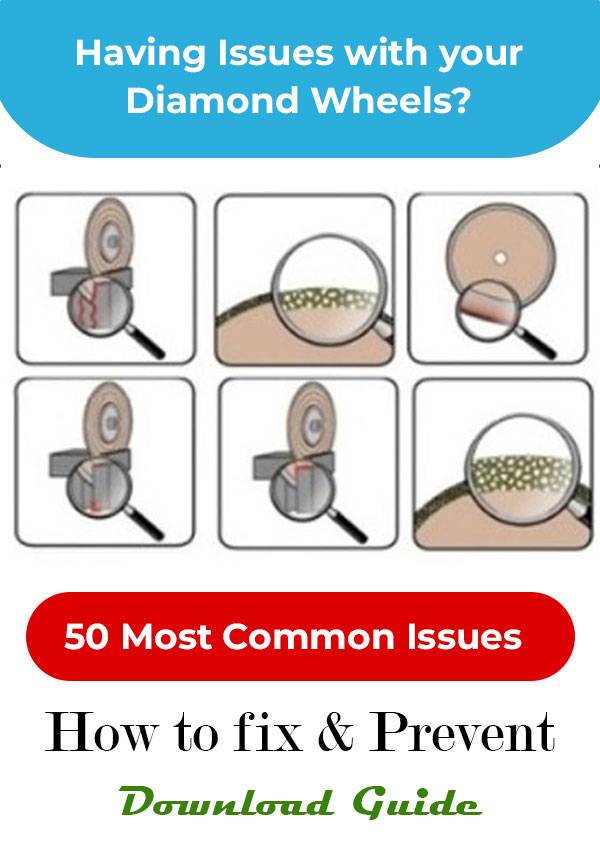

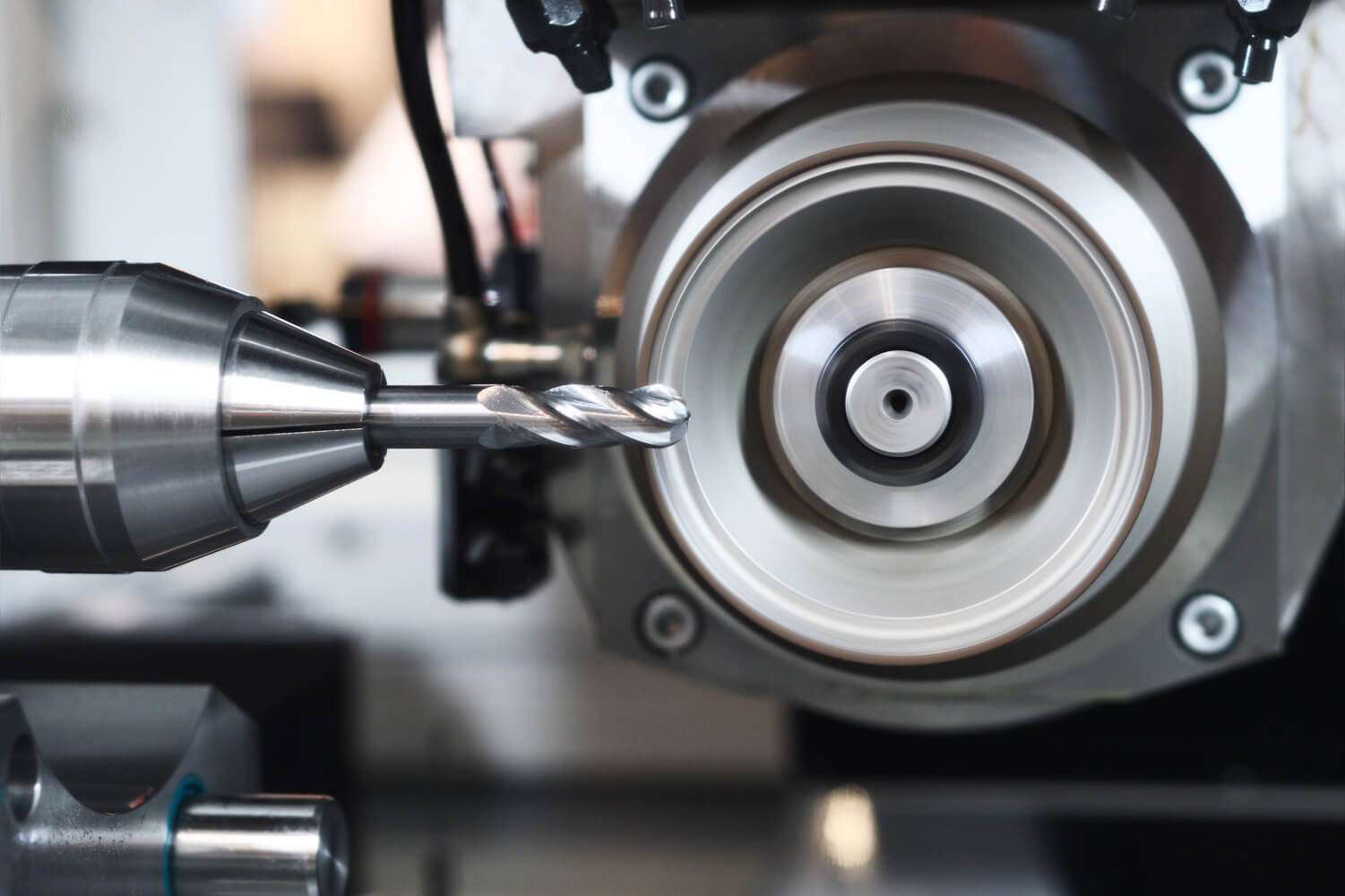

Electroplated Diamond Twist Drills

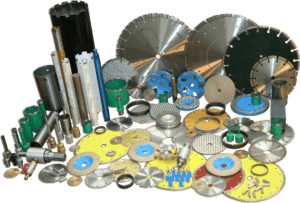

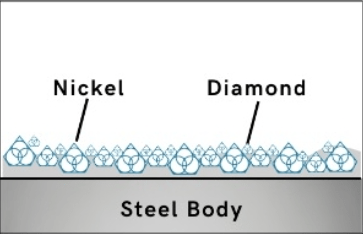

How SMART CUT ® Bond Works?

Sharpest And Finest Quality Diamonds

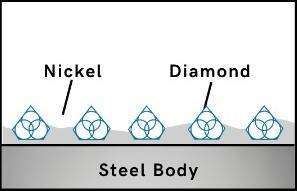

Diamonds or CB Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT ® Bond Diamond Bond makes sure every diamond is in the right place. and at the right time, working where you need it most.

Diamonds or CBN Crystals

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT ® remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

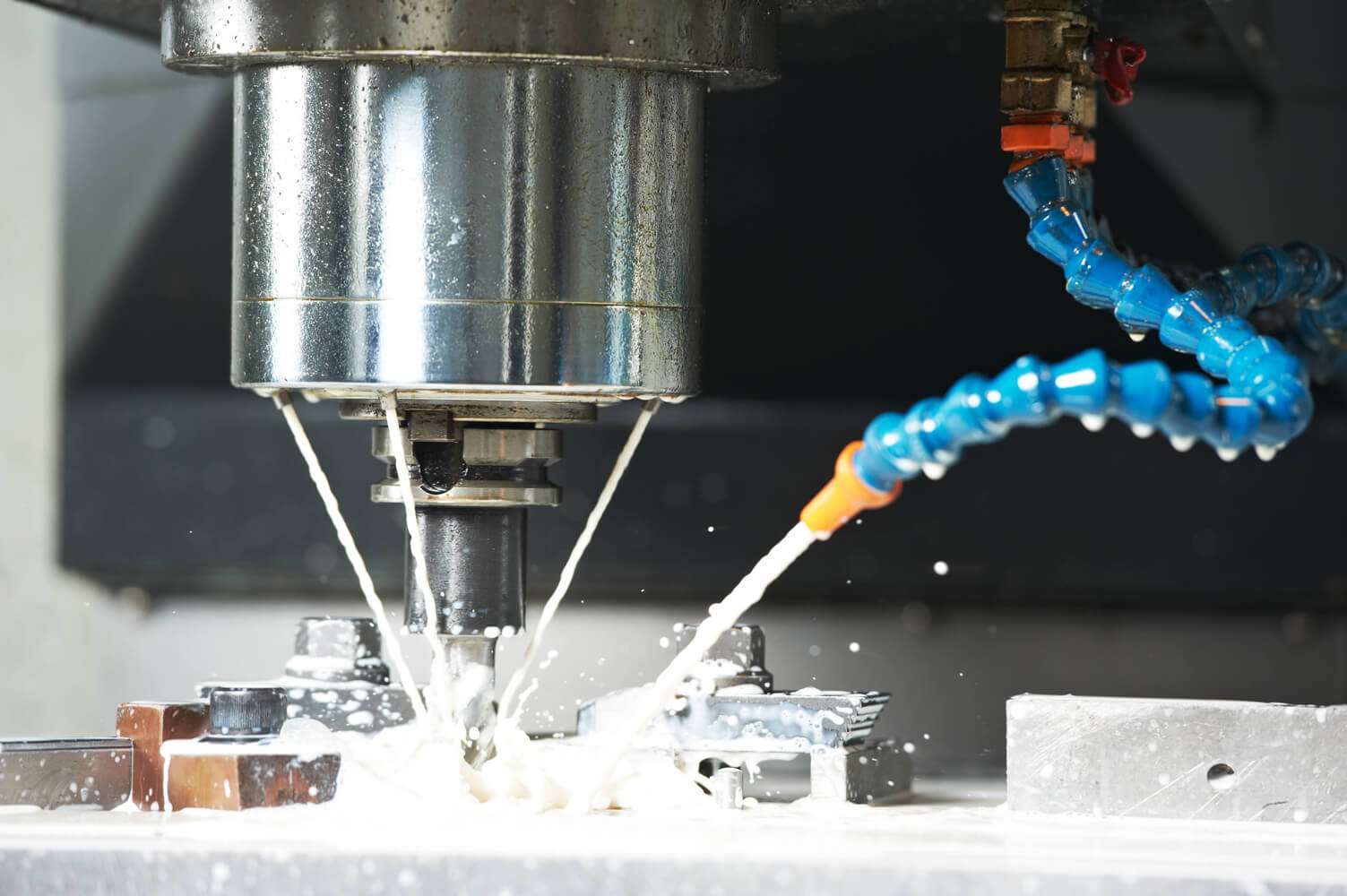

Advanced Formulated Open Diamond Bond Design

This advanced formulated open diamond bond design insures minimal chipping, fast

cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

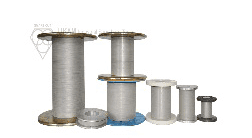

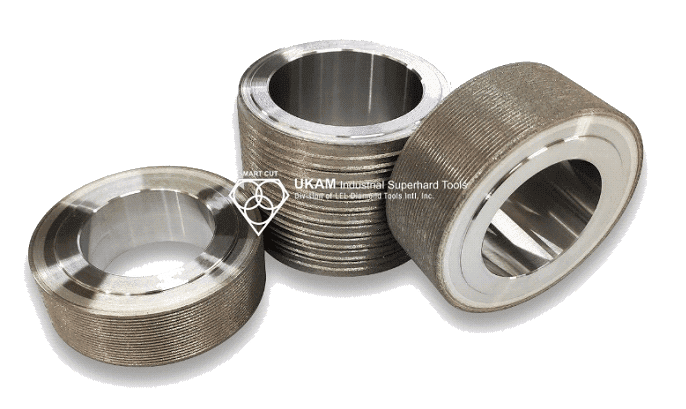

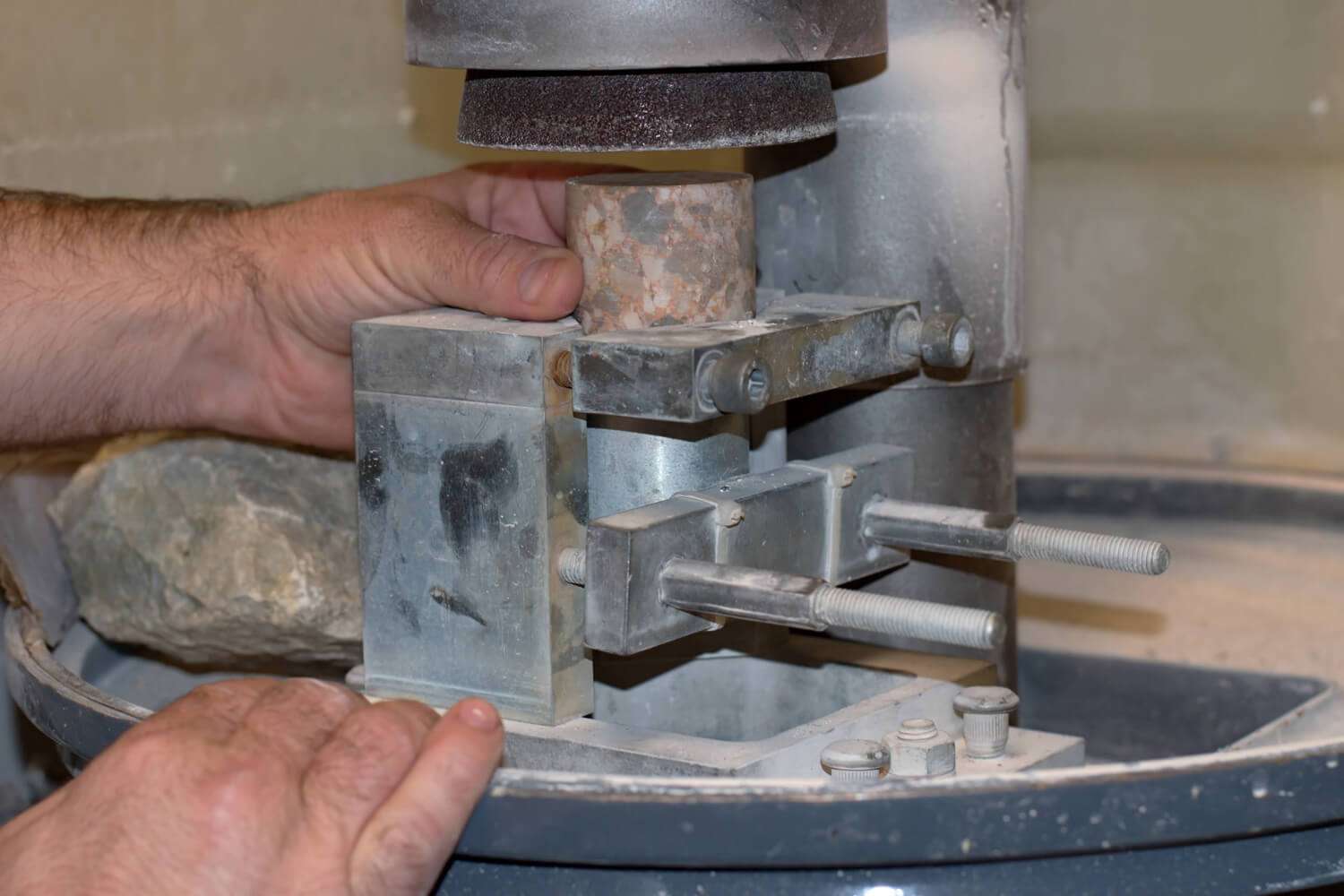

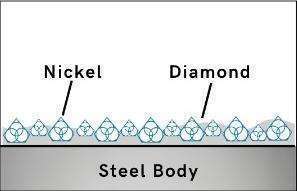

About Nickel Bond (Electroplated) Tools

Electroplated (nickel bond) diamond products usually have a single layer of diamonds, held by a tough durable nickel alloy. Nickel is frequently used as a base for plating diamond. Because of its excellent strength, toughness and flexibility during the plating process. Electroplated diamond products are able to retain their original shape and dimensions thought their working life. Unlike sintered (meal bond) or resin bond diamond products, where diamond particles are buried in bond and held together by metal or resin binder deep inside. Electroplating allows diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.

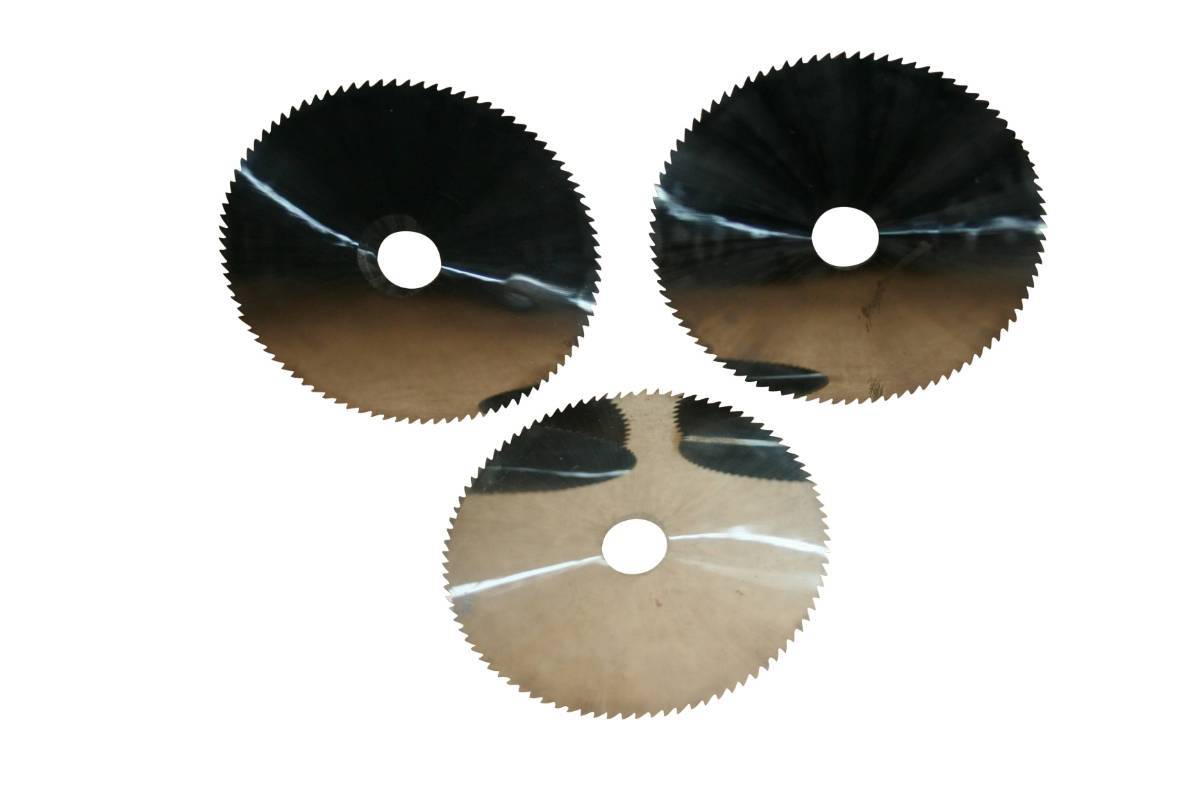

Faster & Freer Action

Diamond cut off blades made utilizing SMART CUT technology are much more aggressive than your conventional Blades. They can cut faster, while still leaving behind a smooth finish free of material deformation.

Longer Life

In most cases tools manufactured utilizing SMART CUT technology, will outlast other conventional nickel bonded diamond blades. SMART CUT diamond CBN tools are more sturdy than tools manufactured with conventional technologies. They are capable to retain their form and bond configuration all the way through the tools life.

More Consistent Performance

SMART CUT Multi Layered Electroplated diamond cutting blade three diamond layers impregnated inside the bond matrix. Unlike Many Other blade Types, they wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance, with minimum amount of dressing even on the hardest to cut materials

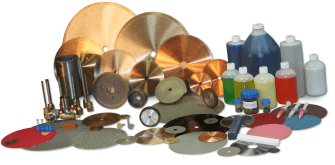

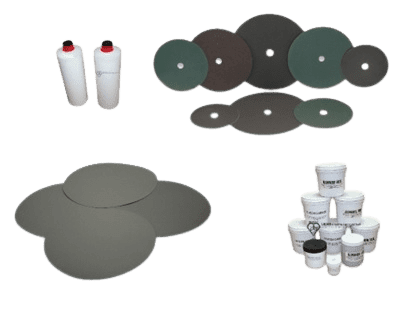

Manufactured Using The Highest Quality Raw Materials

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

Best Performance & Value on the Market

SMART CUT Multi Layered diamond cutting blades are the best investment you can make! They will more than pay for themselves in terms of overall performance and provide best Return on Investment.