Menu

No products in the Quote Basket.

Sign Up to recieve exclusive usage recommendations, illustrated trouble Shooting Guides & sales

9 am to 6 pm PST time

No products in the Quote Basket.

SMART CUT® 16001 are entry level laboratory cutting saw that are very affordably priced, Fast & Accurate sectioning of large variety materials. Coolant is stored below and applied to sample by rotating the blade. Saw table has a large working area and no inhibiting lip. Bull dog grip vise holds all material shapes and swings back out of the way for hand sectioning. Front shield protects operator from cutting waste.

SMART CUT® 16001 are entry level laboratory cutting saw that are very affordably priced, Fast & Accurate sectioning of large variety materials. Coolant is stored below and applied to sample by rotating the blade. Saw table has a large working area and no inhibiting lip. Bull dog grip vise holds all material shapes and swings back out of the way for hand sectioning. Front shield protects operator from cutting waste.

Heavy welded steel chassis with separately welded inner frame to eliminate warp. One piece vise carriage is mounted on a solid key stock with channel iron guide to provide rigidity and strength for fast cuts with heavy loads. Quick return system which allows carriage to be manually returned to any position. Over-running clutch which automatically adjusts to hard rock and changes length of cut as blade cuts through specimen. Made in U.S.A.

INDUSTRIES USED IN:

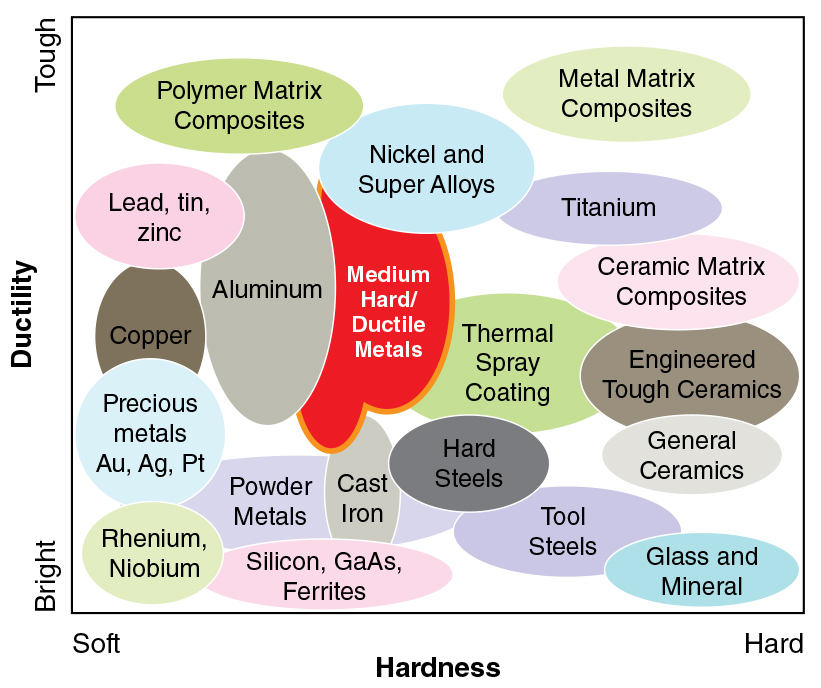

Ferrous & Non-Ferrous Metals:

Download Operating Manuals

The Complete Submersible Pump/Tank is a self-contained pump system that can eliminate city water hook-up for grinding units or supply mixed coolant and light mineral oil to these saws. This unit has a large capacity tank with two graduated dividers to separate sediment, and 10′ of 3/8″ vinyl tubing. Wheels on the tank make moving it easy. All pumps operate on 110V, are supplied with 3 prong grounded plug and cord (CSP805), and pump 200GPH at 1 ft., 105GPH at 5 ft. The tank holds approximately 17.5 gallons.

$350.00Add to cart

Your choice of one (1) quart of SMART CUT™ Water Soluble Coolant or Mineral Oil is included with machine. SMART CUT™ Water Soluble Coolant Reduces material thermal stress, edge damage, and internal cracking, increases blade life, provides better cut quality, preserves material micro structure

Hence, assuring long-term integrity of material being sectioned. Since SMART CUT coolant is both a coolant and lubricant, both the wafering blade and material benefit. Mix ratio is 1:20 (1 part coolant, 20 parts water) on very hard and dense materials and 1:40 (1 part coolant, 40 parts water) on softer materials. Depending on mix ratio 1 quart will produce 5.7 to 9 gallons of coolant when mixed with water. As a coolant, SMART CUT KOOL reduces heat caused by friction. As a lubricant, SMART CUT KOOL lowers friction and surface tension, which increases swarf dispersion.

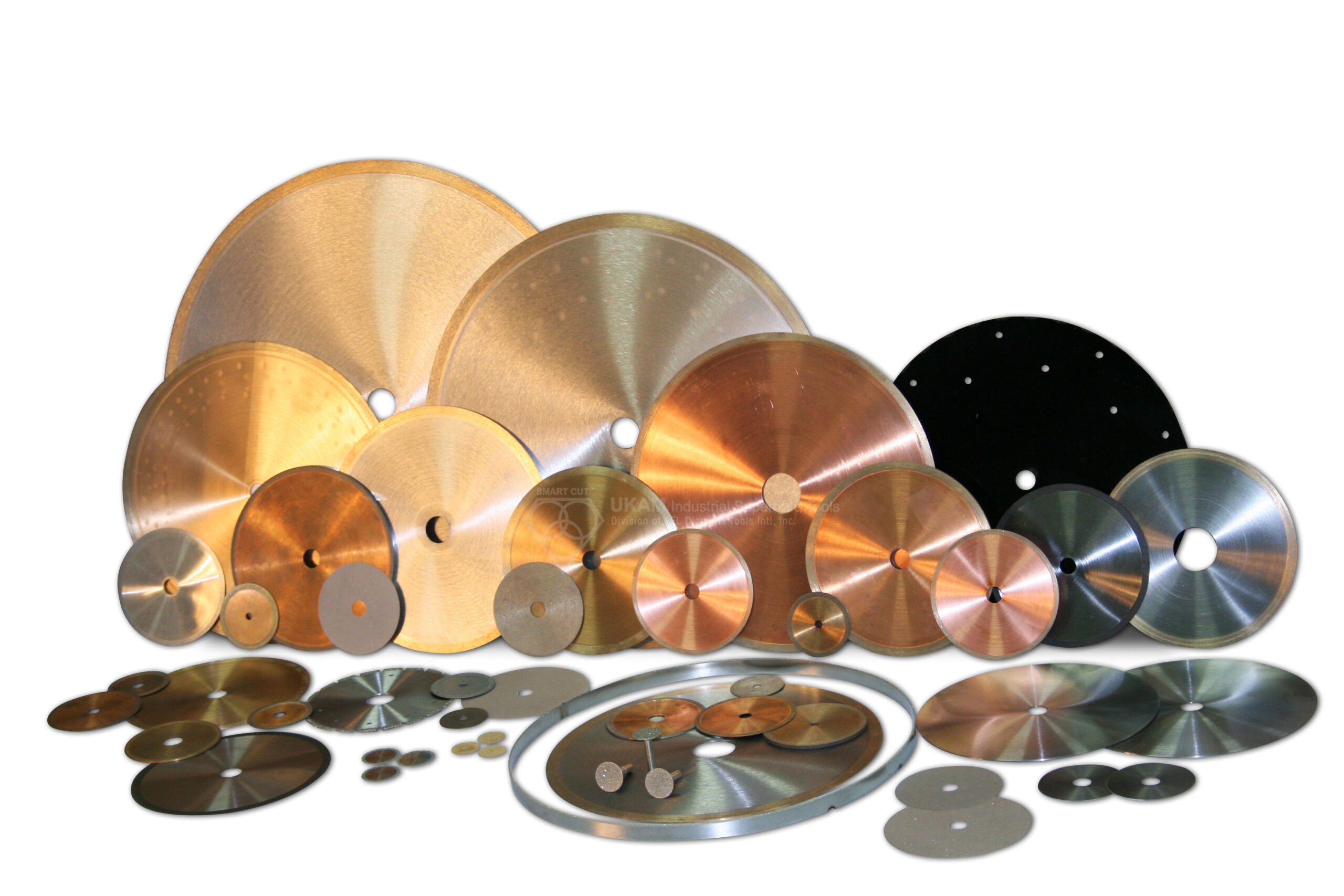

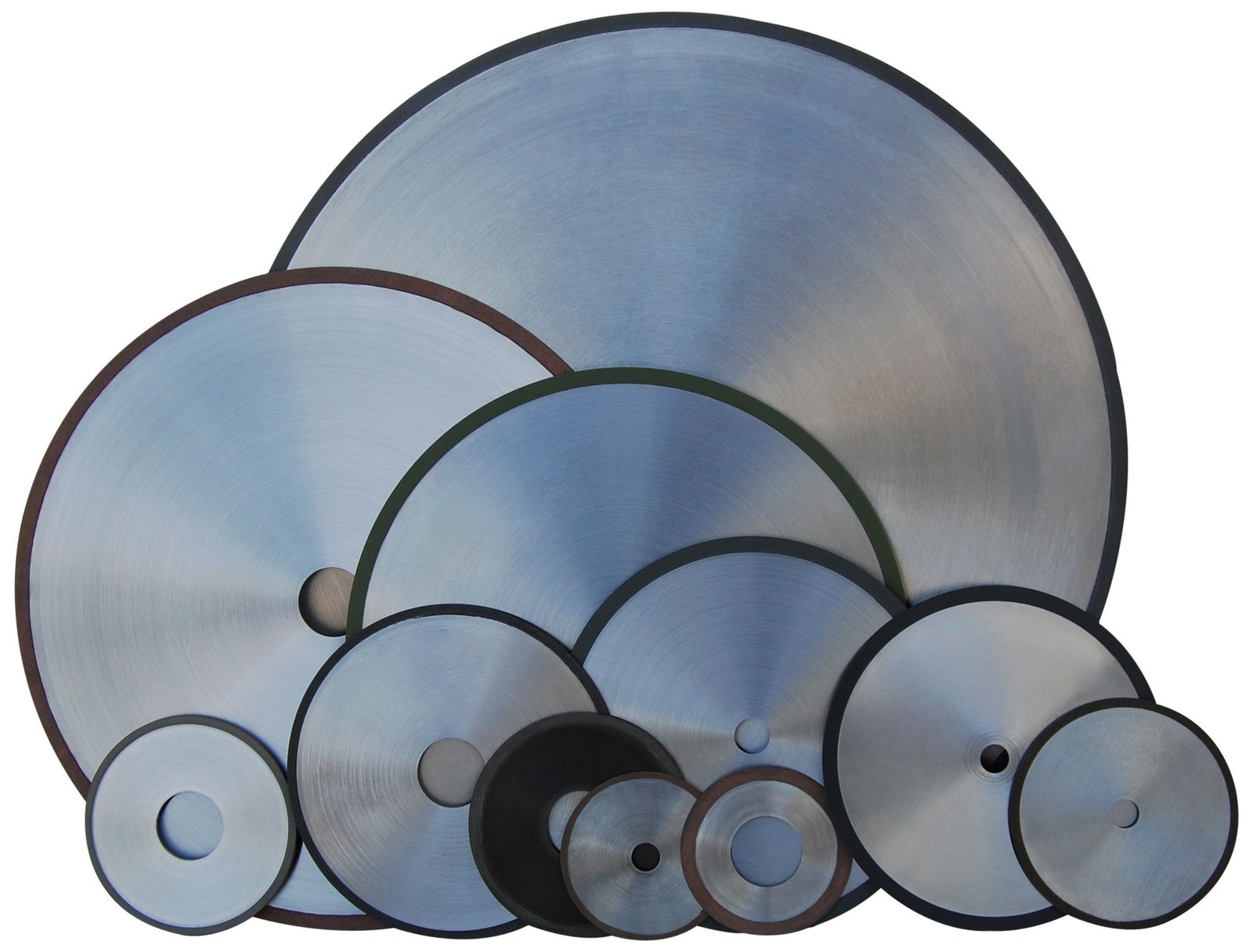

one (1) diamond wafering blade any specification is included FREE OF CHARGE with purchase of any machine (any specification). we have almost unlimited number of diamond & CBN wafering blade specifications in stock available for immediate delivery. Available in different sizes, thickness, arbor sizes, diamond concentrations, diamond mesh sizes, and bond hardness’s. With several thousand unique blade specification in stock not listed on our standard stock program. This insures you will receive the best blade specification possible for your specific application.

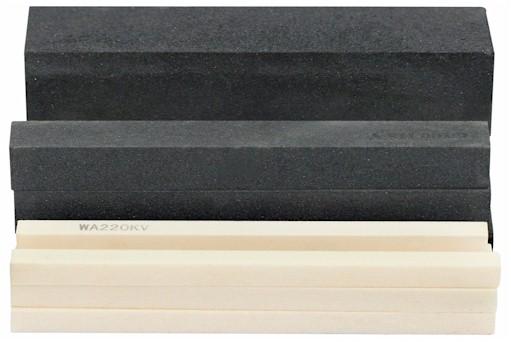

One (1) dressing stick is included with the purchase of any machine free of charge. The dressing stick we supply is similar to the diamond size of the wafering blade you have chosen (or we recommended) for your application. Wafering Blades must be diamonds particles/crystals exposed properly through frequent dressing. Otherwise, the diamond tool will glaze over. They will begin to tear rather than grind which is very destructive. Tearing caused from unexposed diamonds creates friction. This causes uneven wear and/or heat cracks in the wafering blade and/or material being cut. Resulting in premature blade wear, blade tensioning problems, and will eventually destroy the blade. The more frequently the blade is dressed the freer and cooler it will cut with lot more consistency.

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales