Menu

No products in the Quote Basket.

Sign Up to recieve exclusive usage recommendations, illustrated trouble Shooting Guides & sales

9 am to 6 pm PST time

No products in the Quote Basket.

used to create conical holes, expanding existing holes, breaking corners and chamfering holes and polishing existing holes in a large variety of materials. Available from stock in many specifications and we can also custom manufacture to fit almost any application/requirement.

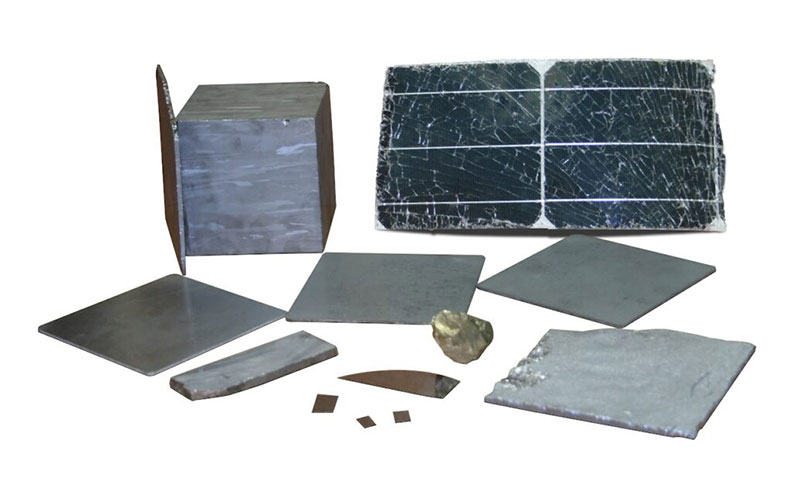

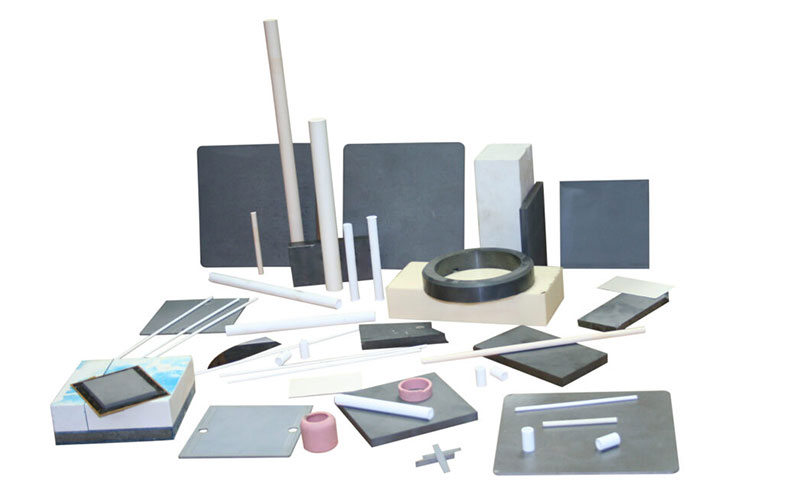

Multi-Layered Electroplated Diamond Countersinks are designed for countersinking operation in materials such as Glass, Quartz, Composites, Graphite Epoxy, Carbon, Boron, Fiberglass, Marble, and many other materials.

Used to create conical holes, expanding existing holes, breaking corners and chamfering holes and polishing existing holes in a large variety of materials. Available from stock in many specifications and we can also custom manufacture to fit almost any application/requirement.

Multi-Layered Electroplated Diamond Countersinks are designed for countersinking operation in materials such as Glass, Quartz, Composites, Graphite Epoxy, Carbon, Boron, Fiberglass, Marble, and many other materials.

Bond Type: Nickel Bond (Plated) Multi Layered Edge Type: diamond countersink

Diamond Grit Size: Medium Fine

Transition Angle

Overall Length

Shank Diameter:

Recommended Operating Speed: 500 to 4,000 (depending on diameter)

Maximum Operating Speed: 4,000.

Always drill with a coolant and use submerged-pressure sensitive feed.

Recommended Coolant: water, for ultra hard materials best results will be achieved with mineral oil or synthetic water soluble coolant.

Tab Content

Image | Name | COMPATIBILITY WITH DRILL SERIES | Price | Quantity | Add to cart |

|---|---|---|---|---|---|

Recommended for use in Diamond Tools 150 Grit Size (mesh… | $15.39 | Max: Min: 1 Step: 1 | |||

Recommended for coarser grits found in segment wheels, core drills… | $15.99 | Max: Min: 1 Step: 1 | |||

$34.81 | Max: Min: 1 Step: 1 | ||||

Recommended for use in Diamond Tools 150 Grit Size (mesh… | $39.47 | Max: Min: 1 Step: 1 | |||

Recommended for coarser grits found in segment wheels, core drills… | $39.47 | Max: Min: 1 Step: 1 | |||

$99.81 | Max: Min: 1 Step: 1 | ||||

$317.41 | Max: Min: 1 Step: 1 | ||||

$1,745.00 | Max: Min: 1 Step: 1 |

Image | A | B | C | D | E | L | Price | Quantity | Add to cart |

|---|---|---|---|---|---|---|---|---|---|

3/26" | 47/64" | 5/16" | 1/4" | 42 degrees | 2" | $65.70 | Max: Min: 1 Step: 1 | ||

1/4" | 51/64" | 5/16" | 1/4" | 42 degrees | 2" | $78.41 | Max: Min: 1 Step: 1 | ||

3/4" | 1-3/16" | 1/4" | 3/8" | 42 degrees | 2" | $97.58 | Max: Min: 1 Step: 1 | ||

3/4" | 1-3/16" | 1/4" | 3/8" | 42 degrees | 2" | $116.35 | Max: Min: 1 Step: 1 | ||

1 | 1-5/8" | 3/8" | 3/8" | 42 degrees | 2" | $128.12 | Max: Min: 1 Step: 1 | ||

1-1/8" | 2" | 12" | 3/8" | 42 degrees | 2" | $144.30 | Max: Min: 1 Step: 1 | ||

1-1/2" | 2.490" | 0.526" | 3/8" | 42 degrees | 4.5" | $163.42 | Max: Min: 1 Step: 1 |

Diamonds or CB Crystals are activated only at the exposed layer. As Bond Matrix layer begin to wear out, diamonds in a new Bond Matrix layer are immediately activated, substituting the already used up diamond layer. The SMART CUT ® Bond Diamond Bond makes sure every diamond is in the right place. and at the right time, working where you need it most.

The newly exposed diamonds don’t effect diamonds already working on the material. Unlike many other diamond bonds, diamonds in a SMART CUT ® remains sharp and grow sharper with each cut, prolonging product life and consistent performance.

This advanced formulated open diamond bond design insures minimal chipping, fast

cut, constant speed of cut, minimal cutting noise, and most important of all, consistent performance.

Diamond drills made utilizing SMART CUT technology are much more aggressive than your conventional Tools. They can cut faster, while still leaving behind a smooth finish free of material deformation.

In most cases tools manufactured utilizing SMART CUT technology, will outlast other conventional nickel bonded diamond CBN drills. SMART CUT diamond CBN tools are more sturdy than tools manufactured with conventional technologies. They are capable to retain their form and bond configuration all the way through the tools life.

SMART CUT Multi Layered Electroplated Diamond Drills have three diamond layers impregnated inside the bond matrix. Unlike Many Other drill Types, they wear evenly, and are known for their consistency. You will get consistent cutting speed, and overall consistent performance, with minimum amount of dressing even on the hardest to cut materials

Only the highest quality synthetic diamonds and raw materials are used in the manufacturing process. The highest quality standards and product consistency is maintained, using sophisticated inspection and measurement equipment.

SMART CUT Multi Layered Electroplated Diamond Drills are the best investment you can make! Although they may cost more than electroplated (nickel bond), Diamond Drills. They will more than pay for themselves in terms of overall performance and provide best Return on Investment.

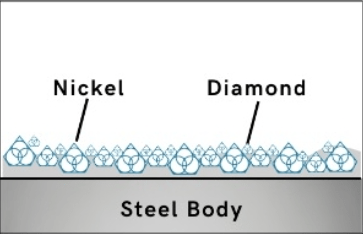

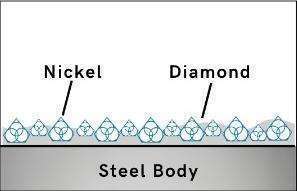

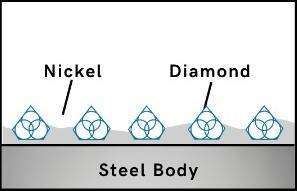

Electroplated (nickel bond) diamond products usually have a single layer of diamonds, held by a tough durable nickel alloy. Nickel is frequently used as a base for plating diamond. Because of its excellent strength, toughness and flexibility during the plating process. Electroplated diamond products are able to retain their original shape and dimensions thought their working life. Unlike sintered (meal bond) or resin bond diamond products, where diamond particles are buried in bond and held together by metal or resin binder deep inside. Electroplating allows diamond particles to protrude from the bond matrix, providing a free, faster cutting action with minimum heat generation.

they have several layers of diamonds, held by a tough durable nickel alloy. Providing high diamond concentration, better diamond crystal retention and maximum diamond particle (grit) exposure/protrusion ratio. This provides freer, faster cutting action with minimum heat generation. Advantages of this type of technology include: longer tool life, more uniformity in performance, less stress to material being worked on, minimum material deformation, and better preservation of true material micro structure. This is specially important for more delicate, sensitive applications such as: glass, crystals, silicon wafers, carbon composites, sapphire, etc.

Take a scrap piece of material. Make sure it is firmly held together in place and does not move. Take the counter sink and lower it to piece of material until its sharp point barely touches material surface. Using your drilling machine slowly rotate counter sink (very slowly). If the counter sink produces a straight point (dot) than you countersinking operation will not have any problems. If its starts to wobble even just slightly produce scratches of slightly eclipse circle (not perfect dot). This means the diamond counter sink is not properly centered (installed) in your drilling machine chuck. Adjust and center your counter sink until you are able to produce perfect dot.

Another very important concept in using your diamond counter sink is finding a perfect center in your hole. Make sure that your counter sink is perfectly centered in your drilling machine chuck. Bring up your material until the counter sink sharp point touches the center of your hole. Make sure their are no gaps in hole between material and countersink (that countersink) absorbs in entire diameter of your hole. Make sure the material will not wobble while the countersink is in use.

Signup for email offers, updates, and more

UKAM Industrial Superhard Tools is a U.S. High Technology, Specialty Diamond Tool & Equipment manufacturer. We specialize in producing ultra thin & high precision cutting blades and precision cutting machines diamond drills, diamond micro tools, standard & custom advanced industrial diamond tools and consumables.

Shipping Methods

Safe & Secure Payments

© Copyright 1990-2024. UKAM Industrial Superhard Tools – Terms of Use

No products in the Quote Basket.

No account yet?

Create an AccountSign up to receive exclusive usage recommendations, Illustrated Trouble Shooting Guides & Sales

Recommended RPM’s

These RPM ranges are approximate and may need to be adjusted based on the specific characteristics of the material you are working with and the performance of your diamond countersink. Always start at a lower RPM and gradually increase the speed while monitoring the tool's performance and the quality of the countersink being created.