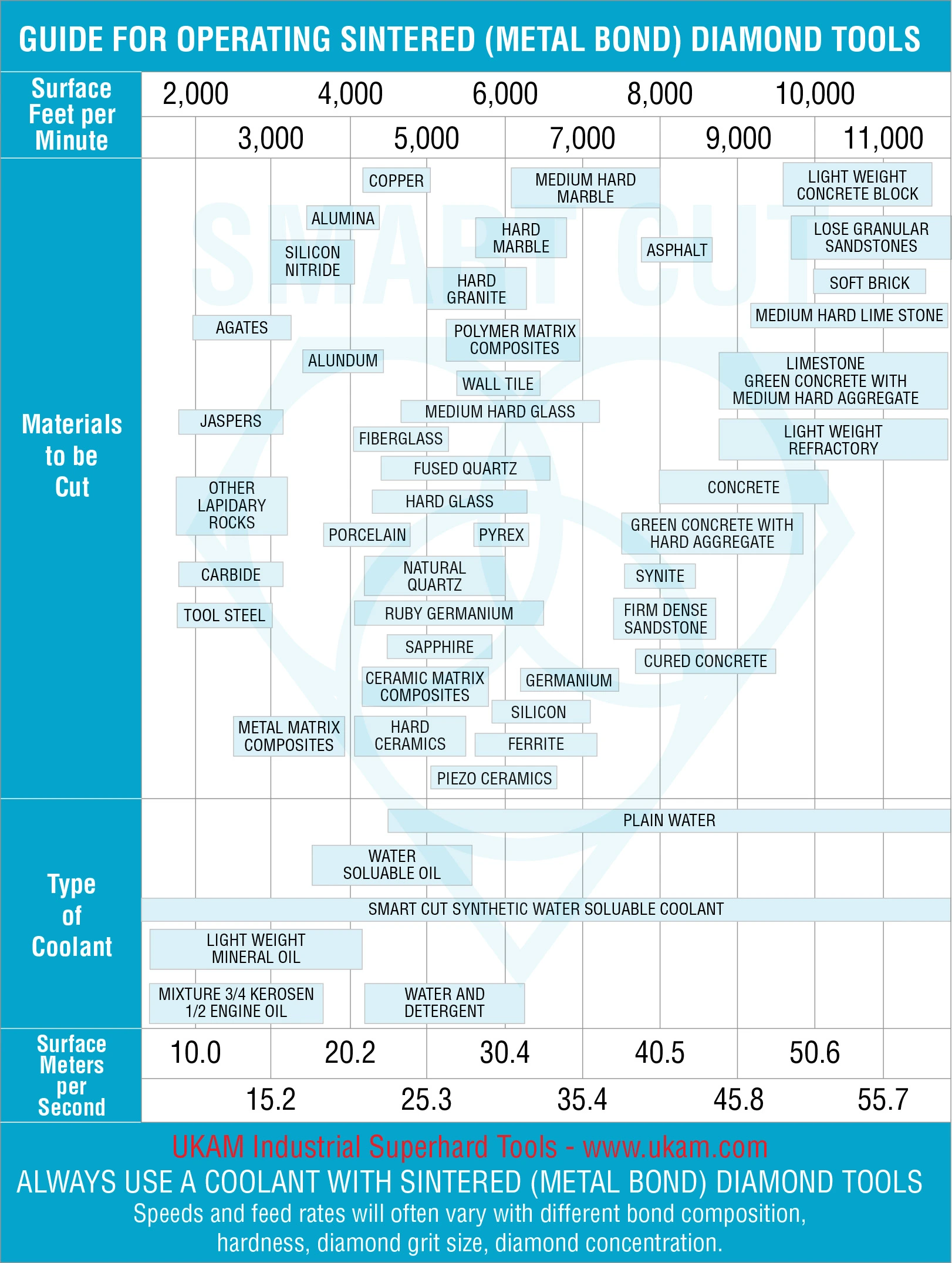

Material Machining Parameters

The material machining parameters such as the RPM’s, fee rate, coolant or lubricant to use depends on the material properties

RPM (Revolutions Per Minute)

The RPM setting determines the speed at which the cutting tool or the workpiece rotates. The correct RPM is crucial for achieving efficient cutting, optimal tool life, and the desired surface finish.

-

Material Hardness: Softer materials typically allow for higher RPMs, while harder materials require lower RPMs to reduce tool wear.

Material Hardness: Softer materials typically allow for higher RPMs, while harder materials require lower RPMs to reduce tool wear.

-

Tool Material and Type: Diamond tools, due to their hardness and wear resistance, often allow for higher RPMs compared to conventional tool materials.

Tool Material and Type: Diamond tools, due to their hardness and wear resistance, often allow for higher RPMs compared to conventional tool materials.

-

Diameter of Tool: The larger the tool diameter, the lower the RPM, following the principle that cutting speed (measured in surface feet per minute or meters per minute) should remain constant.

Diameter of Tool: The larger the tool diameter, the lower the RPM, following the principle that cutting speed (measured in surface feet per minute or meters per minute) should remain constant.

Feed Rate

Feed rate is the speed at which the tool moves through the material or the material moves past the tool. It's typically measured in inches per minute (IPM) or millimeters per minute (MM/min).

-

Material Hardness and Toughness: Tougher materials generally require slower feed rates to reduce the risk of tool breakage and to manage force and heat generation.

Material Hardness and Toughness: Tougher materials generally require slower feed rates to reduce the risk of tool breakage and to manage force and heat generation.

-

Tool Material and Geometry: The strength and design of the cutting tool dictate how aggressively it can cut. Diamond tools can often support higher feed rates due to their exceptional hardness and wear resistance.

Tool Material and Geometry: The strength and design of the cutting tool dictate how aggressively it can cut. Diamond tools can often support higher feed rates due to their exceptional hardness and wear resistance.

-

Operation Type: Finishing operations usually have lower feed rates than roughing operations to achieve a finer surface finish.

Operation Type: Finishing operations usually have lower feed rates than roughing operations to achieve a finer surface finish.

Coolants and Lubricants

Coolants and lubricants serve to reduce heat and friction, flush away chips, and sometimes protect against corrosion. The choice of coolant or lubricant depends on several factors:

-

Material Being Machined: Some materials, such as aluminum, may require water-soluble coolants to prevent overheating, while others, like titanium, might benefit from coolants with extreme pressure additives.

Material Being Machined: Some materials, such as aluminum, may require water-soluble coolants to prevent overheating, while others, like titanium, might benefit from coolants with extreme pressure additives.

-

Machining Operation: Operations like deep-hole drilling require coolants with excellent chip evacuation capabilities.

Machining Operation: Operations like deep-hole drilling require coolants with excellent chip evacuation capabilities.

-

Environmental and Health Considerations: Regulations and workplace safety standards may influence the choice of coolants, pushing towards the use of safer, more environmentally friendly options.

Environmental and Health Considerations: Regulations and workplace safety standards may influence the choice of coolants, pushing towards the use of safer, more environmentally friendly options.

Material Machining Parameters

The material machining parameters such as the RPM’s, fee rate, coolant or lubricant to use depends on the material properties

-

Material Hardness and Toughness: Tougher materials generally require slower feed rates to reduce the risk of tool breakage and to manage force and heat generation.

Material Hardness and Toughness: Tougher materials generally require slower feed rates to reduce the risk of tool breakage and to manage force and heat generation.

-

Tool Material and Geometry: The strength and design of the cutting tool dictate how aggressively it can cut. Diamond tools can often support higher feed rates due to their exceptional hardness and wear resistance.

Tool Material and Geometry: The strength and design of the cutting tool dictate how aggressively it can cut. Diamond tools can often support higher feed rates due to their exceptional hardness and wear resistance.

-

Operation Type: Finishing operations usually have lower feed rates than roughing operations to achieve a finer surface finish.

Operation Type: Finishing operations usually have lower feed rates than roughing operations to achieve a finer surface finish.

Coolants and Lubricants

Coolants and lubricants serve to reduce heat and friction, flush away chips, and sometimes protect against corrosion. The choice of coolant or lubricant depends on several factors:

-

Material Being Machined: Some materials, such as aluminum, may require water-soluble coolants to prevent overheating, while others, like titanium, might benefit from coolants with extreme pressure additives.

Material Being Machined: Some materials, such as aluminum, may require water-soluble coolants to prevent overheating, while others, like titanium, might benefit from coolants with extreme pressure additives.

-

Machining Operation: Operations like deep-hole drilling require coolants with excellent chip evacuation capabilities.

Machining Operation: Operations like deep-hole drilling require coolants with excellent chip evacuation capabilities.

-

Environmental and Health Considerations: Regulations and workplace safety standards may influence the choice of coolants, pushing towards the use of safer, more environmentally friendly options.

Environmental and Health Considerations: Regulations and workplace safety standards may influence the choice of coolants, pushing towards the use of safer, more environmentally friendly options.

Material Comparison Parameters

The material machining parameters such as the RPM’s, fee rate, coolant or lubricant to use depends on the material properties

1. Density (g/cm³)

-

Definition: Density is the mass of a material per unit volume. It's a fundamental physical property that indicates how compactly the atoms or molecules are packed together.

Definition: Density is the mass of a material per unit volume. It's a fundamental physical property that indicates how compactly the atoms or molecules are packed together.

-

Significance: In machining, density affects the weight of the material and can influence the choice of machining parameters, such as feed rates and speeds.

Significance: In machining, density affects the weight of the material and can influence the choice of machining parameters, such as feed rates and speeds.

-

Typical Applications: High-density materials are often used in applications requiring significant weight in a small form factor, like aerospace counterweights or in applications requiring high strength and durability.

Typical Applications: High-density materials are often used in applications requiring significant weight in a small form factor, like aerospace counterweights or in applications requiring high strength and durability.

-

Machining Challenges: Heavier, denser materials may require more power to machine and can lead to increased tool wear.

Machining Challenges: Heavier, denser materials may require more power to machine and can lead to increased tool wear.

2. Hardness (Knoop)

-

Definition: Hardness, measured here by the Knoop scale, is a material's resistance to indentation and abrasion. The Knoop hardness test is specifically suitable for brittle materials or thin sheets.

Definition: Hardness, measured here by the Knoop scale, is a material's resistance to indentation and abrasion. The Knoop hardness test is specifically suitable for brittle materials or thin sheets.

-

Significance: Hardness directly correlates to wear resistance but also to how difficult a material is to machine.

Significance: Hardness directly correlates to wear resistance but also to how difficult a material is to machine.

-

Typical Applications: Hard materials are used in cutting tools, wear-resistant surfaces, and components subjected to high stress.

Typical Applications: Hard materials are used in cutting tools, wear-resistant surfaces, and components subjected to high stress.

-

Machining Challenges: Hard materials can cause rapid tool wear, necessitating the use of harder tool materials like polycrystalline diamond or cubic boron nitride.

Machining Challenges: Hard materials can cause rapid tool wear, necessitating the use of harder tool materials like polycrystalline diamond or cubic boron nitride.

3. Tensile Strength (MPa)

-

Definition: Tensile strength is the maximum stress that a material can withstand while being stretched or pulled before breaking.

Definition: Tensile strength is the maximum stress that a material can withstand while being stretched or pulled before breaking.

-

Significance: It's an important measure of a material's mechanical performance, especially in applications where it is subject to stretching or pulling forces.

Significance: It's an important measure of a material's mechanical performance, especially in applications where it is subject to stretching or pulling forces.

-

Typical Applications: Materials with high tensile strength are used in structures under tension, cables, and fasteners.

Typical Applications: Materials with high tensile strength are used in structures under tension, cables, and fasteners.

-

Machining Challenges: Materials with high tensile strength may be tougher to machine and can lead to increased cutting forces and tool wear.

Machining Challenges: Materials with high tensile strength may be tougher to machine and can lead to increased cutting forces and tool wear.

4. Modulus of Elasticity (GPa)

-

Definition: The modulus of elasticity, or Young's modulus, measures a material's stiffness or rigidity. It's the ratio of stress (force per unit area) to strain (deformation) in the elastic deformation phase.

Definition: The modulus of elasticity, or Young's modulus, measures a material's stiffness or rigidity. It's the ratio of stress (force per unit area) to strain (deformation) in the elastic deformation phase.

-

Significance: A higher modulus indicates a stiffer material. This property is crucial in applications where deflection must be minimized.

Significance: A higher modulus indicates a stiffer material. This property is crucial in applications where deflection must be minimized.

-

Typical Applications: Used in the design of structures and components where precise dimensional control is necessary.

Typical Applications: Used in the design of structures and components where precise dimensional control is necessary.

-

Machining Challenges: Stiffer materials can be more difficult to machine due to higher forces required for deformation and potential for tool deflection.

Machining Challenges: Stiffer materials can be more difficult to machine due to higher forces required for deformation and potential for tool deflection.

5. Thermal Conductivity (W/m·K)

-

Definition: Thermal conductivity is a measure of a material's ability to conduct heat.

Definition: Thermal conductivity is a measure of a material's ability to conduct heat.

-

Significance: It influences how quickly a material can dissipate heat, affecting temperature control during machining.

Significance: It influences how quickly a material can dissipate heat, affecting temperature control during machining.

-

Typical Applications: Materials with high thermal conductivity are used in heat sinks, thermal insulation, and applications requiring efficient heat transfer.

Typical Applications: Materials with high thermal conductivity are used in heat sinks, thermal insulation, and applications requiring efficient heat transfer.

-

Machining Challenges: Materials with low thermal conductivity can retain heat in the cutting zone, potentially affecting tool life and workpiece integrity. High thermal conductivity materials may require different cooling or cutting strategies to manage heat dissipation.

Machining Challenges: Materials with low thermal conductivity can retain heat in the cutting zone, potentially affecting tool life and workpiece integrity. High thermal conductivity materials may require different cooling or cutting strategies to manage heat dissipation.

Advanced Ceramics Materials

|

Material |

Density (g/cm³) |

Hardness (Knoop) |

Tensile Strength (MPa) |

Modulus of Elasticity (GPa) |

Thermal Conductivity (W/m·K) |

Typical Applications |

Machining Challenges |

|---|---|---|---|---|---|---|---|

|

Alumina (Al2O3) |

3.9 - 4.2 |

2000 - 2500 |

250 - 350 |

350 - 400 |

20 - 35 |

Electrical insulation, wear parts, refractory products |

Hard and brittle, requires diamond grinding tools |

|

Silicon Carbide (SiC) |

3.1 - 3.2 |

2800 - 3500 |

400 - 550 |

400 - 450 |

120 - 200 |

Abrasives, refractory materials, semiconductor devices |

Extremely hard, challenging to machine without specialized tools |

|

Beryllia (BeO) |

2.85 |

1000 - 2000 |

300 - 350 |

300 - 320 |

250 - 300 |

Electronic substrates, thermal management components |

Toxic dust, requires handling with safety precautions |

|

Boron Carbide (B4C) |

2.52 |

2750 |

350 - 400 |

450 - 470 |

20 - 30 |

Armor, abrasive materials, nozzles |

Hard and abrasive, difficult to machine and wear on tools |

|

Boron Nitride (BN) |

2.1 - 2.3 |

10 - 20 (Hex) |

N/A |

20 - 700 (Type dependent) |

20 - 600 (Type dependent) |

High-temperature lubricants, insulators |

Soft in hexagonal form, but machining can be challenging due to layer separation |

|

Graphite |

1.5 - 1.8 |

10 - 20 |

10 - 50 |

9 - 15 |

120 - 140 |

Electrodes, refractories, lubricants |

Brittle and messy, can contaminate if not carefully handled |

|

Piezoelectric Compositions |

Varied |

Varied |

Varied |

Varied |

Varied |

Sensors, actuators, transducers |

Material sensitivity requires precise machining methods |

|

Pyrite |

4.9 - 5.2 |

600 - 650 |

N/A |

N/A |

0.1 - 0.25 |

Decorative use, mineral collections |

Not typically machined for industrial applications |

|

Sapphire |

3.95 - 4.03 |

2000 |

400 - 600 |

345 - 400 |

25 - 35 |

Watch crystals, substrates, optical components |

Very hard, requires diamond sawing and polishing |

|

Zirconia (ZrO2) |

5.5 - 6.0 |

1200 - 1400 |

200 - 240 |

200 - 210 |

2 - 3 |

Biomedical implants, cutting tools, oxygen sensors |

Tough and wear-resistant, requires diamond or cubic boron nitride (CBN) tools |

|

Steatite |

2.7 - 2.8 |

800 - 850 |

70 - 100 |

100 - 120 |

2.5 - 3.5 |

Electrical insulators, ceramic mounts |

Easier to machine than harder ceramics, but still requires care to prevent chipping |

|

Cordierite |

2.5 - 2.8 |

700 - 900 |

50 - 100 |

50 - 100 |

1 - 3 |

Kiln furniture, heat exchangers |

Low thermal expansion but can be brittle, careful machining needed |

|

Ferrites |

4.5 - 5.0 |

600 - 630 |

N/A |

N/A |

5 - 10 |

Magnetic cores, inductors, transformers |

Brittle and magnetic, can be challenging to machine without affecting magnetic properties |

Composite Materials

|

Material |

Density (g/cm³) |

Knoop Hardness (kg/mm²) |

Mohs Hardness |

Tensile Strength (MPa) |

Thermal Conductivity (W/m·K) |

Typical Applications |

Machining Challenges |

|---|---|---|---|---|---|---|---|

|

Polymer Matrix Composites (PMC) |

Varied |

Varied |

Varied |

Varied |

Varied |

Aerospace, automotive parts |

Cutting may cause delamination; requires special tools. |

|

Metal Matrix Composites (MMC) |

Varied |

Varied |

Varied |

Varied |

Varied |

High-performance automotive and aerospace components |

Abrasive on tools, challenging to machine. |

|

Ceramic Matrix Composites (CMC) |

Varied |

Varied |

Varied |

Varied |

Varied |

Aerospace engines, thermal protection systems |

Very hard; requires specialized machining processes. |

|

Graphite Carbide |

2.1 - 2.2 |

2500 - 2800 |

9-10 |

N/A |

120 - 200 |

High-temperature environments, mechanical seals |

Brittle, producing conductive dust during machining. |

|

Honeycomb Structures |

Very Low |

N/A |

N/A |

Varied |

Very Low |

Aerospace and automotive sectors for lightweight structures |

Requires precise cutting techniques to prevent crushing. |

|

Fiber (General) |

Varied |

Varied |

Varied |

Varied |

Varied |

Reinforcement materials in composites |

Can be difficult to cut without fraying; abrasive on tools. |

|

Resin |

1.1 - 1.2 |

15-30 |

1-2 |

55 - 70 |

0.1 - 0.5 |

Matrix materials in composites, adhesives |

Sticky residue can gum up tools; requires careful curing. |

|

Aramid Fibers |

1.44 |

500-600 |

2-3 |

3620 - 4340 |

0.04 - 0.58 |

Bulletproof vests, high-strength ropes |

Abrasive to cutting tools; challenging to cut cleanly. |

|

Carbon Fibers |

1.75 - 2.0 |

1000-1100 |

10 |

3500 - 7000 |

2 - 5 |

High-performance composites, sporting goods |

Requires diamond-coated tools for clean cuts. |

|

Boron |

2.34 |

3000 |

9-10 |

3100 - 3800 |

27 |

Aerospace structures, neutron absorbers |

Very hard and brittle; difficult to process. |

|

E-Glass |

2.54 |

600 |

6 |

3400 |

1.0 |

Glass-reinforced plastics, electrical insulation |

Wear on tools; handling glass fibers requires care. |

|

S-Glass |

2.49 |

610 |

6 |

4570 |

1.0 |

Aerospace and military applications for high-strength composites |

Similar to E-Glass but with higher wear on tools. |

|

Silicon Carbide (SiC) |

3.1 - 3.2 |

2485 - 2970 |

9-10 |

400 - 550 |

120 - 200 |

Abrasives, brake discs, high-temperature parts |

Extremely hard, requiring diamond tools for machining. |

|

Silicon Nitride (Si3N4) |

3.2 - 3.4 |

1200 - 1500 |

8-9 |

600 - 900 |

15 - 30 |

Bearings, cutting tools, engine parts |

Hard and brittle; specialized equipment needed for machining. |

|

Titanium |

4.506 |

800 - 850 |

6 |

900 - 1200 |

22 |

Aerospace, medical implants, high-performance automotive |

Work hardening and high chemical reactivity with tools. |

|

Diboride (Assuming B4C) |

2.52 |

2800 - 3500 |

9-10 |

350 - 400 |

20 - 30 |

Armor, abrasive applications |

Extreme hardness and abrasiveness to tools. |

Construction Materials

|

Material Category |

Density (kg/m³) |

Compressive Strength (MPa) |

Knoop Hardness (kg/mm²) |

Mohs Hardness |

Typical Applications |

|---|---|---|---|---|---|

|

Asphalt |

2,300 - 2,500 |

N/A |

N/A |

-2 |

Highways, driveways |

|

Concrete |

2,400 |

20 - 40 |

N/A |

-3 |

Structural components |

|

Cured Concrete |

2,400 |

20 - 40 (Increases with age) |

N/A |

-3 |

Same as concrete |

|

Reinforced Concrete |

2,400 |

20 - 40 (Varies) |

N/A |

-3 |

Buildings, bridges |

|

Green Concrete |

2,300 - 2,500 |

20 - 40 |

N/A |

-3 |

Eco-friendly projects |

|

Masonry |

500 - 2,000 |

2 - 30 |

Varies |

Varies |

Walls, partitions |

|

Bricks |

1,600 - 1,900 |

10 - 35 |

-1000 |

-6.5 |

Walls, pavements |

|

Natural Stone |

2,200 - 2,700 |

50 - 200 |

Varies |

2 - 7 |

Facades, countertops |

|

Artificial Stone |

1,800 - 2,400 |

30 - 100 |

N/A |

-3 - 7 |

Decorative elements |

|

Abrasive Materials |

Varies |

N/A |

Varies |

Varies |

Surface treatment |

|

Building Materials |

Varies |

Varies |

N/A |

N/A |

Construction |

|

Paving |

Varies |

N/A |

N/A |

N/A |

Walkways, patios |

|

Sidewalks |

N/A |

N/A |

N/A |

N/A |

Pedestrian paths |

|

Expansion Joints |

N/A |

N/A |

N/A |

N/A |

Thermal expansion |

Glass Materials

|

Material |

Density (kg/m³) |

Compressive Strength (MPa) |

Knoop Hardness (kg/mm²) |

Mohs Hardness |

Typical Applications |

Machining Challenges |

|---|---|---|---|---|---|---|

|

Soda Lime Glass |

2500 |

1000 |

585 |

5 |

Bottles, windows, glassware |

Brittle; sensitive to thermal shock |

|

Borosilicate Glass |

2230 |

820 |

620 |

6 |

Lab glassware, cookware, thermal windows |

Lower thermal expansion but still requires careful handling |

|

Ceramic Glass |

2500 |

N/A |

N/A |

N/A |

Cooktops, fireplace doors |

High hardness and thermal resistance complicate cutting/drilling |

|

Quartz Glass |

2200 |

1100 |

820 |

7 |

High-temperature optics, semiconductor processes |

Extreme hardness and brittleness; specialized tools required |

|

Pyrex (Brand) |

2230 |

820 |

620 |

6 |

Cookware, lab equipment |

Similar to borosilicate; durable but needs careful machining |

|

Optical Glass |

Varies |

N/A |

Varies |

Varies |

Lenses, prisms, optical instruments |

Requires precision to maintain optical properties |

|

Electronic Glass |

Varies |

N/A |

Varies |

N/A |

Displays, semiconductors |

Thin and fragile; often processed via etching or laser cutting |

|

Technical Glass |

Varies |

N/A |

Varies |

N/A |

Industrial, scientific applications |

Specific challenges depend on glass type; often requires custom processing |

|

Glass Tubing |

2500 |

1000 |

585 |

5 |

Lab glassware, architectural elements |

Risk of cracking; requires delicate handling and cutting techniques |

|

Photonics |

Varies |

N/A |

Varies |

N/A |

Fiber optics, laser technology |

Precision cutting and assembly are critical to maintain function |

|

Glass Components |

Varies |

N/A |

Varies |

N/A |

Varied industrial, commercial uses |

Complex shapes demand precise and careful machining |

|

Borofloat Glass |

2230 |

820 |

620 |

6 |

Specialty applications with thermal shock resistance |

Similar to borosilicate with added challenges due to size and thickness |

|

Stained Glass |

2500 |

N/A |

N/A |

N/A |

Artistic installations, windows |

Requires artistic cutting techniques; fragility is a concern |

|

Art Glass |

Varies |

N/A |

N/A |

N/A |

Decorative items, artwork |

Custom designs necessitate precise and often hand-crafted machining |

|

Glass Assemblies |

Varies |

N/A |

N/A |

N/A |

Complex components, architectural structures |

Assembly precision is key; individual components may have unique challenges |

|

Float Glass |

2500 |

1000 |

585 |

5 |

Windows, mirrors, general building glass |

Large sheets require scoring and breaking; risk of sharp edges |

|

Fused Silica/Fused Quartz |

2200 |

1100 |

820 |

7 |

High-precision optics, UV transmission |

Very hard and brittle; requires diamond tools for effective machining |

|

Automotive Glass |

2500 |

N/A |

N/A |

5-6 |

Windshields, side windows |

Laminated and tempered types pose different machining challenges |

|

Flat Glass |

2500 |

1000 |

585 |

5 |

General purpose glass in buildings, vehicles |

Similar to float glass; must be cut to size with care |

| 1737F Glass |

Varies |

N/A |

N/A |

N/A |

Electronic substrates, display glass |

Specifically formulated for electronics; machining often involves scribing and breaking |

|

B270/Crown Glass |

Varies |

N/A |

Varies |

Varies |

Optical applications, high clarity needs |

Requires precision machining for optical clarity |

| Tempered Glass |

2500 |

N/A |

620-670 |

6-7 |

Safety applications, vehicles, buildings |

Cannot be machined after tempering due to risk of shattering |

Stone Materials

|

Material |

Density (kg/m³) |

Compressive Strength (MPa) |

Knoop Hardness (kg/mm²) |

Mohs Hardness |

Typical Applications |

Machining Challenges |

|---|---|---|---|---|---|---|

|

Granite |

2600-3000 |

100-250 |

1400-2000 |

6-7 |

Countertops, flooring |

Hardness requires diamond tools |

|

Marble |

2500-2800 |

70-100 |

200-400 |

3-5 |

Sculpture, architecture |

Softness leads to scratches; acid sensitivity |

|

Limestone |

2300-2600 |

30-250 |

150-200 |

3-4 |

Building facades, flooring |

Susceptible to acid erosion |

|

Marble-Limestone |

Varies |

Varies |

Varies |

3-5 |

Decorative interior elements |

Combination of marble and limestone challenges |

|

Onyx |

2500-2700 |

70 |

100-200 |

6-7 |

Decorative items, jewelry |

Can be brittle; care in cutting required |

|

Quartz |

2600 |

70-90 |

1200-1300 |

7 |

Countertops, decorative items |

Hard; abrasive to cutting tools |

|

Porcelain |

2400-2600 |

35-50 |

800-1000 |

7-8 |

Tiles, sanitary ware |

Hardness; requires diamond tools for cutting |

|

Sandstone |

2200-2700 |

20-170 |

200-300 |

6-7 |

Building and paving materials |

Porosity varies; can wear tools |

|

Serpentine |

2500-2600 |

100-200 |

150-200 |

3-6 |

Countertops, decorative art |

Soft, may contain asbestos which poses health risk |

|

Soapstone |

2700-3000 |

40-70 |

100-200 |

1 |

Countertops, carving |

Soft; easy to scratch and cut |

|

Flagstone |

Varies |

Varies |

Varies |

Varies |

Paving, patios |

Variability in hardness and porosity |

|

Quarry Tile |

2000-2200 |

30-50 |

500-800 |

7-8 |

Flooring, paving |

Hard and durable; abrasive on tools |

|

Slate |

2700-2800 |

50-200 |

150-300 |

5-6 |

Roofing, flooring |

Cleavage planes can be a challenge in cutting |

|

Engineered Stone |

2400-2500 |

50-90 |

1200-1400 |

7 |

Countertops, flooring |

Consistent but hard; wears tools |

|

Composite Stone |

Varies |

Varies |

Varies |

Varies |

Construction, decorative uses |

Depends on the composite materials; varied challenges |

|

Precious & Semi-precious Stone |

Varies |

Varies |

Varies |

7-10 |

Jewelry, decorative items |

Hardness varies; some stones very brittle |

|

Porphyry |

2500-2800 |

150-250 |

2000-3000 |

6-7 |

Paving, columns |

Hard and tough; difficult to work |

|

Cantera |

2100-2400 |

15-40 |

100-200 |

3-4 |

Sculpture, architectural elements |

Soft; easier to shape but can erode |

|

Black Granite |

2900-3100 |

100-250 |

1400-2000 |

6-7 |

Countertops, memorials |

Similar to granite; requires diamond tools |

|

Basalt |

2800-3000 |

150-300 |

500-600 |

6 |

Paving, tiles |

Hard and abrasive; tough on machinery |

|

Bluestone |

2700-3000 |

100-200 |

300-700 |

5-6 |

Paving, architectural details |

Hard; can vary in composition |

|

Calcarenite |

2200-2500 |

20-70 |

100-200 |

3-4 |

Building materials |

Soft and porous; easy to work but less durable |

|

Greenstone |

2900-3100 |

100-250 |

400-600 |

5-7 |

Architectural, ornamental uses |

Tough; varies in hardness |

Lapidary Materials

|

Material |

Density (kg/m³) |

Knoop Hardness (kg/mm²) |

Mohs Hardness |

Typical Applications |

Machining Challenges |

|---|---|---|---|---|---|

|

Agate |

2600 |

800 |

6.5-7 |

Jewelry, decorative items |

Hardness requires specialized cutting tools |

|

Ametrine |

2650 |

1050 |

7 |

Jewelry |

Color zoning can challenge even cutting |

|

Amethyst |

2650 |

750 |

7 |

Jewelry, decorative arts |

Susceptible to heat damage during cutting |

|

Azurite |

3800 |

N/A |

3.5-4 |

Mineral collections, pigments |

Soft, easy to carve but prone to scratching |

|

Cubic Zirconia |

5800 |

1200-1400 |

8.5 |

Jewelry (diamond substitute) |

Requires diamond-coated tools for cutting |

|

Emerald |

2710 |

1350 |

7.5-8 |

High-end jewelry |

Inclusions can make cutting and setting challenging |

|

Garnet |

3900 |

1300 |

6.5-7.5 |

Abrasives, jewelry |

Variability in hardness among types |

|

Gemstones |

Varies |

Varies |

Varies |

Jewelry, decoration |

Cutting to maximize beauty often requires expertise |

|

Jade |

3300 |

1200 |

6-7 |

Carvings, jewelry |

Toughness makes carving labor-intensive |

|

Quartz |

2650 |

1200 |

7 |

Jewelry, decorative items |

Hardness; abrasive to cutting tools |

|

Lapis Lazuli |

2500-2800 |

N/A |

5-5.5 |

Jewelry, decoration |

Soft; susceptible to scratching during machining |

|

Meteorites |

Varies |

N/A |

Varies |

Collectibles, jewelry |

Metal content and structure complicate cutting |

|

Opal |

2100-2500 |

700 |

5.5-6.5 |

Jewelry |

Fragility requires careful handling to prevent cracking |

|

Onyx |

2500-2700 |

100-200 |

6-7 |

Jewelry, decorative items |

Can be brittle; care in cutting required |

|

Petrified Wood |

2200-2400 |

N/A |

7-8 |

Decorative items, jewelry |

Hardness varies; some pieces can be tough to polish |

|

Rhodonite |

3400-3600 |

N/A |

5.5-6.5 |

Jewelry, carvings |

Can show cleavage; careful cutting necessary |

|

Rough Gem Stone |

Varies |

Varies |

Varies |

Jewelry (prior to cutting/polishing) |

Each stone type presents unique challenges |

|

Ruby |

4000 |

1800 |

9 |

High-end jewelry |

Hardness requires diamond cutting tools |

|

Tanzanite |

3350 |

700 |

6.5-7 |

Jewelry |

Risk of thermal shock; careful heating during cutting |

|

Topaz |

3500 |

1350 |

8 |

Jewelry |

Cleavage planes require careful handling |

|

Tourmaline |

3000-3300 |

1000-1100 |

7-7.5 |

Jewelry |

Broad color range; some colors more prone to cracking |

|

Tsavorite |

3700 |

1600-1800 |

7-7.5 |

Jewelry |

Similar to garnet; requires careful cutting due to inclusions |

|

Turquoise |

2700-2900 |

N/A |

5-6 |

Jewelry, decoration |

Porous nature makes it sensitive to chemicals and pressure |

Optical Glass / Photonic Materials

|

Material |

Density (kg/m³) |

Knoop Hardness (kg/mm²) |

Mohs Hardness |

Typical Applications |

Machining Challenges |

|---|---|---|---|---|---|

|

UV Materials |

Varies |

Varies |

Varies |

UV optics, lithography |

Material-specific; often require diamond tooling for precision shaping |

|

Excimer Grade Fused Silica |

-2200 |

500-600 |

7 |

UV laser systems |

Brittle, requiring careful handling; diamond grinding/polishing |

|

UV Grade CaF2 |

-3180 |

158-160 |

4 |

UV lenses, windows |

Soft, cleavage planes present machining challenges |

|

Quartz |

-2650 |

820 |

7 |

Optical components, quartz heaters |

Hardness requires diamond tooling; prone to thermal shock |

|

BK-7 |

-2510 |

610 |

6 |

General optical applications |

Relatively easy to machine but requires precision polishing |

|

ZKN-7 |

Varies |

Varies |

Varies |

High refractive index optics |

Specific data not widely available; similar challenges to other optical glasses |

|

Pyrex/Tempax |

-2230 |

418 |

5-6 |

Lab equipment, cookware |

Thermal resistant, but still requires careful thermal management |

|

Various Flint Types |

Varies |

Varies |

Varies |

Corrective lenses, prisms |

Hard and brittle, varying widely with specific composition |

|

Various Crown Types |

Varies |

Varies |

Varies |

Eyeglass lenses, low dispersion optics |

Easier to machine than flint types, but precision is key |

|

Various Filter Types |

Varies |

Varies |

Varies |

Filters for cameras, telescopes |

Machining less of a concern than coating and assembly precision |

|

Borofloat Glass |

-2230 |

620 |

6 |

Specialty optics, substrates |

Resistant to thermal shock, but machining requires diamond tools |

|

Mirror Substrate Material |

Varies |

Varies |

Varies |

Telescope mirrors, laser mirrors |

Depends on material; glass substrates require careful polishing |

|

Zerodur |

-2530 |

Varies |

-8 |

Telescope mirrors, precision optics |

Very hard and zero expansion; requires specialized equipment for shaping |

|

Ule |

-2210 |

Varies |

Varies |

Telescope mirrors, metrology components |

Very low thermal expansion; machining is specialized and costly |

|

Stainless Steel |

-8000 |

160-500 |

3-4 |

Optical system frames |

Relatively easy to machine but hardens with work; corrosion-resistant |

|

Aluminum |

-2700 |

250-350 |

2.5-3 |

Mirror coatings, mounts |

Easy to machine but requires finishing to prevent oxidation |

|

IR Material |

Varies |

Varies |

Varies |

IR optics, windows |

Specific to material; e.g., Germanium is brittle and requires careful handling |

|

Silicon |

-2330 |

1150 |

7 |

Mirrors, lenses in IR systems |

Brittle, requiring diamond grinding and careful handling |

|

Germanium |

-5323 |

780 |

6 |

IR lenses, windows |

Brittle and sensitive to thermal shock; expensive to machine |

|

ZnSe |

-5240 |

120 |

2.5 |

CO2 laser optics, IR windows |

Soft but toxic dust requires careful handling and machining |

|

ZnS |

-4090 |

210 |

3 |

IR windows, lenses |

Soft, can be machined but generates hazardous dust |

|

Glass |

Varies |

Varies |

Varies |

General optics, windows, lenses |

Challenges depend on type; generally requires diamond tooling for shaping |

Semiconductor Materials

|

Material |

Density (kg/m³) |

Knoop Hardness (kg/mm²) |

Mohs Hardness |

Typical Applications |

Machining Challenges |

|---|---|---|---|---|---|

|

Silicon (Si) |

-2330 |

1150 |

7 |

Brittle, requires diamond cutting tools |

|

|

Germanium (Ge) |

-5323 |

780 |

6 |

IR optics, semiconductor devices |

Sensitive to thermal shock, toxic dust |

|

Gallium Arsenide (GaAs) |

-5317 |

750 |

-6 |

High-speed electronic devices |

Toxicity of arsenic requires careful handling |

|

Gallium Nitride (GaN) |

-6150 |

1300 |

-9 |

LED, high-frequency devices |

Hard and brittle; difficult to cut |

|

Indium Phosphide (InP) |

-4810 |

580 |

-6 |

Telecommunications, photonic devices |

Toxic material; requires protective measures |

|

Silicon Carbide (SiC) |

-3210 |

2480 |

-9-10 |

Power electronics, high-temperature applications |

Extreme hardness; diamond tools necessary |

|

Aluminum Gallium Arsenide (AlGaAs) |

-4810 |

Varies |

Varies |

Optoelectronics, laser diodes |

Similar to GaAs; handling arsenic content |

|

Indium Gallium Arsenide (InGaAs) |

-5870 |

Varies |

Varies |

NIR detectors, high-speed electronics |

Fragile and expensive to produce |

|

Cadmium Telluride (CdTe) |

-6240 |

Varies |

-2 |

Solar panels |

Toxic; requires handling in controlled environments |

|

Gallium Phosphide (GaP) |

-4070 |

Varies |

-6 |

LEDs, semiconductor devices |

Brittle, similar challenges to GaAs |

|

Silicon Germanium (SiGe) |

Varies |

Varies |

Varies |

Heterojunction transistors, RF applications |

Handling similar to silicon but with adjusted parameters |

|

Zinc Selenide (ZnSe) |

-5240 |

120 |

2.5 |

IR optics, CO2 laser systems |

Soft, but toxic dust requires care in machining |

|

Lead Sulfide (PbS) |

-7500 |

Varies |

-3 |

IR detectors, photodetectors |

Toxicity of lead and sensitivity to moisture |

|

Cadmium Selenide (CdSe) |

-5820 |

Varies |

-2 |

Quantum dots, optoelectronic devices |

Toxicity requires careful environmental controls |

|

Silicon Germanium Carbon (SiGeC) |

Varies |

Varies |

Varies |

Electronics, heterojunction bipolar transistors |

Specifics depend on the Si/Ge/C ratios |

|

Copper Indium Gallium Selenide (CIGS) |

Varies |

Varies |

Varies |

Thin-film solar cells |

Complexity in deposition, toxicity concerns |

|

Aluminum Nitride (AlN) |

-3260 |

1200 |

-9 |

Electronic substrates, microwave devices |

Hard and brittle; diamond tools for machining |

|

Cadmium Sulfide (CdS) |

-4820 |

Varies |

-2-3 |

Photocells, thin-film transistors |

Toxic; careful handling required |

|

Silicon Oxide (SiO2) |

-2200 |

820 |

7 |

Optical fibers, microelectronics |

Brittle; requires specialized cutting techniques |

|

Zinc Telluride (ZnTe) |

-6700 |

Varies |

-2 |

Solar cells, semiconductor layers |

Soft, but care must be taken due to toxicity |

|

Zinc Oxide (ZnO) |

-5600 |

200 |

4 |

Varistors, transparent conductors |

Abrasive; requires careful machining |

|

Gallium Antimonide (GaSb) |

-5900 |

Varies |

-5 |

IR components, thermophotovoltaic devices |

Similar handling to GaAs with additional antimony considerations |

|

Silicon Germanium Tin (SiGeSn) |

Varies |

Varies |

Varies |

Electronic and photonic devices |

Complex composition adds to machining difficulty |

|

Cadmium Zinc Telluride (CdZnTe) |

Varies |

Varies |

-2 |

Radiation detectors, solar cells |

Toxic and brittle; requires special care |

|

Mercury Cadmium Telluride (HgCdTe) |

Varies |

Varies |

-2 |

IR detectors |

Extremely toxic and sensitive; specialized facilities needed |

Metallography Materials

|

Material |

Density (kg/m³) |

Knoop Hardness (kg/mm²) |

Mohs Hardness |

Typical Applications |

Machining Challenges |

|---|---|---|---|---|---|

|

Steel (various grades) |

7800-8050 |

120-700 |

4-8 |

Construction, tools |

Variability in hardness, depending on alloy and heat treatment |

|

Aluminum (various alloys) |

2700 |

250-350 |

2.5-3 |

Aerospace, automotive |

Soft, can stick to tools, requires sharp cutters |

|

Copper |

8960 |

210 |

3 |

Electrical wiring, plumbing |

Soft, malleable, can work harden |

|

Titanium (various alloys) |

4500 |

800 |

6 |

Aerospace, medical devices |

Hard, reactive to oxygen at high temperatures |

|

Nickel-based alloys (Inconel) |

8200-8500 |

300-550 |

5-7 |

Jet engines, chemical plants |

Very hard, abrasive, generates heat during machining |

|

Magnesium (various alloys) |

1740-1880 |

N/A |

2.5 |

Lightweight structures, automotive |

Flammable as dust, requires careful handling |

|

Cast Iron |

6800-7300 |

210-410 |

4-5 |

Machinery parts, cookware |

Brittle, can wear tools quickly |

|

Adhesives and Sealants |

Varies |

N/A |

N/A |

Joining materials, sealing |

N/A (not typically machined) |

|

Stainless Steel (various grades) |

7900-8000 |

250-700 |

4-6 |

Kitchenware, medical instruments |

Work hardening, requires lubrication and coolants |

|

Brass |

8530-8730 |

200 |

3 |

Decorative, musical instruments |

Soft, easy to machine but requires sharp tools |

|

Bronze |

7700-8900 |

300 |

3 |

Bearings, historical artifacts |

Harder than brass, can be tough on tools |

|

Zinc |

7140 |

120 |

2.5 |

Corrosion protection coatings |

Low melting point, easy to machine |

|

Glass |

2200-2500 |

500-600 |

5-6 |

Windows, lenses |

Brittle, requires diamond-coated tools for machining |

|

Cobalt-based alloys |

8300-8900 |

300-700 |

5-7 |

Medical implants, turbines |

Hard and tough, requires advanced machining techniques |

|

Superalloys (Hastelloy) |

8000-9000 |

300-500 |

5-7 |

Aerospace, chemical reactors |

Difficult to machine, requires specialized tools |

|

Ceramics (alumina, zirconia) |

3800-5800 |

1000-1500 |

8.5-9 |

Biomedical implants, cutting tools |

Very hard, brittle, requires diamond grinding |

|

Polymers (plastics, elastomers) |

900-1400 |

N/A |

N/A |

Consumer goods, automotive |

Can melt or deform if not machined at correct speeds |

|

Coatings (paints, thermal spray coatings) |

Varies |

N/A |

N/A |

Surface protection, decoration |

N/A (applied, not machined) |

|

Semiconductor materials (silicon, GaAs) |

2330-5317 |

850-1100 |

7 |

Electronics, solar cells |

Brittle, requires precision handling |

|

Refractory metals (tungsten, molybdenum) |

19250-10280 |

2000-4000 |

7-7.5 |

High-temperature applications |

Very hard, high melting points, challenging to machine |

|

Precious metals (gold, silver) |

19300-10490 |

25-70 |

2.5-3 |

Jewelry, electronics |

Soft, malleable, requires care to avoid deformation |

|

Refractory ceramics (boron nitride) |

2000-3500 |

10-20 |

1-2 |

High-temperature insulators |

Soft in one direction, hard in another, challenging to shape precisely |

|

Electronic materials |

Varies |

Varies |

Varies |

Electronics, PCBs |

Specific to material; e.g., PCBs require etching, not machining |

|

Biomaterials (biodegradable polymers) |

1100-1400 |

N/A |

N/A |

Medical devices, tissue engineering |

Sensitive to heat and moisture, can be difficult to process |

Ayan Sadyk is a materials scientist and process engineer with over two decades of experience in the industrial diamond tooling sector. His expertise lies in integrating ultra-thin diamond blades, CBN wheels, and advanced cutting systems into precision manufacturing workflows for applications in optics, semiconductors, and technical ceramics.

With a background in materials behavior and surface integrity, Mr. Sadyk brings a data-driven, application-specific approach to cutting and grinding process development. He has worked closely with manufacturers and R&D facilities across Eastern Europe, North America, and the Middle East, helping optimize tool life, surface finish, and process stability.

As an author, he focuses on bridging materials science with tooling innovation—writing on topics such as blade wear mechanisms, thermal effects in hard material sectioning, and adaptive process design.

ARE YOU USING RIGHT TOOLS

FOR YOUR APPLICATION?

LET US

HELP YOU

HAVING ISSUES WITH

YOUR CURRENT TOOLS?

Knowledge Center

Diamond Tool Coolants Why, How, When & Where to Use

Selecting the Right Coolant Method for your Diamond & CBN Tools

How to Selecting Right Diamond Tools for your application

How to properly use Diamond Tools

Why use diamond

Diamond vs CBN (cubic boron nitride) Tools

What is Diamond Mesh Size and how to select best one for your application

What is Diamond Concentration and which to use for your application

Choosing The Correct Diamond Bond Type

Ayan Sadyk is a materials scientist and process engineer with over two decades of experience in the industrial diamond tooling sector. His expertise lies in integrating ultra-thin diamond blades, CBN wheels, and advanced cutting systems into precision manufacturing workflows for applications in optics, semiconductors, and technical ceramics.

With a background in materials behavior and surface integrity, Mr. Sadyk brings a data-driven, application-specific approach to cutting and grinding process development. He has worked closely with manufacturers and R&D facilities across Eastern Europe, North America, and the Middle East, helping optimize tool life, surface finish, and process stability.

As an author, he focuses on bridging materials science with tooling innovation—writing on topics such as blade wear mechanisms, thermal effects in hard material sectioning, and adaptive process design.