Diamond Tools For Lapidary Industry

Welcome to UKAM Industrial Superhard Tools. We are small, independently owned US Manufacturer of Professional Sintered (metal bond) & Plated Diamond Tools with SMART CUT™ technology. Our products for the lapidary, precious, semi precious stone and gemstone industries. Our standard and custom products offer BEST PERFORMANCE & VALUE FOR YOUR MONEY. Here you will find the largest selection and variety of standard tools available from stock & our capabilities to produce custom tools to your specifications.

Lapidary Materials

- Tanzanite

- Topaz

- Tsavorite

- Urquoise

- Gemstones

- Jade Tourmaline

- Quartz

- Agate

- Ametrine

- Amethyst

- Azurile

- Zirconia

- Emerald

- Garnet

- Lapis Lazuli

- Meteorites

- Opal

- Onyx

- Petrified Wood

- Rhodonite

- Rubie

Fantacy Faceting Tools

Designed for advanced gemstone artists and facetors who wish to go beyond standard flat faceting to create complex, three-dimensional optical effects. These tools are used with fantasy faceting machines such as Ultra Tec to produce intricate grooves, concave facets, and detailed surface designs.

Circle Cutters, Sintered (Metal Bond)

Circle Cutters are precision-engineered diamond tools designed for gemstone artists who demand both accuracy and creative freedom. Built with a cylindrical body and a cutting rim or inner edge, these tools allow the production of exact circular or concave shapes that are difficult, if not impossible, to achieve with traditional methods. Each cutter is manufactured with sintered (metal bond) construction, incorporating premium-grade diamond concentrations for long-lasting performance and consistency. This design ensures durability even under the rigorous demands of competition-level faceting. Optimized for use on fantasy faceting machines such as the Ultra Tec, Circle Cutters give both professionals and advanced enthusiasts the ability to introduce entirely new dimensions of brilliance and design into their work.

In practice, Circle Cutters excel in creating concave facets with precise geometry and symmetry. These concave features transform an ordinary gemstone into a striking work of art by amplifying light return and producing unique optical effects. They are especially effective for carving symmetrical circular grooves that enhance brilliance and add artistic detail to crown and pavilion surfaces. In fantasy faceting competitions, Circle Cutters provide a distinct advantage, enabling cutters to experiment with unusual reflective patterns and light interactions that stand apart from traditional flat faceting. Their versatility extends to a wide range of gemstones, from quartz and topaz to sapphire, spinel, and other corundum species, as well as synthetics.

One of the key strengths of Circle Cutters is their ability to provide uniform depth control, ensuring accuracy and repeatability across multiple stones. This consistency dramatically reduces the trial-and-error process common with hand-carving, saving valuable time and improving reliability. These cutters are produced in a wide variety of diameters and are offered in grit sizes typically ranging from 260 mesh (coarse) for shaping, 600 mesh (medium) for refining, up to 1200 and 3000 mesh (fine) for pre-polishing. The choice of grit allows the faceter to progress efficiently from rough shaping to detail finishing.

Circle Cutters are also designed to operate at specific angles, typically between 60° and 90°, depending on the desired effect. A 60° angle is often used for deeper concave grooves with more pronounced optical play, while 90° angles are ideal for uniform circular cuts with sharp definition. The availability of multiple angle options makes these cutters highly adaptable to both artistic and technical faceting requirements.

By reducing material waste and streamlining the cutting process, Circle Cutters not only improve efficiency but also expand the artistic possibilities available to the faceter. They allow cutters to move seamlessly from standard designs into advanced fantasy faceting with confidence, knowing the tools will deliver precision and durability at every stage. Designed for compatibility with leading fantasy faceting machines, Circle Cutters are an essential addition for anyone looking to elevate their gemstone artistry. Whether in professional production, competition cutting, or creative exploration, these tools provide the reliability, control, and flexibility needed to bring imaginative gemstone designs to life.

ADVANTAGES:

- Provide uniform depth control for concave cuts and grooves

- Ensure high accuracy and repeatability across multiple stones

- Save significant time compared to hand-carving or non-specialized tools

- Available in a wide range of diameters, angles (commonly 60° and 90°), and grit sizes (260 to 3000 mesh)

- Constructed from sintered (metal bond) for long service life and durability

- Reduce material waste while expanding artistic design possibilities

- Fully compatible with leading fantasy faceting machines

V-Groove Wheels, Sintered (Metal Bond)

V-Groove Wheels are specialized diamond tools designed with a sharp “V”-shaped profile that allows faceters to cut crisp, clean decorative grooves into gemstone surfaces. Manufactured with sintered (metal bond) construction and high-quality diamond concentrations, these wheels deliver the durability and precision required for both artistic gemstone cutting and professional production. They are widely used on fantasy faceting machines such as the Ultra Tec, where precise angles and repeatable patterns are essential to advanced gemstone design.

These wheels are most often employed to create starburst, sunray, and channel-like patterns on the crown, table, or pavilion of gemstones. The V-profile makes it possible to add both functional depth and decorative geometry, greatly enhancing light performance and visual appeal. In fantasy faceting competitions, V-Groove Wheels are invaluable for achieving unusual reflective effects that set stones apart from standard designs. They are available in a range of included angles, most commonly 60° and 90°, giving the cutter flexibility in shaping either deeper, narrower grooves or wider, bolder channels.

V-Groove Wheels are produced in multiple grit sizes to accommodate different stages of cutting. Coarse options, such as 260 mesh, are well suited for fast material removal and shaping. Medium grits, such as 600 mesh, refine the groove and prepare it for polishing. Fine grits, ranging from 1200 to 3000 mesh, allow for smooth pre-polish surfaces that reduce the time and effort required in final finishing. Their construction and grit selection make them suitable for a wide variety of materials, from quartz and topaz to corundum species like sapphire and spinel, as well as synthetic gemstones.

ADVANTAGES:

- Produce sharp, clean, and well-defined grooves and channels

- Available in common included angles of 60° and 90° for different design effects

- Offered in grit sizes ranging from 260 mesh (coarse) to 3000 mesh (fine)

- Manufactured in sintered (metal bond) for maximum durability and long service life

- Provide repeatable accuracy for competition cutting and professional gemstone design

- Allow creation of decorative starburst, sunray, and geometric patterns that enhance optical performance

- Compatible with leading fantasy faceting machines, including Ultra Tec

Diamond Tool Accessories

Dressing Sticks

Dressing Sticks are available from stock to dress all types of blades. Available in different sizess, grits, and abrasive types.

Stiffeners for Blades

Wheel Stiffeners provide stability, rigidity & additional support for your blades. They help in prventing the blade from loosing wobbling

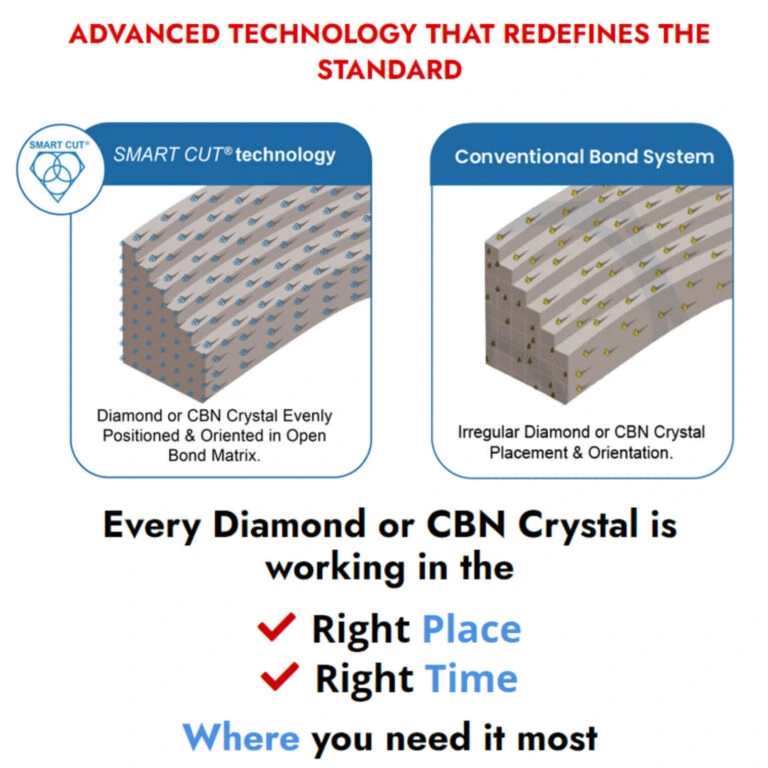

ITS WHAT YOU CANT SEE THAT MAKES ALL THE DIFFERENCE

SMART CUT® technology

We can help you:

Advanced technology that allows every diamond to be oriented and evenly positioned inside diamond bond matrix. Every diamonds works in the right place and at the right time, where you need it most

- Improve Tool Life

- SAVE TIME & MONEY

- Obtain More Consistent Results

- Improve Surface Finish

- Preserve True Material Microstructure

- Reduce & eliminate Material Deformation

- Improve Consumable Life & Overall Performance

Why Work With Us?

Comprehensive Source Of Information On Diamond Tools

The more you understand about what we can do for you the better our partnership will be. Here you will find most comprehensive source of information and optimizing and improving your cutting, drilling, grinding and polishing on the web. Find

everything you ever wanted to know about diamond tools. Many of our articles have been published in several leading industry magazines.

Large Inventory & Custom Manufacturing

We have the largest variety of diamond tools available in stock for lapidary, precious, semi precious stone and gemstone industries. we regularly produce custom diamond tools to better fit customers specific needs & specifications. Just about any diamond tool can be designed and manufactured per customer drawing or specifications.

Experience Makes All The Differences

UKAM Industrial Superhard Tools is one of the companies behind the original THIN KERF Sintered (metal bond) diamond blades & drills for lapidary application. Producing blades sold under "private label" for a number of well known equipment manufacturers. Our proprietary diamond tool chemistry, precision manufacturing methods, modern quality control methods, allow us to control and regulate the dozens of variables that affect diamond tool life, quality of cut, and consistent performance. Discover why some of the Leading Fortune 500 companies, Industry, Military, Jewelry manufacturers, to Professional Lapidary Hobbyists around the world prefer SMART CUT® diamond tools.

Best Value For The Money

We are always looking for partners to work with in expanding the market reach. We produce and offer highest quality products at very attractive pricing. While we may not be the lowest cost solution provider. Our products offer one of the best Return on Investment available & quality, that you cant find anywhere. We offer amazing discounts based on quantity. Lets us develop a win, win relationship.

Unmatched Performance & Quality

Our standard and custom products offer the best performance and value for your money.

count on us to provide higher level of performance compared to what is typically available in the market. While standard tools for stone may be sufficient in many cases, they often fall short when dealing with tougher materials and challenging applications.

Don't struggle with inferior tools - DEMAND THE BEST!

Time, Money, & Material - you will save will more than pay for these TOOLS in short period of time

Let Us Help You:

- Improve Tool Life

- Save Time & Money

- Obtain More Consistent Results

- Improve Surface Finish

- Save Material

- Reduce & eliminate Clipping

- Improve Overall Performance

Related Products

SMART CUT® Micro & Miniature Core Drills

SMART CUT® Micro & Miniature Diamond Core Drills

SMART CUT® 010DME (SMCDU)

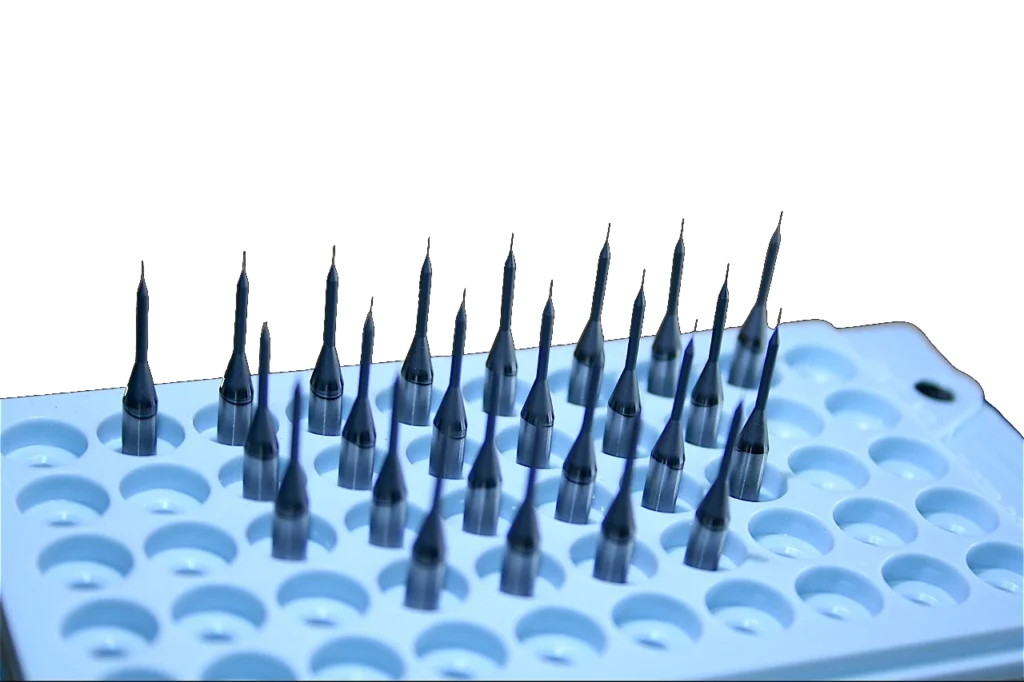

CVD Micro Drills

Micro Drills

SMART CUT® CVD diamond micro drills are used for drilling micro holes in large variety of hard and brittle materials such as sapphire, high density ceramics, micro-circuit substrates, glass, silicon, various wafers, substrates, tubes etc We offer large variety of standard stock & custom micro drills from 0.05mm diameter to 6mm. with 3mm and 3.2mm shanks, and various heald lengths from 0.5mm and up, and flute specifications.PCD (Polycrystalline) Micro Drills

Diamond Micro Drills

SMART CUT® PCD (Polycrystalline Diamond) Micro Drills are precision-engineered tools designed for applications that demand exceptional hardness, wear resistance, and dimensional accuracy. They are available starting from 0.4 mm in diameter, with a wide selection of head lengths and standard shank diameters of 3 mm and 3.2 mm. Each drill features a sintered polycrystalline diamond tip bonded to a carbide or tungsten substrate, providing superior rigidity, heat resistance, and extended tool life. These micro drills are widely used in the semiconductor, electronics, EDM electrode manufacturing, and die and mold industries. In semiconductor production, they are used for machining monocrystalline silicon, inspection and cleaning jigs, and precision fixture fabrication. In EDM electrode manufacturing, they are ideal for drilling graphite electrodes and other hard-to-machine materials that quickly wear down conventional tools.SMART CUT® Diamond & CBN Micro Drills, Sintered (Metal Bond)

Carbide Micro Drills

SMART CUT® 005DME MCDU

Recently Viewed Products